Environment-friendly softening agent grafted regenerated rubber and preparation method thereof

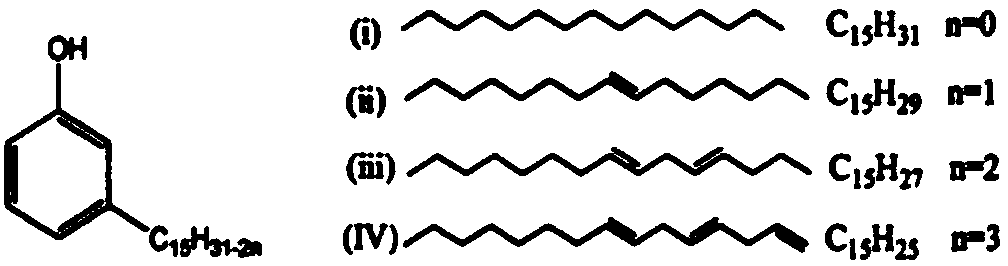

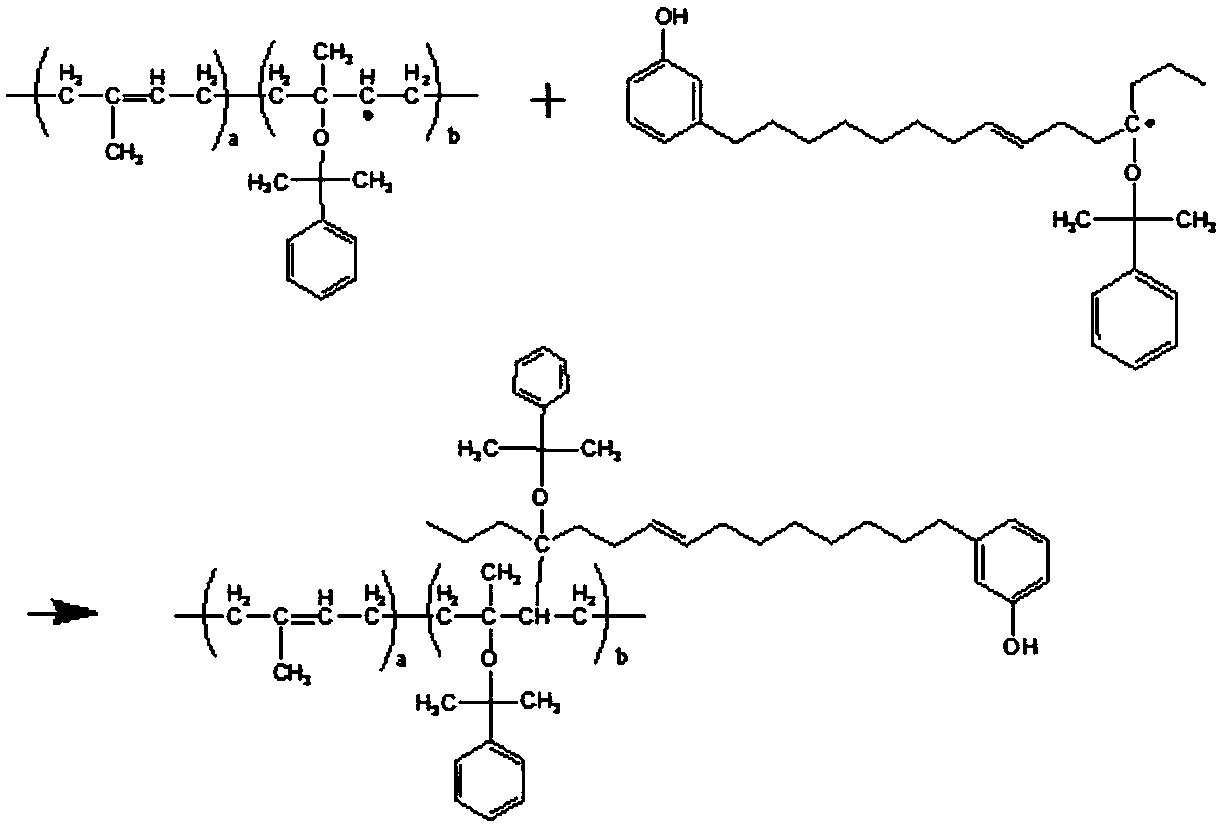

A technology of regenerated rubber and softener, which is applied in the field of environmentally friendly softener grafted regenerated rubber and its preparation, which can solve the problems of easy migration of softener, bluish products, Mooney rebound, etc., and achieve low content and excellent physical and mechanical properties. Improvement, Mooney stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

