Patents

Literature

30results about How to "Not easy to move out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

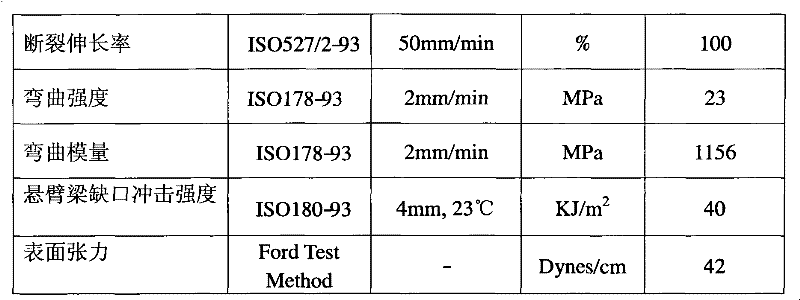

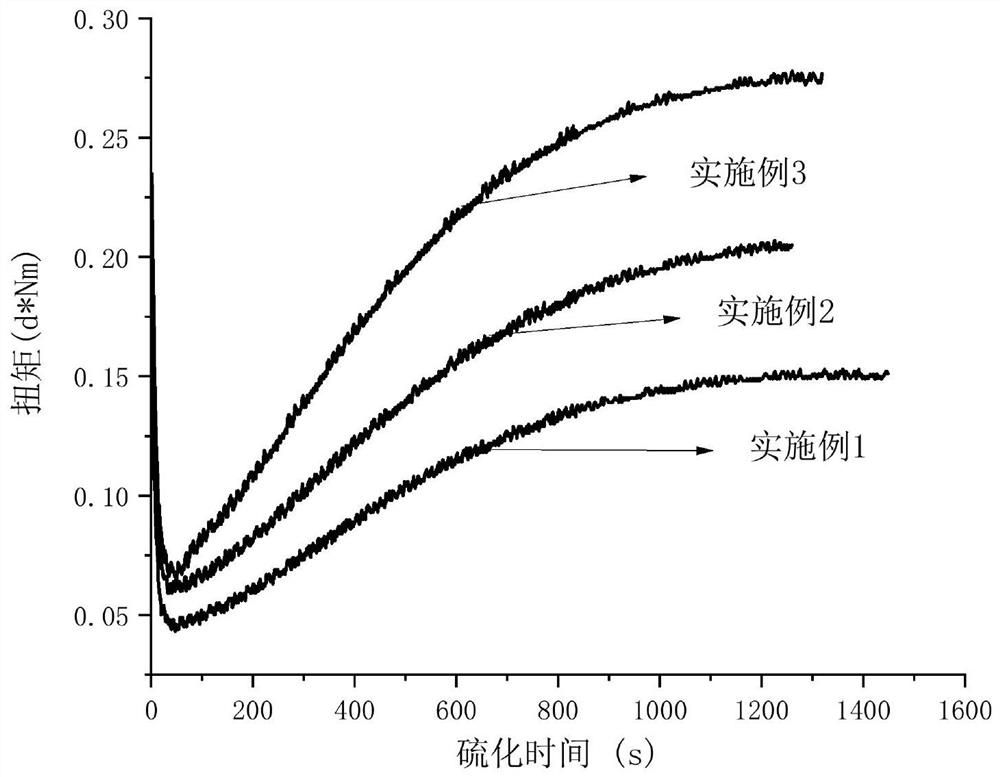

Sizing material for self-adhesive rubber water-stop belt and preparation method for sizing material

The invention belongs to the technical field of self-adhesive rubber water-stop belts, and particularly relates to a sizing material for a self-adhesive rubber water-stop belt and a preparation method for the sizing material. According to the main technical scheme adopted by the invention, the preparation method comprises: adding diene rubber into an internal mixer to plastify, and then adding an active agent, an anti-ageing agent, a reinforcing agent, operation oil and a functional filler into the internal mixer to mix with natural rubber; then, discharging and cooling mixed rubber master batch; and adding the discharged rubber master batch into an open mill, and adding a vulcanizing agent to mix, and carrying out thin-passing and batching-off, thereby obtaining the sizing material. The self-adhesive rubber water-stop belt prepared from the sizing material can be used for firmly connecting a self-adhesive layer with a concrete interface layer, thereby greatly improving adhesion between the water-stop belt and concrete, and effectively solving water leakage and water mixing problems of expansion joints, deformation joints and construction joints.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

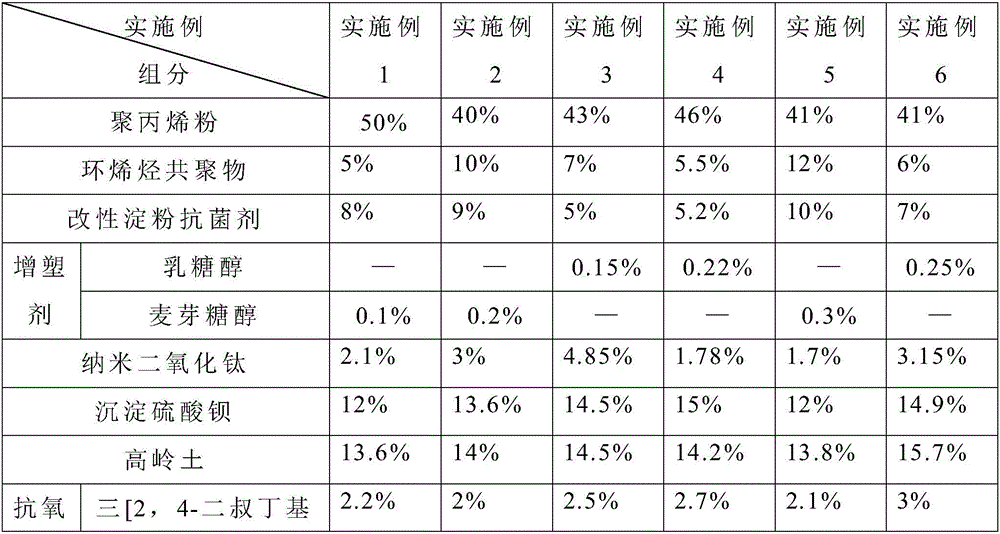

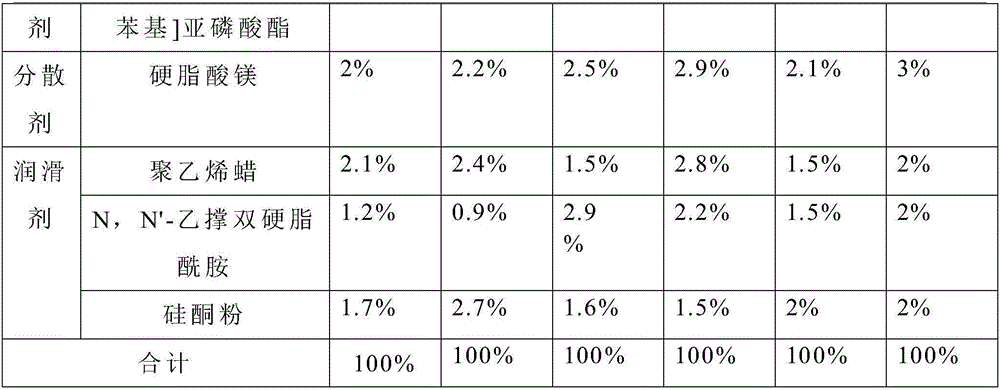

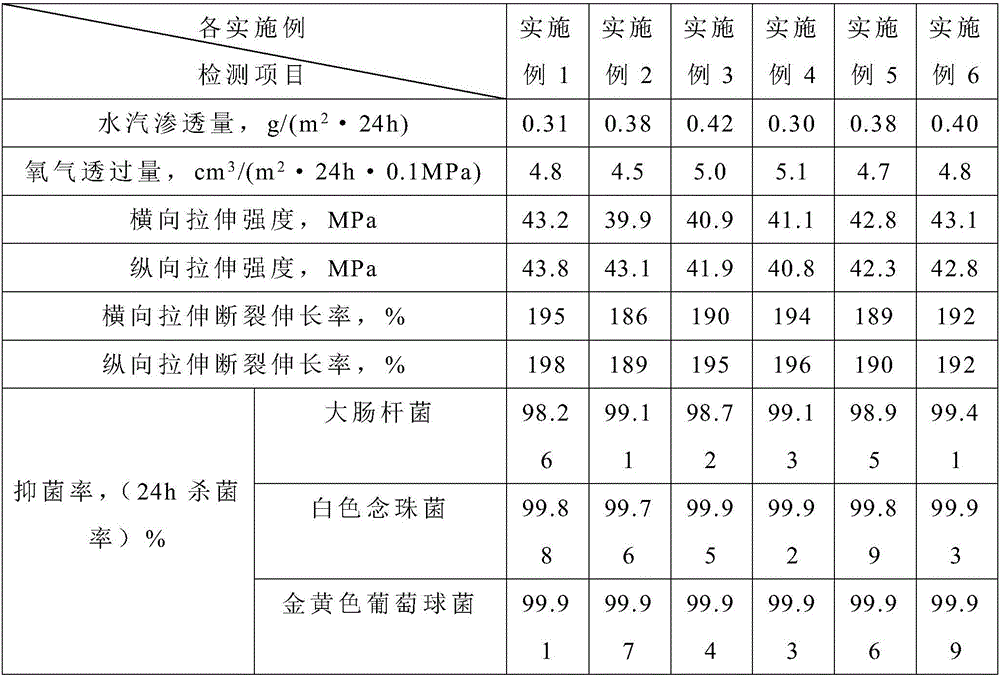

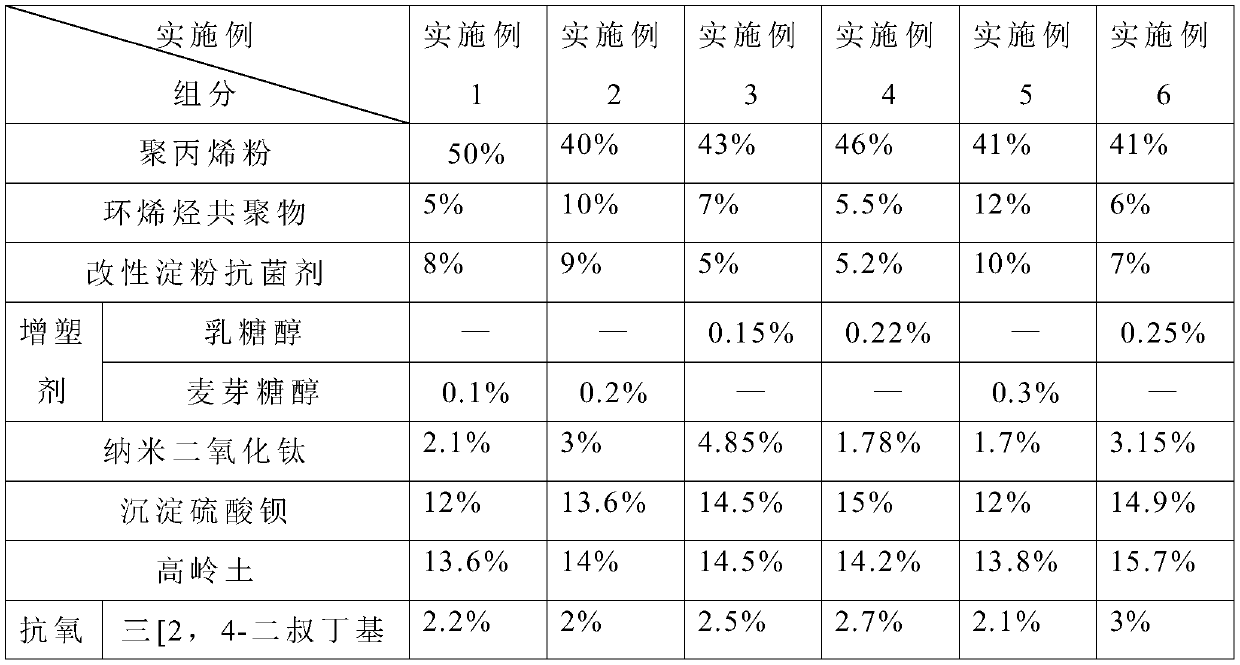

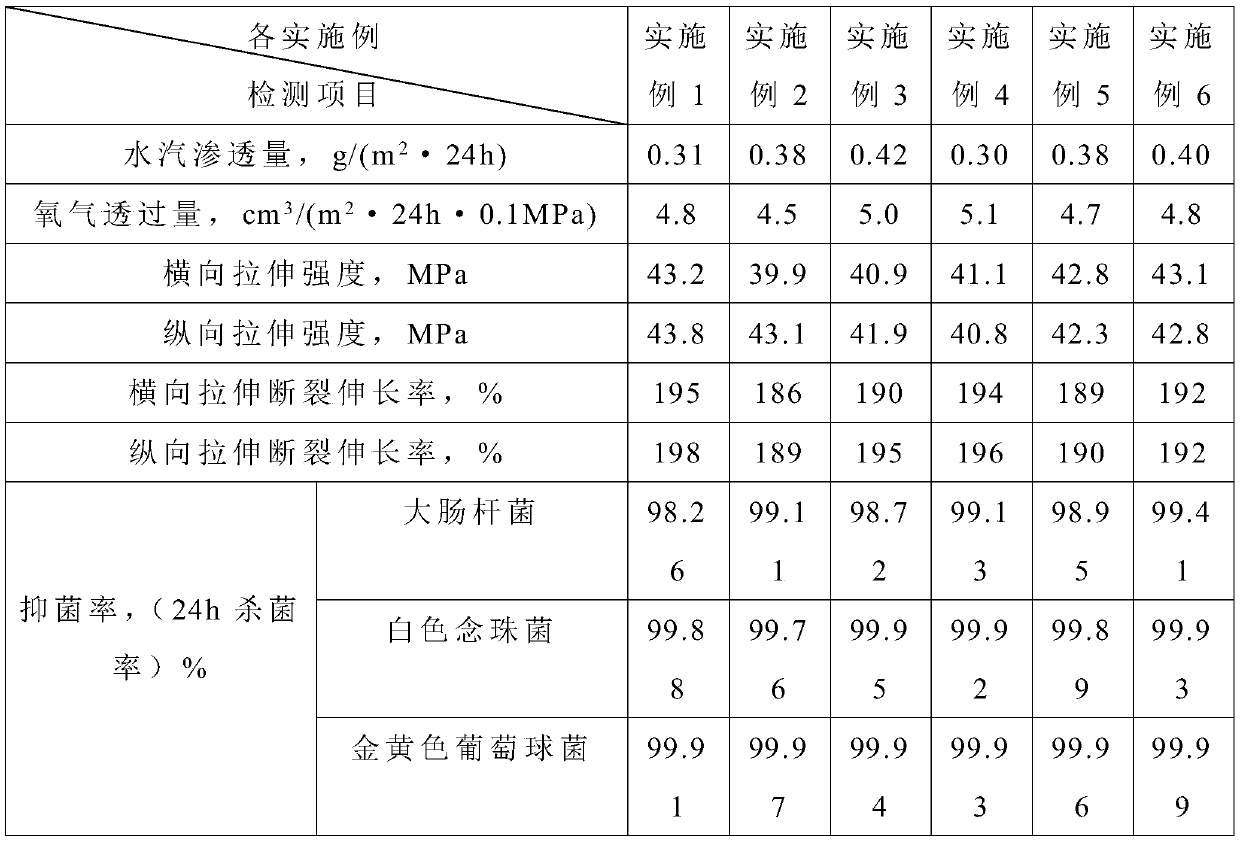

Antibacterial high barrier polypropylene color master batch for hygienic product packaging material and preparation method thereof

The invention relates to antibacterial high barrier polypropylene color master batch for a hygienic product packaging material and a preparation method thereof and belongs to the technical field of polypropylene color master batch. The antibacterial high barrier polypropylene color master batch for the hygienic product packaging material provided by the invention is prepared from the following components in percentages by mass: 40-50% of polypropylene powder, 5-12% of a cycloolefin copolymer, 5-10% of a modified starch antibacterial agent, 0.1-0.3% of a plasticizer, 1.7-4.85% of nano titanium dioxide, 12-15% of precipitated barium sulfate, 13.6-15.7% of kaolin, 2-3% of an antioxidant, 2-3% of a dispersant and 5-6.5% of a lubricant. The color master batch serving as a soft packaging material for a hygienic product has an excellent barrier property and good antibacterial activity.

Owner:JINJIANG XINBANG NEW MATERIAL TECH

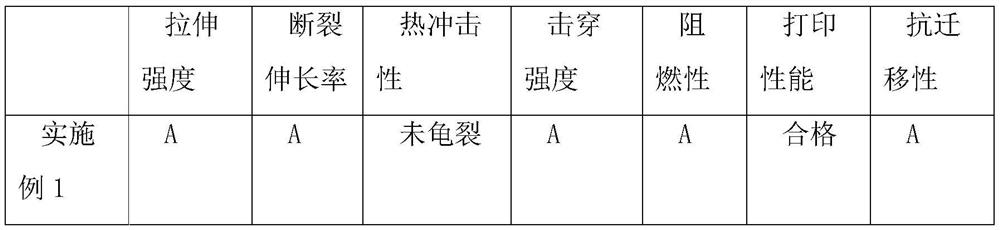

Laser marking halogen-free identification heat shrink tube and manufacturing method thereof

ActiveCN112210160AImprove flame retardant performanceDoes not affect acid resistanceHalogenPlasticizer

The invention provides a laser marking halogen-free marking heat shrinkable tube which is prepared from the following raw materials in parts by weight: 10-40 parts of polyethylene, 15-45 parts of a flame retardant, 15-30 parts of laser marking powder, 1-10 parts of a plasticizer, 25-75 parts of an ethylene-vinyl acetate copolymer and 1-8 parts of an assistant, wherein the flame retardant is a halogen-free flame retardant. According to the technical scheme, the organic halogen-free flame retardant and the inorganic halogen-free flame retardant are mixed, so that the whole material can still obtain better flame retardant property under the condition of less use, the content of the laser marking powder in the whole material can be ensured, the marking definition is improved, and the acid resistance of the whole material is not influenced. According to the technical scheme, all the components are green and non-toxic, and good environmental protection performance is achieved.

