Degradable resin and method for preparing straw by using degradable resin

A technology for degrading resins and straws, which can be used in applications, household utensils, tubular objects, etc. It can solve the problems of easy migration of fillers, poor heat resistance of straws, and inability to meet food contact requirements, etc., to meet food contact requirements, Effect of improving heat resistance and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

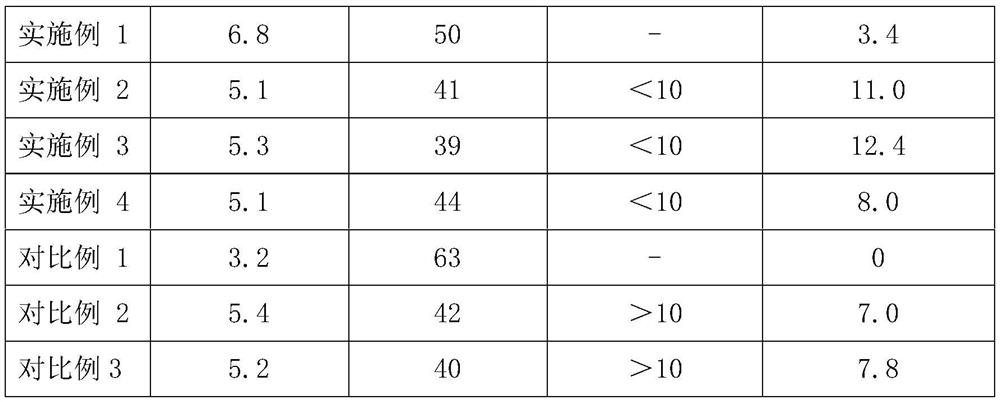

Examples

Embodiment 1

[0024] A degradable resin, based on 100 parts, comprising the following raw material components: 89 parts of polylactic acid, 10 parts of toughening agent, 0.5 part of lubricant, 0.1 part of nucleating agent, 0.1 part of compatibilizer, and 0.2 part of plasticizer , 0.1 part of antioxidant;

[0025] Wherein polylactic acid selects PLAlx175 for use; Described toughening agent is polybutylene succinate (PBS); Lubricant selects ethylene bisstearamide for use; Nucleating agent selects nano silicon dioxide for use; Compatibilizer selects epoxy for use Cross-linking agent; plasticizer selects vegetable oil for use, and antioxidant selects 6-tertiary butyl-4-methylphenol for use.

[0026] A kind of preparation method of degradable resin,

[0027] (1) Add polylactic acid, toughening agent, lubricant, nucleating agent, compatibilizer, plasticizer and antioxidant to the low-speed mixer in proportion and mix evenly;

[0028] (2) Add the uniformly mixed materials into the twin-screw ext...

Embodiment 2

[0031] A degradable resin, based on 100 parts, comprising the following raw material components: 71 parts of polylactic acid, 10 parts of toughening agent, 12 parts of filler, 3 parts of coupling agent, 0.3 parts of lubricant, 0.1 part of nucleating agent, 0.1 part of compatibilizer, 3.2 parts of vegetable oil, 0.3 part of antioxidant;

[0032] Wherein polylactic acid selects PLAlx175 for use; Described toughening agent is polybutylene succinate (PBS); Filler selects talcum powder for use; Coupling agent selects the mixture of titanate and lauric acid for use; Fatty acid amide; nano silicon dioxide as nucleating agent; epoxy crosslinking agent as compatibilizer; vegetable oil as plasticizer, and 6-tertiary butyl-4-methylphenol as antioxidant.

[0033] A kind of preparation method of degradable resin,

[0034] (1) First, take talcum powder, lauric acid and titanate coupling agent, and stir at a high speed for 20 minutes at 70°C-86°C to activate the surface to produce amphiphil...

Embodiment 3

[0039] A degradable resin, based on 100 parts, comprising the following raw material components: 71 parts of polylactic acid, 10 parts of toughening agent, 12 parts of filler, 3 parts of coupling agent, 0.3 parts of lubricant, 0.1 part of nucleating agent, 0.1 part of compatibilizer, 3.2 parts of vegetable oil, 0.3 part of antioxidant;

[0040] Wherein polylactic acid selects PLAlx175 for use; Described toughening agent is polybutylene succinate (PBS); Filler selects tapioca starch for use; Coupling agent selects the mixture of titanate and lauric acid for use; Fatty acid amide; nano silicon dioxide as nucleating agent; epoxy crosslinking agent as compatibilizer; vegetable oil as plasticizer, and 6-tertiary butyl-4-methylphenol as antioxidant.

[0041] A kind of preparation method of degradable resin is the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com