Production method of chemical pump damping sound absorption and noise reduction sealing rubber

A sealing rubber and production method technology, applied in the field of polymer materials, can solve the problems of pressure resistance, vibration reduction, weather resistance and corrosion resistance, difficult to achieve balance, porous can not guarantee sealing, complex preparation methods, etc., to achieve good hydrophobicity, Increase the relaxation absorption effect, improve the effect of acid and alkali corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

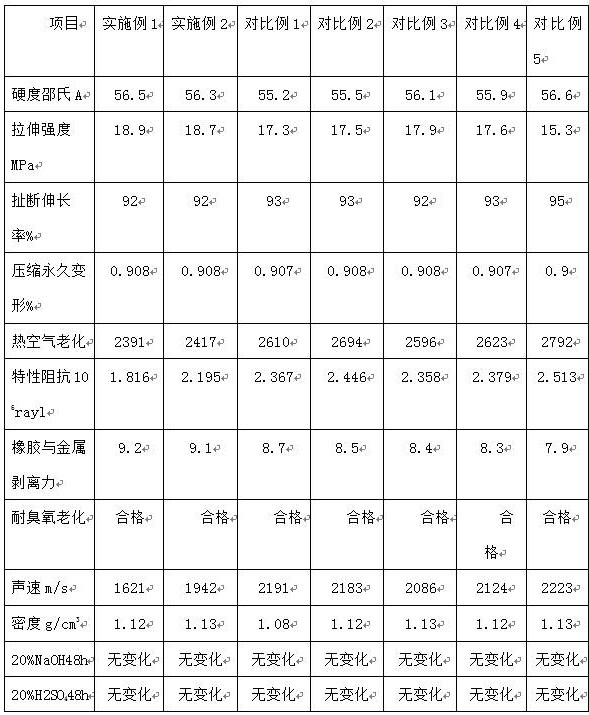

Examples

Embodiment 1

[0021] A method for producing chemical pump sound-absorbing and noise-reducing sealing rubber, comprising the following steps:

[0022](1) Preparation of chlorosulfonated butyl rubber: Dissolve pulverized butyl rubber in carbon tetrachloride at 75°C to form 100 parts of a 150 g / L solution, add 0.4 parts of ethanolamine and azobisisobutyronitrile to it 0.2 parts of initiator, blow chlorine gas and sulfur dioxide into the glue solution at 70°C with a volume ratio of 1:2 chlorosulfonating agent, the chlorine content is 1.0%, and when the sulfonation degree is 0.190meq / g, remove the acid gas and add diisopropylamine Neutralize to pH 7.4, add water to the quenched glue, the mixture of water and quenched glue is emulsified to form a slurry of neutralized sulfonated polymer, remove the solvent from the slurry, and separate it from the water (2) Adjust the temperature of the open mill to 85°C, adjust the roll distance to 0.65mm, and add 105 parts of chlorosulfonated butyl rubber to th...

Embodiment 2

[0024] (1) Preparation of chlorosulfonated butyl rubber: Dissolve pulverized butyl rubber in carbon tetrachloride at 65°C to form 100 parts of a 100g / L solution, add 0.2 parts of ethanolamine and azobisisobutyronitrile to it 0.1 part of initiator, blow chlorine gas and sulfur dioxide into the glue solution at 70°C with a volume ratio of 1:2 chlorosulfonating agent, the chlorine content is 1.0%, and when the sulfonation degree is 0.170meq / g, remove the acid gas and add diisopropylamine Neutralize to pH 7.2, add water to the quenched glue, the mixture of water and quenched glue is emulsified to form a slurry of neutralized sulfonated polymer, remove the solvent from the slurry, and separate it from the water (2) Adjust the temperature of the open mill to 80~85°C, adjust the roller distance to 0.6~0.65mm, add step (1) to obtain chlorosulfonated butyl rubber 100~105 parts, make the rubber cover the front roller, add the mixture of 1 part of stearic acid and 5 parts of sericite pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com