A kind of hybrid nanoparticle, preparation method and anti-ultraviolet application

A technology of hybrid nanoparticles and hybrid particles, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of inapplicability to large-scale production, complicated preparation process, and difficulty in industrial promotion , to achieve excellent anti-ultraviolet effect, simple preparation method, and improve the effect of toughness and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

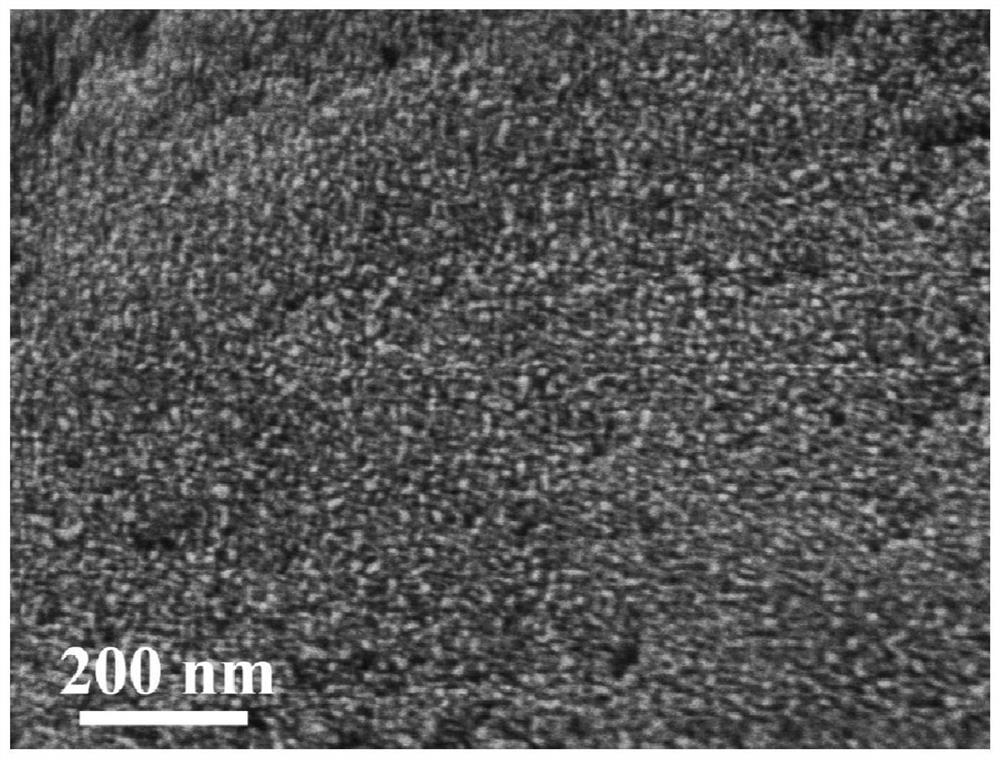

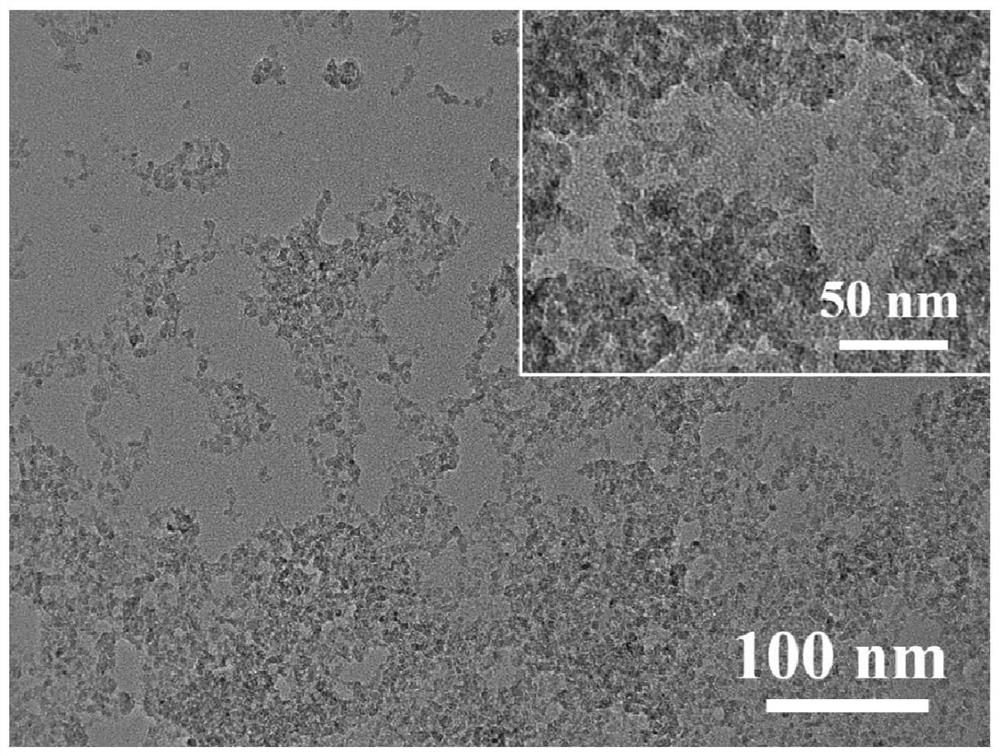

[0036] (1) Preparation of precursor dispersion: the titanium dioxide precursor dispersion is obtained by hydrolysis of titanium salt. Mix ethanol, isopropanol, and deionized water (volume ratio 15:85:10) into 120ml of compound solvent, and add 0.009 mol (3.06g) tetrabutyl titanate, after 30min vigorous stirring to obtain a suspension of a large amount of white precipitate, centrifuged, washed, and then uniformly dispersed in 90ml deionized water to obtain dispersion A; for the preparation of dopamine precursor solution, 0.0001mol (0.019g) dopamine hydrochloride monomer was dissolved in 5ml deionized water to obtain dispersion B;

[0037] (2) Synthesis of hybrid nanoparticles: adjust pH=2 with dilute hydrochloric acid, uniformly mix dispersion A and dispersion B for 1 hour, then adjust pH=7.5 with dilute sodium hydroxide solution, and then reflux reaction at 80°C 10h, obtain the dispersion liquid of titanium dioxide / polydopamine hybrid nanoparticle; Centrifugation, washing, dry...

Embodiment 2

