Half cutting machine of culture medium for experiments

A kind of test-use and matrix technology, applied in the field of culture medium, can solve the problems of inaccurate cutting and easy relative movement, etc., and achieve the effect of not easy to move outward and ensure smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

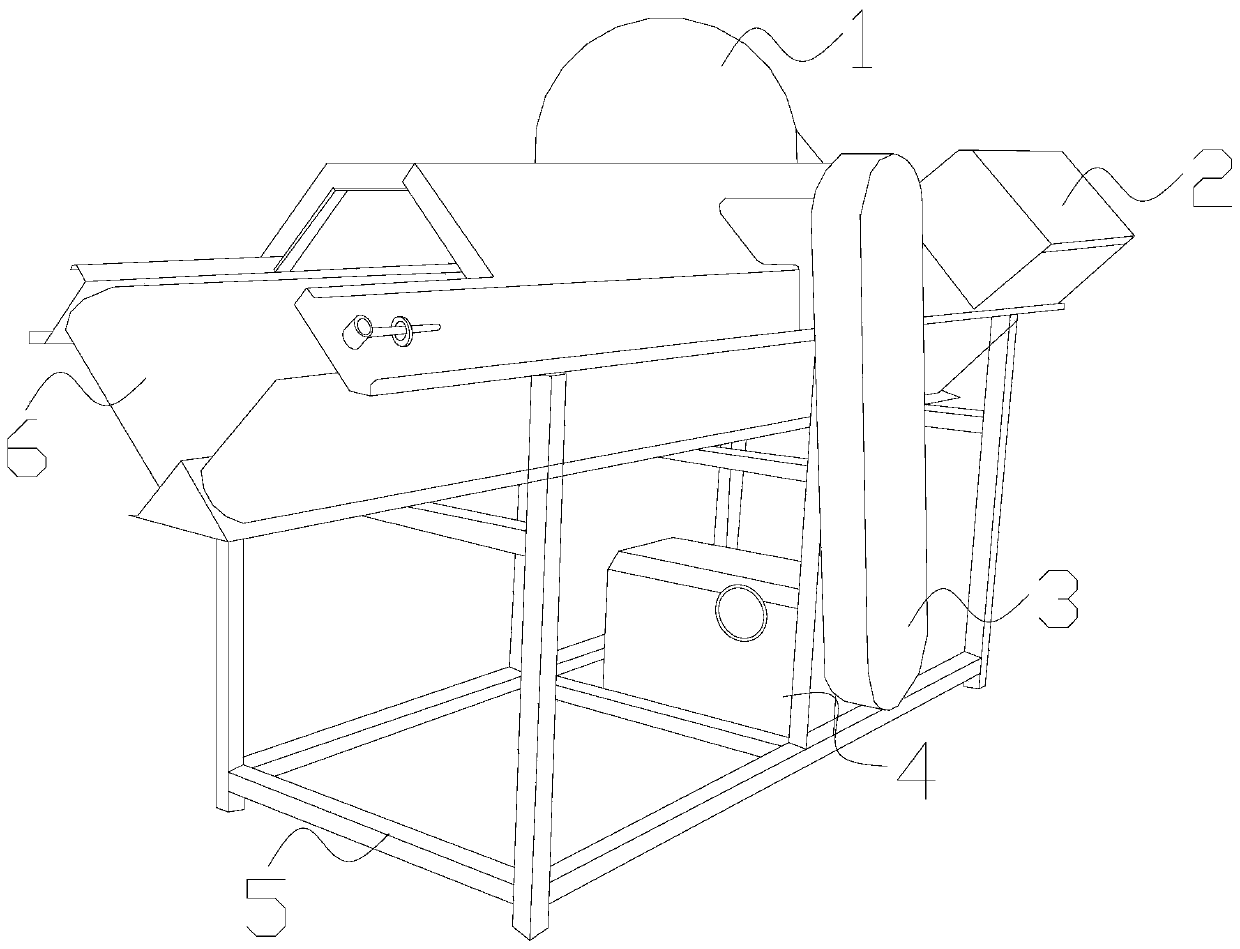

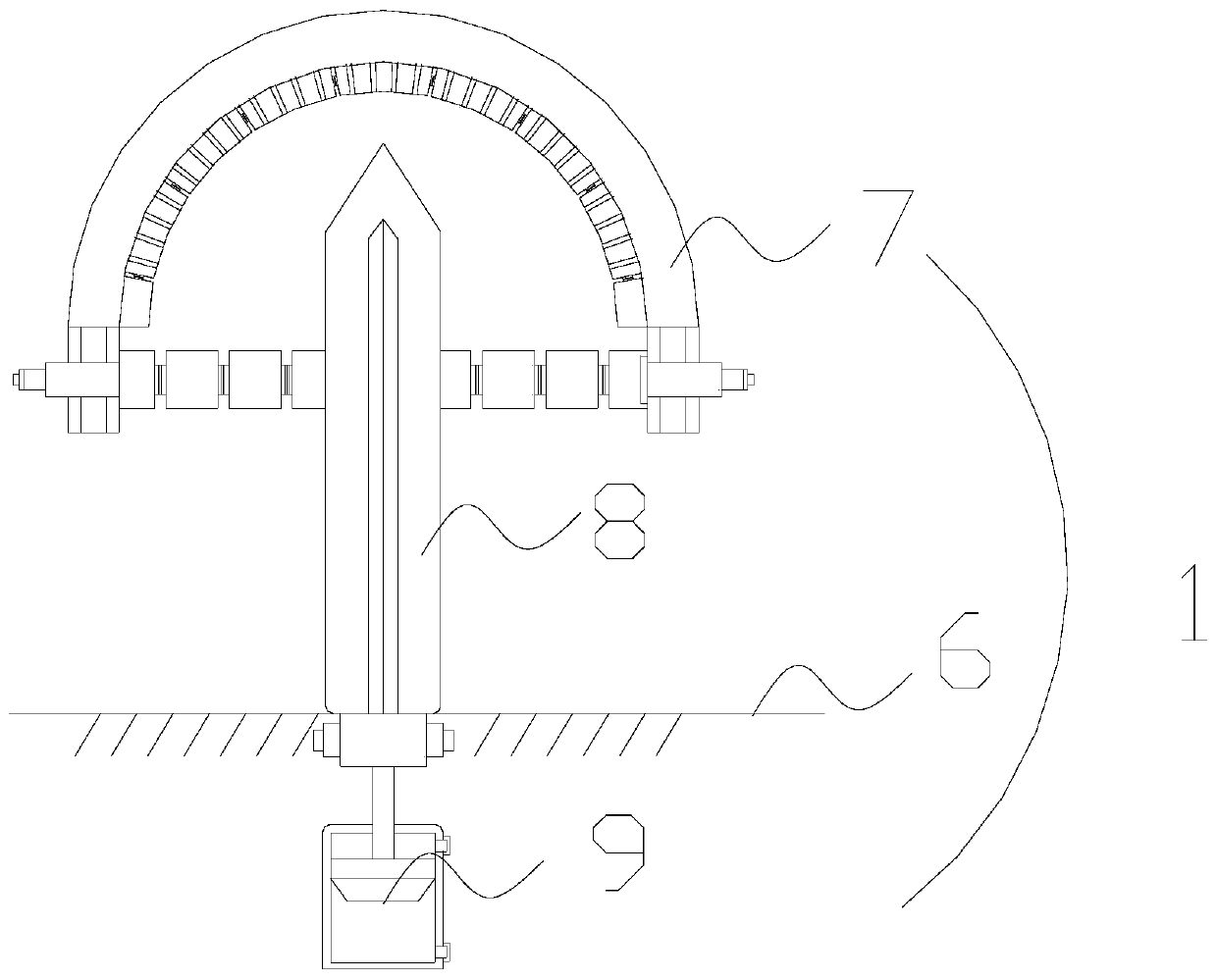

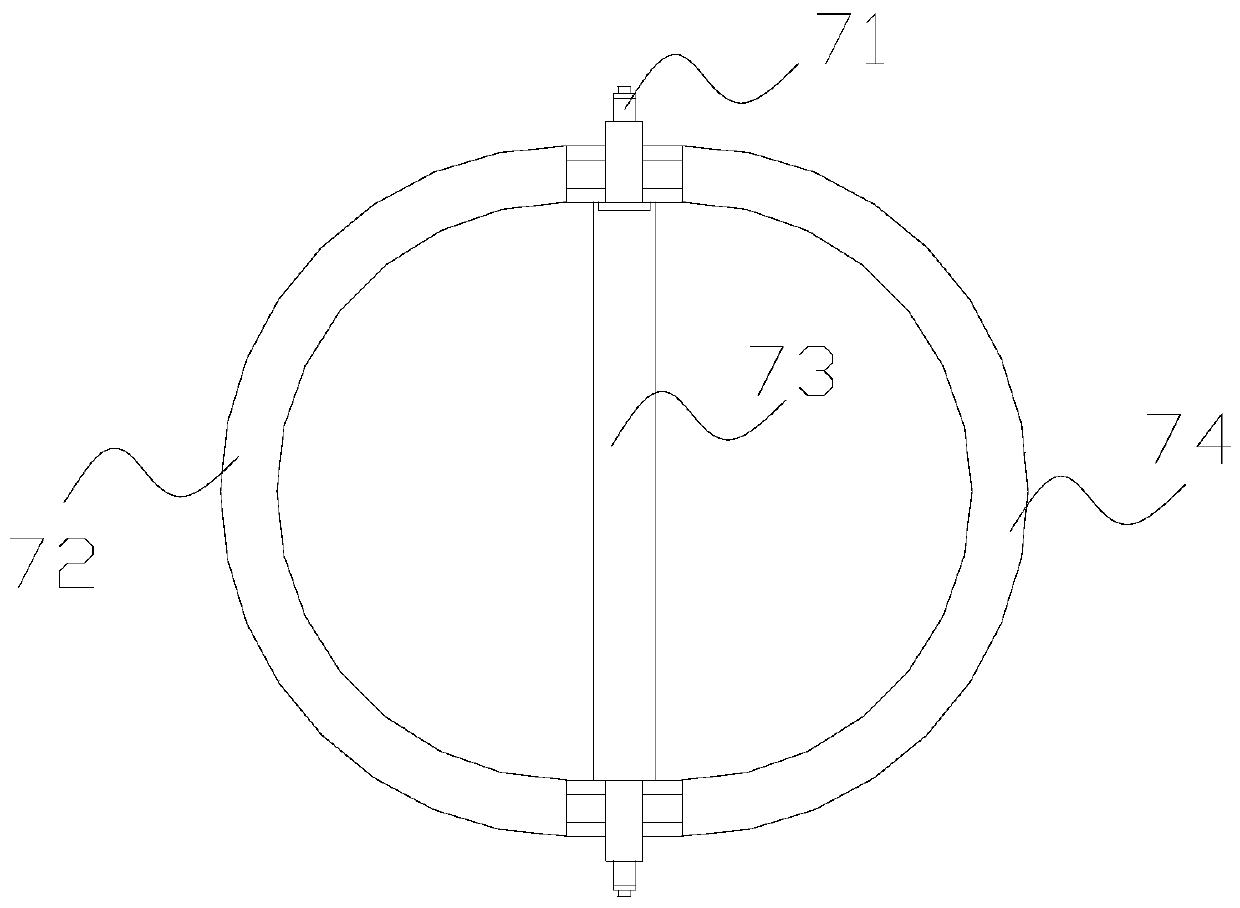

[0025] see Figure 1-Figure 6 , a test culture substrate half-cutting machine, the invention provides a test culture substrate half-cutting machine, its structure includes a half-cut structure 1, a control box 2, a belt 3, a motor 4, an underframe 5, a delivery platform 6, The bottom of the delivery platform 6 is movably equipped with an underframe 5, and one end of the