Antioxidant anti-ultraviolet microsphere, preparation method and application

An anti-ultraviolet and anti-oxidation technology, which is applied in the field of preparation, anti-oxidation and anti-ultraviolet microspheres, can solve the problems that anti-oxidation and anti-ultraviolet microspheres have not been seen, and achieve excellent ultraviolet shielding performance, simple preparation method, and excellent anti-oxidation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

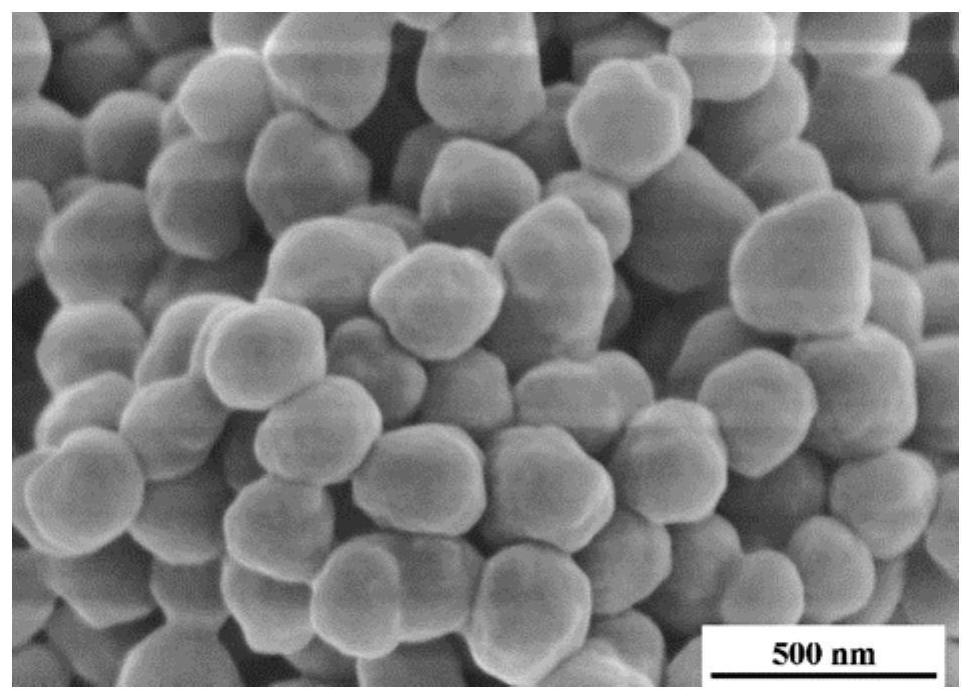

[0043] (1) Preparation of maleic anhydride copolymer microspheres: Weigh 5.21 g of styrene, 4.90 g of maleic anhydride, 0.52 g of divinylbenzene (molar ratio of 100:100:8) and 0.10 g of initiator azobis Isobutyronitrile (1wt% of the total mass of maleic anhydride and styrene) was added to a 250mL three-necked flask, and then 140mL of isoamyl acetate was added, and the reaction system was connected after ultrasonic dissolving. The concentrations of styrene and maleic anhydride were 0.35mol respectively. / L; pass N 2 After 30 minutes, the three-necked flask was placed in an oil bath at 70°C, reacted under a nitrogen atmosphere for 6 hours, the product was centrifuged at 10,000 r / min for 5 minutes, washed three times with anhydrous methanol, and then dried in a vacuum oven to obtain Maleic anhydride copolymer microspheres 1 ;

[0044] (2) Amination of microspheres: weigh 2g Maleic anhydride copolymer microspheres 1 , add 60 mL of a mixed solution of ethanol and water (volume...

Embodiment 2

[0048] (1) Preparation of maleic anhydride copolymer microspheres: Weigh 5.21 g of styrene, 4.90 g of maleic anhydride, 0.99 g of ethylene glycol dimethacrylate (molar ratio of 100:100:10) and 0.10 g of initiator Dibenzoyl peroxide (1wt% of the total mass of maleic anhydride and styrene) was added to a 250mL three-necked flask, and then 100mL of ethyl butyrate was added, and after ultrasonic dissolution, the reaction system was connected, and the concentration of styrene and maleic anhydride was 0.5mol / L respectively; pass N 2 After 30 minutes, the three-necked flask was placed in an oil bath at 80°C, reacted under nitrogen atmosphere for 3 hours, the product was centrifuged at 10,000 r / min for 5 minutes, washed three times with anhydrous methanol, and then dried in a vacuum oven to obtain Maleic anhydride copolymer microspheres 2 ;

[0049] (2) Amination of microspheres: weigh 2g Maleic anhydride copolymer microspheres 2 , add 40 mL of a mixed solution of ethanol and wat...

Embodiment 3

[0052] (1) Preparation of maleic anhydride copolymer microspheres: Weigh 5.91g α-methylstyrene, 4.90g maleic anhydride and 0.52g crosslinking agent divinylbenzene (molar ratio is 100:100:8) and 0.11 g g Initiator azobisisobutyronitrile (1wt% of the total mass of maleic anhydride and α-methylstyrene) was added to a 100mL three-necked flask, followed by 50mL isoamyl acetate, and after ultrasonic dissolution, the reaction system was connected, styrene and the concentration of maleic anhydride are 1mol / L respectively; 2 After 30 minutes, the three-necked flask was placed in an oil bath at 70°C, reacted under a nitrogen atmosphere for 6 hours, the product was centrifuged at 10,000 r / min for 5 minutes, washed three times with anhydrous methanol, and then dried in a vacuum oven to obtain Maleic anhydride copolymer microspheres 3 ;

[0053] (2) Amination of microspheres: weigh 2g Maleic anhydride copolymer microspheres 3 , add 60 mL of a mixed solution of ethanol and water (volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com