A kind of halogen-free high-efficiency flame retardant, flame retardant epoxy resin and preparation method thereof

A technology of epoxy resin and solid epoxy resin, applied in the field of composite materials, can solve the problems of harsh reaction conditions of flame retardant epoxy resin, too high flame retardant addition, poor heat resistance of flame retardant epoxy resin, etc. Achieve excellent transparency, good plasticity, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

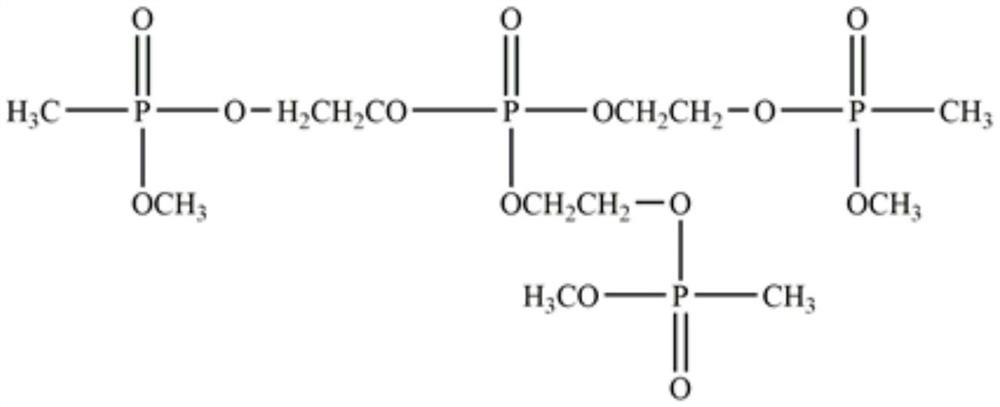

Image

Examples

Embodiment 1

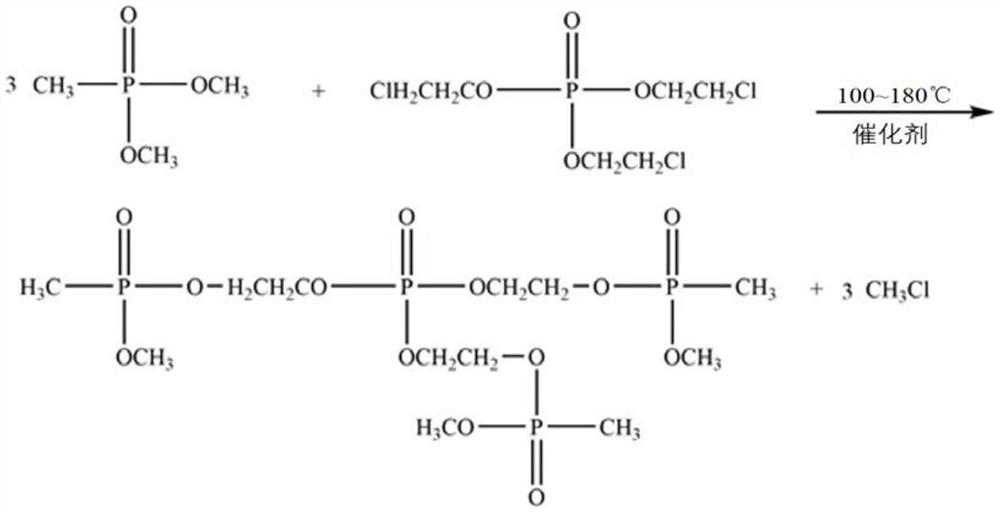

[0034] Preparation of flame retardant:

[0035] In the reactor with gas outlet, add 372g of dimethyl methylphosphonate, add 6g of catalyst sodium carbonate simultaneously, turn on stirring, start to heat up, when the temperature reaches 120 ° C, start to drip tris(2) phosphoric acid into the reactor -Chloroethyl) ester 285g, along with the dropwise addition, there will be a reaction gas methyl chloride to generate, the reaction gas enters the refrigeration compression unit after being condensed by the reactor gas outlet through the condenser to recover, and the dripping is completed, and continue to be slowly warmed up to 160 ℃ Continue the reaction and wait until there is basically no gas discharged, indicating that the reaction is basically complete, and a halogen-free high-efficiency flame retardant is obtained.

[0036] Epoxy Formulation:

[0037]

[0038] The preparation process is as follows:

[0039] In the first step, a certain amount of low-viscosity epoxy resin,...

Embodiment 2

[0044] Preparation of flame retardant:

[0045] In the reactor with gas outlet, add 372g of dimethyl methylphosphonate, add 6g of catalyst sodium hydroxide simultaneously, turn on stirring, start to heat up, when the temperature reaches 120 ° C, start to drip tris(phosphoric acid) into the reactor. 2-Chloroethyl) ester 300g, along with the dropwise addition, there will be reaction gas methyl chloride to generate, and the reaction gas enters the refrigeration compression unit after being condensed by the reactor gas outlet through the condenser and reclaims, and the dripping is completed, and the temperature is continued to be slowly raised to 160 ℃. The reaction is continued at ℃, and when there is basically no gas discharged, it indicates that the reaction is basically complete, and a halogen-free high-efficiency flame retardant is obtained.

[0046] Epoxy Formulation:

[0047]

[0048] The preparation process is as follows:

[0049] In the first step, a certain amount o...

Embodiment 3

[0054] Preparation of flame retardant:

[0055] In the reactor with gas outlet, add 372g of dimethyl methylphosphonate, add 6g of catalyst sodium ethoxide simultaneously, turn on stirring, start to heat up, when the temperature reaches 120 ° C, start to drip tris(2) phosphoric acid into the reactor -Chloroethyl) ester 300g, along with the dropwise addition, there will be reaction gas methyl chloride to generate, and the reaction gas enters the refrigeration compression unit after being condensed by the reactor gas outlet through the condenser to recover, and the dripping is completed, and continue to be slowly warmed up to 160 ℃ Continue the reaction and wait until there is basically no gas discharged, indicating that the reaction is basically complete, and a halogen-free high-efficiency flame retardant is obtained.

[0056] Epoxy Formulation:

[0057]

[0058] The preparation process is as follows:

[0059] In the first step, a certain amount of low-viscosity epoxy resin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com