Bacteriostatic high-barrier polypropylene masterbatch for hygienic product packaging materials and preparation method thereof

A technology for packaging materials and hygienic products, which is applied in the field of bacteriostatic high-barrier polypropylene masterbatch and its preparation for hygienic product packaging materials, and can solve the problem of weakened antibacterial properties, poor antibacterial properties, and poor compatibility between antibacterial agents and polyolefins and other problems, to achieve the effect of long-lasting antibacterial, excellent antibacterial and high barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

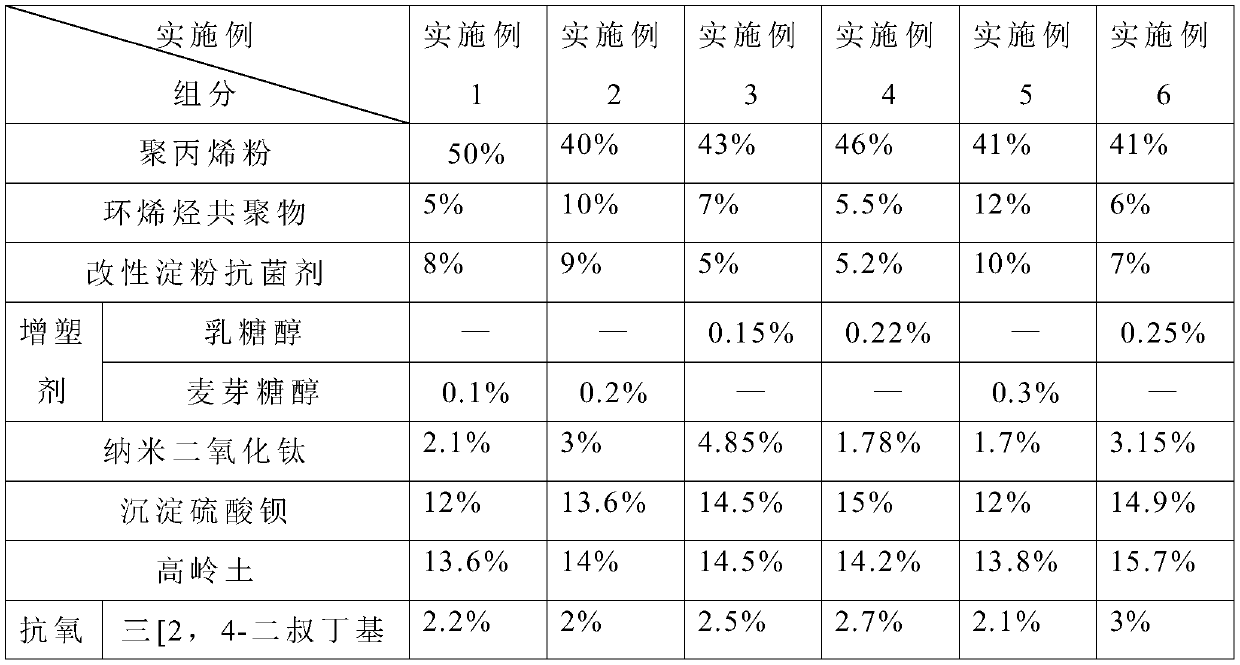

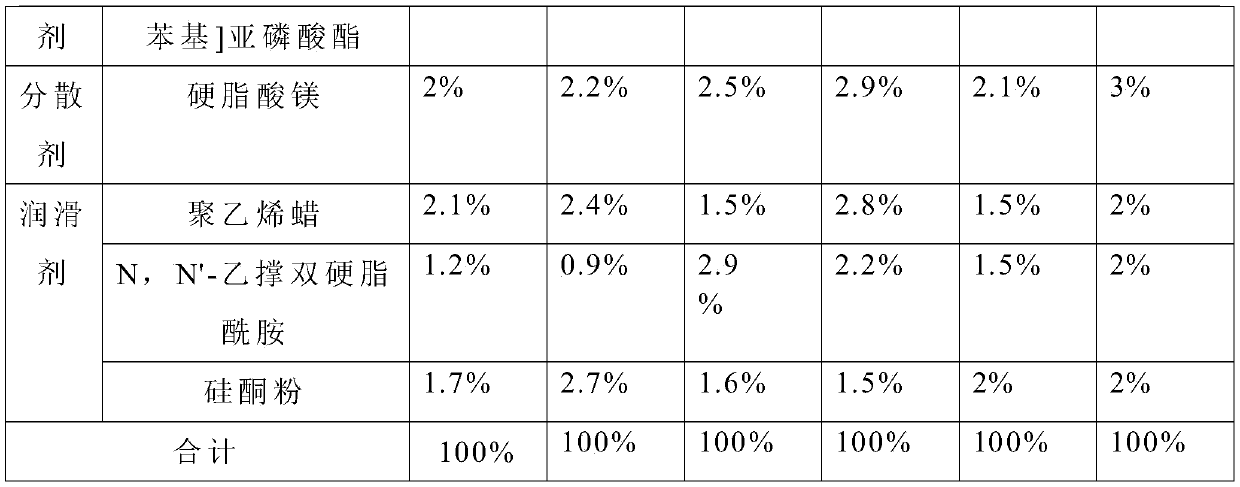

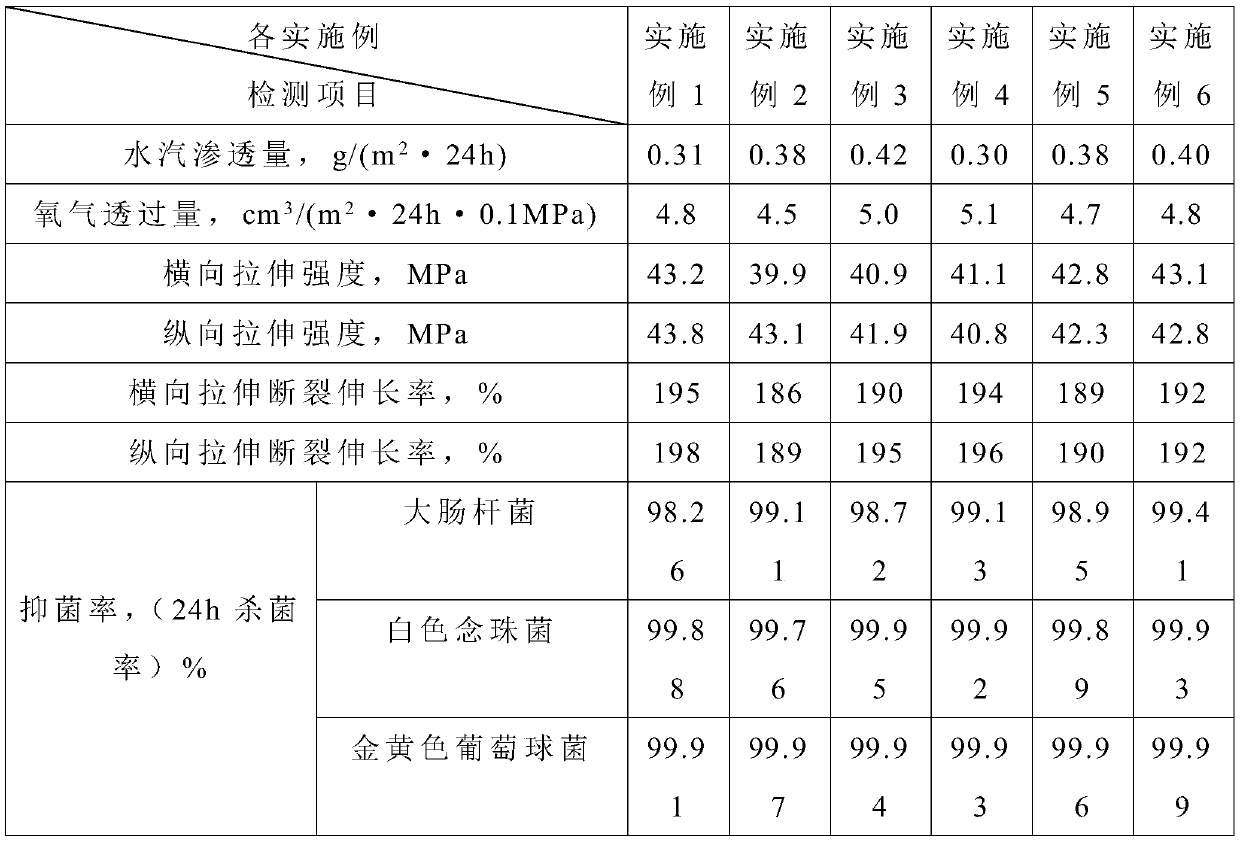

Examples

Embodiment 1

[0039] Step 1, weighing each raw material according to the mass ratio, crushing the polypropylene powder and the cycloolefin copolymer until passing through a 500-mesh sieve for later use;

[0040] Step 2: Add the pulverized polypropylene powder, cycloolefin copolymer, modified starch antibacterial agent, plasticizer, nano-titanium dioxide, precipitated barium sulfate, kaolin, antioxidant, dispersant and lubricant into the high mixer in sequence , mixed evenly, and then sent to a constant temperature dehumidification drying box at 35°C for constant temperature dehumidification until the moisture content of the mixture reaches 5-10%;

[0041] Step 3: feed the mixture obtained in Step 2 into a three-screw extruder and granulate at 225° C. to obtain the antibacterial high-barrier polypropylene color masterbatch for hygienic product packaging materials.

[0042] Wherein the modified starch antibacterial agent is prepared according to the following method: cationic starch and water...

Embodiment 2

[0044] Step 1, weighing each raw material according to the mass ratio, crushing the polypropylene powder and the cycloolefin copolymer until passing through a 500-mesh sieve for later use;