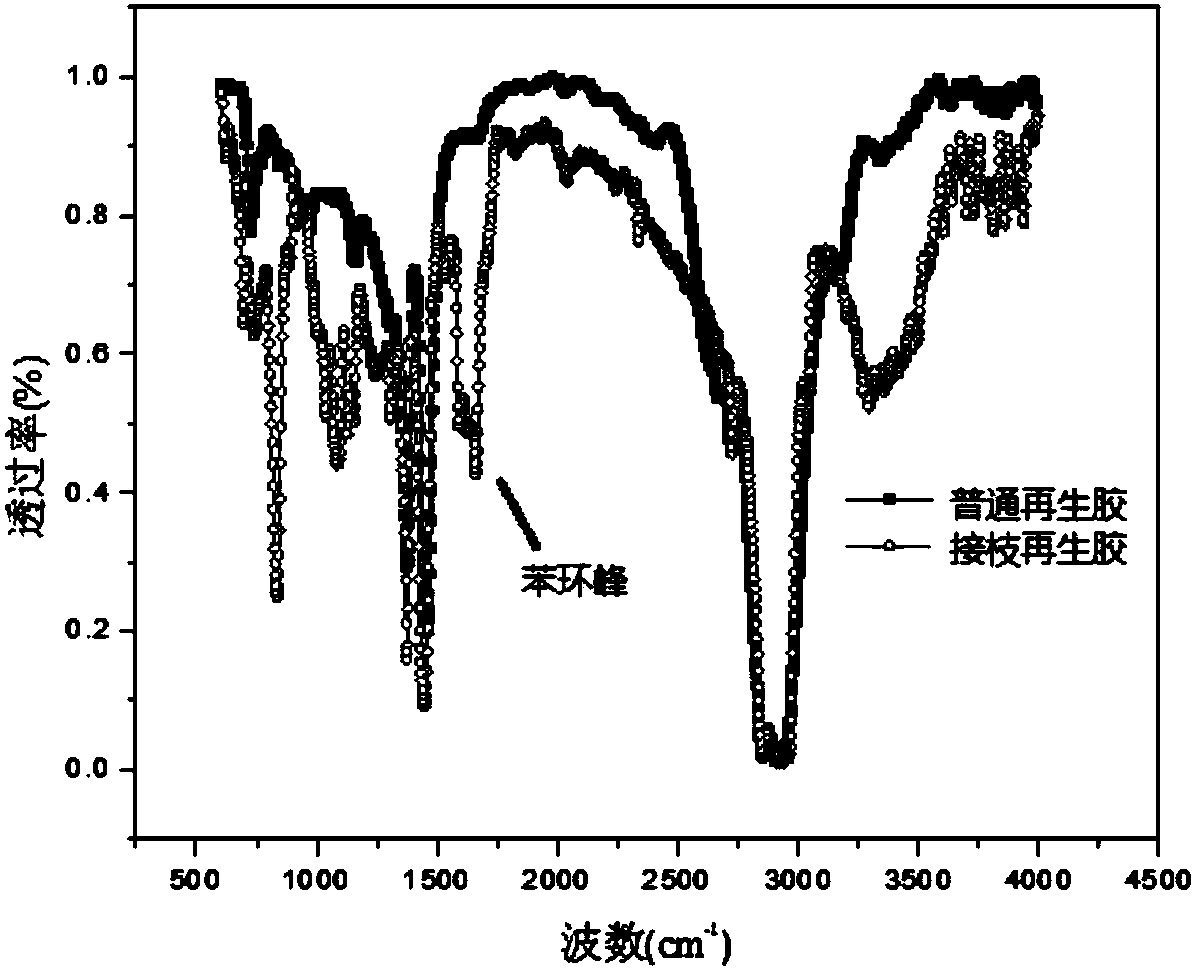

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of softening agent graft regenerated rubber, concrete steps are:

[0027] 1) In parts by weight, add 500 parts by mass of 30-mesh waste rubber powder, 70 parts by mass of cardanol, 2.5 parts by mass of activator, and 20 parts of calcium carbonate into a high-speed mixer and mix evenly; temperature is 80°C, and time is 6 minutes;

[0028] 2) Add the uniformly mixed materials into the internal mixer at a temperature of 200° C., a rotating speed of 40 rpm, and a mixing time of 20 minutes; when mixing for 6 minutes, add 0.5 parts by mass of dicumyl peroxide initiator;

[0029] 3) The reclaimed rubber powder is discharged after cooling, and the discharge temperature is 50°C; the reclaimed rubber powder is thinly passed through the open mill, the roller distance is 0.5mm, the time is 1min, and the final 5mm roller distance is removed to obtain an environmentally friendly softener. sticks of recycled rubber.

Embodiment 2

[0031] A kind of preparation method of softening agent graft regenerated rubber, concrete steps are:

[0032] 1) In parts by weight, add 500 parts by mass of 30-mesh waste rubber powder, 70 parts by mass of cardanol, 2.5 parts by mass of activator, and 20 parts of calcium carbonate into a high-speed mixer and mix evenly; temperature is 80°C, and time is 6 minutes;

[0033] 2) Add the uniformly mixed materials into the internal mixer at a temperature of 200° C., a rotating speed of 40 rpm, and a mixing time of 20 minutes; when mixing for 6 minutes, add 1 mass part of dicumyl peroxide initiator;

[0034] 3) The reclaimed rubber powder is discharged after cooling, and the discharge temperature is 50°C; the reclaimed rubber powder is thinly passed through the open mill, the roller distance is 0.5mm, the time is 1min, and the final 5mm roller distance is removed to obtain an environmentally friendly softener. sticks of recycled rubber.

Embodiment 3

[0036] A kind of preparation method of softening agent graft regenerated rubber, concrete steps are:

[0037] 1) In parts by weight, add 500 parts by mass of 30-mesh waste rubber powder, 70 parts by mass of cardanol, 2.5 parts by mass of activator, and 20 parts of calcium carbonate into a high-speed mixer and mix evenly; temperature is 80°C, and time is 6 minutes;

[0038] 2) Add the uniformly mixed materials into the internal mixer at a temperature of 200° C., a rotating speed of 40 rpm, and a mixing time of 20 minutes; when mixing for 6 minutes, add 1.5 parts by mass of dicumyl peroxide initiator;

[0039] 3) The reclaimed rubber powder is discharged after cooling, and the discharge temperature is 50°C; the reclaimed rubber powder is thinly passed through the open mill, the roller distance is 0.5mm, the time is 1min, and the final 5mm roller distance is removed to obtain an environmentally friendly softener. sticks of recycled rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com