Polymer composite material as well as preparation method and application thereof

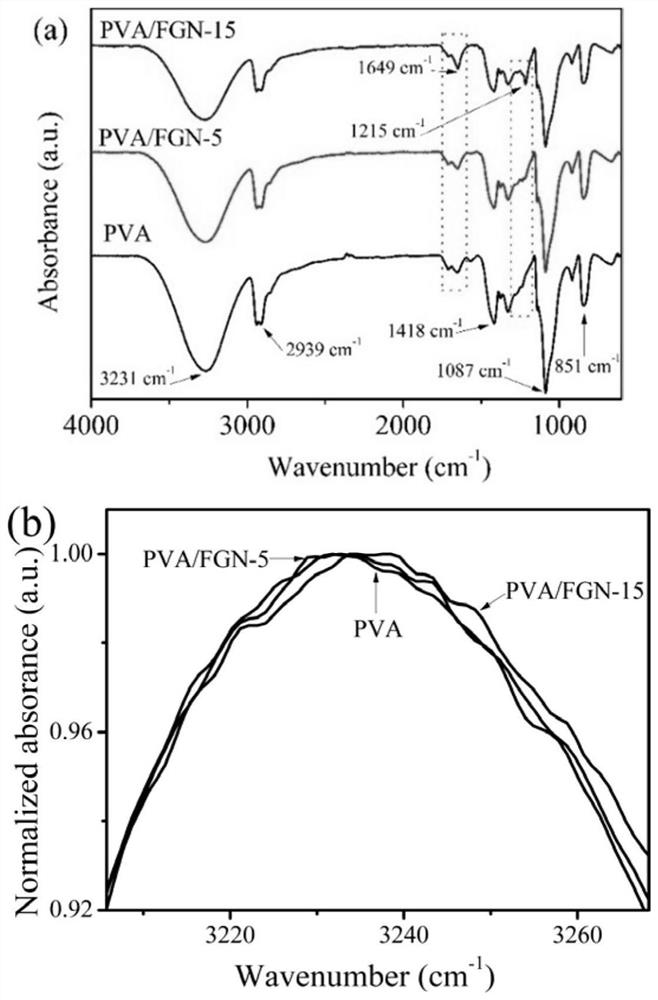

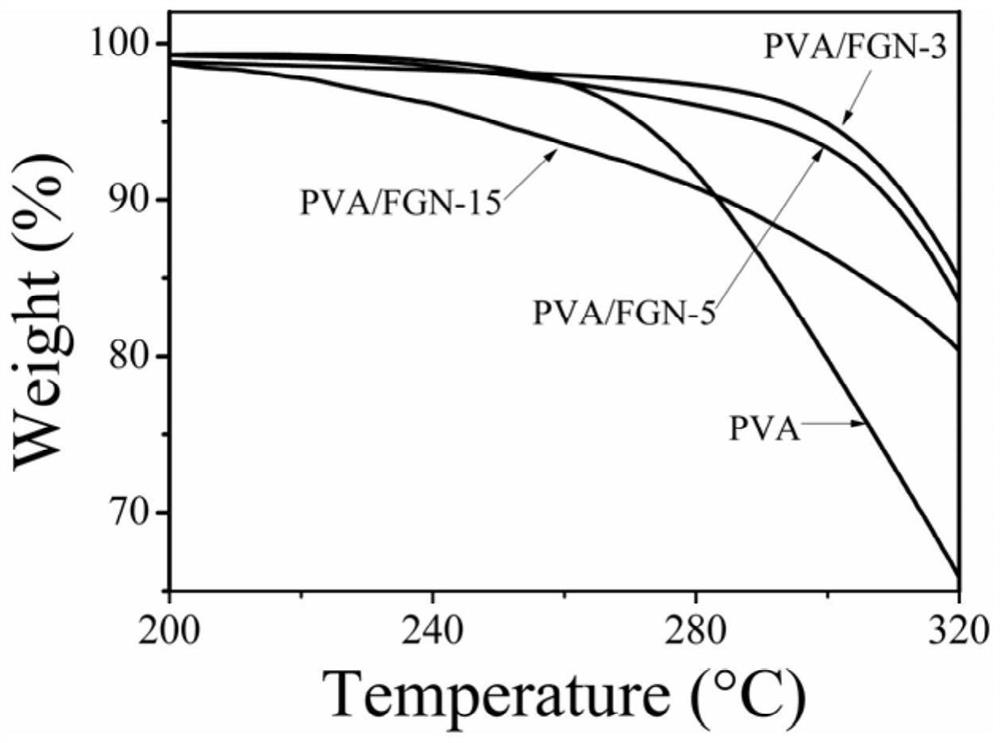

A composite material and polymer technology, applied in the field of polymer composite materials and their preparation, can solve the problems of insignificant improvement effect of polyvinyl alcohol thermal properties, low addition amount, etc. The effect of increasing the decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the preparation method of the above-mentioned polymer composite material, according to the mass ratio, the aqueous dispersion of fluorinated graphene nanosheets with a concentration of 0.5 to 1.0 mg / mL and the polyvinyl alcohol with a concentration of 20.0 to 50.0 mg / mL are dispersed in water The liquid is mixed evenly, and then vacuum-dried at a temperature of 60°C to 80°C.