Owner:大连联合高分子材料有限公司

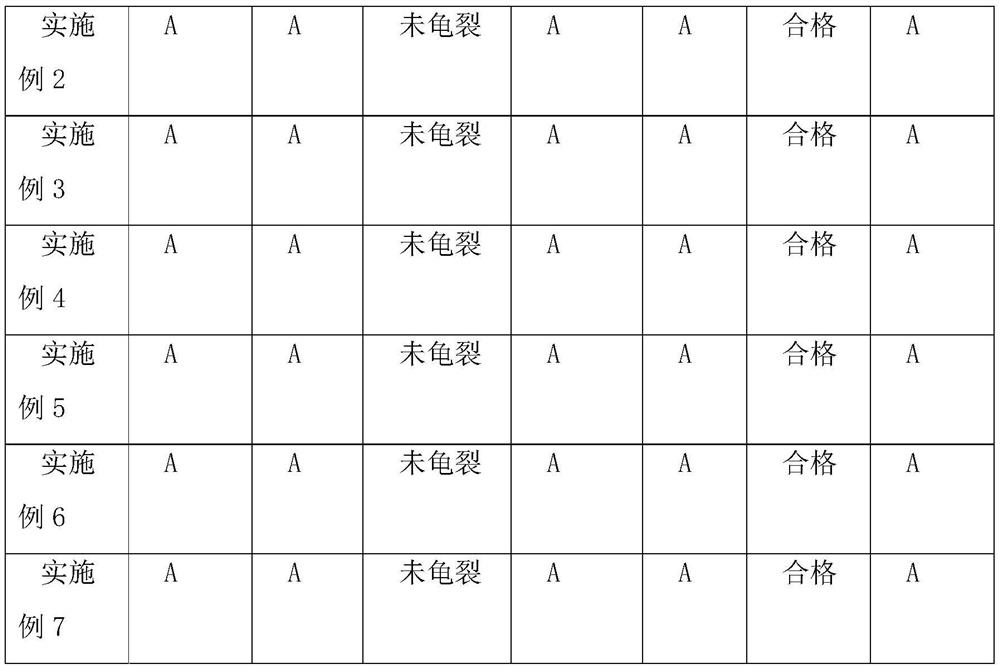

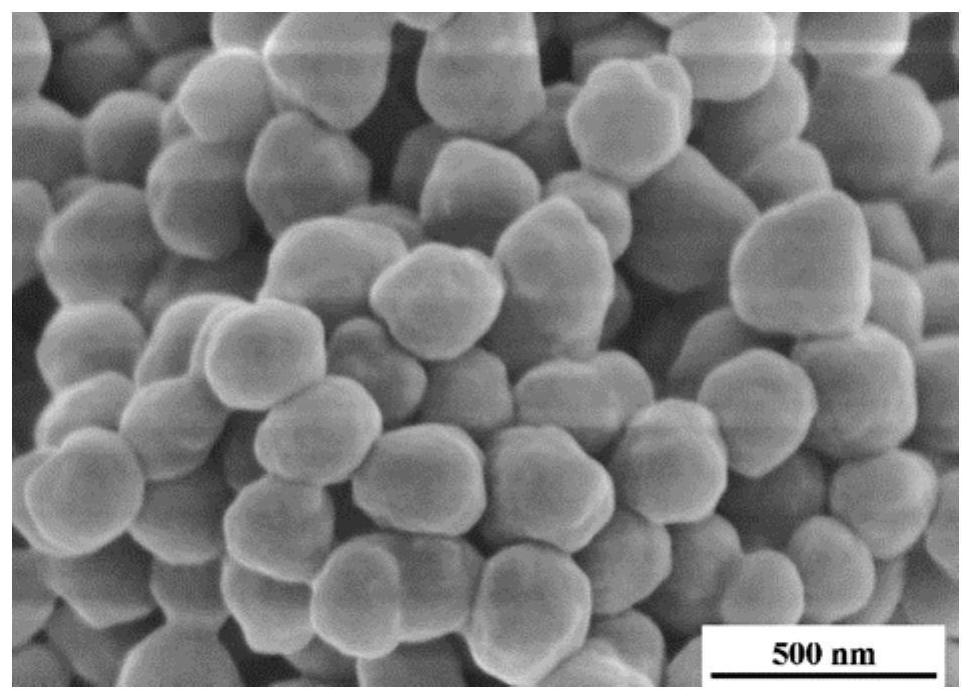

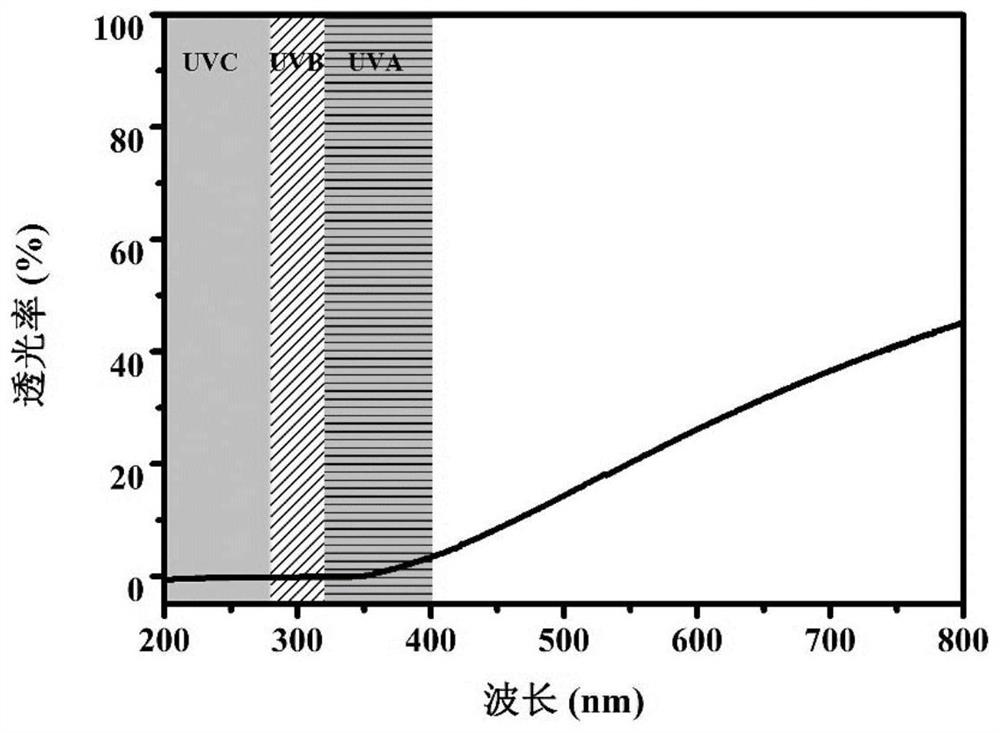

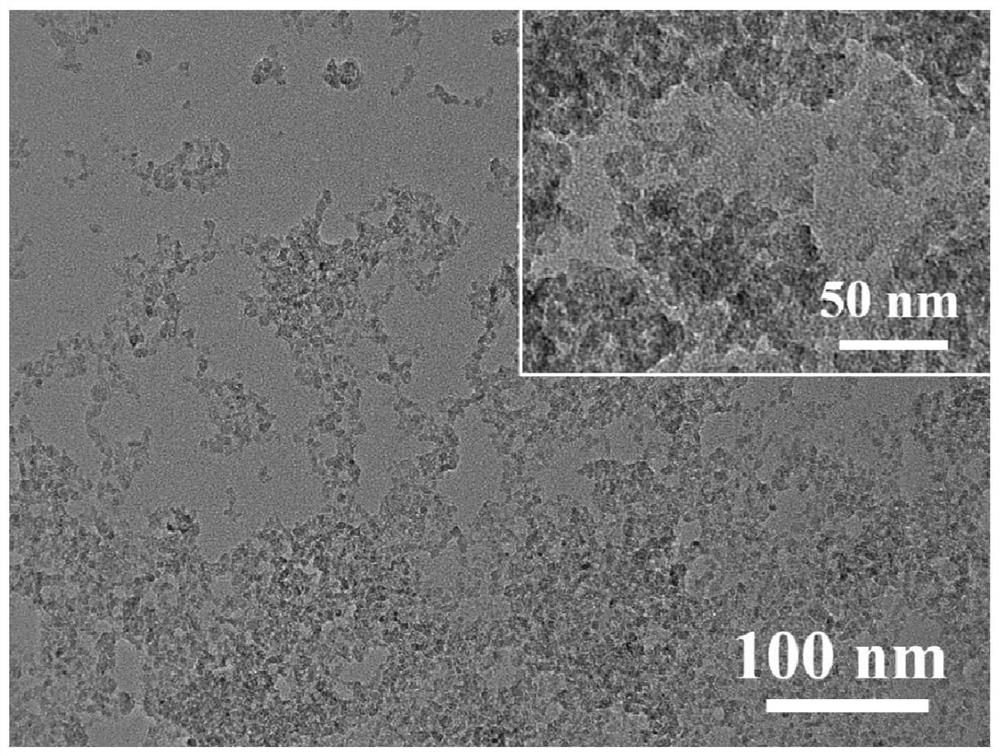

Antioxidant anti-ultraviolet microsphere, preparation method and application

The invention provides an antioxidant anti-ultraviolet microsphere, a preparation method and application, and belongs to the technical field of high polymer materials. The preparation method comprises the following steps: firstly, preparing maleic anhydride copolymer microspheres by a simple and efficient self-stabilization precipitation polymerization method, and centrifuging or filtering and purifying after the reaction is finished to obtain the microspheres; then carrying out amination modification on the microspheres by using ethidene diamine, and grafting a phenolic acid antioxidant to the surfaces of the aminated microspheres through EDC / NHS mediated amidation reaction to obtain the anti-oxidation and anti-ultraviolet microspheres. The prepared microspheres can be used for preparing antioxidant ultraviolet shielding composite materials, and have great application potential in the fields of food packaging materials, sunscreen skin care, coatings and the like.

Owner:JIANGNAN UNIV

Post-chain extending flame-retardant waterborne polyurethane modified by hyperbranched blended hard segment

InactiveCN106977681AImprove flame retardant performanceNot easy to move outEvaporationMechanical property

The invention relates to a post-chain extending flame-retardant waterborne polyurethane modified by a hyperbranched blended hard segment, and belongs to the field of flame-retardant materials. The waterborne polyurethane is prepared by a method with the following steps of dewatering macromolecular polyols, adding a hydrophilic chain extender and diisocyanate, and reacting until the content of -NCO is not changed; adding phosphor-containing polyol micromolecules until the content of -NCO is not changed; adding a salt forming agent A, so as to obtain a prepolymer; adding water into the prepolymer, and then adding an acetone / butanone / N-methyl pyrrolidone solution of a phosphorus-containing diamine chain extender, so as to obtain an emulsion; adding the emsulion into an AWHBPU water solution neutralized by a salt forming agent B to emulsify, and performing rotary evaporation to remove the solvent, so as to obtain the waterborne polyurethane. The waterborne polyurethane has the advantages that by modifying flame retardance via the hard segment, the flame-retardant property is improved, and the halogen-free and environment-friendly effects are realized; by modifying via post-chain extending, the flame-retardant property is improved, the mechanical property is improved, and the stability is improved; by blending the AWHBPU and the post-chain extending flame-retardant waterborne polyurethane, the mechanical property and stability are further improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Hyperbranched poly-blend soft-segment modified chain extension anti-flaming waterborne polyurethane

InactiveCN107099132AImprove flame retardant performanceNot easy to move outMechanical propertySoft segment

The invention relates to hyperbranched poly-blend soft-segment modified chain extension anti-flaming waterborne polyurethane, which belongs to the field of flame retardant materials. The waterborne polyurethane is prepared by the following steps of after dehydrating macromolecule polyhydric alcohol, adding a hydrophilic chain extender and diisocyanate, reacting until -NCO content is constant, adding a phosphorus containing polyhydric alcohol macromolecule until -NCO content is constant, and adding a salt-forming agent A to obtain a prepolymer; adding water into the prepolymer, adding an acetone / butanone / N-methyl pyrrolidone solution of a phosphorus-containing diamine chain extender after adding water, and obtaining an emulsion; adding the emulsion into an AWHBPU water solution neutralized by a salt-forming agent B for emulsifying, spin-evaporating to remove a solvent, and obtaining the waterborne polyurethane. The waterborne polyurethane is subjected to soft-segment anti-flaming modification, so that a flame retardant property is improved, and the waterborne polyurethane is halogen-free and environmentally-friendly; through chain extension modification, a flame retardant property is improved, a mechanical property is improved, and the stability is improved; through blending the AWHBPU and the chain extension anti-flaming waterborne polyurethane, a mechanical property and the stability are further improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Iron-leak-preventing structure for permeable brick of hot metal ladle and replacing method for iron-leak-preventing permeable brick

The invention provides an iron-leak-preventing structure for a permeable brick of a hot metal ladle and a replacing method for the iron-leak-preventing permeable brick. The replacing method for the iron-leak-preventing permeable brick specifically comprises the steps of: firstly disassembling building bricks of an original working layer which is not less than 600mm from the outer edge of the permeable brick; taking out the old permeable brick; mounting a novel permeable brick; reserving a gap between the periphery of the novel permeable brick and each of original permanent layers of the hot metal ladle; then filling the gaps with brine blended clayey ramming mass and performing ramming; then building the disassembled part with magnesia carbon bricks in a wet building manner and meanwhile, reserving gaps between the periphery of the permeable brick and the built working layers; pouring a corundum self-flowing pouring material; and then performing natural preservation 6-8h to enter a baking stage. The structure provided by the invention is simple and convenient in building construction, can avoid an iron-leak phenomenon as the permeable brick is replaced, and is good in iron-leak-preventing effect, so that the potential safety hazard of the hot metal ladle due to iron leakage is avoided.

Owner:武汉精鼎科技股份有限公司

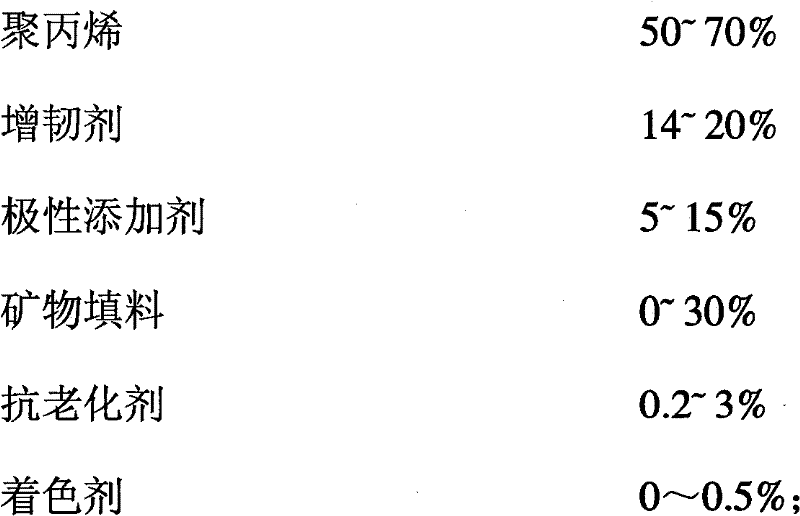

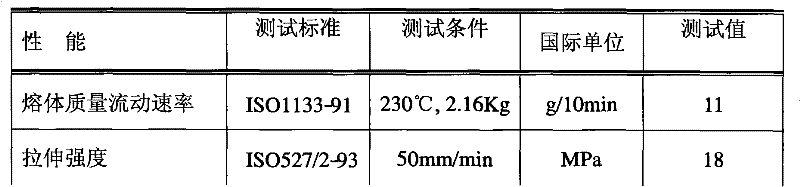

High-polarity polypropylene material and application thereof as inner and outer decorative parts of automobile

ActiveCN101717548BIncrease surface polarityLower surface energySuperstructure subunitsBumpersPolymer scienceDyne

The invention discloses a high-polarity polypropylene material and the application thereof as inner and outer decorative parts of an automobile. The material is prepared from the following components in percentage by weight: 50-89 polypropylene, 5-25 flexibilizer, 0-30 mineral filler, 5-15 polar additives, 0.2-3 age resister and 0-0.5 colorant, and the components are premixed and then are extruded out by a double-screw extruder to prepare particles, thereby preparing the high-polarity modified polypropylene material. The surface tension of the material is as high as 37 dyne / cm<2>, dope-binding strength is high, an automobile bumper formed by the material can be coated without being pretreated, and when being used for preparing the inner decorative part for the automobile, the material hasgood property of binding other materials.

Owner:WUHAN JINFA TECH CO LTD

Micro-crosslinking self-repairing sealant as well as preparation method and application thereof

ActiveCN114456745AStrong stickinessIncrease stickinessNon-macromolecular adhesive additivesMacromolecular adhesive additivesForeign matterPolymer science

According to the micro-crosslinking tire self-repairing sealant and the preparation method thereof, the sealant has extremely low modulus and extremely high self-adhesion and has certain elasticity, and when a tire is punctured by foreign matter, the sealant can immerse into gaps under the action of tire pressure to bond cracks, so that the tire pressure is guaranteed. The sealant main body is preferably selected from butyl rubber, brominated butyl rubber and medium-molecular-weight polyisobutene, the softening agent is preferably selected from low-molecular-weight polyisobutene, the low-molecular-weight polyisobutene has excellent compatibility with the medium-molecular-weight polyisobutene and the butyl rubber and is not easy to migrate out, and the sealant is endowed with extremely strong viscosity while the modulus of the sealant is reduced.

