Halogen-free phosphorus-based synergistic flame retardant and flame-retardant polymer composite material and preparation method thereof

A flame retardant polymer, synergistic flame retardant technology, applied in the field of flame retardants, can solve problems such as increasing the cost of final products, unfavorable industrial production, restricting the application of flame retardants, etc. The effect of flue gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Halogen-free phosphorus-based synergistic flame retardant, the formula is PPEPAA1%, APP 50%, MPP 48%, molecular sieve 1%.

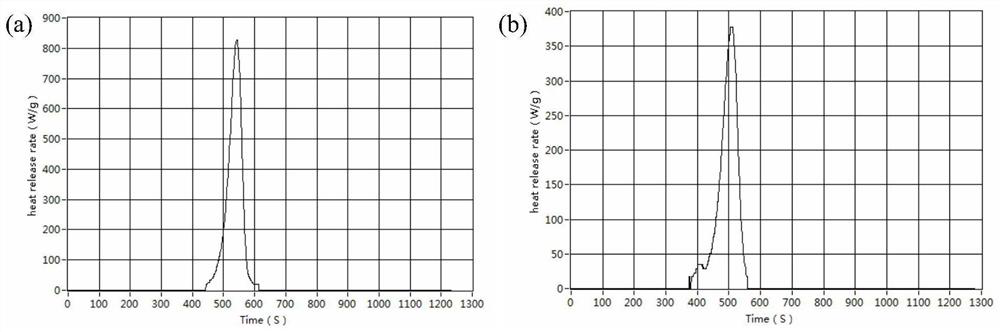

[0053] Flame retardant polymer composite material formula: 30% flame retardant, 0.3% antioxidant, 69.7% polypropylene;

[0054] The limiting oxygen index of the flame-retardant polymer composite material is 30.2%, the UL-94 vertical burning test reaches the V-1 level, the tensile strength is 21.71MPa, and the impact strength is 3.218KJ / m 2 , heat release rate 185.31W / g, total smoke production 8.05m 2 .

[0055] A method for preparing a halogen-free phosphorus-based synergistic flame retardant and a flame-retardant polymer material, the steps are as follows:

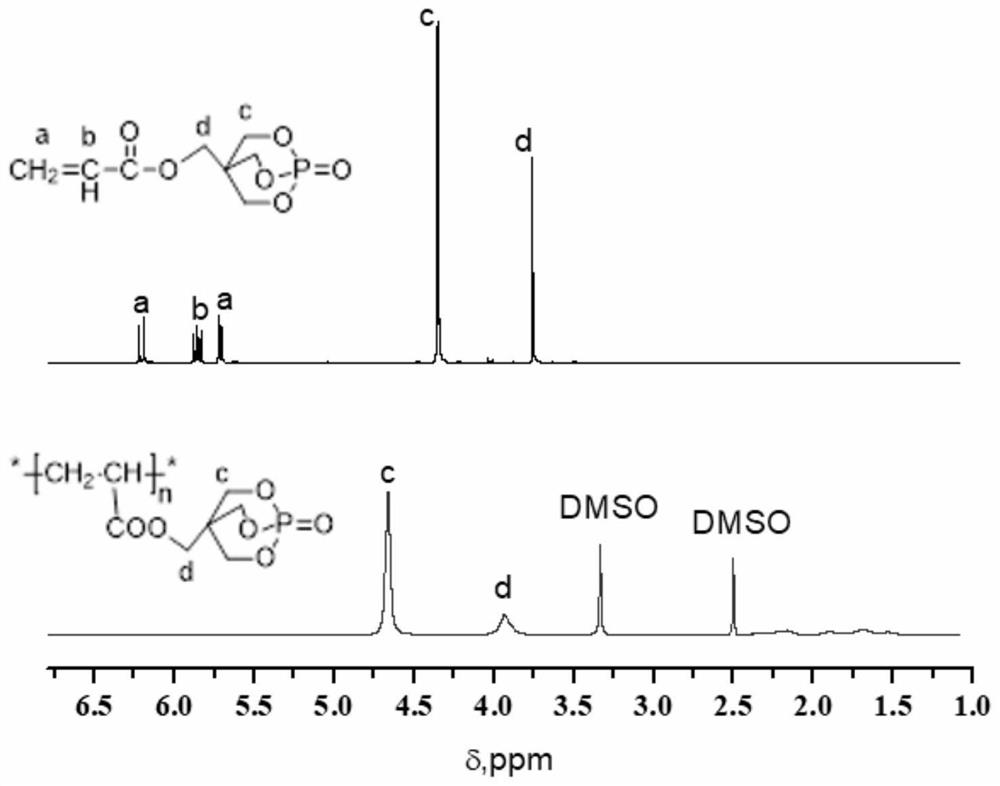

[0056] 1. The synthetic method of pentaerythritol phosphate acrylate (PEPAA)

[0057] Add cage pentaerythritol phosphate alcohol PEPA (54.0g, 0.3mol) to 200ml dichloromethane and stir, then add 42ml triethylamine, after the temperature drops to -10°C, add acryloyl chloride (27.2g, 0.3mol) i...