[0028] Preferably, the aqueous dispersion of fluorinated graphene nanosheets is prepared by the following method: dispersing fluorinated graphene in a solvent, and subjecting it to ultrasonic and centrifugation to obtain exfoliated fluorinated graphene nanosheets; Graphene nanosheets dispersed in water.

[0029] Further preferably, the solvent is one or more of isopropanol, N-methylpyrrolidone, and N,N-dimethylformamide dichloromethane.

[0030] Further preferably, the sonication is performed using a water bath sonicator, the power of the water bath sonicator is 30-100 W, and the son...

Embodiment 1

[0037] (1) Disperse the fluorinated graphene powder in N-methylpyrrolidone, reflux at 60°C for 2 h, sonicate for 24 h (50 W) on a water bath ultrasonic instrument, and then centrifuge the dispersion at 3000 rpm for 30 min , to obtain exfoliated fluorinated graphene nanosheets; the above dispersion was filtered, weighed and redispersed in water to form a 1 mg / mL aqueous dispersion of fluorinated graphene.

[0038] (2) Add polyvinyl alcohol particles into water, stir at 80°C until completely dissolved, and prepare a 20.0 mg / mL polyvinyl alcohol aqueous dispersion.

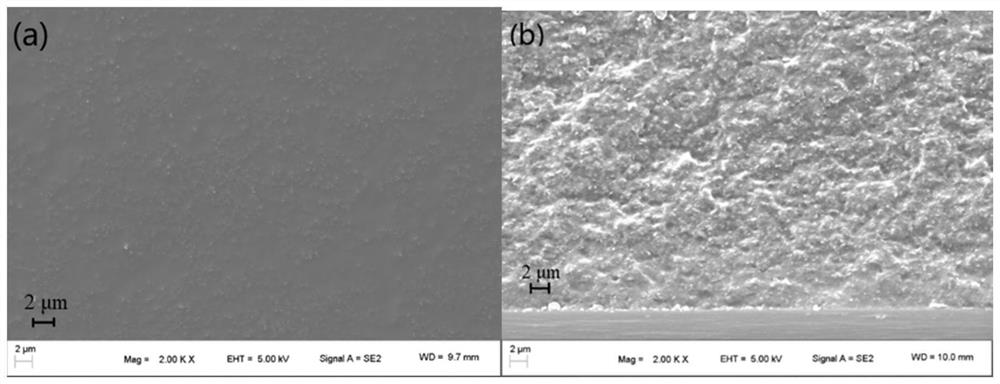

[0039] (3) Add 2.0 mL of fluorinated graphene aqueous dispersion to 9.9 mL of polyvinyl alcohol aqueous dispersion, sonicate for 30 minutes, stir for 30 minutes, pour into a glass surface dish, and dry in a vacuum oven at 60°C to 80°C Dried into a film to obtain a polyvinyl alcohol composite film in a uniform light brown transparent state.

Embodiment 2

[0041](1) Disperse the fluorinated graphene powder in N-methylpyrrolidone, reflux at 60°C for 2 h, sonicate for 24 h (50 W) on a water bath ultrasonic instrument, and then centrifuge the dispersion at 3000 rpm for 30 min , to obtain exfoliated fluorinated graphene nanosheets. The above dispersion was filtered, weighed and re-dispersed in water to form a 1.0 mg / mL aqueous dispersion of graphene fluoride.

[0042] (2) Add polyvinyl alcohol particles into water, stir at 80°C until completely dissolved, and prepare a 30.0 mg / mL polyvinyl alcohol aqueous dispersion.

[0043] (3) Add 6.0 mL of the aqueous dispersion of fluorinated graphene to 6.5 mL of the polyvinyl alcohol aqueous dispersion, sonicate for 30 minutes, stir for 30 minutes, pour into a glass watch glass, and place in a vacuum oven at 60°C to 80°C Dry to form a film to obtain a polyvinyl alcohol composite material film in a uniform light brown transparent state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com