Owner:BEIJING UNIV OF CHEM TECH

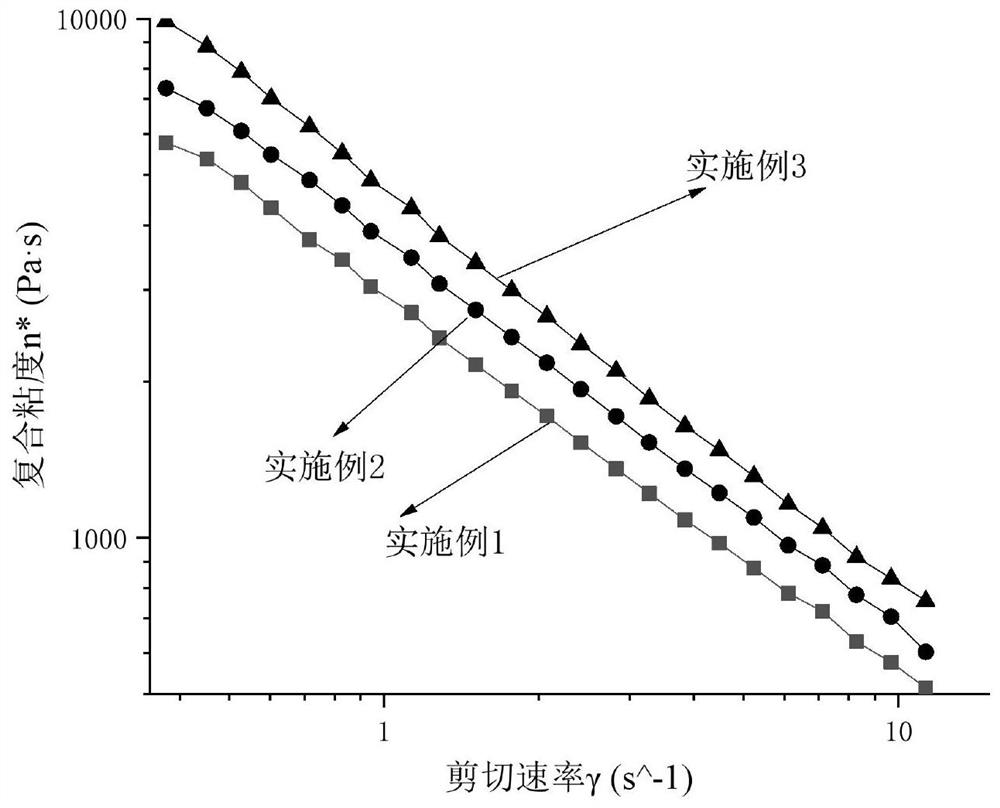

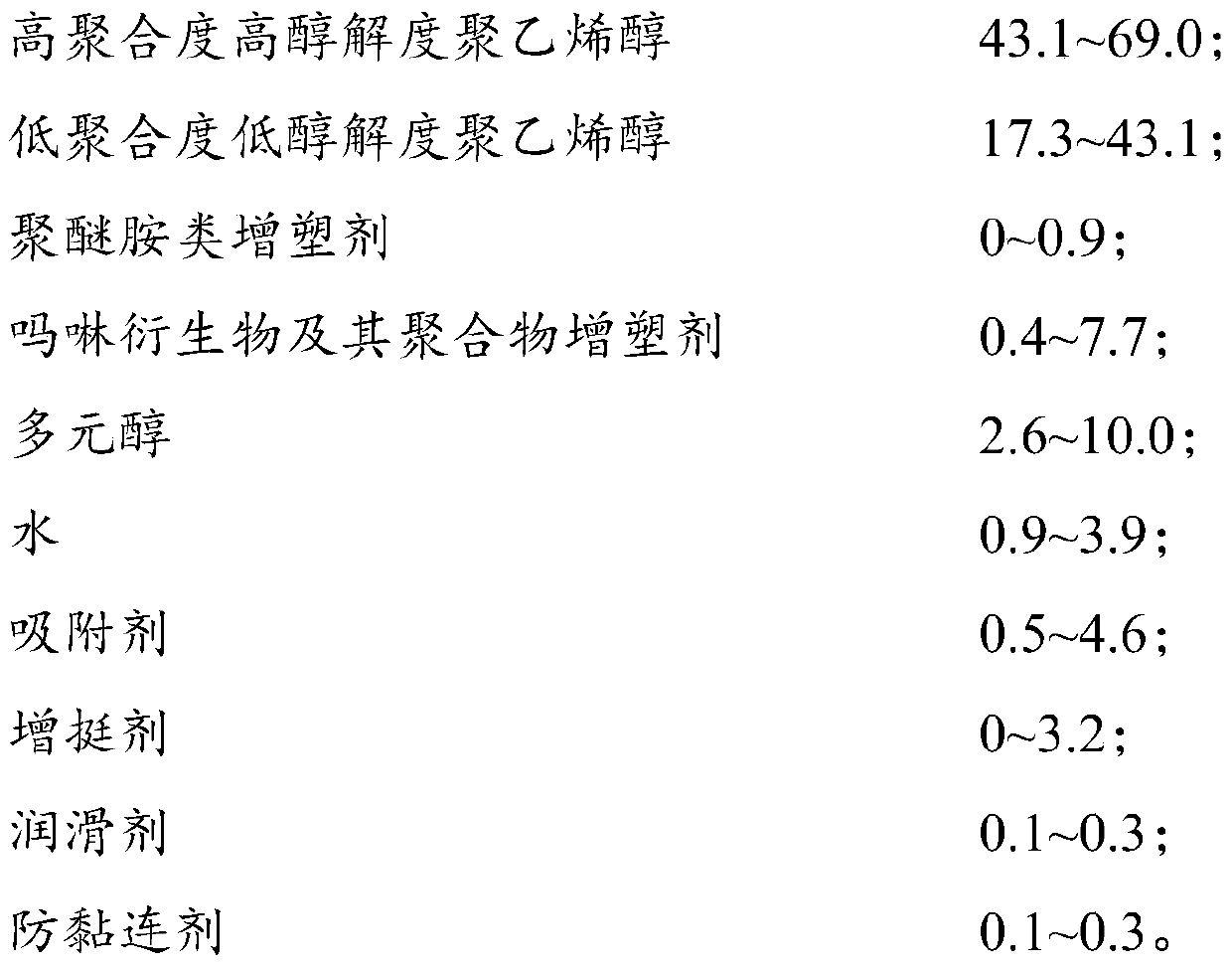

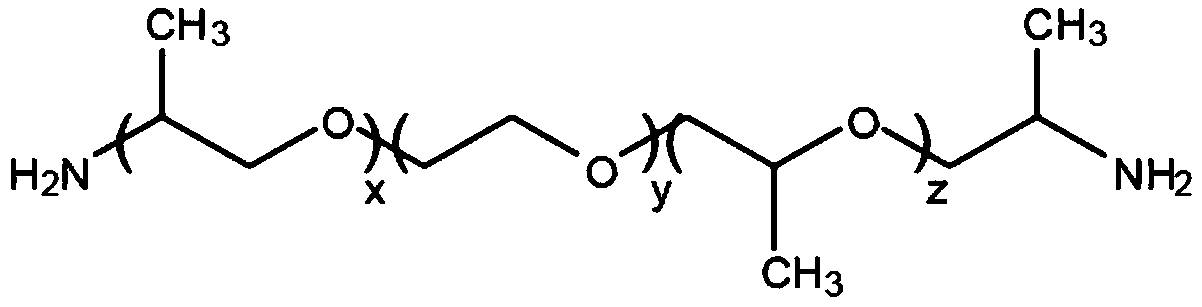

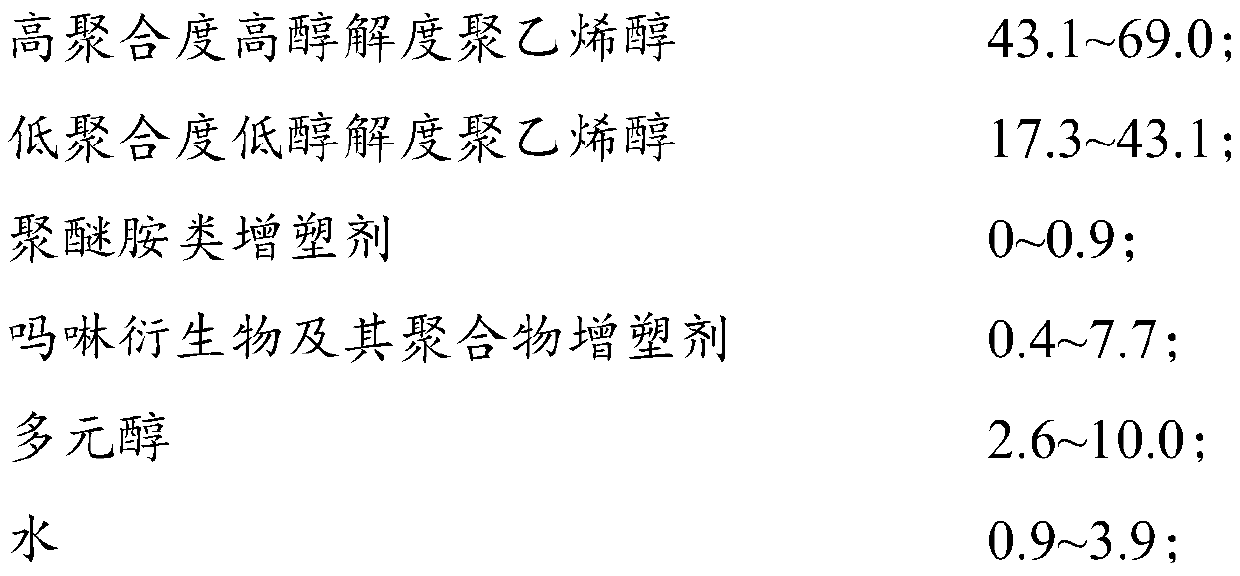

Composition containing polyvinyl alcohol, film preparing method and film

PendingCN109777016AHas internal plasticizing effectHas content augmentationPVA - Polyvinyl alcoholPolymer chemistry

The invention relates to a composition containing polyvinyl alcohol. The composition includes components by weight in parts in the specification. The composition allows an obtained polyvinyl alcohol film to have good rigidity and stiffness.

Owner:JIANGMEN PROUDLY WATER SOLUBLE PLASTIC CO LTD

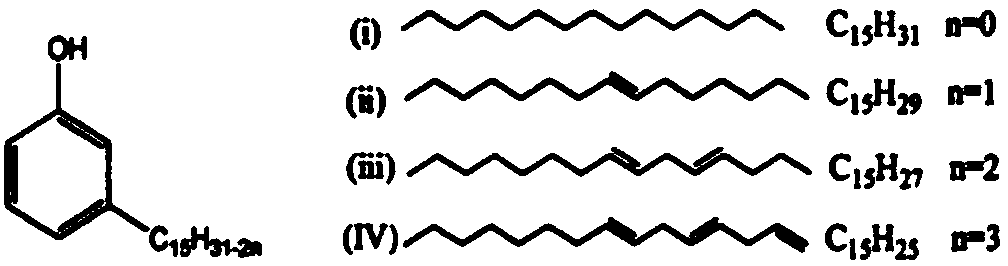

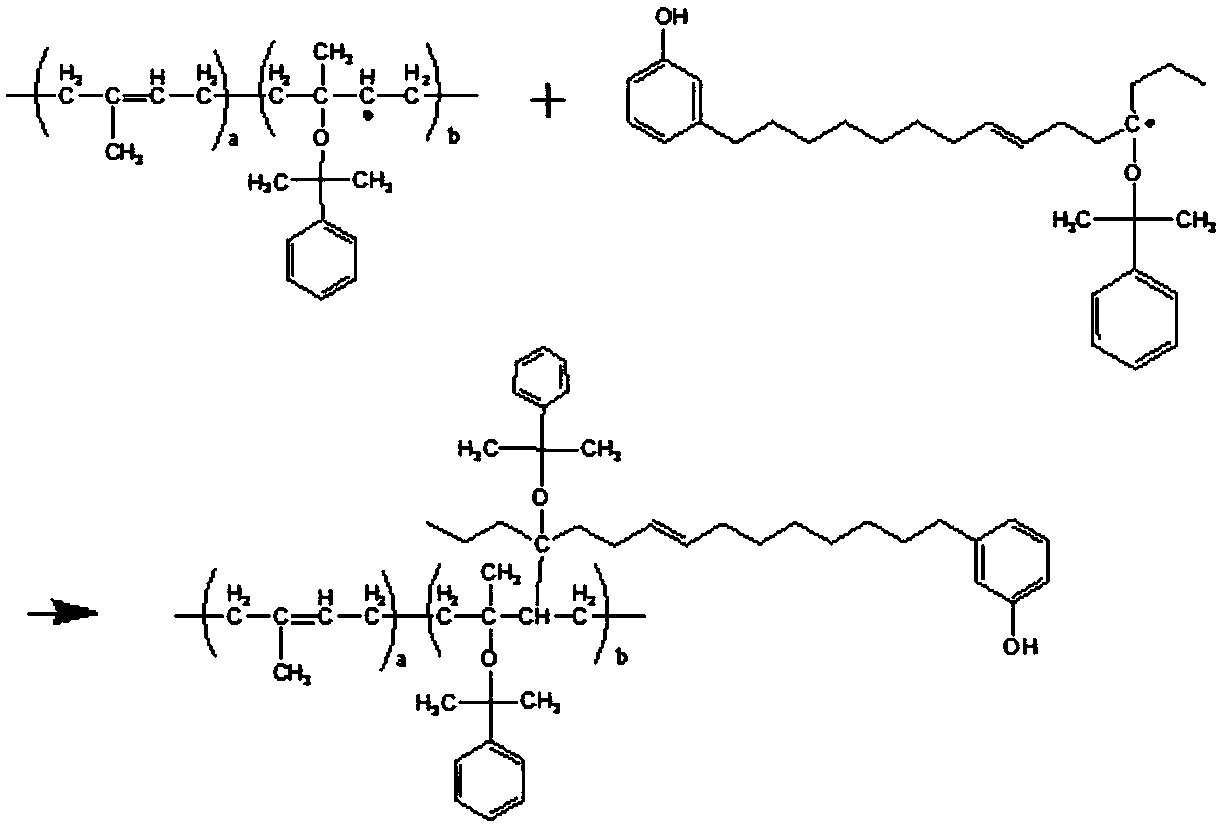

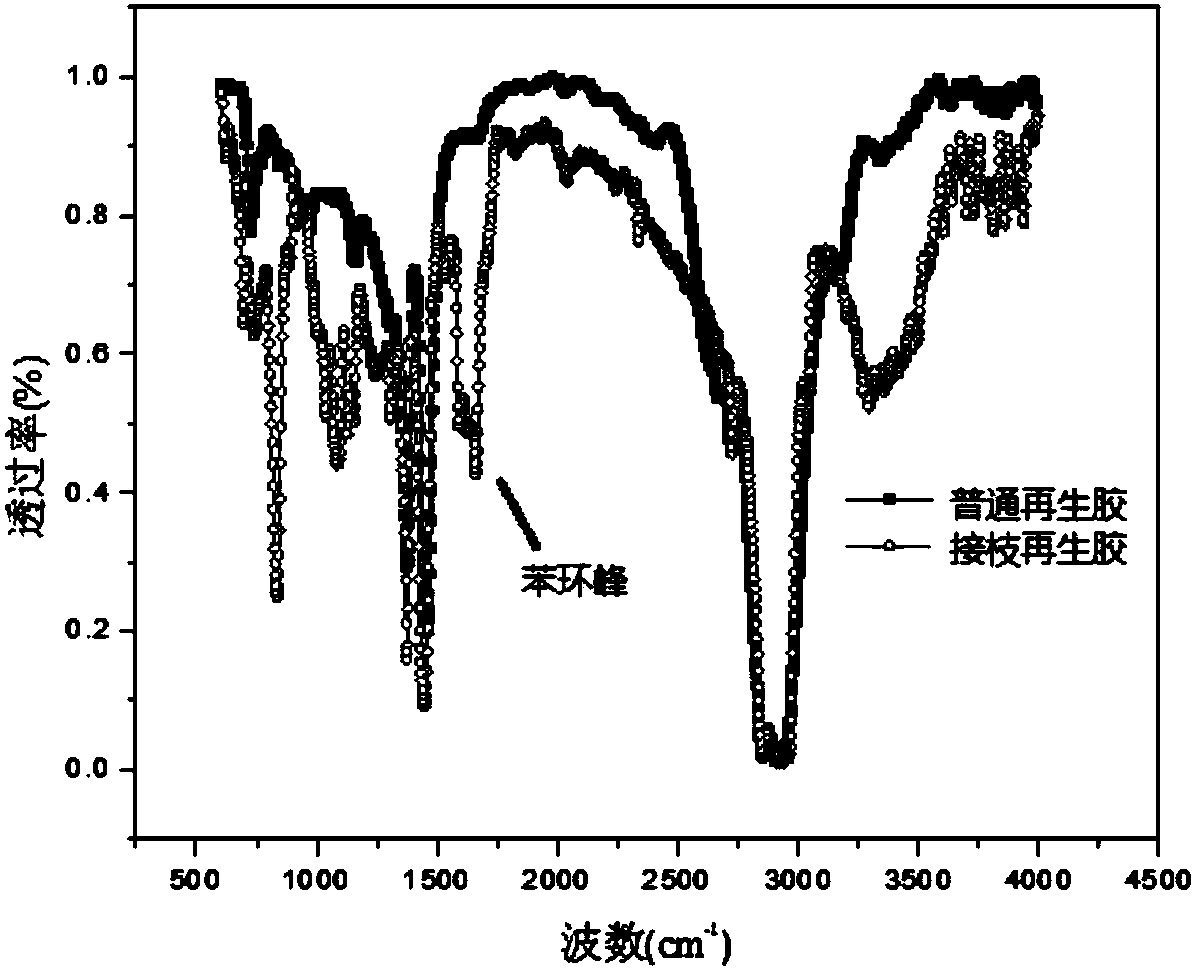

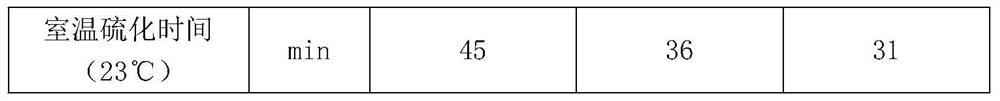

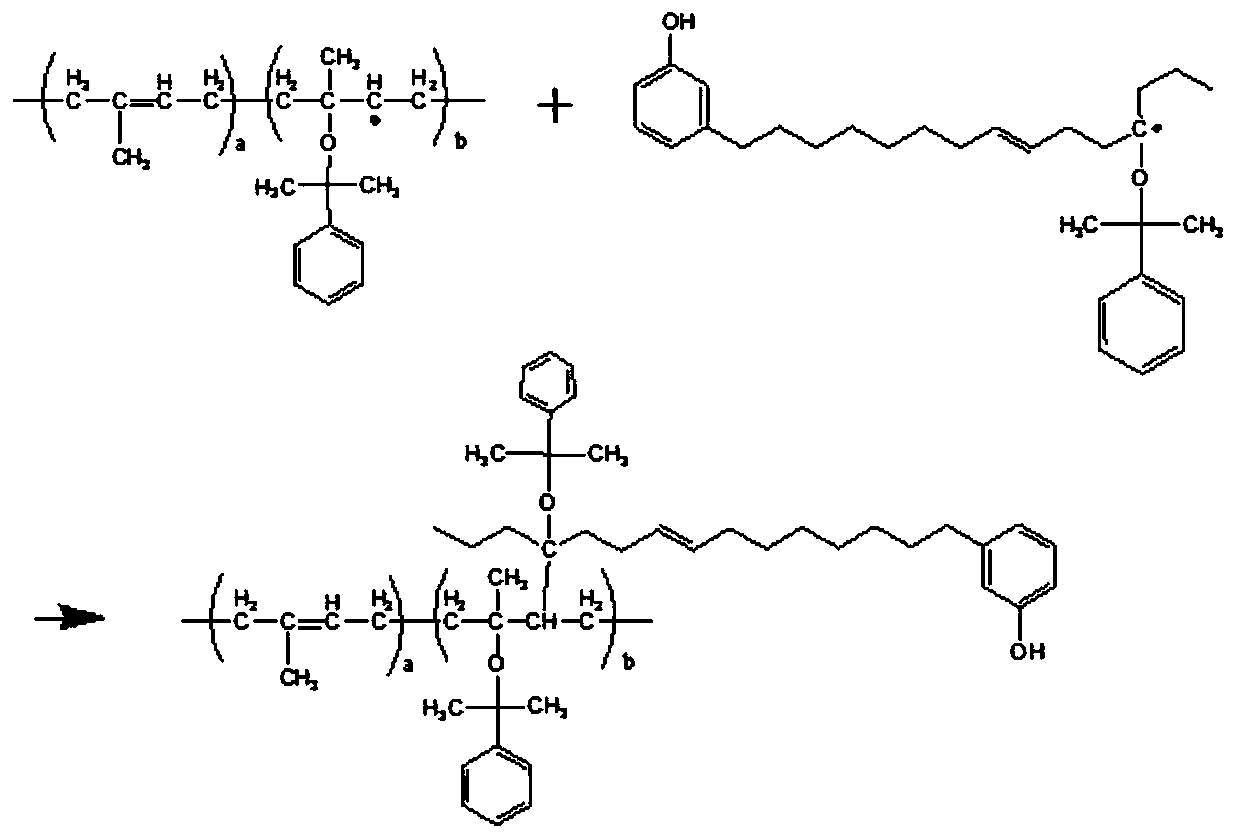

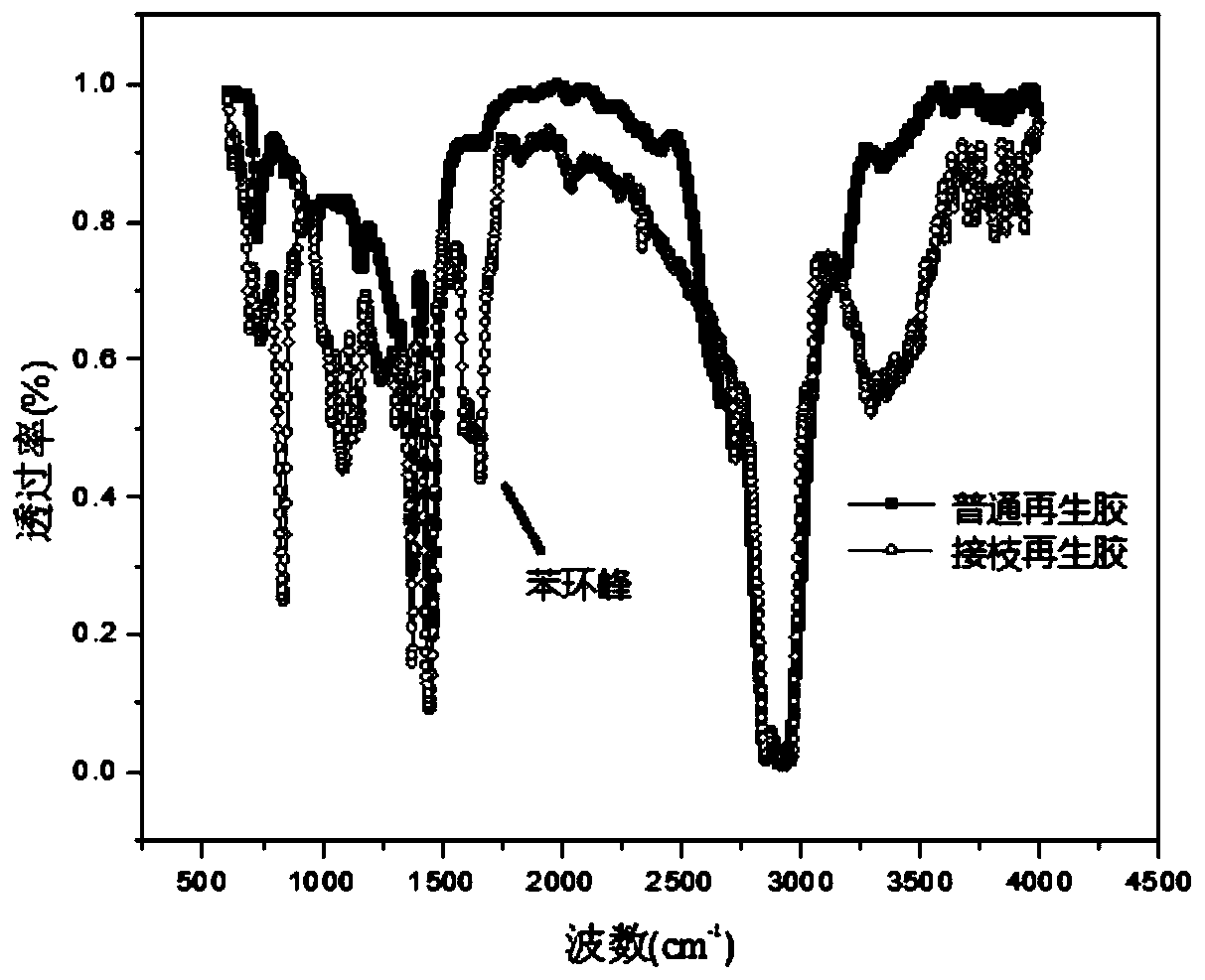

Environment-friendly softening agent grafted regenerated rubber and preparation method thereof

The invention provides environment-friendly softening agent grafted regenerated rubber and a preparation method thereof. The preparation method comprises the following steps: taking vegetable oil containing phenolic hydroxyl groups and unsaturated alkyl chains as a regenerated rubber softening agent, adding an organic peroxide initiator in the waste rubber powder regeneration process, initiating double-bond or three-bond rupture to the regenerated rubber to produce free radicals, combining the free radicals with free radicals formed by a thermal oxidation effect in the rubber powder regeneration process, and grafting a free softening agent in the regenerated rubber onto a main chain of the regenerated rubber. The regenerated rubber prepared by the method disclosed by the invention has theadvantages of being green, environment-friendly, non-blueing, excellent in mechanical property and stable in Mooney.

