Micro-crosslinking self-repairing sealant as well as preparation method and application thereof

A sealant and self-repairing technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems affecting product performance, long processing time, high processing temperature, etc., to achieve strong viscosity and not easy to move out , the effect of low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

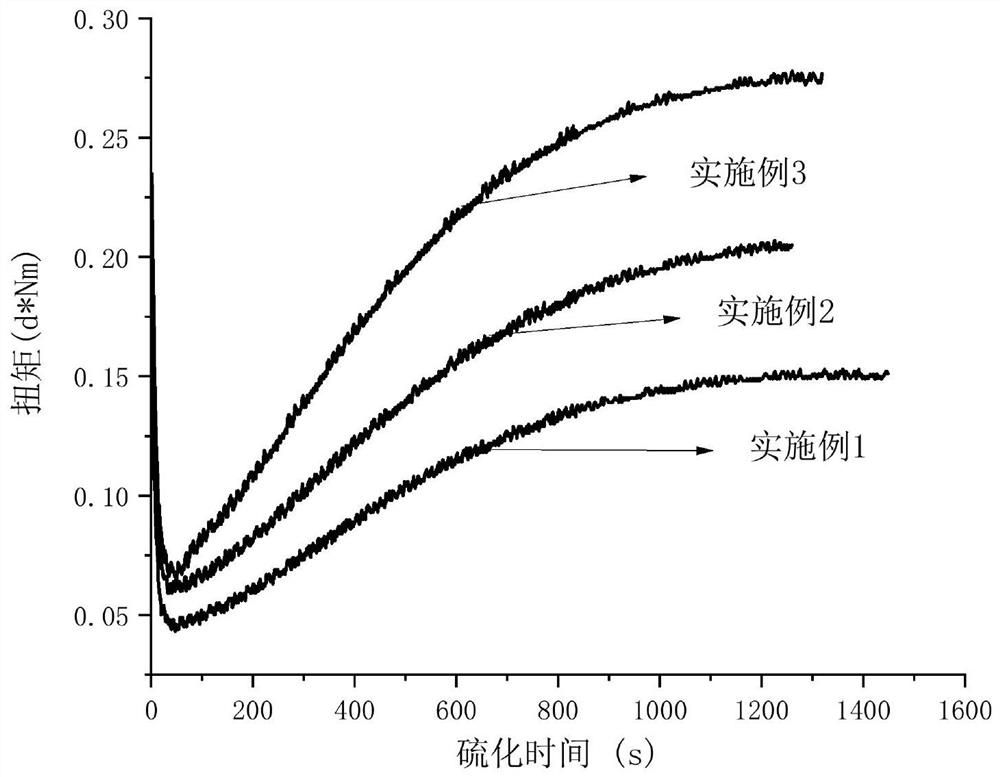

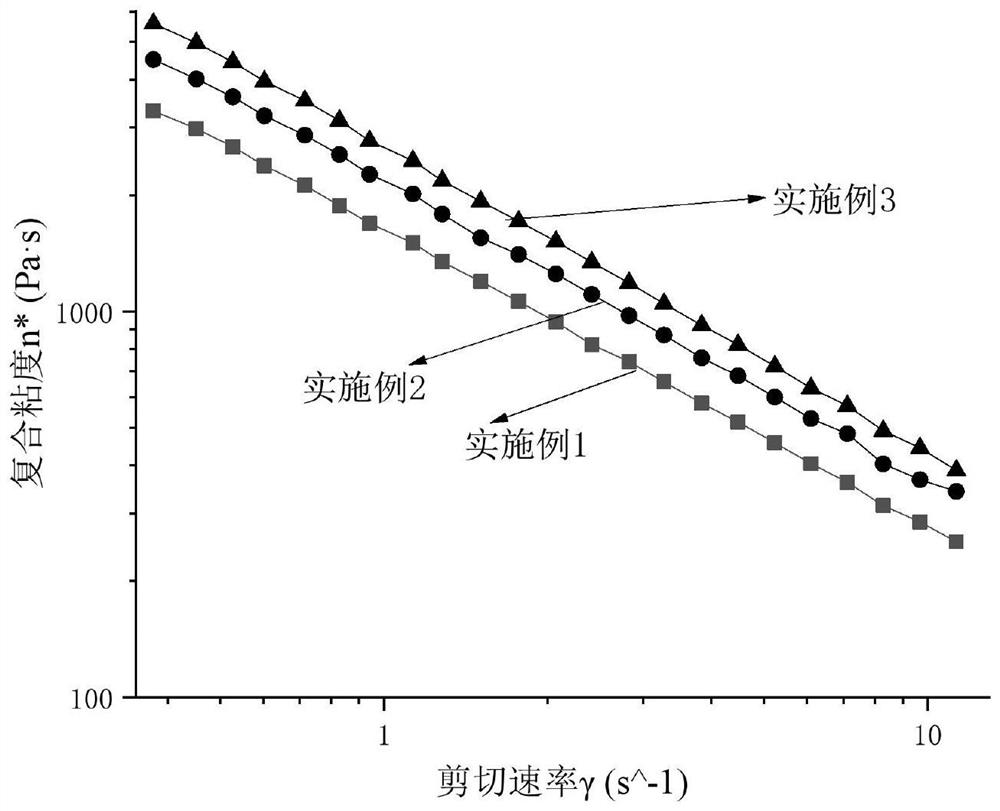

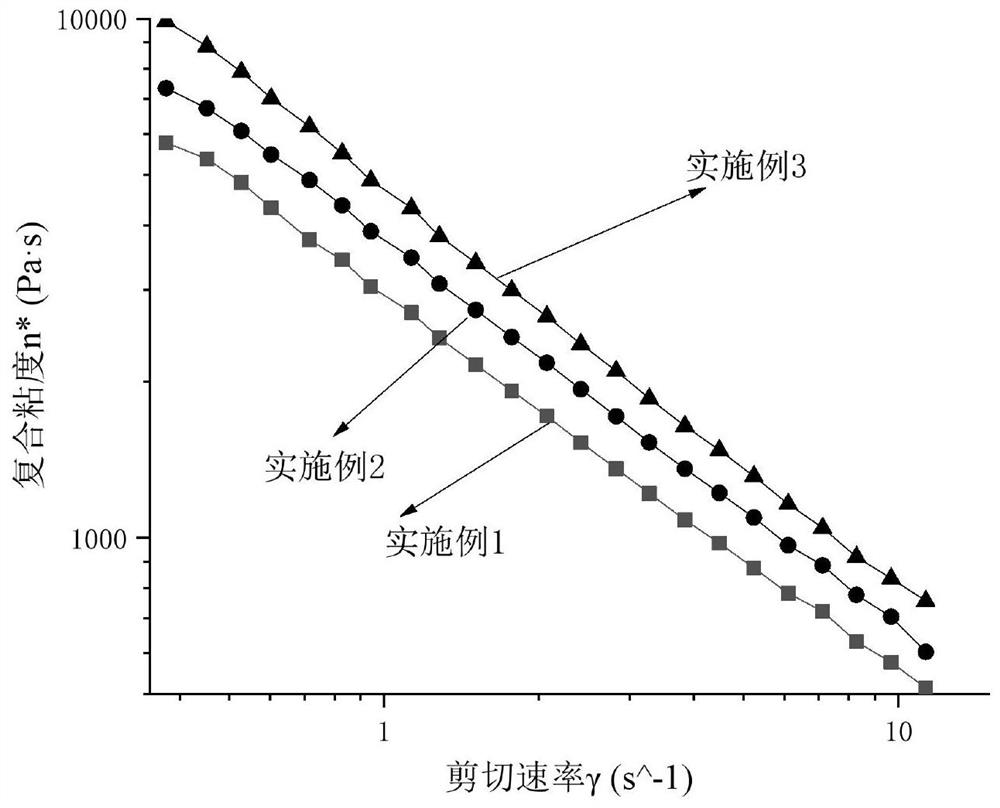

[0054] 112 parts of butyl rubber 1953 (2.5% unsaturation), 48 parts of medium molecular weight polyisobutylene PIB8950 (0.06% unsaturation), 50 parts of low molecular weight polyisobutylene (PIB2300), 3.2 parts of antioxidants 1010, 24 Parts of calcium carbonate, 24 parts of carbon black N220, 5 parts of tackifying resin, 5 parts of homogenizer HA40, 2 parts of sulfur, 2 parts of accelerator TMTD, 7.2 parts of n-dodecane mercaptan were blended at 40°C with an internal mixer, and used for later use. . Afterwards, the product was blended with another part of low molecular weight polyisobutylene PIB2300 through an extruder (the addition amounts of Examples 1 to 3 were 142 parts, 110 parts, and 78 parts, respectively) at 120° C. to form a strong viscous viscous kneading. glue. In Examples 1-3, the ratios of 1:1.2, 1:1, and 1:0.8 were used as the variables respectively according to the low molecular weight and high activity polyisobutylene PIB2300 and the matrix material, and the ...

Embodiment 4~6