[0039](1) Preparation of precursor dispersion: the titanium dioxide precursor dispersion is obtained by hydrolysis of titanium salt. Mix ethanol, isopropanol, and deionized water (volume ratio 15:85:10) into 120ml of compound solvent, and add 0.009 mol (2.278g) titanium isopropoxide, after 30min vigorous stirring to obtain a suspension of a large amount of white precipitate, centrifuged, washed, and then evenly dispersed in 90ml deionized water to obtain dispersion A; the preparation of dopamine precursor solution, 0.0001mol ( 0.019g) dopamine hydrochloride monomer was dissolved in 5ml deionized water to obtain dispersion B;

[0040] (2) Synthesis of hybrid nanoparticles: adjust pH=2 with dilute hydrochloric acid, uniformly mix dispersion A and dispersion B for 1 hour, then adjust pH=7.5 with dilute sodium hydroxide solution, and then reflux reaction at 90°C 6h, to obtain the dispersion of titanium dioxide / polydopamine hybrid nanoparticles; centrifugation, washing, drying can ...

Embodiment 3

[0042] (1) Preparation of precursor dispersion: the titanium dioxide precursor dispersion is obtained by hydrolysis of titanium salt. Mix ethanol, isopropanol, and deionized water (volume ratio 15:85:10) into 120ml of compound solvent, and add 0.009 mol (3.06g) tetrabutyl titanate, after 30min vigorous stirring to obtain a suspension of a large amount of white precipitate, centrifuged, washed, and then uniformly dispersed in 90ml deionized water to obtain dispersion A; for the preparation of dopamine precursor solution, 0.0001mol (0.0232g) DHI monomer was dissolved in 5ml deionized water to obtain dispersion B;

[0043] (2) Synthesis of hybrid nanoparticles: adjust pH=3 with acetic acid, uniformly mix dispersion A and dispersion B for 1 h, then adjust pH=7.5 with Tris aqueous solution (pH=8.5), and then reflux at 75°C React for 12 hours to obtain a dispersion of titanium dioxide / polydopamine hybrid nanoparticles; centrifugation, washing, and drying can obtain Hybrid Nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com