Owner:QINGDAO UNIV OF SCI & TECH

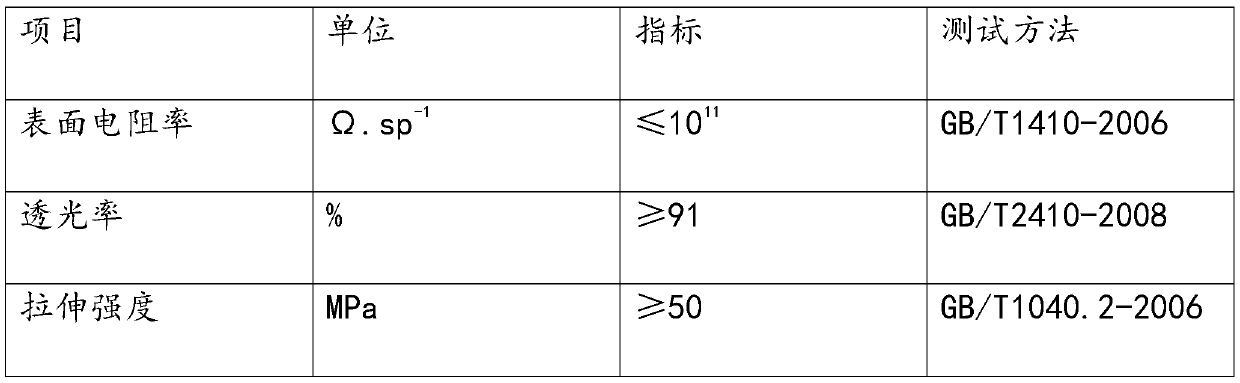

Production process of PMMA monomer copolymerized organic glass

The invention provides a PMMA monomer copolymerized organic glass production process. The PMMA monomer copolymerized organic glass production process comprises the following steps: 1) preparing raw materials from the following components in percentage by mass: 79-85% of methyl methacrylate, 5-10% of an antistatic agent, 5-10% of an intermediate monomer and 1-3% of an initiator; 2) weighing the rawmaterials in proportion, adding the methyl methacrylate and the initiator in the step 1) into a dissolving device together, and carrying out mutual dissolution reaction for later use; and 3) weighingthe raw materials in proportion, adding the double-bond-containing antistatic agent in the step 1) and an intermediate monomer into a high-temperature dispersion device together, dissolving the double-bond-containing antistatic agent into the intermediate monomer through ultrasonic treatment, and taking out for later use. The transparent anti-static organic glass formed by copolymerization has the characteristics of high light transmittance, excellent anti-static performance, low possibility of migration of the anti-static agent, simple process and low cost, and has a wide application prospect.

Owner:ZHEJIANG LONGYOU ZHANYU ACRYLIC

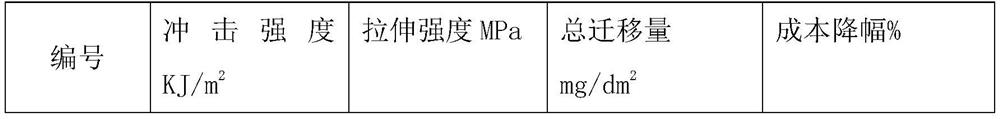

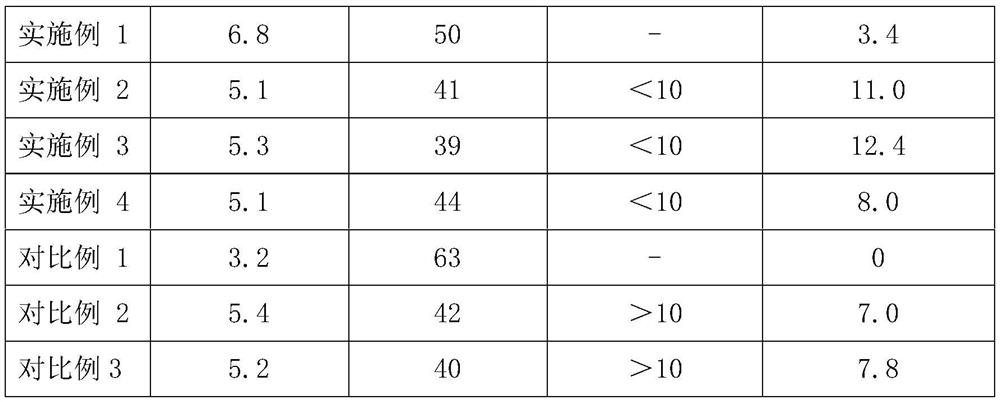

Degradable resin and method for preparing straw by using degradable resin

PendingCN113999504AImprove heat resistance and impact strengthMeet food contact requirementsTubular articlesAnoxomerPlasticizer

The invention relates to degradable resin and a method for preparing a straw from the degradable resin. The degradable resin is prepared from the following raw material components in 100 parts by weight: 70 to 95 parts of polylactic acid, 1 to 10 parts of a toughening agent, 0.5 to 15 parts of a filling agent, 0.1 to 1 part of a lubricating agent, 0.05 to 0.2 part of a nucleating agent, 0.08 to 0.3 part of a compatilizer, 0.1 to 2 parts of a plasticizer, 0.1 to 1 part of an antioxidant and 0.1 to 3 parts of a coupling agent; wherein the polylactic acid is PLAlx175; the toughening agent is poly (butylene succinate) (PBS); the filling agent is a mixture of one or more of starch and bamboo fiber powder; and the coupling agent is a mixture of one or more of titanate or lauric acid. According to the invention, the straw solves the problems that an existing straw is poor in heat resistance, the filler is easy to migrate out, and the food contact requirement cannot be met.

Owner:浙江中科应化生态新材料科技有限公司

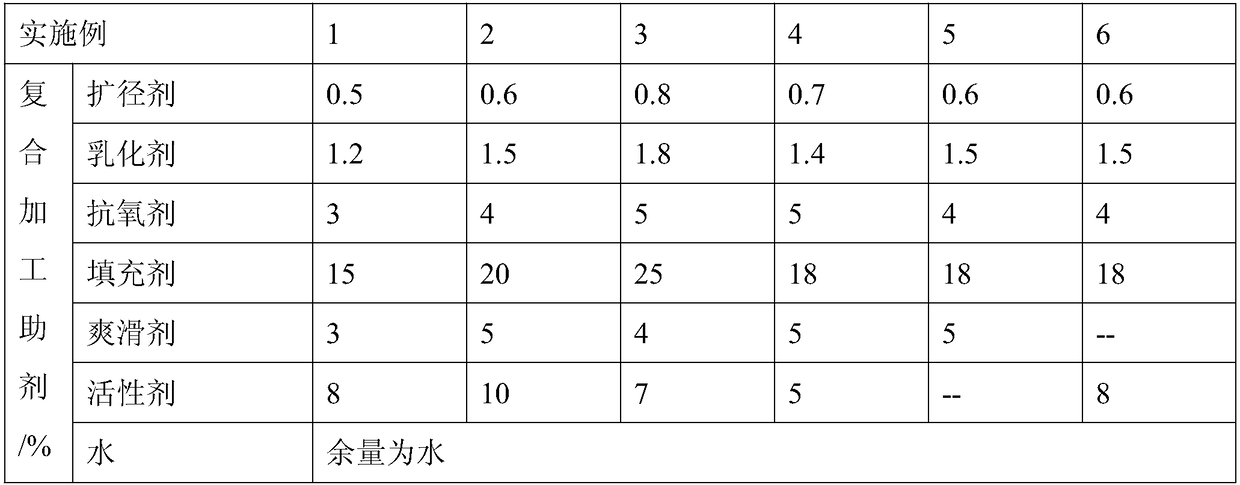

Composite processing additive for plastic thin film and preparation method thereof

The invention relates to a composite processing additive for a plastic thin film and a preparation method thereof. The composite processing additive is prepared from the following components in percentage: 0.5 to 0.8% of diameter expanding agent, 1.2 to 1.8% of emulsifier, 3 to 5% of antioxidant, 15 to 25% of filling agent, 3 to 5% of slipping agent, 5 to 10% of activator, and the balance of water. The preparation method comprises the following steps of S1, preparing raw materials; S2, preparing the emulsifier; S3, preparing a processing additive mixed solution; S4, aging. The composite processing additive has the advantages that the cost is low, the application range is broad, and the stability is good.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

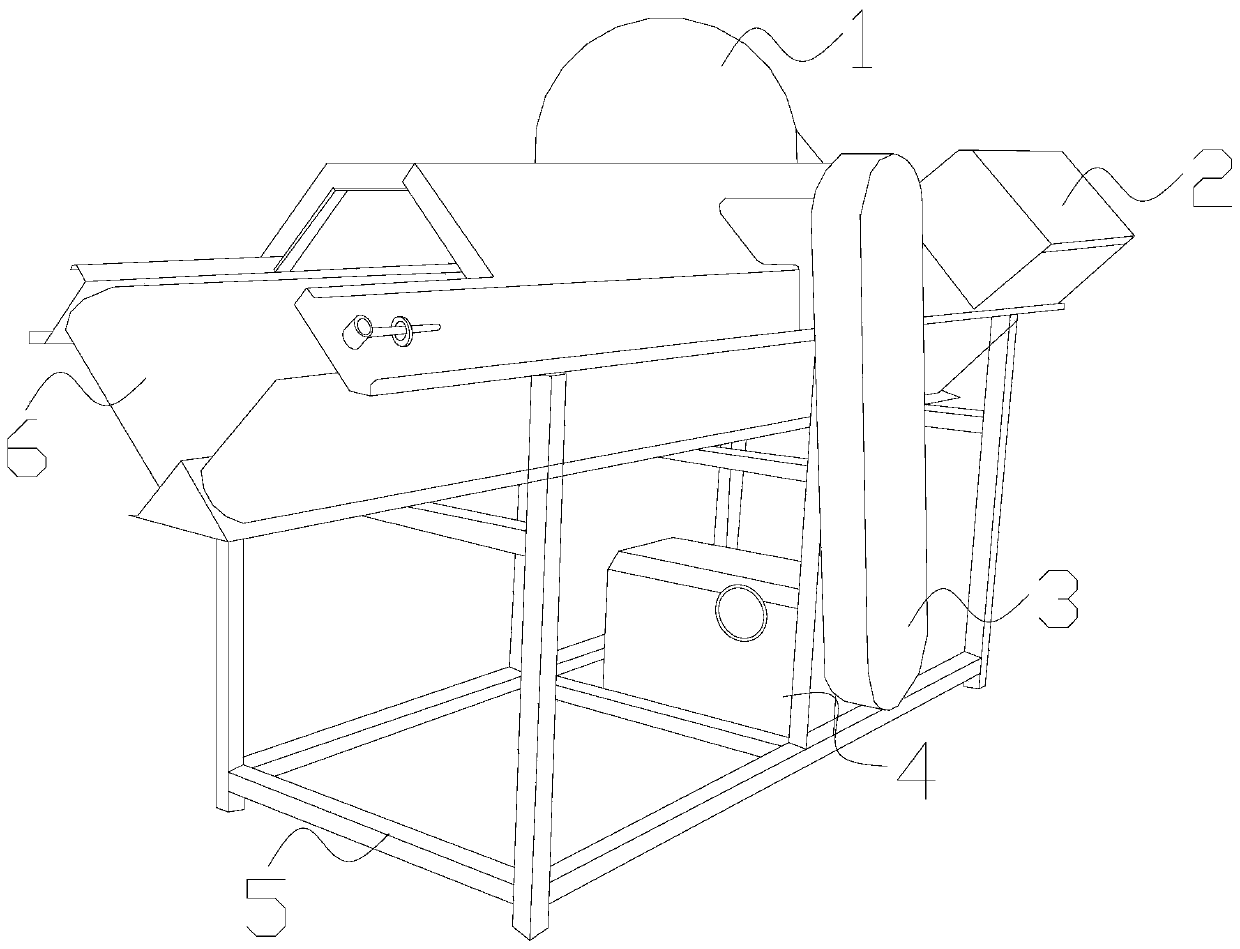

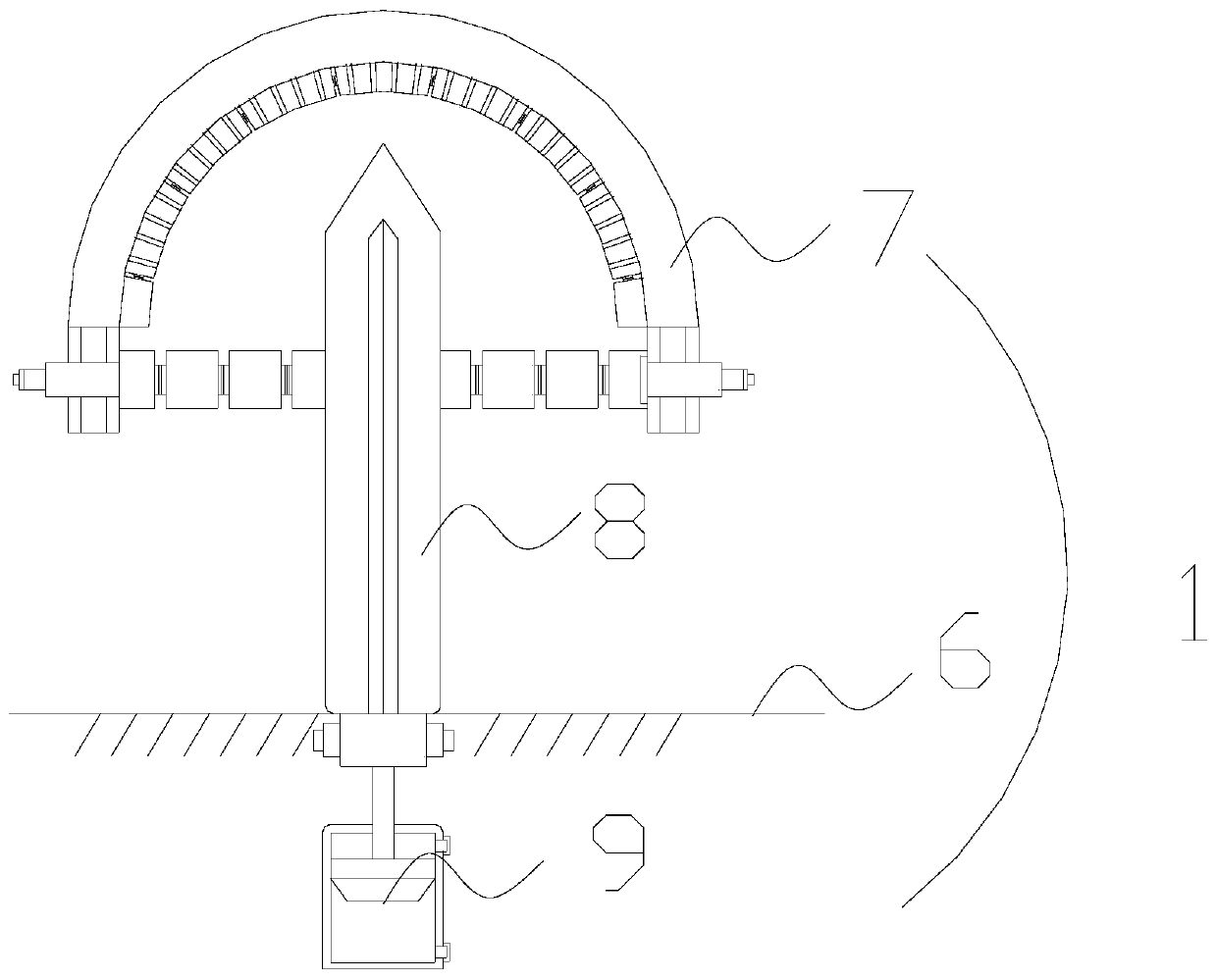

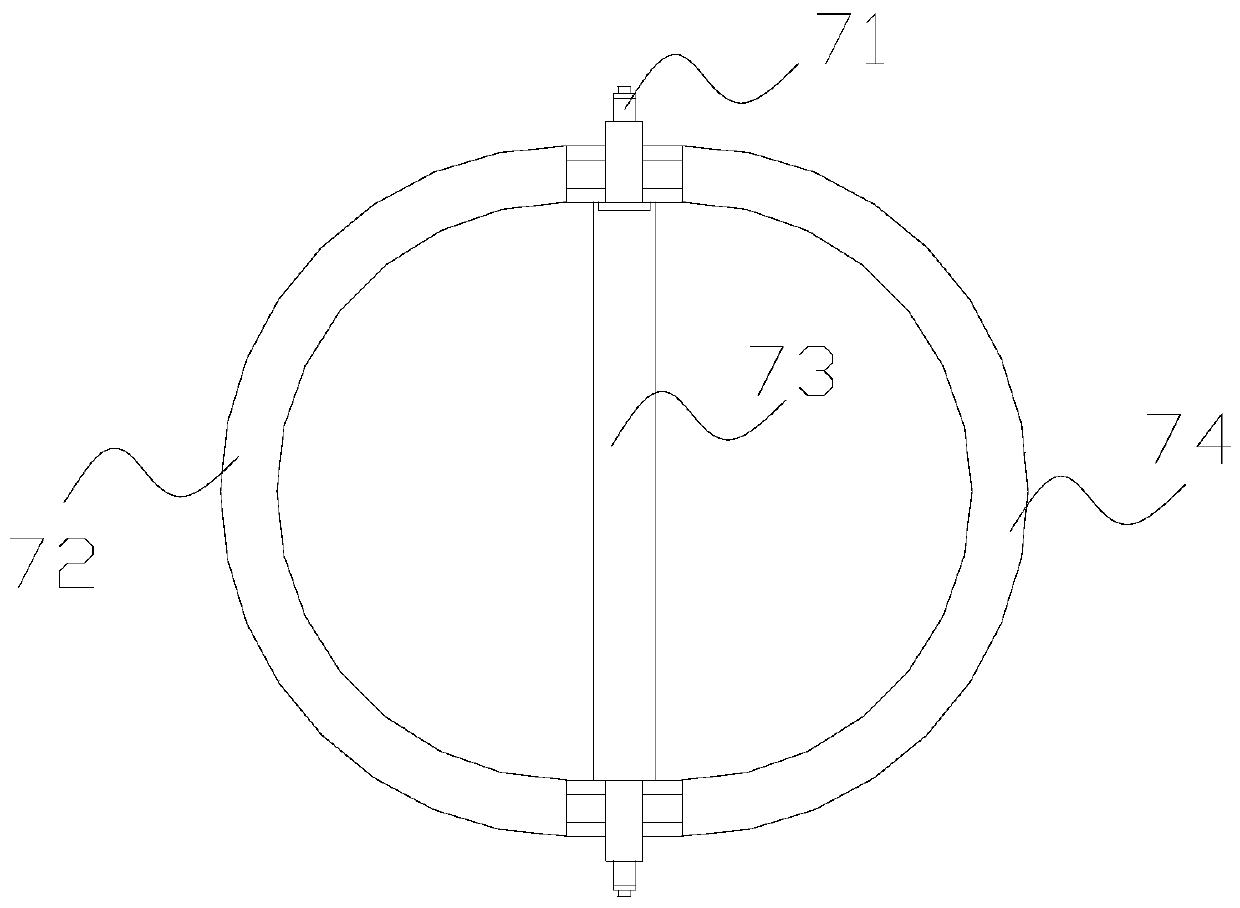

Half cutting machine of culture medium for experiments

InactiveCN111590652ANot easy to move outGuaranteed flatnessMetal working apparatusPhysicsElectric machinery

The invention discloses a half cutting machine of a culture medium for experiments. The half cutting machine structurally comprises a half cutting structure, a control box, a belt, a motor, a bottom rack and a conveying platform. The bottom of the conveying platform is movably provided with the bottom rack, one end of the conveying platform is movably provided with the half cutting structure and the control box, one side of the control box is provided with the belt, and one end of the belt is mechanically connected with the conveying platform. According to the half cutting machine, a first clamping sheet, second clamping sheets and a third clamping sheet form a triangular structure, the surfaces of the first clamping sheet, the second clamping sheets and the third clamping sheet are smooth, the culture medium is half wrapped for fixing and prevented from relatively sliding, the globular or original culture medium is halved, and a cutter directly upwards cuts off the culture medium fromthe bottom and directly cuts the culture medium into halves. According to the half cutting machine, the first clamping sheet, the second clamping sheets and the third clamping sheet are semi-circulararc plates, the head and tail ends are slightly bent to fix the culture medium, the cutter upwards cuts the culture medium from the bottom, the culture medium is not prone to moving outwards, and thecut culture medium is more precise.

