Composite processing additive for plastic thin film and preparation method thereof

A composite processing aid and plastic film technology, which is applied in the field of plastic additives, can solve the problems of film processing aids such as poor versatility, single performance, and instability, and achieve stable and uniform dimensions, ensure stability, and be easy to process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

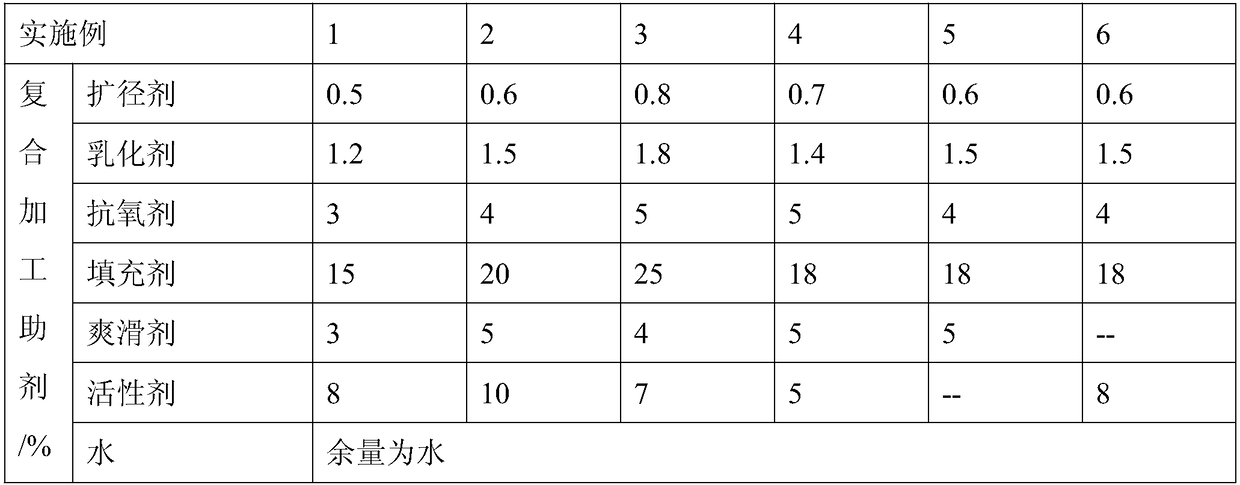

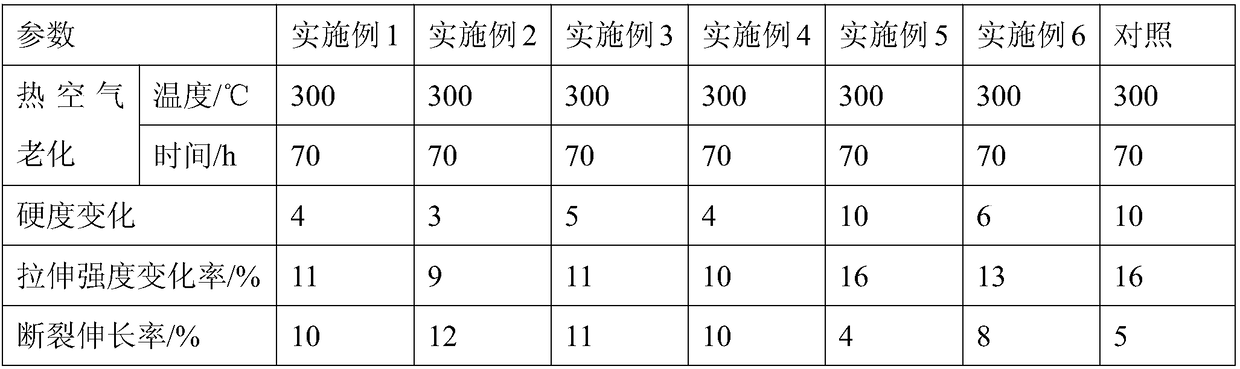

[0027] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0028] A compound processing aid for plastic film, which is composed of the following components: 0.5-0.8% diameter expander, 1.2-1.8% emulsifier, 3-5% antioxidant, 15-25% filler, smooth Agent 3-5%, active agent 5-10%, and the balance is water.

[0029] Specifically, it consists of the percentages of the following components: diameter expander 0.6%, emulsifier 1.5%, antioxidant 4%, filler 20%, slip agent 5%, active agent 10%, and the balance is water.

[0030] Specifically, the diameter expander is at least one of trisodium phosphate, sodium sulfate, sodium chloride, tripotassium phosphate, potassium sulfate and / or potassium chloride.

[0031] Specifically, the emulsifier is at least one of lauryl phosphate, potassium lauryl phosphate and / or sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com