A room temperature vulcanized rubber strip for automatic repair of conveyor belt and preparation method thereof

A room temperature vulcanization, conveyor belt technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of inconvenient storage of adhesive strips, poor stickiness and poor repair quality, etc., to improve the overall polarity and viscosity, not easy to emigrate, dispersibility and solubility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

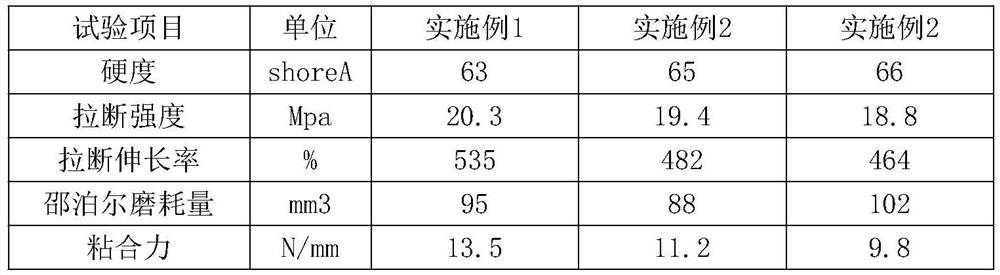

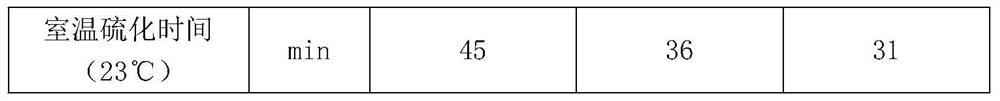

Embodiment 1

[0023] A room temperature vulcanized rubber strip for conveyor belt automatic repair provided by the present invention comprises a rubber strip 1 and a rubber strip 2, and the rubber strip 1 includes the following raw materials in parts by weight: 80 parts of natural rubber plasticized rubber, terminal functional Melt-solution polystyrene-butadiene rubber 20 parts, zinc oxide 5 parts, stearic acid 1.5 parts, anti-aging agent 5 parts, alkyl phenolic tackifying resin 6 parts, high wear-resistant carbon black 30 parts, bisphenol A 5 parts, sulfur 2.0 The rubber strip two includes the following raw materials in parts by weight: 100 parts of end-group functionalized solution-polymerized styrene-butadiene rubber, 30 parts of carboxyl-terminated liquid nitrile rubber, 40 parts of high wear-resistant carbon black, zinc isopropyl xanthate 1.0 parts, 0.3 parts of phthalic anhydride.

[0024] Wherein, the molar mass ratio of the rubber strip 1 and the rubber strip 2 is 1:1, and the formu...

Embodiment 2

[0035]A room temperature vulcanized rubber strip for automatic repair of a conveyor belt, comprising a rubber strip 1 and a rubber strip 2, the rubber strip 1 comprising the following raw materials in parts by weight: 60 parts of natural rubber plasticized rubber, terminal functionalized solution polystyrene butadiene 40 parts of rubber, 4 parts of zinc oxide, 1.0 part of stearic acid, 5 parts of anti-aging agent, 10 parts of alkylphenolic tackifying resin, 40 parts of high wear-resistant carbon black, 10 parts of bisphenol A, 2.5 parts of sulfur; the rubber strip Two include the following raw materials in parts by weight: 80 parts of end-group functionalized solution-polymerized styrene-butadiene rubber, 20 parts of carboxyl-terminated liquid nitrile rubber, 40 parts of high wear-resistant carbon black, 1.8 parts of zinc isopropyl xanthate, phthalate 0.5 parts of formic anhydride.

[0036] Wherein, the molar mass ratio of the rubber strip 1 and the rubber strip 2 is 1:1, and ...

Embodiment 3

[0043] A room temperature vulcanized rubber strip for automatic repair of conveyor belts, comprising a rubber strip 1 and a rubber strip 2, the rubber strip 1 comprising the following raw materials in parts by weight: 50 parts of natural rubber plasticized rubber, terminal functionalized solution polystyrene butadiene 50 parts of rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 5 parts of anti-aging agent, 10 parts of alkylphenolic tackifying resin, 45 parts of high wear-resistant carbon black, 10 parts of bisphenol A, 3.0 parts of sulfur; Bar 2 includes the following raw materials in parts by weight: 70 parts of end-group functionalized solution-polymerized styrene-butadiene rubber, 10 parts of carboxyl-terminated liquid nitrile rubber, 30 parts of high wear-resistant carbon black, 3.0 parts of zinc isopropyl xanthate, phthalate 1.0 parts of diformic anhydride.

[0044] Wherein, the molar mass ratio of the rubber strip 1 and the rubber strip 2 is 1:1, and the formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com