Low-cost corrosion-resistant unsaturated polyester resin, and preparation method and use thereof

A polyester resin, low-cost technology, applied in the field of low-cost corrosion-resistant unsaturated polyester resin and its preparation, can solve the problems of easy occurrence of defects, decreased physical properties of products, surface defects, etc., and achieves improved acid and alkali corrosion resistance. performance, improve corrosion resistance, improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

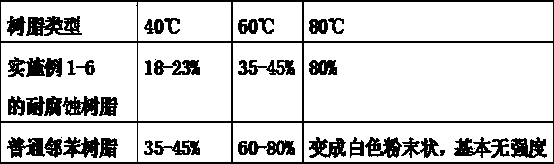

Examples

preparation example Construction

[0049] The preparation method of the unsaturated polyester resin is as follows: under the protection of nitrogen, degrade the glycol and PET at 200°C-220°C for 5-8 hours, cool down to 155-165°C after PET is completely degraded, add dibasic anhydride slowly Heat up to 195°C-200°C for polycondensation reaction for 4-5 hours, until the acid value reaches 35-45mgKOH / g, then vacuum treatment under reduced pressure for 1.5-3 hours, the vacuum degree is ≤0.092Mpa, and the optimal time for vacuuming is 1.5-2.5 hours , keep the temperature of the material at 195-200 °C, add additives including polymerization inhibitors after the acid value reaches 17-25 mgKOH / g, cool to 90-110 °C and add diluent to obtain low-cost corrosion-resistant unsaturated polystyrene Ester resin, wherein the additive that adds comprises inhibitor, copper naphthenate solution and paraffin, and inhibitor is common polymerization inhibitor, as hydroquinone, p-benzoquinone etc., and its add-on is 25% of reactant tota...

Embodiment 1

[0052] Corrosion-resistant unsaturated polyester resin reactants are fed by weight, including the following components:

[0053] Diethylene glycol 700g Propylene glycol 250g D33 glycol 400g

[0054]PET 1450g (obtained by polycondensation reaction of terephthalic acid and ethylene glycol)

[0055] Maleic anhydride 750g Phthalic anhydride 450g

[0056] Styrene 1400g Methyl methacrylate 200g

[0057] Its preparation method comprises the following steps:

[0058] According to the above-mentioned dosage, diethylene glycol, propylene glycol, D33 glycol and PET were degraded and reacted for 8 hours under the protection of nitrogen at 200°C, until the PET was completely degraded, the temperature was lowered to 155°C, and maleic anhydride and phthalic anhydride were added slowly Heat up to 200°C for polycondensation reaction for 5 hours, until the acid value reaches 35mgKOH / g, vacuum treatment under reduced pressure for 1.5 hours, keep the material temperature at 200°C, u...

Embodiment 2

[0061] Corrosion-resistant unsaturated polyester resin reactants are fed by weight, including the following components:

[0062] Neopentyl glycol 200g D33 diol 50g

[0063] PET 350g

[0064] Maleic anhydride 150g

[0065] Styrene 150g Methyl methacrylate 100g

[0066] Its preparation method comprises the following steps:

[0067] According to the above-mentioned dosage, degrade neopentyl glycol, D33 diol and PET at 220°C under the protection of nitrogen for 5 hours, until PET is completely degraded, cool down to 165°C, add maleic anhydride and slowly heat up to 195°C for polycondensation reaction 4 hours, until the acid value reaches 45mgKOH / g, vacuum treatment under reduced pressure for 3 hours, keep the material temperature at 195°C, until the acid value reaches 17mgKOH / g, add 70PPM of copper naphthenate solution, 25PPM of p-benzoquinone and 450PPM of paraffin, and cool Add styrene and methyl methacrylate to 110°C to prepare low-cost corrosion-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com