Leak-proof iron structure and leak-proof iron breathable brick replacement method for iron ladle tank ventilation bricks

A replacement method and a technology of breathable bricks, which are applied in the directions of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of safe production risks, iron leakage accidents, and iron infiltration of molten iron tanks, and achieve good iron leakage prevention effect. The effect of not easy to move out and convenient for masonry construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

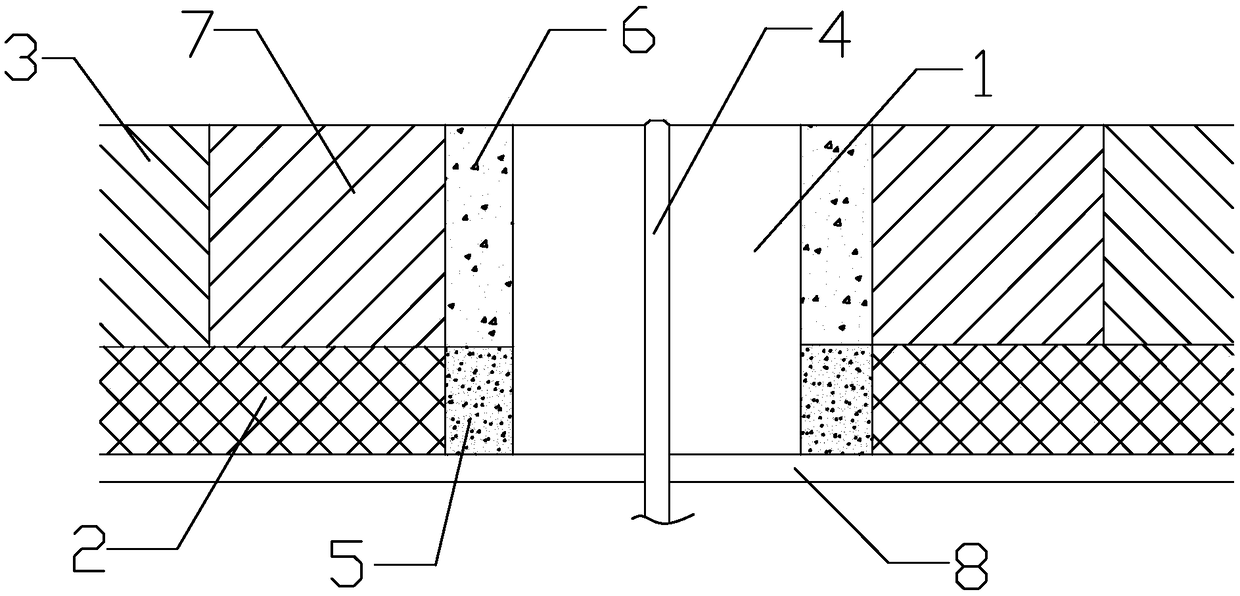

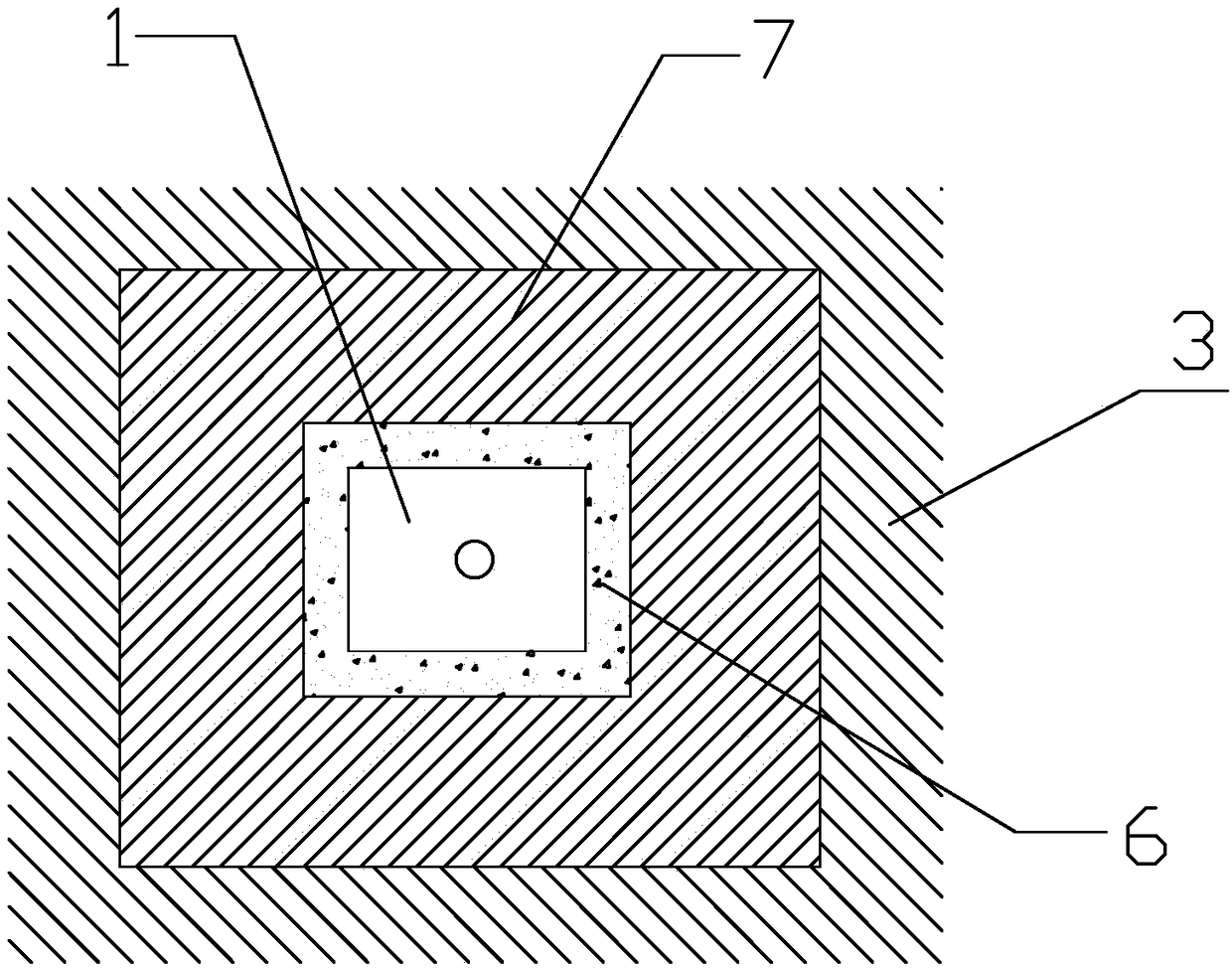

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Such as figure 1 and figure 2 A leak-proof iron structure of a ventilating brick for a molten iron tank shown in , comprises a tank wall of a molten iron tank and a ventilating brick 1 arranged on the tank wall of a molten iron tank, and a vent pipe 4 is arranged on the ventilating brick 1, and the tank wall of the molten iron tank is formed from From the outside to the inside, the molten iron tank shell 8, the permanent layer 2 and the working layer 3 are in turn. The breathable brick 1 is embedded in the permanent layer 2 and the working layer 3, and the vent pipe 4 passes out from the molten iron tank shell 8 and extends to the outside supply The trachea connection is characterized in that a ramming material filling layer 5 is filled between the air-permeable brick 1 and the permanent layer 2, and the ramming material filling layer 5 is formed by fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com