A high-strength, high-temperature-resistant rafm steel and its design method based on machine learning

A machine learning and design method technology, applied in the field of steel materials, can solve complex and time-consuming problems, and achieve good tensile properties and strong generalization capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

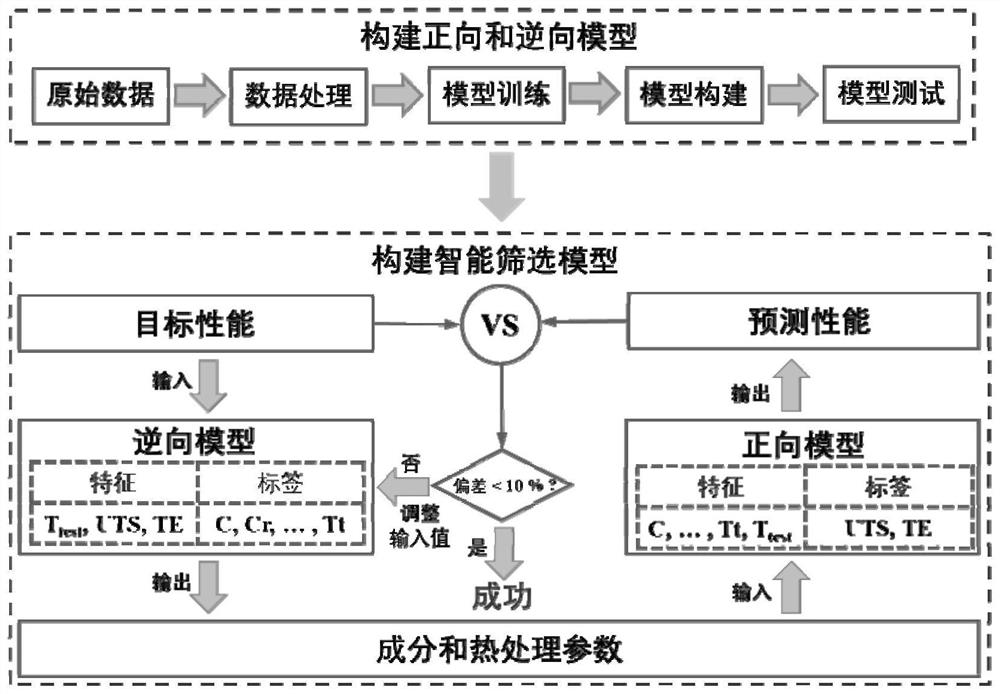

Method used

Image

Examples

Embodiment 1

[0053] A high-strength, toughness and high-temperature-resistant RAFM steel in this embodiment is designed by using the method of the present invention, and the smelting and subsequent heat treatment are carried out in strict accordance with the composition and heat treatment parameters designed in the present invention.

[0054] The RAFM steel includes the following chemical components in mass percent: 0.12%C, 10.5%Cr, 1.6%W, 0.52%Si, 0.6%Mn, 0.27%V, 0.26%Ta, 0.001%Zr, 0.01%Y, 0.002% %Ti, 0.04% N, and the rest are Fe elements and other unavoidable impurity elements. The heat treatment parameters of the RAFM steel are: normalizing temperature (NT) 1050°C, normalizing time (Nt) 20min, tempering temperature (TT) 600°C, tempering time (Tt) 90min.

Embodiment 2

[0056] A high-strength, toughness and high-temperature-resistant RAFM steel in this embodiment is designed by using the method of the present invention, and the smelting and subsequent heat treatment are carried out in strict accordance with the composition and heat treatment parameters designed in the present invention.

[0057] The RAFM steel includes the following chemical components in mass percent: 0.16%C, 9.5%Cr, 1.8%W, 0.48%Si, 0.7%Mn, 0.23%V, 0.10%Ta, 0.005%Zr, 0.05%Y, 0.012% %Ti, 0.02% N, the rest is Fe and other unavoidable impurity elements. The heat treatment parameters of the RAFM steel are: normalizing temperature (NT) 1010°C, normalizing time (Nt) 55min, tempering temperature (TT) 720°C, tempering time (Tt) 50min.

Embodiment 3

[0059] A high-strength, toughness and high-temperature-resistant RAFM steel in this embodiment is designed by using the method of the present invention, and the smelting and subsequent heat treatment are carried out in strict accordance with the composition and heat treatment parameters designed in the present invention.

[0060] The RAFM steel includes the following chemical components in mass percent: 0.13%C, 9.5%Cr, 1.7%W, 0.49%Si, 0.67%Mn, 0.25%V, 0.20%Ta, 0.002%Zr, 0.03%Y, 0.005% %Ti, 0.021% N, and the rest are Fe and other unavoidable impurity elements. The heat treatment parameters of the RAFM steel are: normalizing temperature (NT) 1010°C, normalizing time (Nt) 36min, tempering temperature (TT) 660°C, tempering time (Tt) 76min.

[0061] In the above-mentioned Examples 1-3, other unavoidable impurity elements are Al, Ni, Mo, Nb, Cu, B, S, P, O, and the proportion of each impurity element is: Al: 0-0.010%, Ni: 0~0.005%, Mo: 0~0.005%, Nb: 0~0.010%, Cu: 0~0.010%, B: 0~0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com