delivery platform 6 is movably equipped with a half-cut structure 1 and a control box 2, and one side of the control box 2 is provided with a belt 3, and the belt 3 One end is mechanically connected to the conveying platform 6, the other end of the belt 3 is connected to the motor 4 in transmission, the half-cut structure 1 is provided with a three-clamp ring 7, a cutting knife 8, and a hydraulic cylinder 9, and the three-clamp ring 7 is provided directly below There is a cutting knife 8, and the cutting knife 8 cooperates with the three clamping rings 7, and a hydraulic cylinder 9 is fixedly installed on the b...

Embodiment 2

[0032] see Figure 1-Figure 6 , a test culture substrate half-cutting machine, the invention provides a test culture substrate half-cutting machine, its structure includes a half-cut structure 1, a control box 2, a belt 3, a motor 4, an underframe 5, a delivery platform 6, The bottom of the delivery platform 6 is movably equipped with an underframe 5, and one end of the delivery platform 6 is movably equipped with a half-cut structure 1 and a control box 2, and one side of the control box 2 is provided with a belt 3, and the belt 3 One end is mechanically connected to the conveying platform 6, the other end of the belt 3 is connected to the motor 4 in transmission, the half-cut structure 1 is provided with a three-clamp ring 7, a cutting knife 8, and a hydraulic cylinder 9, and the three-clamp ring 7 is provided directly below There is a cutting knife 8, and the cutting knife 8 cooperates with the three clamping rings 7, and a hydraulic cylinder 9 is fixedly installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com