Owner:常开旭

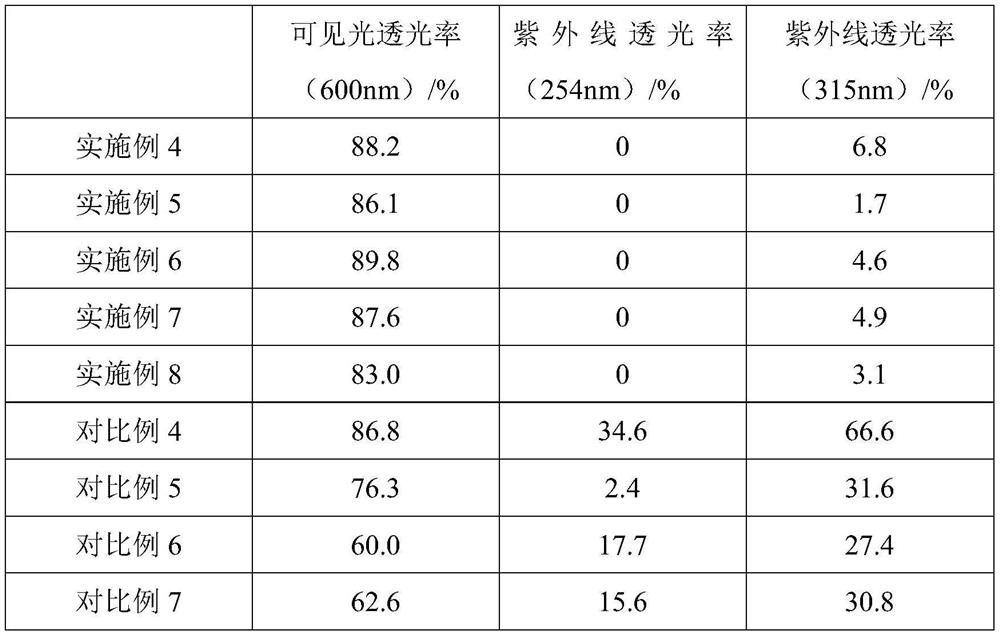

A kind of hybrid nanoparticle, preparation method and anti-ultraviolet application

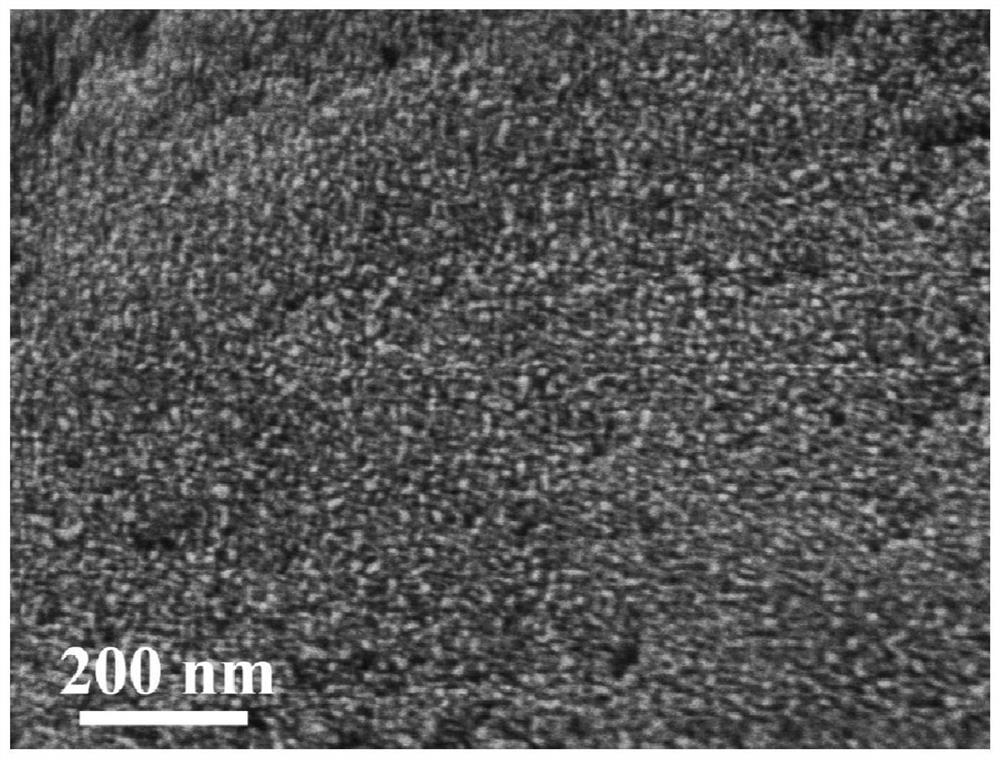

ActiveCN112225894BSmall particle sizeEasy to prepareMaterial nanotechnologyPhotothermal conversionDopamine

A hybrid nanoparticle, a preparation method and an anti-ultraviolet application belong to the technical field of nanocomposite materials. First prepare the amorphous titanium dioxide precursor dispersion and the dopamine / dopamine-like monomer precursor dispersion respectively; then mix the amorphous titanium dioxide precursor dispersion and the dopamine / dopamine-like monomer precursor dispersion, adjust the pH, and heat and stir reaction to obtain a titanium dioxide / polydopamine hybrid particle dispersion; finally, the prepared hybrid particle dispersion is separated and purified by centrifugation or dialysis to obtain titanium dioxide / polydopamine hybrid nanoparticles. The prepared nanoparticles can be used to prepare transparent ultraviolet shielding composite materials, and have excellent barrier, photocatalysis, and photothermal conversion properties. Further, it can be applied in packaging materials, window materials, agricultural film materials, sunscreen and skin care and other fields.

Owner:JIANGNAN UNIV

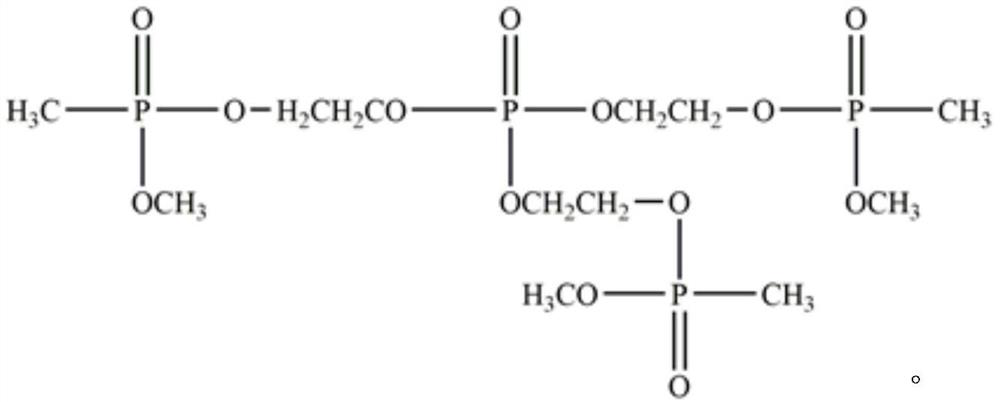

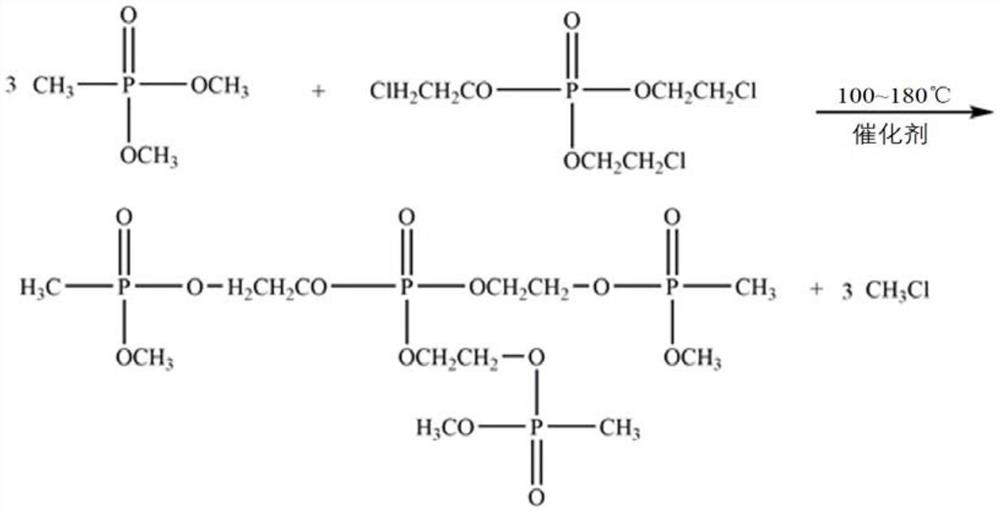

Halogen-free high-efficiency flame retardant, flame-retardant epoxy resin and preparation method thereof

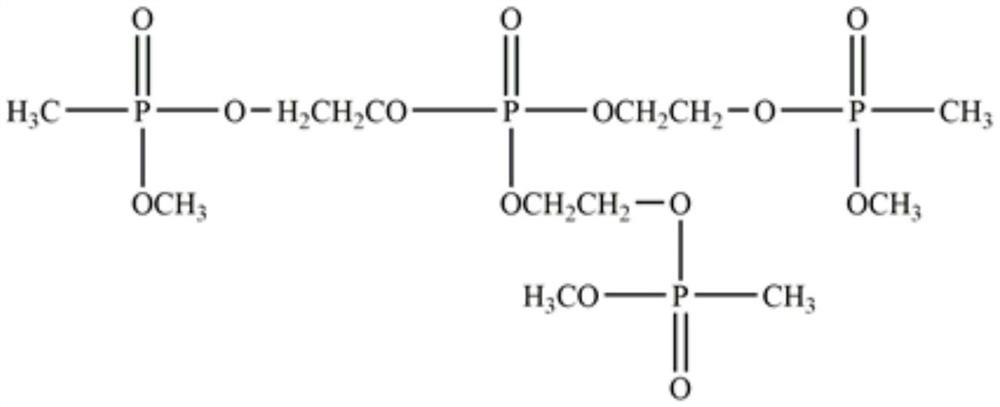

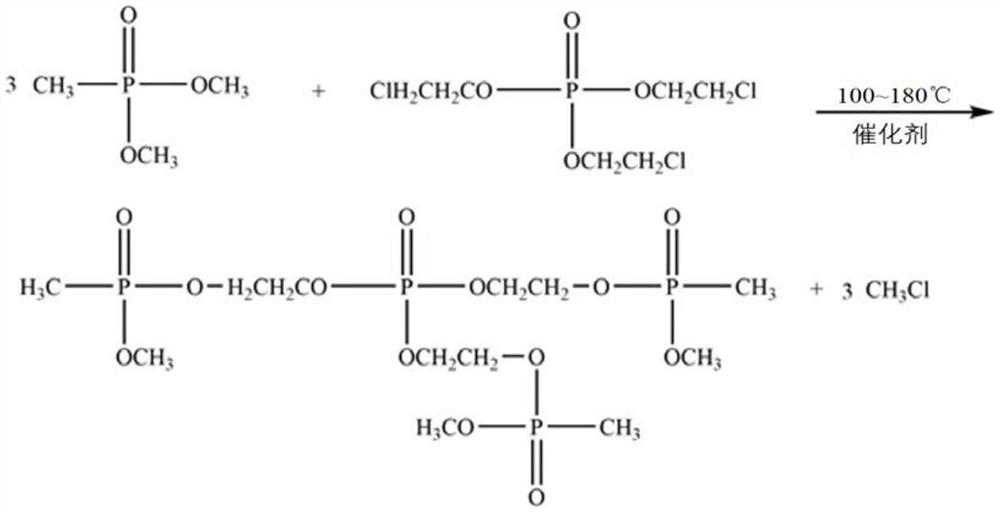

ActiveCN112175234AHigh flame retardant efficiencyImprove flame retardant performanceGroup 5/15 element organic compoundsPolymer scienceDimethyl methylphosphonate

The invention provides a halogen-free high-efficiency flame retardant, flame-retardant epoxy resin and a preparation method thereof. The halogen-free high-efficiency flame retardant is synthesized bythe following method: adding dimethyl methylphosphonate, tris (2-chloroethyl) phosphate and a catalyst into a reaction device, heating to 100-180 DEG C, reacting for 2-10 hours under a stirring condition, and finishing the reaction when no gas is generated in the reaction system, thereby obtaining the product. The flame-retardant epoxy resin adopting the halogen-free high-efficiency flame retardant comprises low-viscosity epoxy resin, solid epoxy resin, the halogen-free high-efficiency flame retardant, a toughening agent, a curing agent and an accelerant. The halogen-free high-efficiency flameretardant prepared by the invention is high in phosphorus content and large in molecular weight, and the flame-retardant epoxy resin using the halogen-free high-efficiency flame retardant is good inflame-retardant effect and not easy to separate out.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Bacteriostatic high-barrier polypropylene masterbatch for hygienic product packaging materials and preparation method thereof

The invention relates to a preparation method of a modified starch antibacterial agent, a bacteriostatic high-barrier polypropylene color master batch for a hygiene product packaging material and a preparation method of the polypropylene color master batch and belongs to the technical field of polypropylene color master batches. The bacteriostatic high-barrier polypropylene color master batch forthe hygiene product packaging material disclosed by the invention is prepared from the following components in percentage by mass: 41-46% of polypropylene powder, 5.5-10% of a cycloolefin copolymer, 5.2-9% of a modified starch antibacterial agent, 0.15-0.25% of a plasticizer, 1.78-3.15% of nanometer titania, 13.6-14.9% of precipitated barium sulfate, 13.8-14.5% of kaolin, 2.1-2.7% of an antioxidant, 2.2-2.9% of a dispersing agent and 6-6.2% of a lubricating agent. The color master batch has excellent barrier property and good antibacterial activity while serving as a flexible packaging material of hygiene products.

