Composition containing polyvinyl alcohol, film preparing method and film

A polyvinyl alcohol and composition technology, applied in the field of polyvinyl alcohol-containing compositions, can solve the problems of low-molecular plasticizers affecting the blown film process, affecting the health of users, and residual biological toxicity, etc., achieving good environmental protection effects, Cost saving and less odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation method of sample 1:

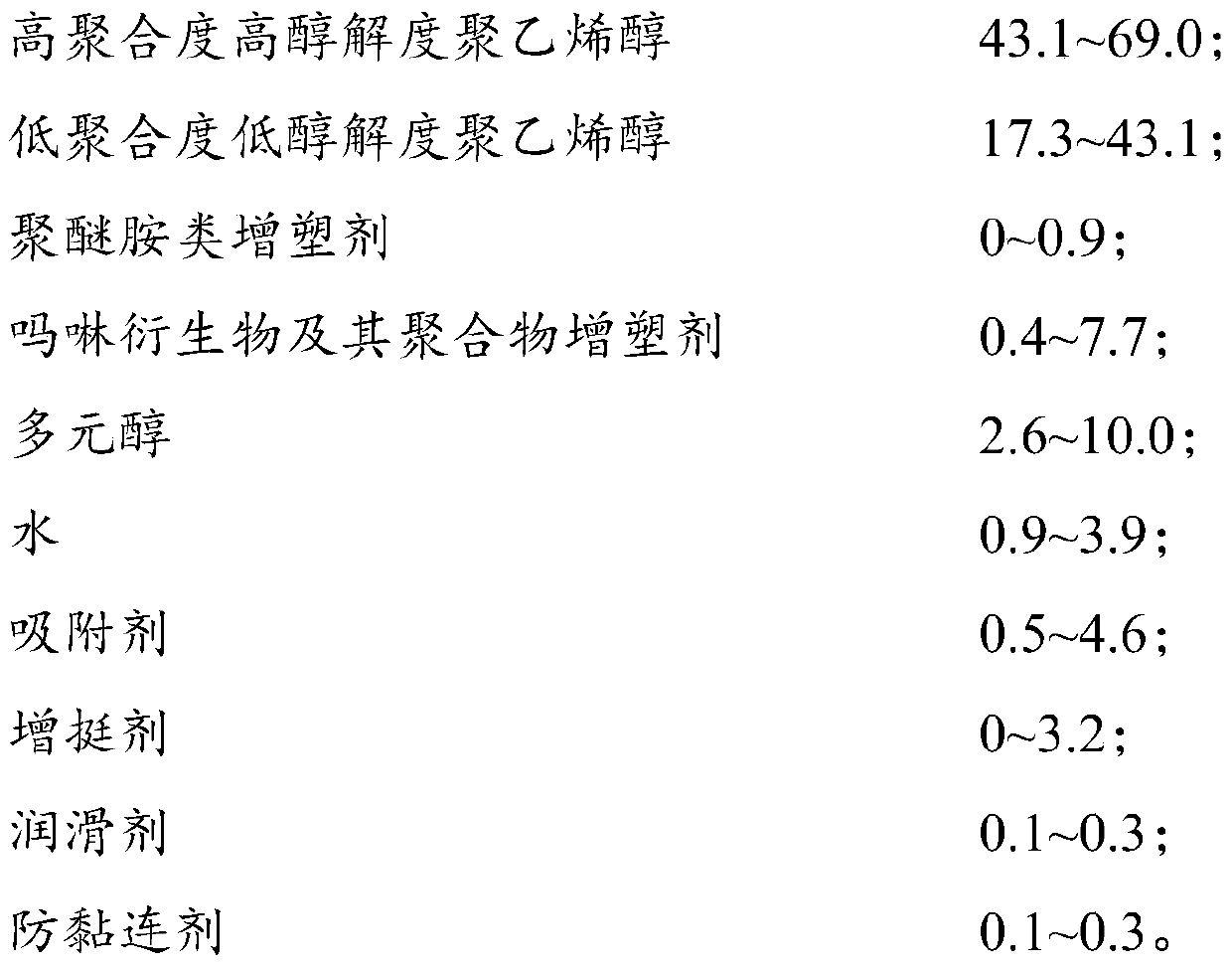

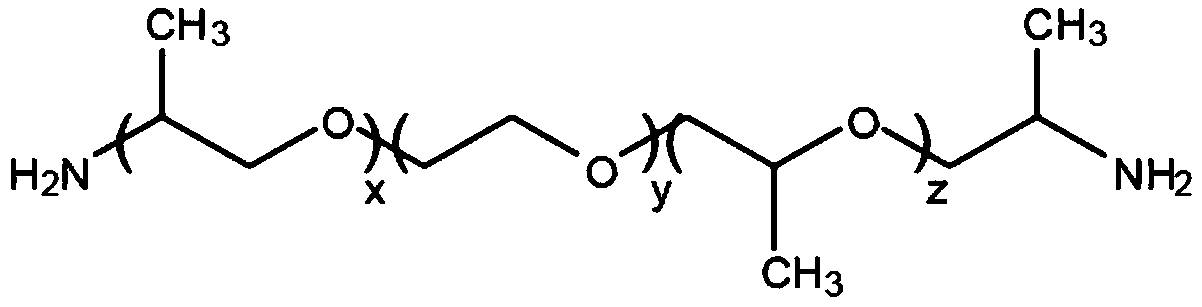

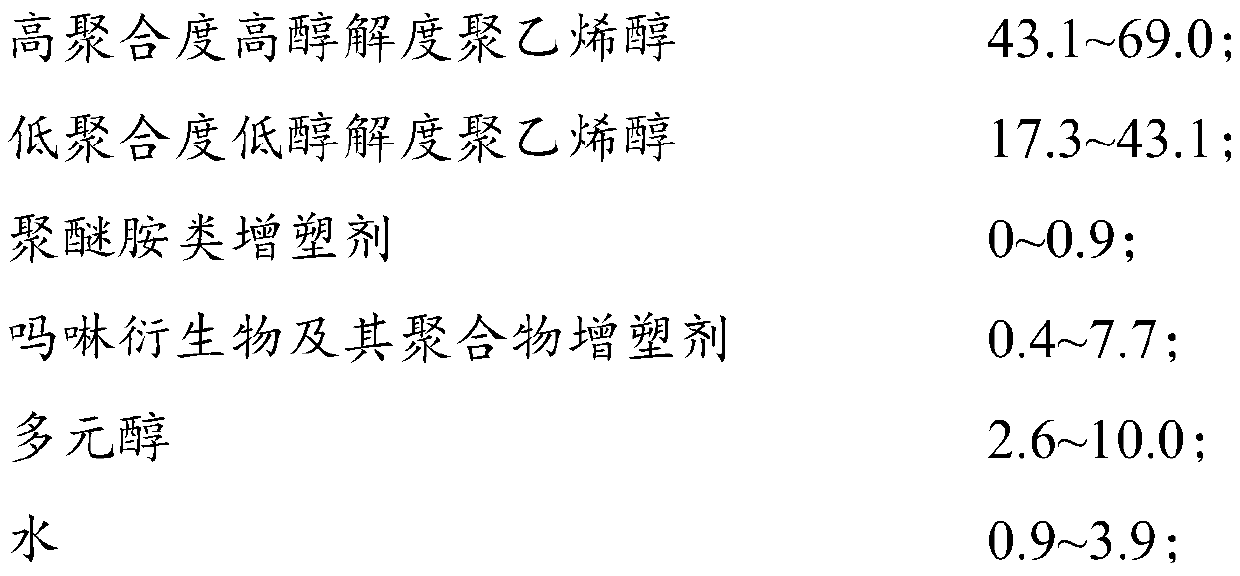

[0049] 1) Weigh 47.1 parts by weight of polyvinyl alcohol with high degree of polymerization and high alcoholysis (namely 1799 type polyvinyl alcohol), 31.4 parts by weight of low-polymerization and low degree of alcoholysis polyvinyl alcohol (namely 0588 type polyvinyl alcohol), 350r / min, the stirring time is 10 minutes, and then continue to add 0.4 parts by weight of polyetheramine plasticizer ED900, N-methylmorpholine oxide-3.9 parts by weight, and 9.4 parts by weight of glycerol into the high-speed mixer When the material temperature rises to 80-85°C, continue to add 3.9 parts by weight of deionized water, 0.5 parts by weight of halloysite powder, 3.2 parts by weight of talc powder, and 0.1 parts by weight of EBS into the high-speed mixer. , 0.1 parts by weight of hydrophilic fumed silica, continue to mix for 5 minutes, then seal the stirred materials for 15 hours, and cool down naturally;

[0050] 2) The material obtained in step 1) is...

Embodiment 2

[0053] Preparation method of sample two:

[0054] 1) Weigh 46 parts by weight of polyvinyl alcohol with high degree of polymerization and high alcoholysis (namely 1799 type polyvinyl alcohol), and 30.6 parts by weight of low-polymerization and low degree of alcoholysis polyvinyl alcohol (namely 0588 type polyvinyl alcohol), 350r / min, the stirring time is 10 minutes, and then continue to add 0.4 parts by weight of polyetheramine plasticizer ED900, 7.7 parts by weight of N-methylmorpholine oxide, and 7.7 parts by weight of glycerol into the high-speed mixer. Continue to mix for 35 minutes; when the material temperature rises to 80-85°C, continue to add 3.8 parts by weight of deionized water, 0.5 parts by weight of halloysite powder, 3.1 parts by weight of talc powder, 0.1 parts by weight of EBS, and pro- 0.1 parts by weight of aqueous fumed silica, continue to mix for 4 minutes, and then seal the stirred materials for 10 hours, and cool down naturally;

[0055] 2) The material obtai...

Embodiment 3

[0058] Preparation method of sample three:

[0059] 1) Weigh 49.7 parts by weight of polyvinyl alcohol with high degree of polymerization and high alcoholysis degree (namely 1799 type polyvinyl alcohol), and 33.1 parts by weight of polyvinyl alcohol with low degree of polymerization and low degree of alcoholysis (namely 0588 type polyvinyl alcohol) at the rotating speed. 350r / min, the stirring time is 10 minutes, and then continue to add 0.4 parts by weight of polyetheramine plasticizer ED900, 0.4 parts by weight of N-methylmorpholine oxide, and 9.9 parts by weight of glycerol into the high-speed mixer. Continue to mix for 35 minutes; when the material temperature rises to 80-85°C, continue to add 2.5 parts by weight of deionized water, 3.0 parts by weight of halloysite powder, 0.8 parts by weight of talc powder, 0.1 parts by weight of EBS, and pro- 0.1 parts by weight of water-based fumed silica, continue to mix for 5 minutes, and then keep the stirred materials sealed for 15 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com