[0045] Step 2: Add the pulverized polypropylene powder, cycloolefin copolymer, modified starch antibacterial agent, plasticizer, nano-titanium dioxide, precipitated barium sulfate, kaolin, antioxidant, dispersant and lubricant into the high mixer in sequence , mixed evenly, and then sent to a constant temperature dehumidification drying box at 40°C for constant temperature dehumidification until the moisture content of the mixture reaches 5-10%;

[0046] Step 3: feed the mixture obtained in Step 2 into a three-screw extruder and granulate at 230° C. to obtain the antibacterial high-barrier polypropylene color masterbatch for hygienic product packaging materials.

[0047] Wherein the modified starch antibacterial agent is prepared according to the following method: cationic starch and water...

Embodiment 3

[0049] Step 1, weighing each raw material according to the mass ratio, crushing the polypropylene powder and the cycloolefin copolymer until passing through a 500-mesh sieve for later use;

[0050] Step 2: Add the pulverized polypropylene powder, cycloolefin copolymer, modified starch antibacterial agent, plasticizer, nano-titanium dioxide, precipitated barium sulfate, kaolin, antioxidant, dispersant and lubricant into the high mixer in sequence , mixed evenly, and then sent to a constant temperature dehumidification drying box at 40°C for constant temperature dehumidification until the moisture content of the mixture reaches 5-10%;

[0051] Step 3: feed the mixture obtained in Step 2 into a three-screw extruder and granulate at 230° C. to obtain the antibacterial high-barrier polypropylene color masterbatch for hygienic product packaging materials.

[0052]Wherein the modified starch antibacterial agent is prepared according to the following method: cationic starch and water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com