Owner:JINJIANG XINBANG NEW MATERIAL TECH

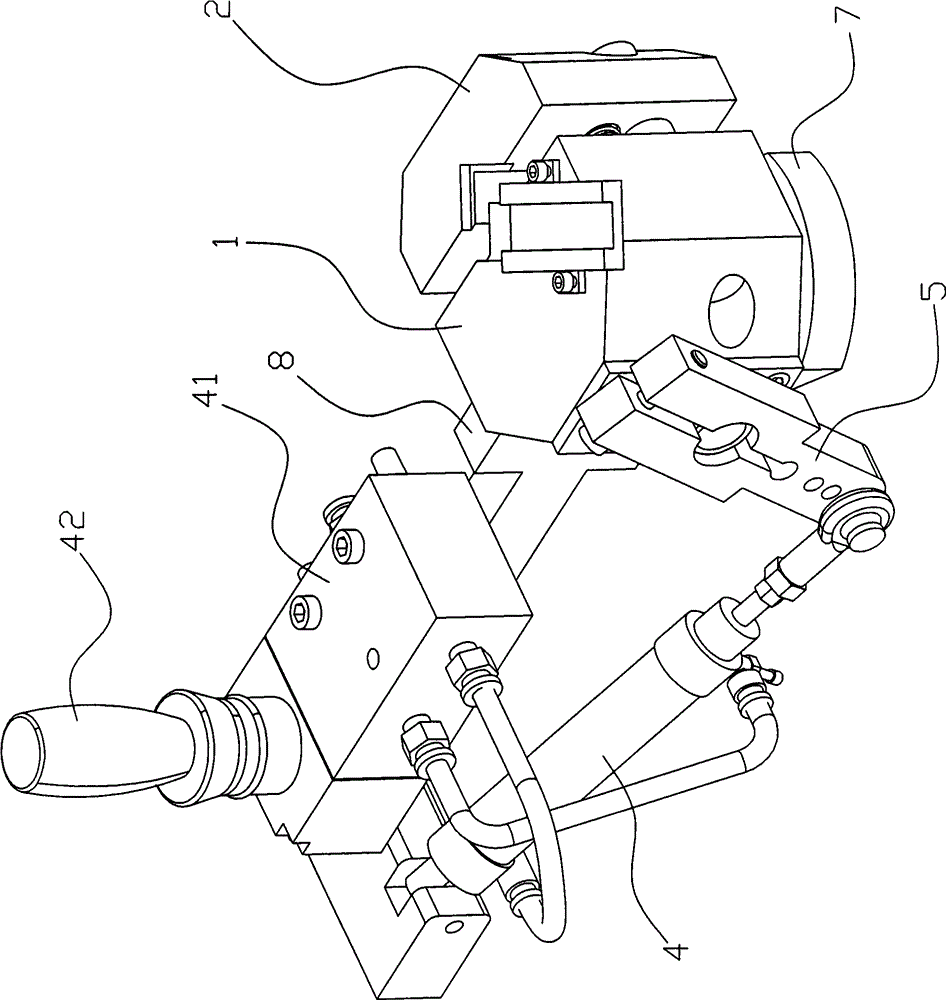

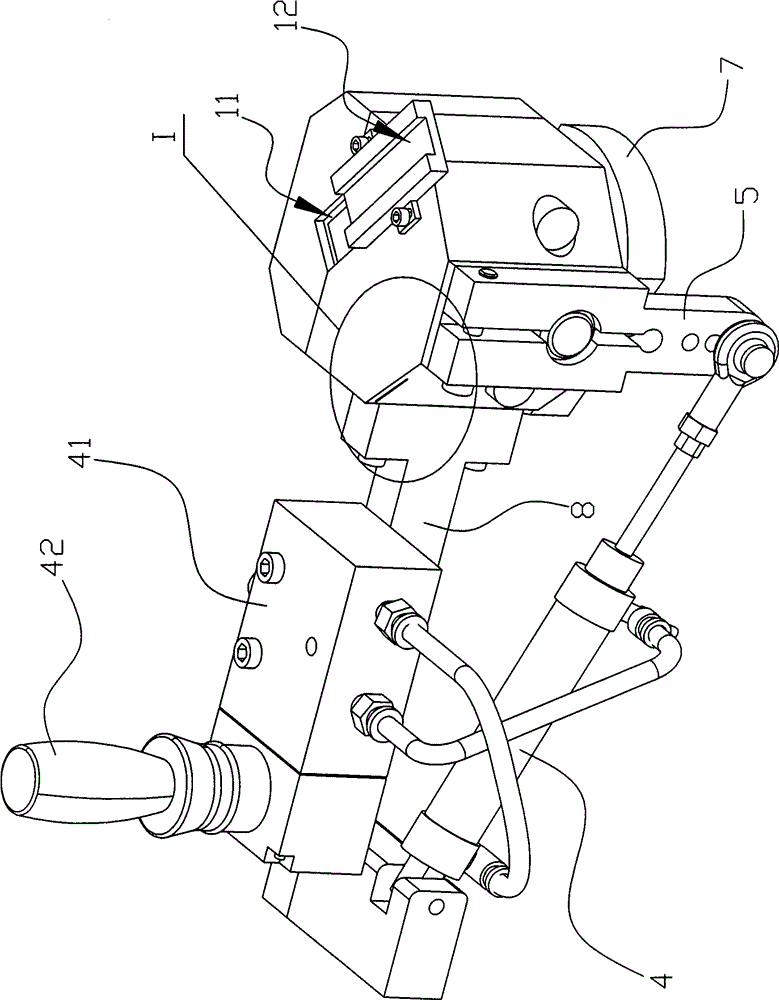

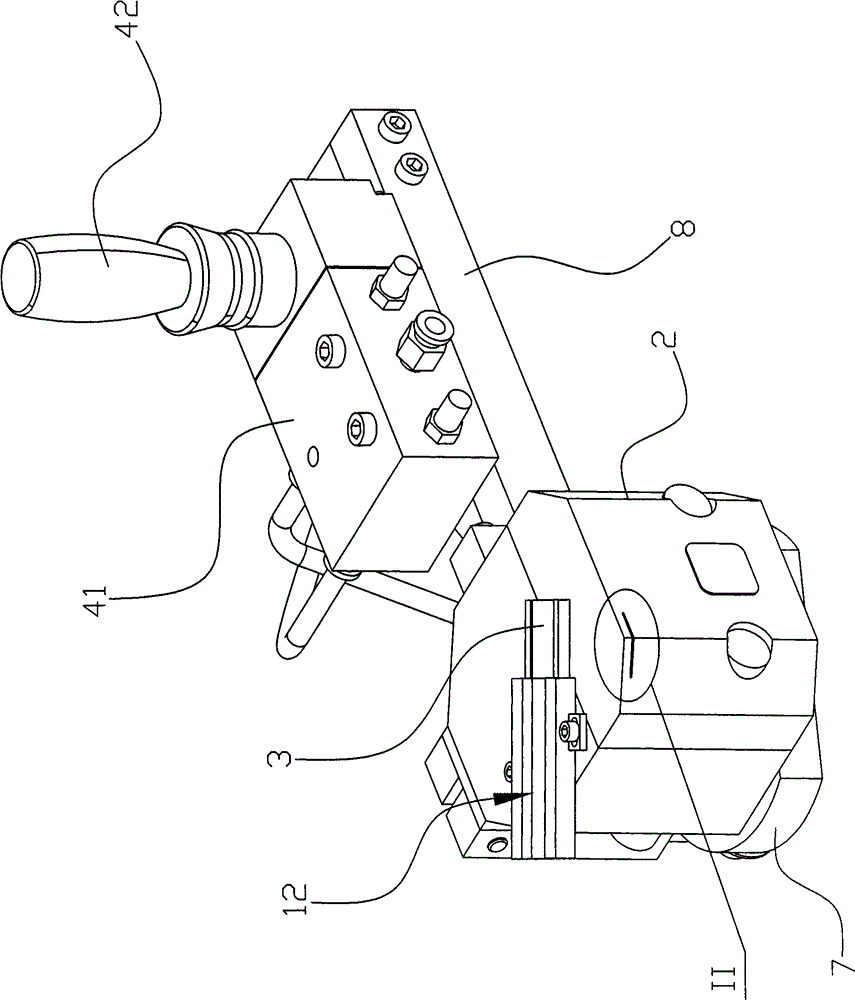

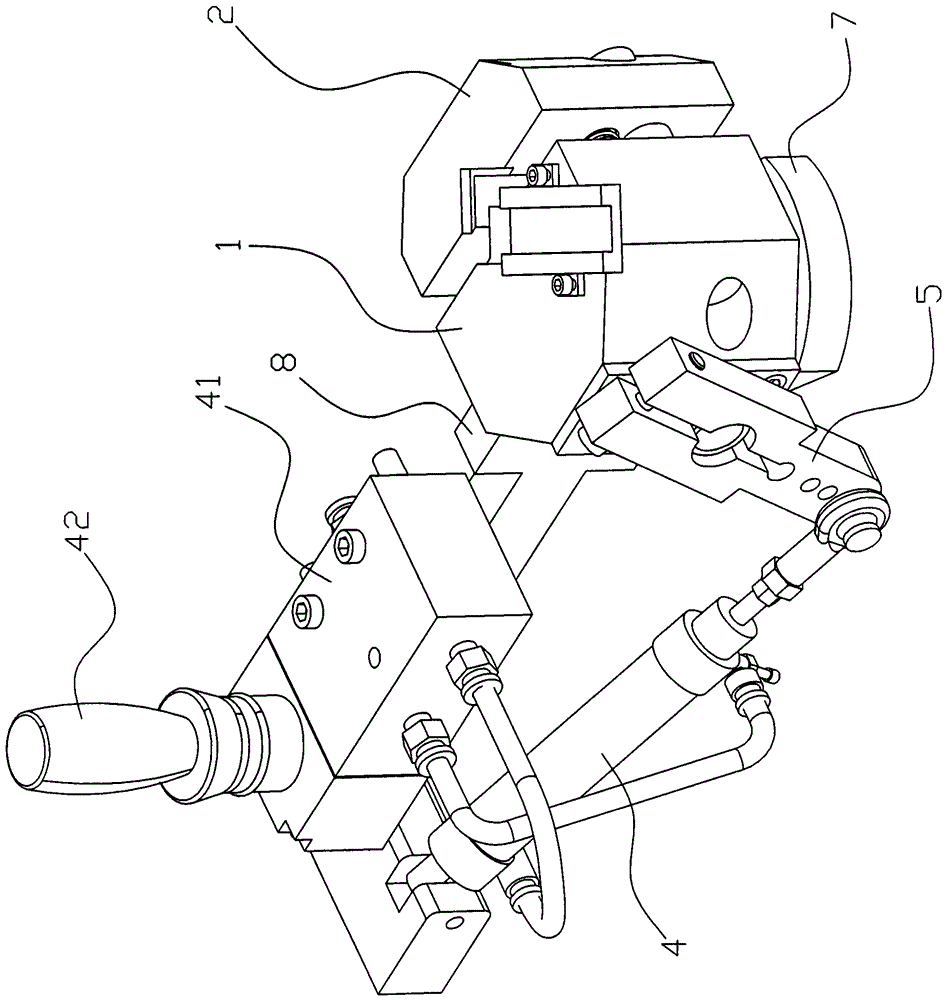

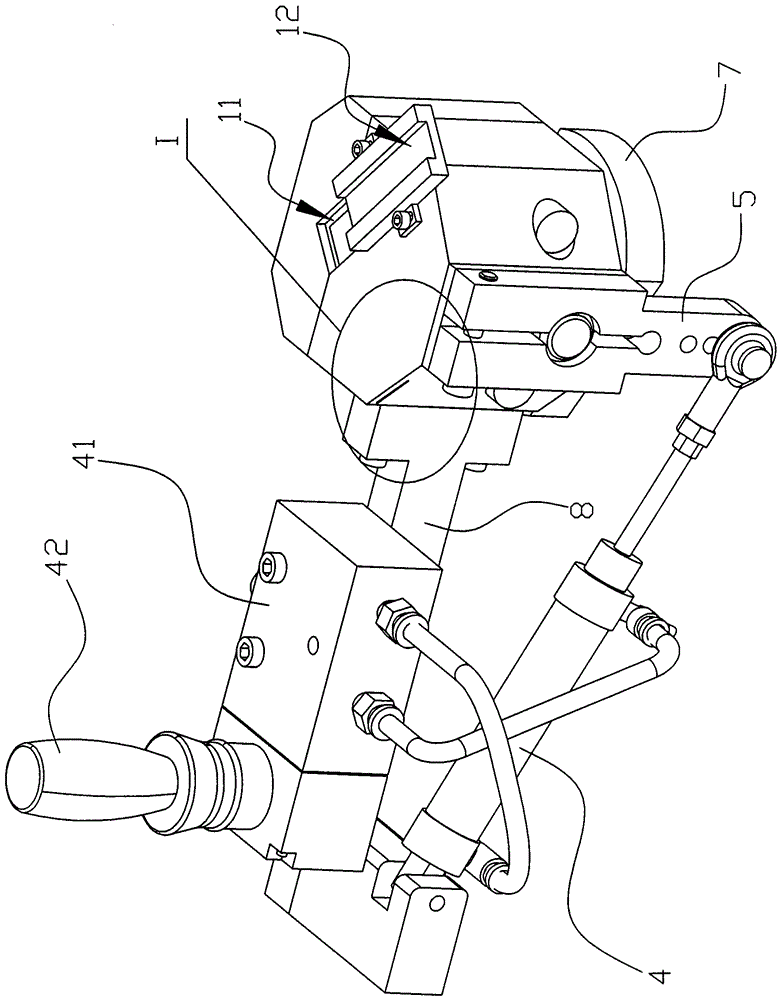

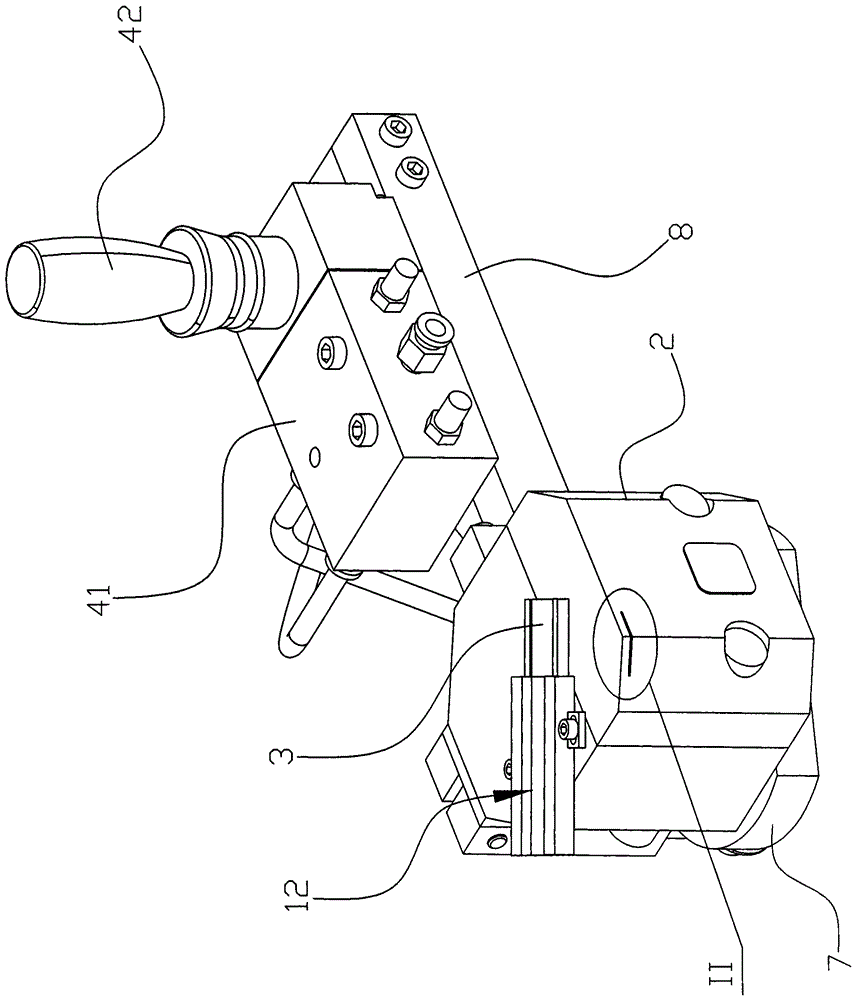

Electrode block welding fixing device

InactiveCN104959758AOpen stable and preciseOpen quicklyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh frequency vibration

An electrode block welding fixing device comprises a fixing clamp capable of fixing a welded piece. The fixing clamp comprises a fixed portion (1) and a moving portion (2). The moving portion (2) is driven by a driving portion to move leftwards and rightwards relative to the fixed portion (1). Gaps are formed in the corresponding positions of the fixed portion (1) and the moving portion (2) respectively. When the moving portion (2) is driven by the driving portion to be attached to the fixed portion (1), the gaps form a cavity (11) which can contain an electrode block (3) and is matched with the electrode block (3) in shape. The fixing clamp is further provided with a welding groove (12), and the bottom face of the welding groove (12) is flush with the upper surface of the electrode block (3) placed in the cavity (11). The electrode block welding fixing device has the advantages that the electrode block is not prone to moving and disengaging in the welding process, the bottom face of a welding strip can be tightly attached to the upper surface of the electrode block, and the welding effect is good; a seam cavity is formed in the fixing clamp, nylon paper or other separation pieces can be inserted in the seam cavity, and therefore the condition that the electrode block adheres to the fixing clamp in the welding process due to high-frequency vibration is avoided; the driving portion drives the fixing clamp to be quickly opened and firmly fixed.

Owner:NINGBO HI TECH LIHONG NEW MATERIAL TECH

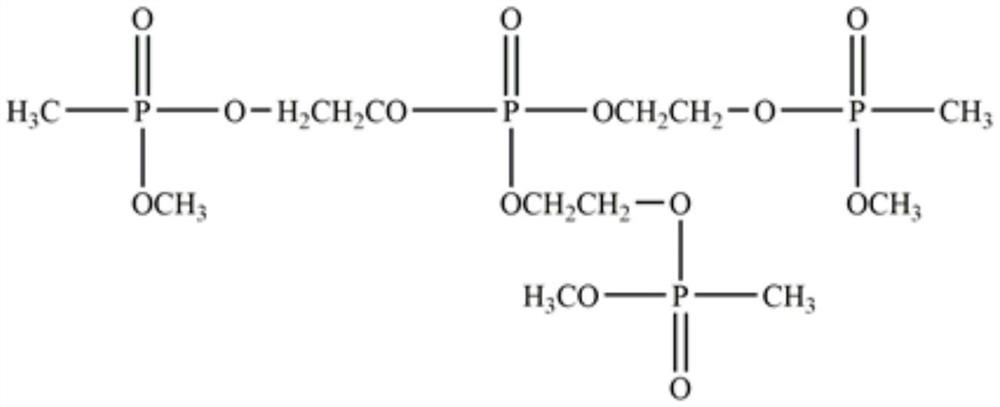

A kind of halogen-free high-efficiency flame retardant, flame retardant epoxy resin and preparation method thereof

ActiveCN112175234BHigh flame retardant efficiencyImprove flame retardant performanceGroup 5/15 element organic compoundsDimethyl methylphosphonatePtru catalyst

The invention provides a halogen-free high-efficiency flame retardant, a flame retardant epoxy resin and a preparation method thereof. The structural formula of the halogen-free high-efficiency flame retardant is: the halogen-free high-efficiency flame retardant is synthesized by the following method: adding dimethyl methylphosphonate, tris(2-chloroethyl) phosphate and a catalyst into a reaction device, The temperature is raised to 100-180°C, and the reaction is carried out for 2-10 hours under stirring conditions. When no gas is generated in the reaction system, the reaction is completed and the product is obtained; the flame-retardant epoxy resin using the halogen-free high-efficiency flame retardant includes low-viscosity epoxy resin Resins, solid epoxy resins, halogen-free high-efficiency flame retardants, toughening agents, curing agents and accelerators. The halogen-free high-efficiency flame retardant prepared by the invention has high phosphorus content and large molecular weight, and the flame retardant epoxy resin has good flame retardant effect and is not easy to separate out.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

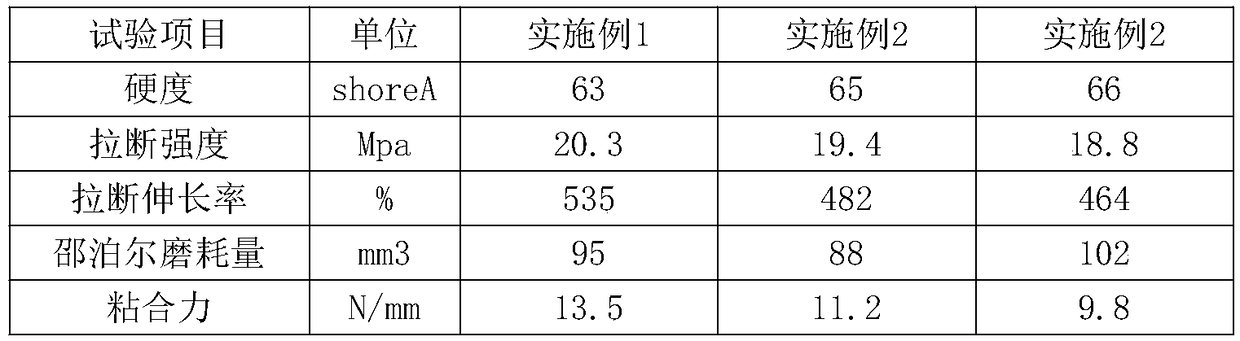

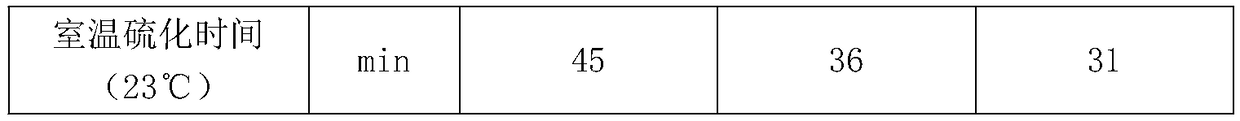

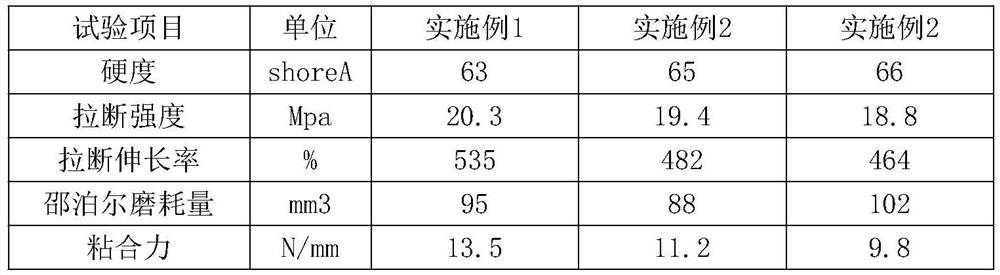

Room temperature vulcanized rubber strip for automatic repair of conveyor belt and preparation method thereof

ActiveCN108774479AImprove stabilityIncrease polarityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEnd-groupWear resistant

The invention discloses a room temperature vulcanized rubber strip for automatic repair of a conveyor belt and a preparation method thereof. The room temperature vulcanized rubber strip comprises a rubber strip 1 and a rubber strip 2. The rubber strip 1 is prepared from the following raw materials in parts by weight: 50 to 80 parts of natural rubber plasticated rubber, 20 to 50 parts of end groupfunctionalized solution polymerized styrene-butadiene rubber, 2 to 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 5 parts of anti-aging agents, 4 to 10 parts of alkyl phenolic tackifying resins, 30 to 45 parts of high wear resistant carbon black, 5 to 10 parts of bisphenol A, and 1.0 to 3.0 parts of sulfur; the rubber strip 2 is prepared from the following raw materials in parts by weight: 70 to 100 parts of end group functionalized solution polymerized styrene-butadiene rubber, 10 to 30 parts of terminal carboxyl liquid nitrile rubber, 30 to 45 parts of high wear resistant carbon black, 1.0 to 3.0 parts of zinc isopropyl xanthate, and 0.3 to 1.0 part of phthalic anhydride. The room temperature vulcanized rubber strip for the automatic repair of the conveyor belt and the preparation method thereof solve technical problems that an adhesive tape for repairing the conveyor belt in the prior art is inconvenient to store, the viscosity is poor, and the repair quality is poor.

Owner:中德(扬州)输送工程技术有限公司

Color master batch applicable to dairy packing material taking polystyrene as base material

The invention discloses a color master batch applicable to a dairy packing material taking polystyrene as a base material. The color master batch comprises 100 to 120 parts of polystyrene, 60 to 80 parts of pigment, 1 to 5 parts of an antibacterial agent, 1 to 5 parts of a lubricant, and 0.6 to 1 part of a dispersant. A preparation process comprises material mixing, blending and extrusion granulation. The color master batch has the advantages that the polystyrene and the antibacterial agent are matched with each other, a polystyrene master batch has excellent antibacterial activity and high-barrier property, the machine-shaping property of the antibacterial agent, the polystyrene and the pigment is enhanced under the action of the lubricant and the dispersant, and meanwhile the antibacterial agent is not easy to emigrate, so that the formed polystyrene color master batch has lasting antibacterial activity after being machined into dairy package, and can enduringly protect the quality of dairy products; the added dispersant is beneficial to sufficient dispersion of the pigment, ensures that the pigment is conveniently adhered to a carrier, and the color is uniform.

