Preparing method of silver nanoparticle mixed filler modified silicone rubber conductive composite material

A conductive composite material and mixed filler technology, applied in nanotechnology and other directions, can solve the problems of poor compatibility, easy agglomeration of nano-silver particles, and difficult composite performance, and achieve short reaction process, uniform particle size, excellent conductivity and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

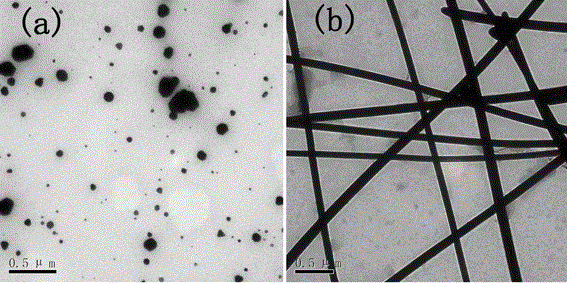

[0028] Stir 1 mol of glucose, 0.85 g of polyvinylpyrrolidone and 1.2 mol of sodium hydroxide at 80°C for 10 minutes to fully and evenly disperse them in deionized water. Slowly drop in, after the drop is completed, the reaction is carried out for 10 minutes, and 1 mol of silane coupling agent 3-aminopropyltriethoxysilane is added. After the reaction is carried out for 6 hours, the silver nanoparticles are aggregated and precipitated, and the reaction solution is centrifuged, and the strong base is discarded. solution, and the muddy product was poured into deionized water for repeated washing, centrifuged, and dried in an oven at 80°C to obtain silane-modified silver nanoparticles, such as figure 1 (a) shown. Disperse 200 g of modified silver nanoparticles, 20 g of silver nanowires, and 100 g of vinyl silicone oil with a viscosity of 60,000 mPa.s in n-hexane at room temperature with high-speed stirring at 500 rpm to form a uniform dispersion, and dropwise add hydrogen-containin...

Embodiment 2

[0030] Stir 2 mol of glucose, 0.85 g of polyvinylpyrrolidone, and 1.2 mol of sodium hydroxide at 60°C for 10 minutes to fully and evenly disperse them in deionized water. Add 1mol of silane coupling agent 3-aminopropyltriethoxysilane for 10 minutes after the addition is completed. After 6 hours of reaction, the silver nanoparticles aggregate and precipitate. Centrifuge the reaction solution and discard the strong base. The reaction solution, and the muddy product was poured into deionized water to wash repeatedly, centrifuged, and dried in an oven at 80°C. Disperse 100 g of modified silver nanoparticles, 100 g of silver nanowires, and 100 g of vinyl silicone oil with a viscosity of 60,000 mPa.s in n-hexane at room temperature under high-speed stirring at 1,000 rpm to form a uniform dispersion, and add 3.5 g of hydrogen silicone oil dropwise and stir After 2 minutes, 0.5 g of the platinum catalyst complex was added, stirred for another 2 minutes, and the reaction solution was p...

Embodiment 3

[0032] Stir 5 mol of glucose, 8.5 g of polyvinylpyrrolidone and 1.2 mol of sodium hydroxide at 60°C for 10 minutes to fully and evenly disperse them in deionized water. Add in 1mol silane coupling agent 3-aminopropyltriethoxysilane for 10 minutes after the addition is completed. After 8 hours of reaction, the silver nanoparticles aggregate and precipitate out. Centrifuge the reaction solution and discard the strong base reaction solution. , and the muddy product was poured into deionized water for repeated washing, centrifuged, and dried in an oven at 80°C. Disperse 100g of modified silver nanoparticles, 50g of silver nanowires, and 100g of vinyl silicone oil with a viscosity of 100,000 mPa.s in n-hexane at room temperature under high-speed stirring at 1500rpm to form a uniform dispersion, then add 3.5g of hydrogen silicone oil dropwise and stir After 2 minutes, 0.1 g of platinum catalyst complex was added and stirred again for 2 minutes, and the reaction solution was poured i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com