Laser marking halogen-free identification heat shrink tube and manufacturing method thereof

A technology of laser marking and heat-shrinkable tubes, which is applied in the field of heat-shrinkable materials, can solve problems such as unclear marking, compressed laser marking powder addition, and large loads of cable components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] As a preferred technical solution, the preparation method of the laser marking powder at least includes the following steps:

[0046] (1) adding polyethylene succinate into an organic solvent, and performing ultrasound under the condition of 60-70° C., to prepare a mixed solution A;

[0047] (2) Add titanium dioxide to the mixed solution A, and perform ultrasonication. After the ultrasonication is completed, place it in an oven at 80-90°C for drying, so that the organic solvent is completely evaporated, and the mixture B is obtained;

[0048] (3) Add carbon nanotubes to ethanol and perform ultrasonication. After the ultrasonication is completed, add it to mixture B and dry it in an oven at 50-60°C to completely evaporate the ethanol to obtain laser marking. pink.

[0049] plasticizer

[0050] As a more preferred technical solution, the plasticizer is a mixture of citrates and stearates, and the weight ratio of the citrates and stearates is (3-5):1.

[0051] As a more...

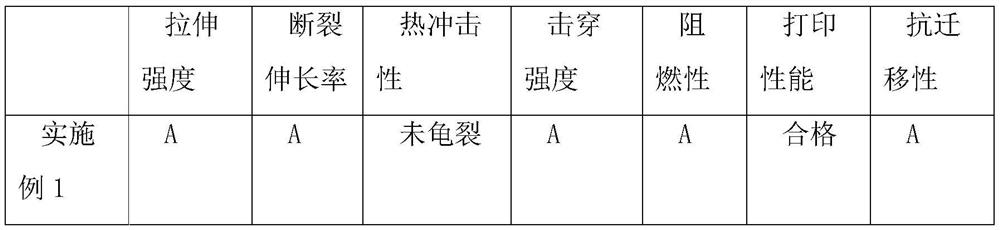

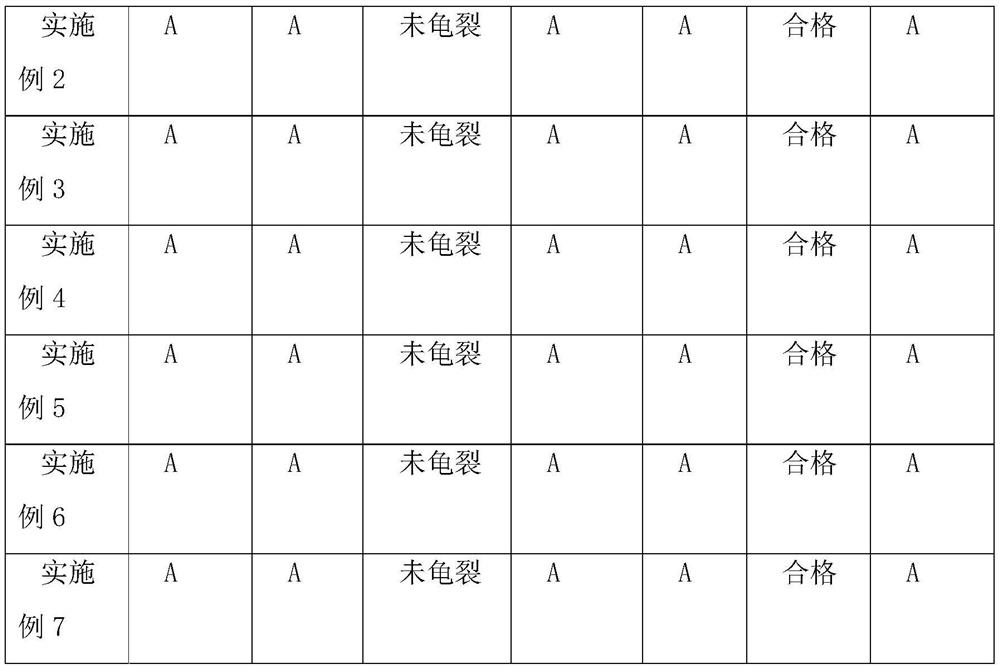

Embodiment 1

[0078] In this embodiment, a heat-shrinkable tube with a laser marking halogen-free mark, in parts by weight, its preparation raw materials include 10 parts of polyethylene, 15 parts of flame retardant, 15 parts of laser marking powder, 1 part of plasticizer, 25 parts of ethylene-vinyl acetate copolymer and 1 part of auxiliary agent, and the flame retardant is a non-halogen flame retardant. The polyethylene includes a density of 0.9225g / cm 3 , polyethylene A with a melt index of 0.25g / 10min and a density of 0.9240g / cm 3 , polyethylene B with a melt index of 1.9 g / 10 min. The weight ratio of polyethylene A and polyethylene B is 3:2.

[0079] The grade of the polyethylene A is: China Shipping Shell 2420D; the grade of the polyethylene B is: China Shipping Shell 2420H.

[0080] The non-halogen flame retardant is a mixture of inorganic non-halogen flame retardants and organic non-halogen flame retardants.

[0081] The inorganic non-halogen flame retardant is magnesium hydroxid...

Embodiment 2

[0096] In this embodiment, a heat-shrinkable tube with a laser marking halogen-free mark, in parts by weight, its preparation raw materials include 12 parts of polyethylene, 25 parts of flame retardant, 20 parts of laser marking powder, 3 parts of plasticizer, 48 parts of ethylene-vinyl acetate copolymer and 2 parts of auxiliary agent, and the flame retardant is a non-halogen flame retardant. The polyethylene includes a density of 0.9225g / cm 3 , polyethylene A with a melt index of 0.25g / 10min and a density of 0.9240g / cm 3 , polyethylene B with a melt index of 1.9 g / 10 min. The weight ratio of polyethylene A and polyethylene B is 3:2.

[0097] The grade of the polyethylene A is: China Shipping Shell 2420D; the grade of the polyethylene B is: China Shipping Shell 2420H.

[0098] The non-halogen flame retardant is a mixture of inorganic non-halogen flame retardants and organic non-halogen flame retardants.

[0099] The inorganic non-halogen flame retardant is magnesium hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com