Owner:北京金天化塑胶有限公司

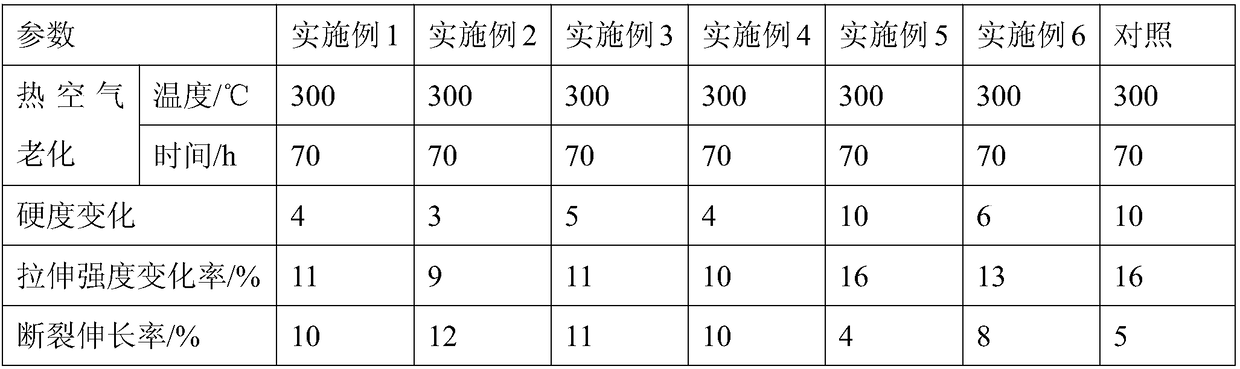

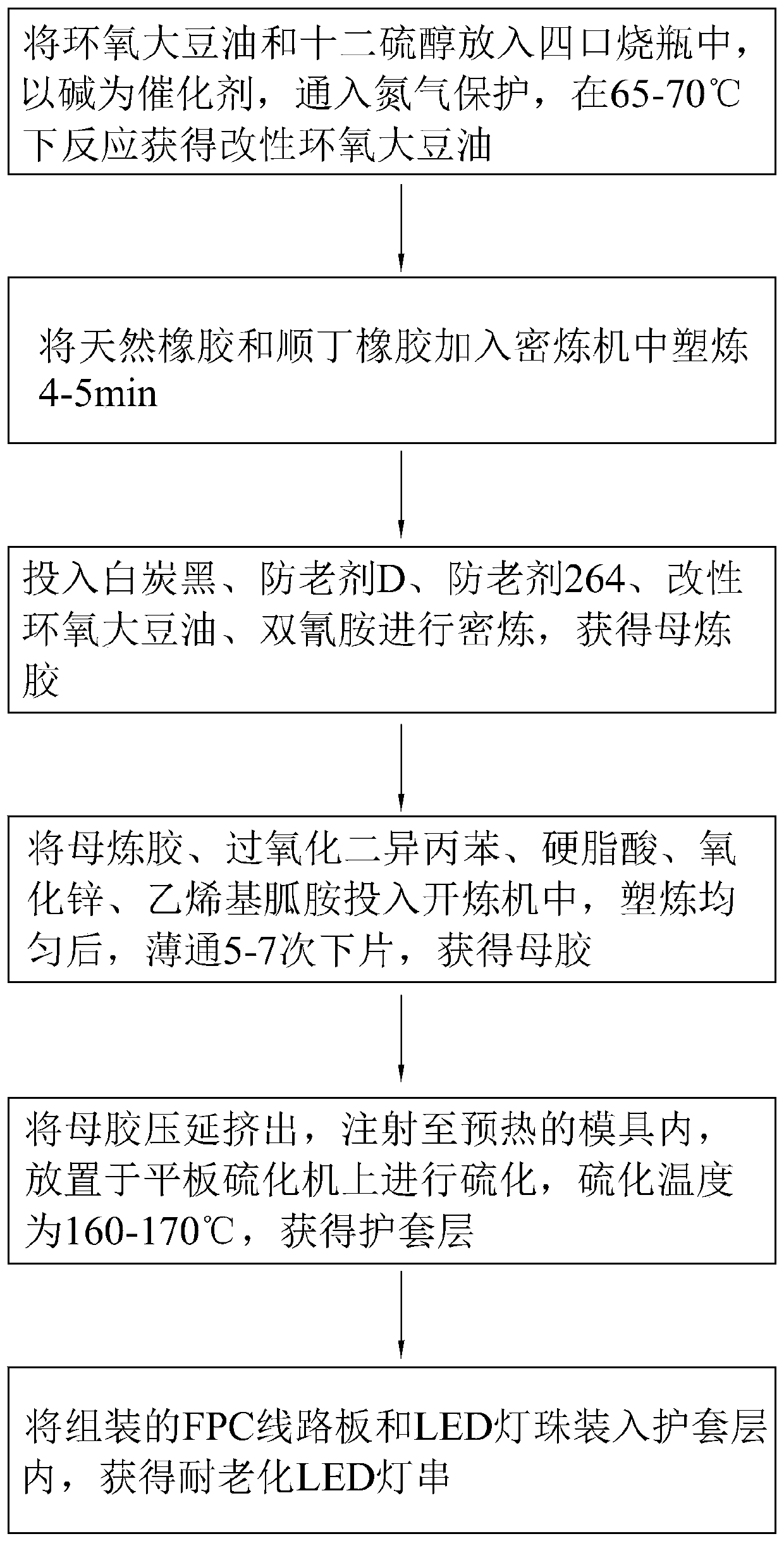

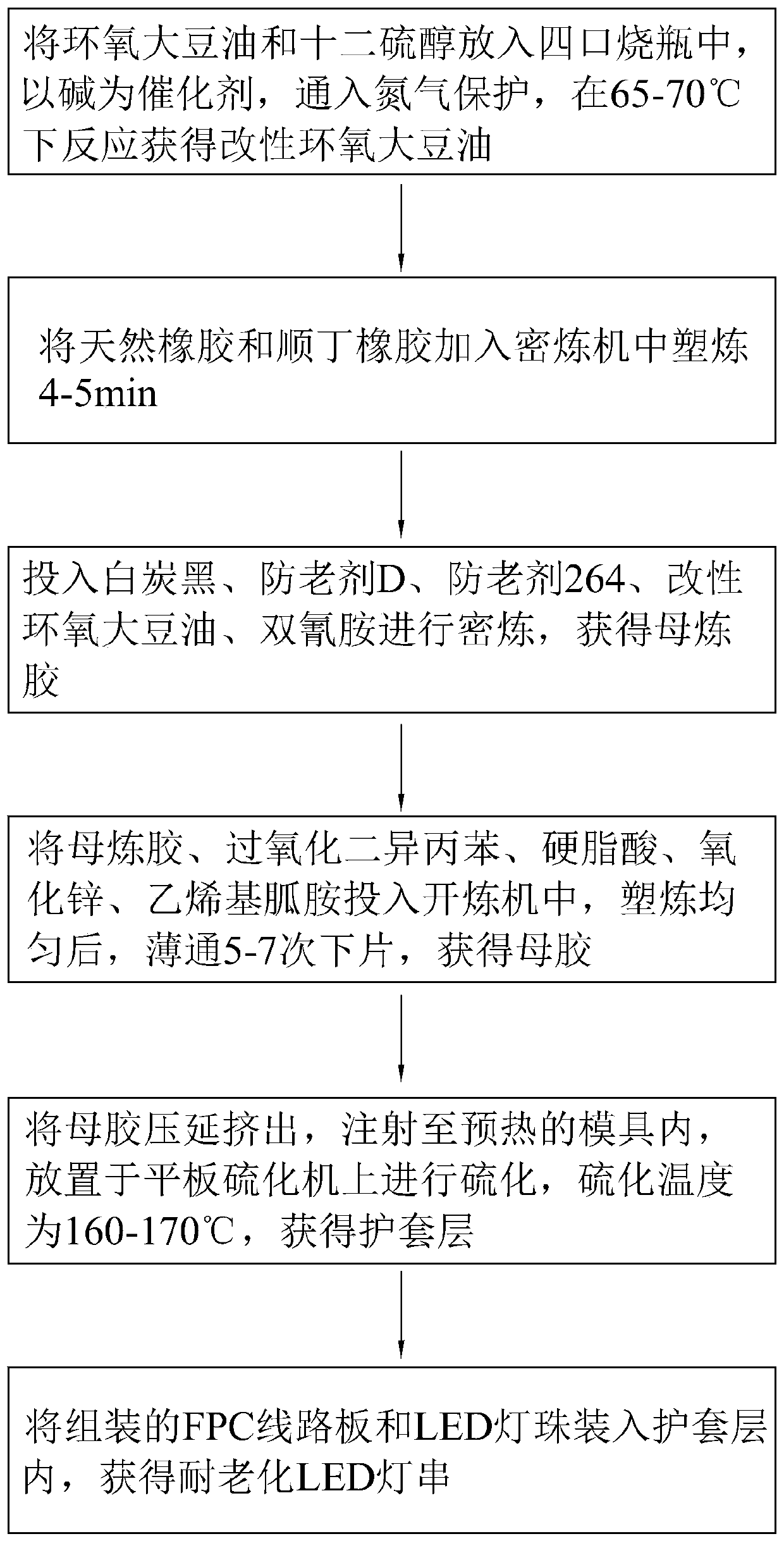

Anti-aging LED string light and preparation method thereof

InactiveCN111138732AGood physical and mechanical propertiesIncrease elasticityProtective devices for lightingElectric lightingVulcanizationWeather resistance

The invention discloses an anti-aging LED string light and a preparation method thereof, belonging to the technical field of lighting devices. The LED string light comprises an FPC circuit board, a plurality of LED lamp beads electrically connected to the FPC circuit board, and a sheath layer wrapping the FPC circuit board and the LED lamp beads. The sheath layer comprises the following raw materials by weight: 25-30 parts of natural rubber, 80 to 85 parts of butadiene rubber, 4-5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 15 to 20 parts of epoxidized soybean oil, 1 to 2 parts of dodecanethiol, 5-8 parts of an amine latent curing agent, 0.3 to 0.5 part of an anti-aging agent, 1-3 parts of a vulcanizing agent and 35-45 parts of a filler. Through cooperation of the natural rubberand the butadiene rubber, the sheath layer has good elasticity, wear resistance and weather resistance. The zinc oxide has a good vulcanization activation effect, and the stearic acid has a good dispersion effect and a good vulcanization promotion effect. The epoxidized soybean oil modified by dodecanethiol has a synergistic effect on the antioxidant, thereby improving the anti-aging effect of the system, so the sheath layer can maintain good light transmittance stability for a long time.

Owner:锐威环球科技(深圳)有限公司

Electrode Block Welding Fixture

InactiveCN104959758BOpen stable and preciseOpen quicklyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh frequency vibration

An electrode block welding fixing device comprises a fixing clamp capable of fixing a welded piece. The fixing clamp comprises a fixed portion (1) and a moving portion (2). The moving portion (2) is driven by a driving portion to move leftwards and rightwards relative to the fixed portion (1). Gaps are formed in the corresponding positions of the fixed portion (1) and the moving portion (2) respectively. When the moving portion (2) is driven by the driving portion to be attached to the fixed portion (1), the gaps form a cavity (11) which can contain an electrode block (3) and is matched with the electrode block (3) in shape. The fixing clamp is further provided with a welding groove (12), and the bottom face of the welding groove (12) is flush with the upper surface of the electrode block (3) placed in the cavity (11). The electrode block welding fixing device has the advantages that the electrode block is not prone to moving and disengaging in the welding process, the bottom face of a welding strip can be tightly attached to the upper surface of the electrode block, and the welding effect is good; a seam cavity is formed in the fixing clamp, nylon paper or other separation pieces can be inserted in the seam cavity, and therefore the condition that the electrode block adheres to the fixing clamp in the welding process due to high-frequency vibration is avoided; the driving portion drives the fixing clamp to be quickly opened and firmly fixed.

Owner:NINGBO HI TECH LIHONG NEW MATERIAL TECH

A room temperature vulcanized rubber strip for automatic repair of conveyor belt and preparation method thereof

ActiveCN108774479BIncrease polarityIncrease stickinessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceVulcanization

The invention discloses a room temperature vulcanized rubber strip for automatic repairing of conveyor belts and a preparation method thereof. 20-50 parts of base functionalized solution polystyrene-butadiene rubber, 2-5 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 5 parts of anti-aging agent, 4-10 parts of alkyl phenolic tackifying resin, 30 parts of high wear-resistant carbon black ‑45 parts, 5‑10 parts of bisphenol A, 1.0‑3.0 parts of sulfur; rubber strip 2 includes the following raw materials in parts by weight: 70‑100 parts of end-group functionalized solution-polymerized styrene-butadiene rubber, 10-parts of carboxyl-terminated liquid nitrile rubber 30 parts, 30-45 parts of high wear-resistant carbon black, 1.0-3.0 parts of zinc isopropyl xanthate, and 0.3-1.0 parts of phthalic anhydride. Inconvenient, sticky and poor repair quality technical issues.

Owner:中德(扬州)输送工程技术有限公司

Color master batch suitable for milk product packaging materials utilizing polypropylene as base material

InactiveCN108892858AGood antibacterial effectExcellent formabilityAntibacterial activityPolypropylene

The invention discloses a color master batch suitable for milk product packaging materials utilizing polypropylene as a base material. The color master batch contains the following components in partsby weight: 100-120 parts of polypropylene, 60-80 parts of pigments, 1-5 parts of an antibacterial agent, 1-5 parts of a lubricating agent and 0.1-0.2 part of a dispersing agent. A production processof the color master batch comprises the following steps: mixing, blending and extrusion granulation. By virtue of the cooperative use of polypropylene and the antibacterial agent, a polypropylene color master batch is endowed with excellent antibacterial property and high barrier property, the processing formation properties of the antibacterial agent, polypropylene and the pigments are enhanced,and meanwhile, the antibacterial agent is unlikely to migrate out, so that the produced polypropylene color master batch has durable antibacterial activity after being produced into a milk product package, and the quality of the mild products can be durably maintained.

Owner:北京金天化塑胶有限公司

A kind of environment-friendly softener grafted regenerated rubber and its preparation method

ActiveCN107759714BEasy to processCompliant with REACH regulationsEnvironmental resistancePolymer science

The invention provides environment-friendly softening agent grafted regenerated rubber and a preparation method thereof. The preparation method comprises the following steps: taking vegetable oil containing phenolic hydroxyl groups and unsaturated alkyl chains as a regenerated rubber softening agent, adding an organic peroxide initiator in the waste rubber powder regeneration process, initiating double-bond or three-bond rupture to the regenerated rubber to produce free radicals, combining the free radicals with free radicals formed by a thermal oxidation effect in the rubber powder regeneration process, and grafting a free softening agent in the regenerated rubber onto a main chain of the regenerated rubber. The regenerated rubber prepared by the method disclosed by the invention has theadvantages of being green, environment-friendly, non-blueing, excellent in mechanical property and stable in Mooney.

Owner:QINGDAO UNIV OF SCI & TECH

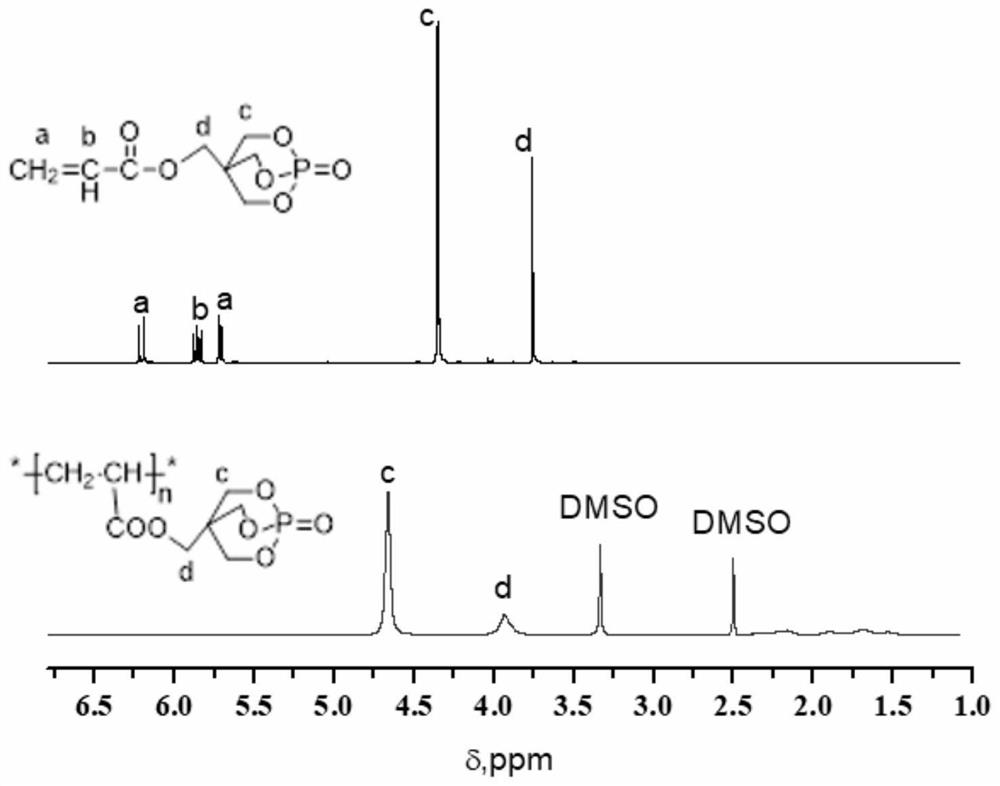

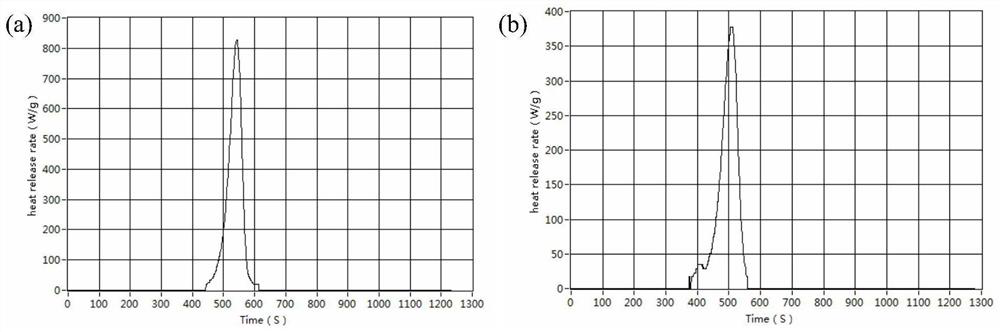

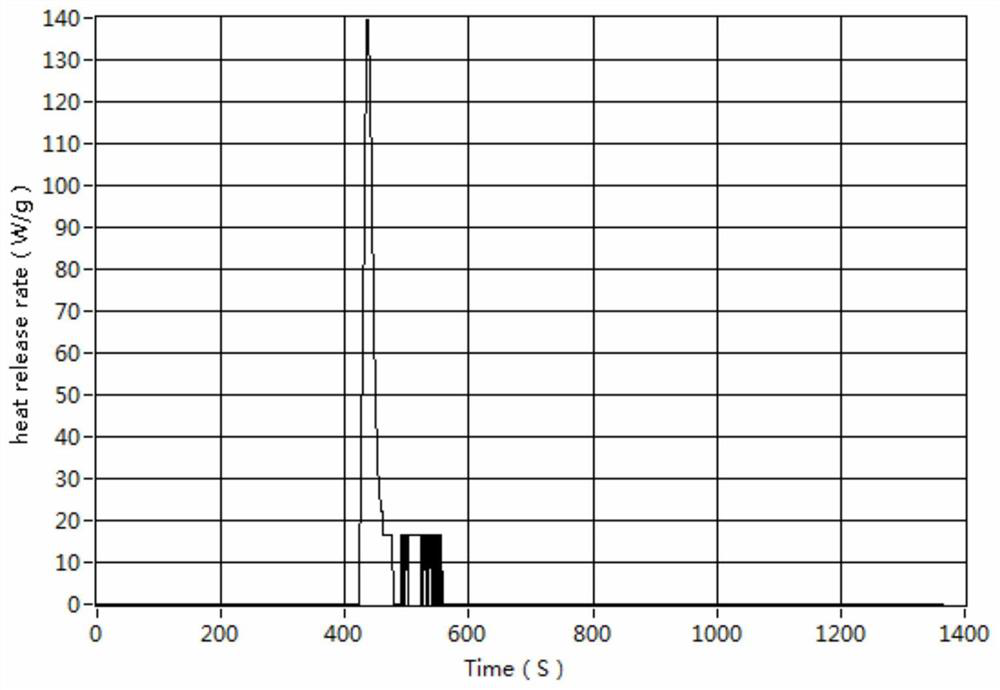

Halogen-free phosphorus-based synergistic flame retardant and flame-retardant polymer composite material and preparation method thereof

Halogen-free phosphorus-based synergistic flame retardant and flame-retardant polymer composite material and preparation method thereof. The composition of the halogen-free phosphorus-based synergistic flame retardant is by mass percentage, PPEPAA: 1-95%, APP: 0-90%, MPP: 0-90%, molecular sieve: 0-25%. Preparation method: including self-polymerization-blending route and in-situ polymerization route. The flame-retardant polymer composite material, its composition by mass percentage, halogen-free phosphorus-based synergistic flame retardant: 20-50%, polymer material: 50-79.7%, antioxidant: 0-0.3%. The flame-retardant polymer composite material has a limiting oxygen index of 28-46.7%, and a UL-94 vertical combustion test of V-1 or above. The heat release rate (HRR) and total smoke generation (TSR) are higher than those of the matrix polymer material. Decreased by 22-84.0% and 12.1-43.02%.