[0065]A total of 160 parts of butyl rubber and medium molecular weight polyisobutylene, 50 parts of low molecular weight polyisobutylene (PIB2300), 3.2 parts of antioxidant 1010, 24 parts of calcium carbonate, 24 parts of carbon black N220, 5 parts of tackifier resin, 5 parts of uniform Agent HA40, 2 parts of sulfur, 2 parts of accelerator TMTD, and 7.2 parts of n-dodecanethiol were blended at 40°C with an internal mixer and used for later use. Afterwards, the product was blended with 142 parts of low-molecular-weight high-activity polyisobutylene at 120° C. in an extruder to form a highly viscous viscous compounded rubber. Examples 4 to 6 were prepared according to the ratio of the base material butyl rubber to the medium molecular weight polyisobutylene at the feeding ratios of 1:1, 7:3, and 9:1. After extrusion coating on the rubber side, the samples were obtained by baking and vulcanizing at 170 °C for the positive vulcanization time. The test results of the vulcanization ...

Embodiment 7~10

[0077] Mix 112 parts of butyl rubber with 48 parts of medium molecular weight polyisobutylene, 50 parts of low molecular weight polyisobutylene (PIB2300), 3.2 parts of antioxidant 1010, 24 parts of calcium carbonate, 24 parts of carbon black N220, 5 parts of tackifier resin (please add The amount of tackifier), 5 parts of homogenizer HA40, 2 parts of sulfur, 2 parts of accelerator TMTD, and n-dodecane mercaptan of different additions were mixed with an internal mixer at 40°C for use, and then the product was put in an extruder. Blended with 142 parts of low molecular weight high activity polyisobutylene at 120°C to form a viscous rubber compound with strong viscosity. In Examples 7-10, the variables were set according to the mass ratio of mercapto compound to butyl rubber of 0:1, 0.032:1, 0.064:1, and 0.093:1, and the samples were obtained after vulcanization at 170°C according to the positive vulcanization time. The test results of the vulcanization performance of the samples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com