Embodiment 2

[0067] Halogen-free phosphorus-based synergistic flame retardant, the formula is PEPAA 2%, APP 55%, MPP 42%, molecular sieve 1%.

[0068] Flame retardant polymer material formula: 28% flame retardant, 0.3% antioxidant, 71.7% polypropylene.

[0069] The limiting oxygen index of the flame-retardant polymer composite material is 38.2%, the UL-94 vertical burning test reaches the V-0 level, the tensile strength is 26.52MPa, and the impact strength is 3.233KJ / m 2 , heat release rate 152.78W / g, total smoke production 7.05m 2 .

[0070] A method for preparing a halogen-free phosphorus-based synergistic flame retardant and a flame-retardant polymer material, the steps are as follows:

[0071] 1. The synthetic method of pentaerythritol phosphate acrylate (PEPAA)

[0072] Add cage pentaerythritol phosphate alcohol PEPA (54.0g, 0.3mol) to 200ml dichloromethane and stir, then add 42ml triethylamine, after the temperature drops to -10°C, add acryloyl chloride (27.2g, 0.3mol) in 200ml di...

Embodiment 3

[0078] Halogen-free phosphorus-based synergistic flame retardant, the formula is PPEPAA 5%, APP 60%, MPP 34%, molecular sieve 1%.

[0079] Flame retardant polymer material formula: 25% flame retardant, 0.3% antioxidant, 74.7% polypropylene

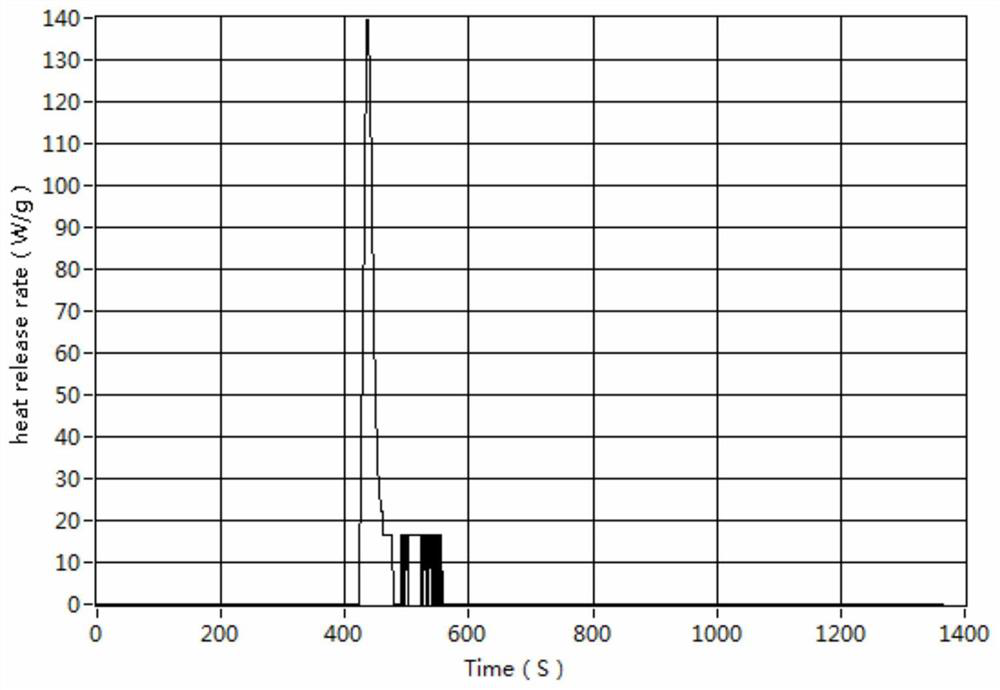

[0080] The limiting oxygen index of the flame-retardant polymer composite material is 43.6%, the UL-94 vertical combustion test reaches the V-0 level, the tensile strength is 29.36MPa, and the impact strength is 3.317KJ / m 2, heat release rate 138.62W / g, total smoke production 5.21m 2 . The flame retardant polypropylene material heat release rate figure of embodiment 3 is as follows image 3 shown.

[0081] The preparation method of the halogen-free phosphorus-based synergistic flame retardant and the flame-retardant polymer material is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com