Owner:SHENYANG FIRE RES INST OF MEM

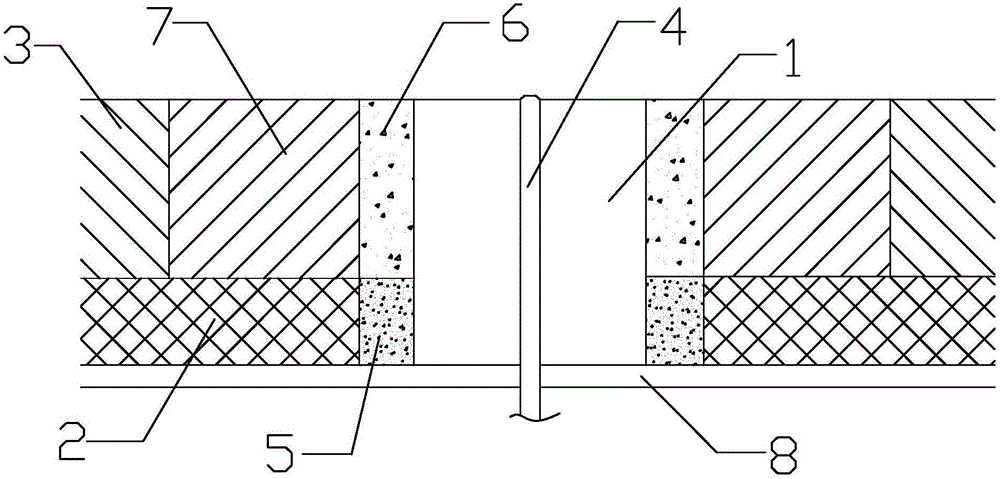

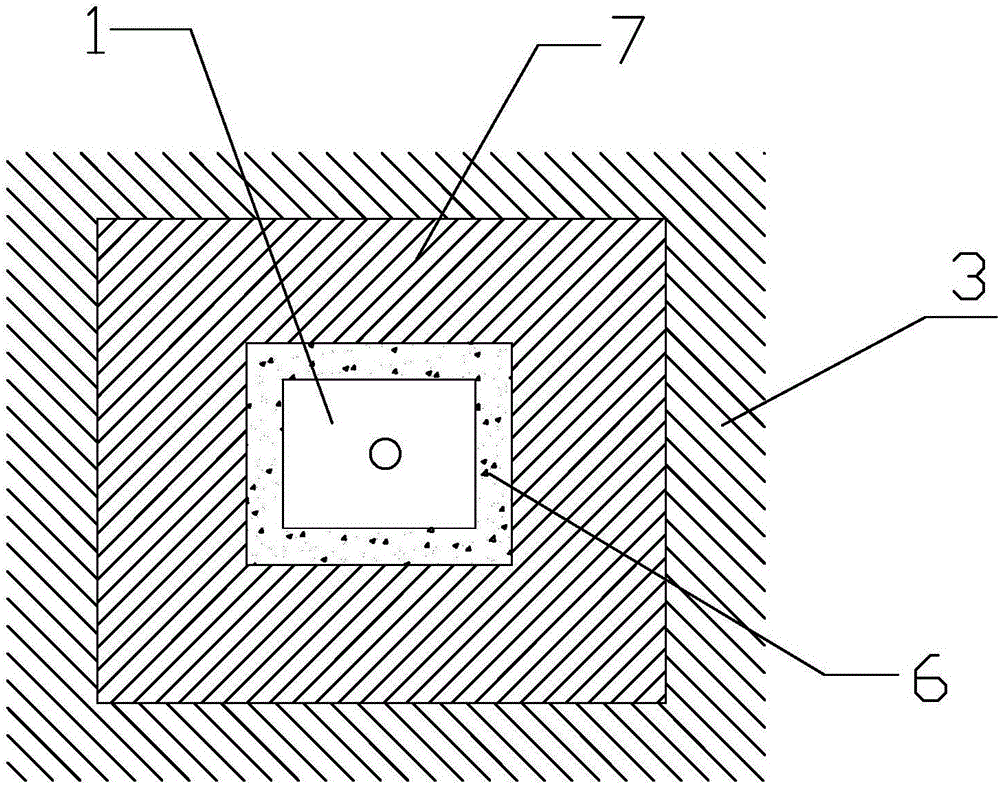

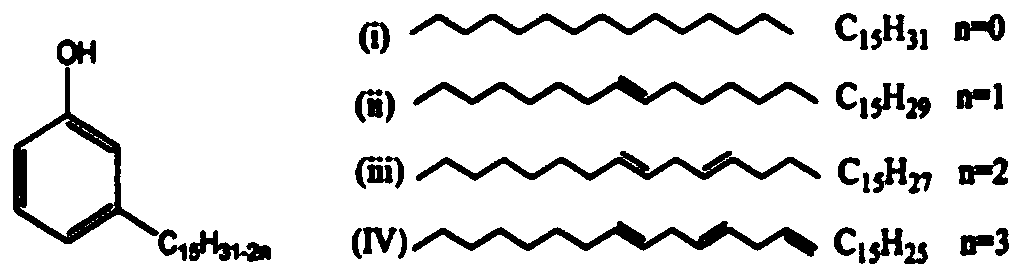

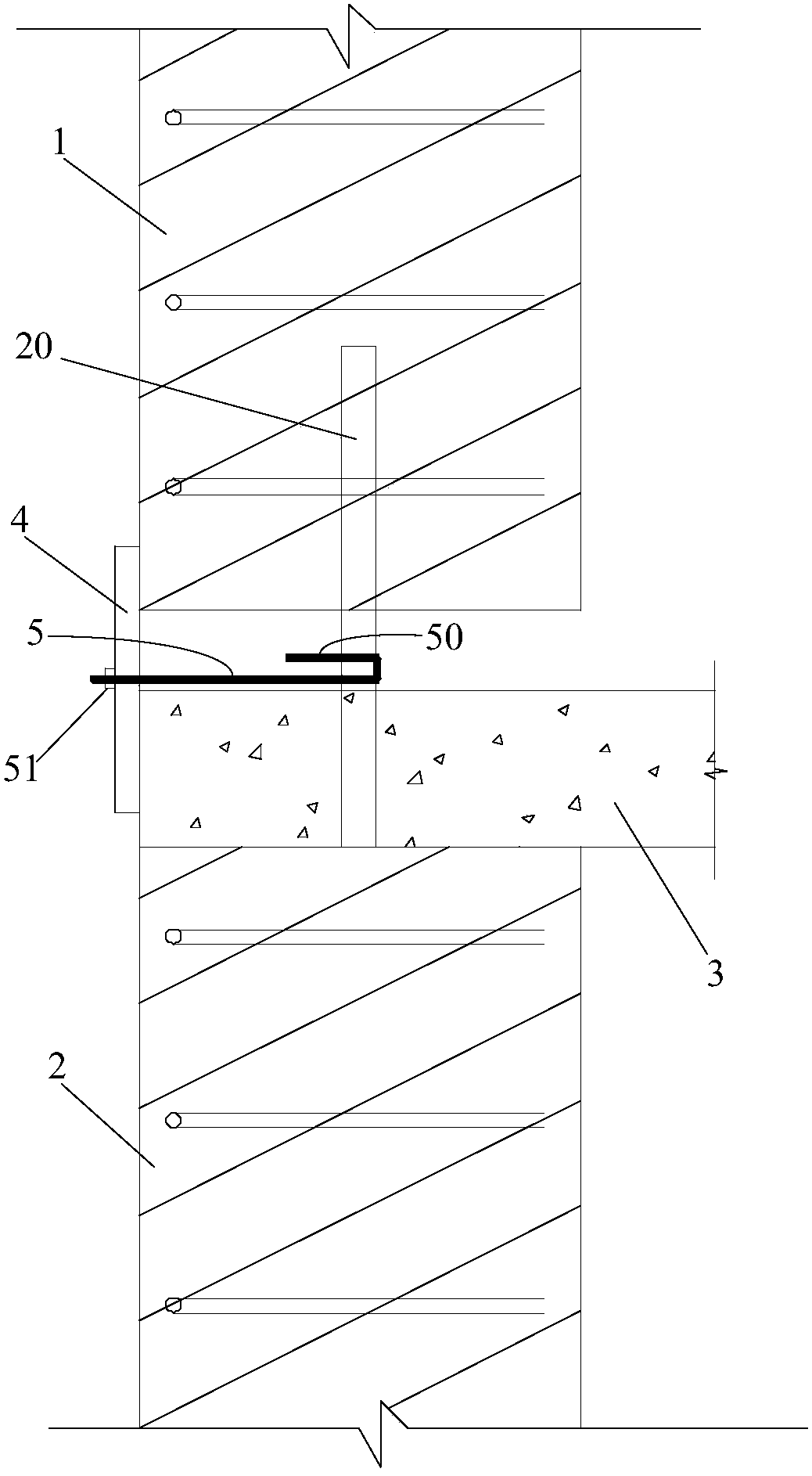

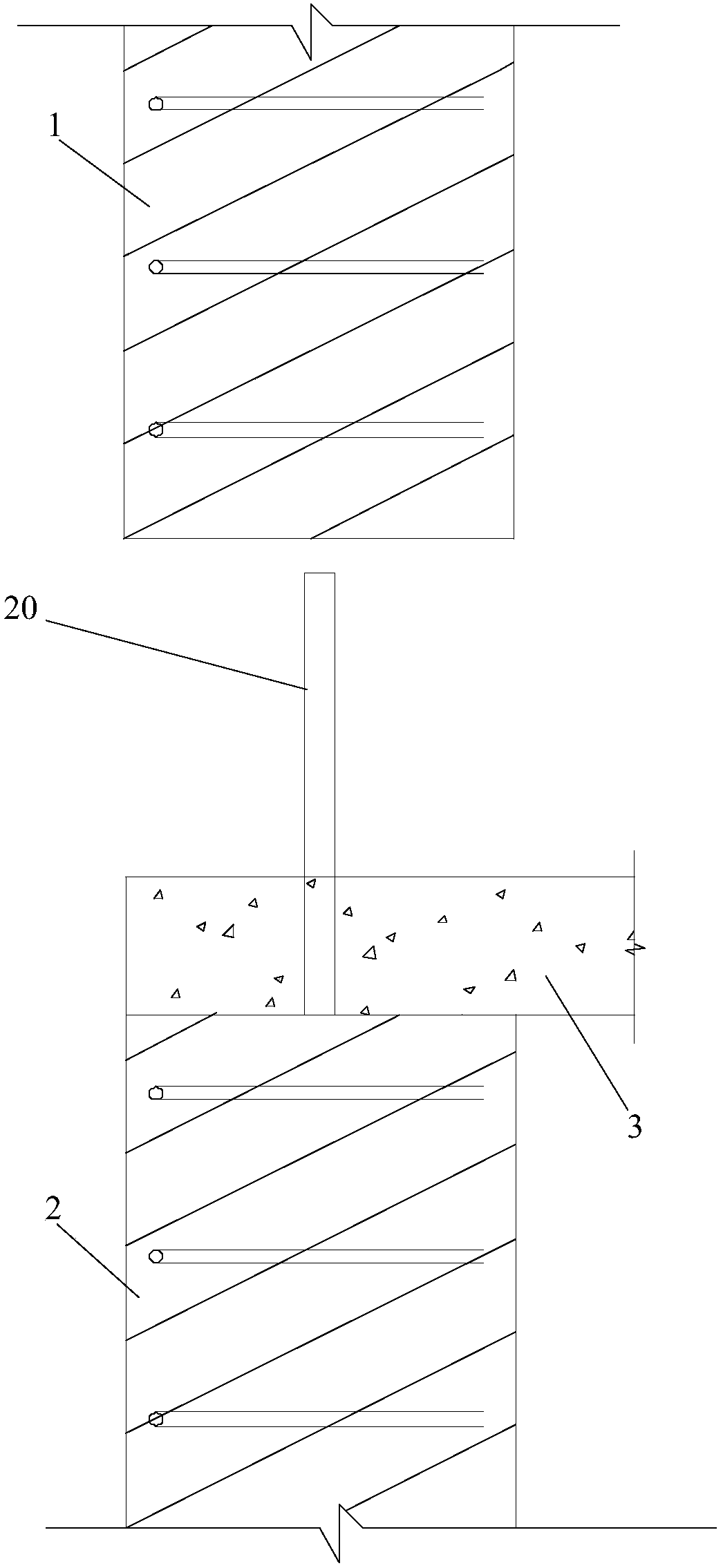

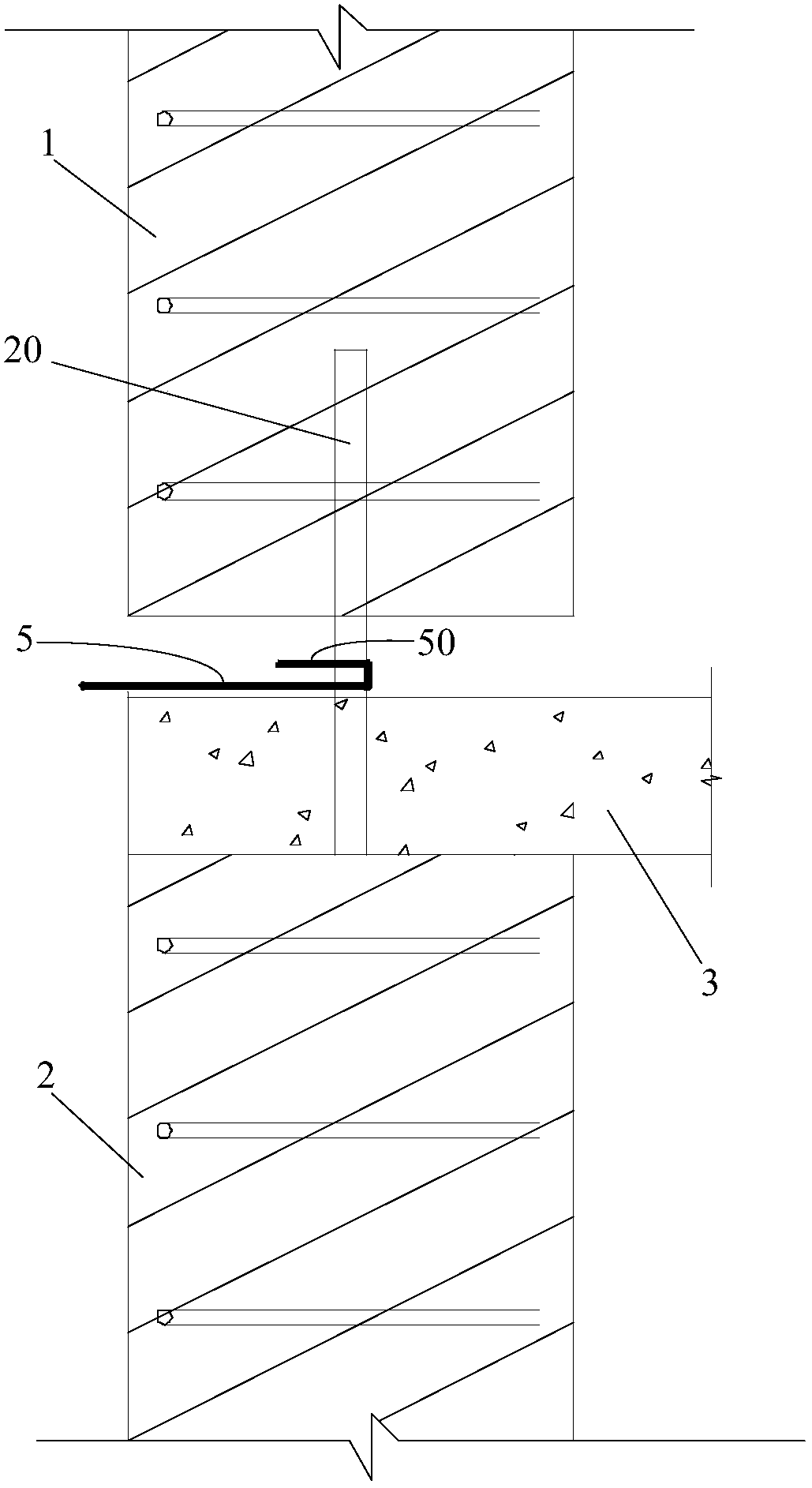

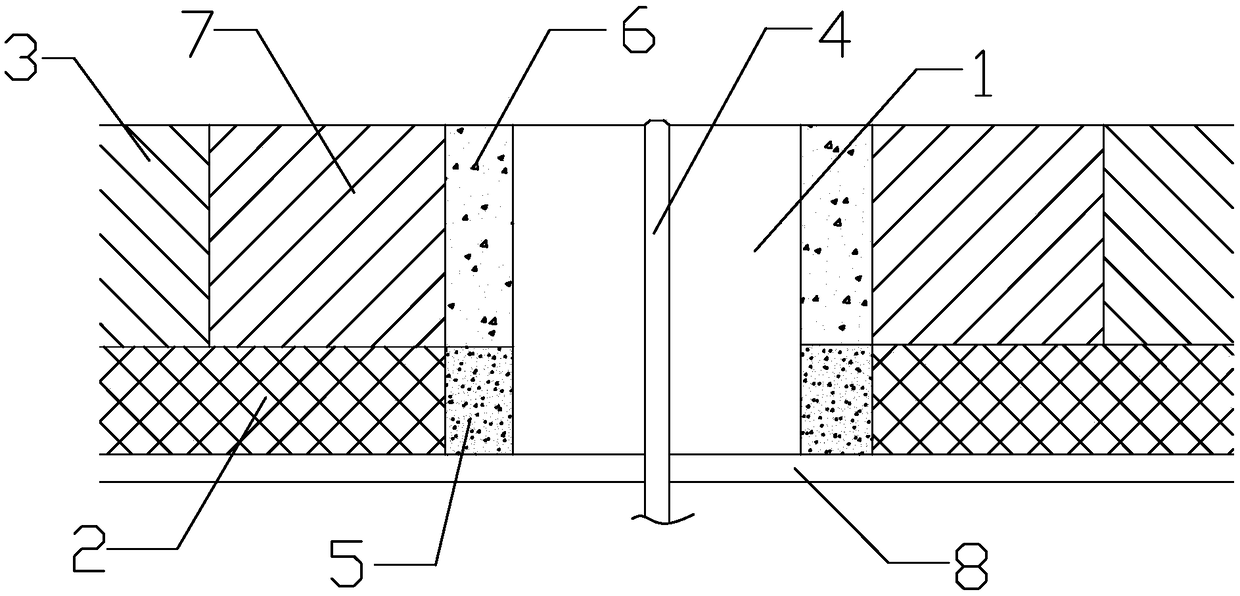

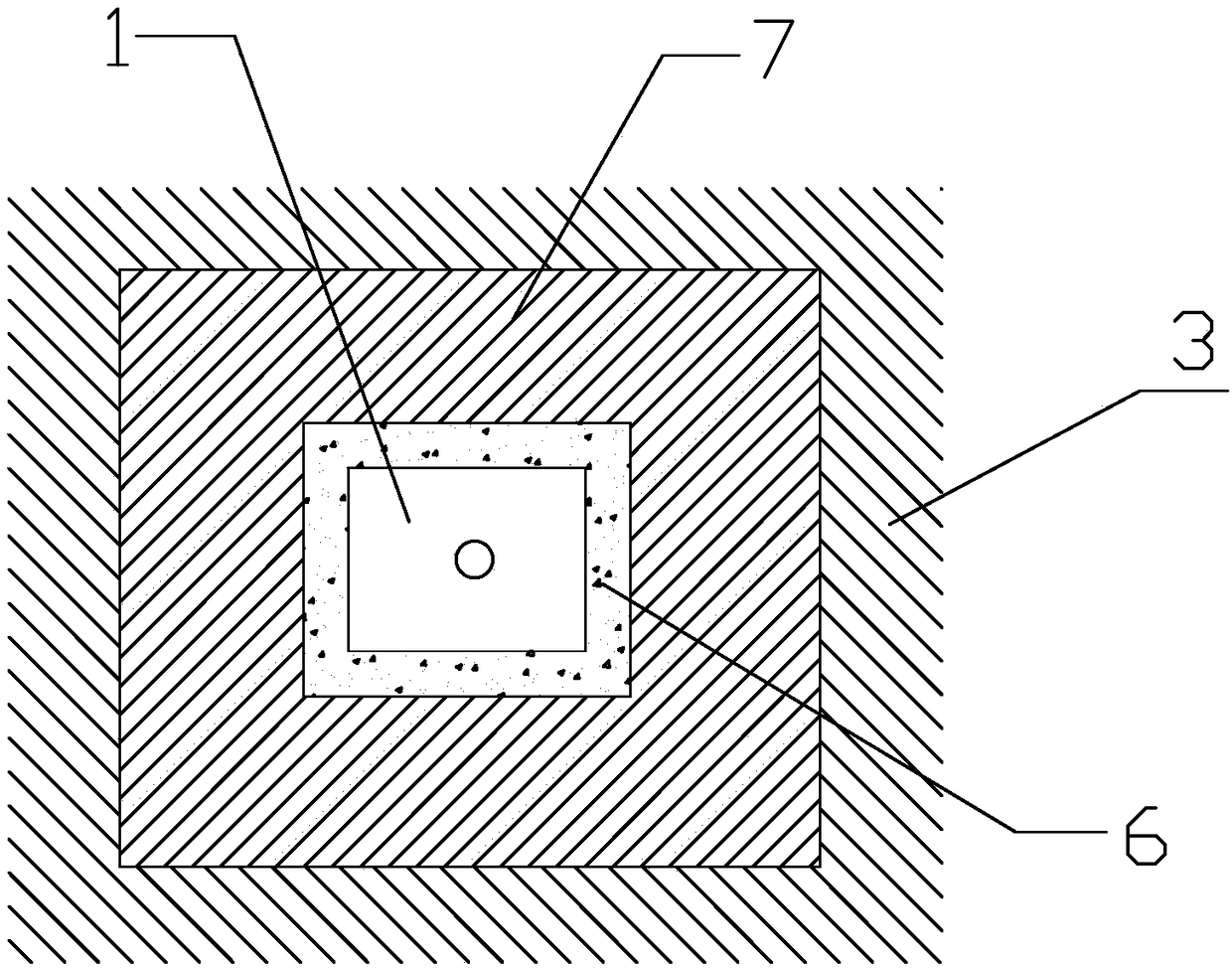

Prefabricated wall limit method and device

ActiveCN105781129BSolve problems such as easy migrationNot easy to move outBuilding material handlingHookingRebar

The invention provides a precast wall limiting method and device. The precast wall limiting method comprises the steps that an upper layer precast wall body is lifted above a floor and connected with a reserved steel bar of a lower layer precast wall body, and the reserved steel bar of the lower layer precast wall body penetrates through a cast-in-place space between the floor and the upper layer precast wall body; a hook part is provided and comprises a fixed end and a hooking end which are opposite, the hooking end of the hook part is stretched into the cast-in-place space from the outside of the upper layer precast wall body and the outside of the floor to be hooked on the reserved steel bar of the lower layer precast wall body; and a clamping plate is provided, the fixed end of the hook part is fixedly arranged on the clamping plate, so that the clamping plate is clamped on the outside of the upper layer precast wall body and the outside of the floor, and the upper layer precast wall body is in a balanced state under the action of the hook part and the clamping plate. Through the precast wall limiting method and device, the problem that an existing precast wall is liable to move outwards after being installed is solved.

Owner:NANCHANG HANGKONG UNIVERSITY +1

Leak-proof iron structure and leak-proof iron breathable brick replacement method for iron ladle tank ventilation bricks

ActiveCN106513651BPrevent looseningIncreased flow distanceMelt-holding vesselsBrickReplacement method

The invention provides an iron-leak-preventing structure for a permeable brick of a hot metal ladle and a replacing method for the iron-leak-preventing permeable brick. The replacing method for the iron-leak-preventing permeable brick specifically comprises the steps of: firstly disassembling building bricks of an original working layer which is not less than 600mm from the outer edge of the permeable brick; taking out the old permeable brick; mounting a novel permeable brick; reserving a gap between the periphery of the novel permeable brick and each of original permanent layers of the hot metal ladle; then filling the gaps with brine blended clayey ramming mass and performing ramming; then building the disassembled part with magnesia carbon bricks in a wet building manner and meanwhile, reserving gaps between the periphery of the permeable brick and the built working layers; pouring a corundum self-flowing pouring material; and then performing natural preservation 6-8h to enter a baking stage. The structure provided by the invention is simple and convenient in building construction, can avoid an iron-leak phenomenon as the permeable brick is replaced, and is good in iron-leak-preventing effect, so that the potential safety hazard of the hot metal ladle due to iron leakage is avoided.

Owner:武汉精鼎科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com