Anti-aging LED string light and preparation method thereof

A technology of LED light strings and LED lamp beads, which is applied in lighting and heating equipment, damage prevention measures for lighting devices, semiconductor devices of light-emitting elements, etc. Overcoming problems such as the decrease of light transmittance, achieving good vulcanization acceleration, excellent comprehensive physical and mechanical properties, and shortening the vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] An aging-resistant LED lamp string, comprising an FPC circuit board, a plurality of LED lamp beads electrically connected to the FPC circuit board, a sheath layer wrapped on the outside of the FPC circuit board and the LED lamp beads, and the sheath layer is calculated in parts by weight. The raw material composition of the layer is shown in Table 1.

[0055] Wherein, the antiaging agent adopts the mixture of antiaging agent D and antiaging agent 264.

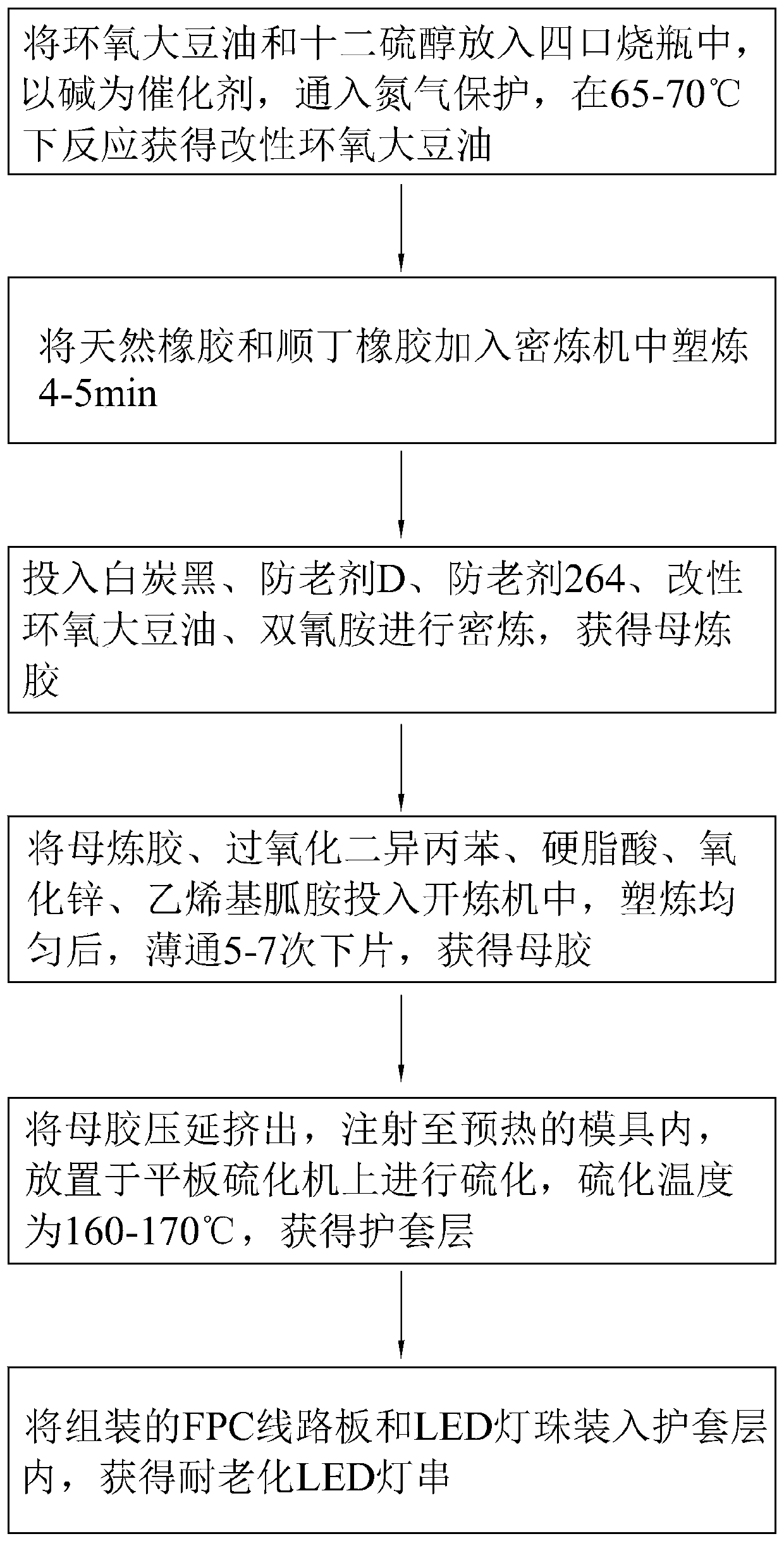

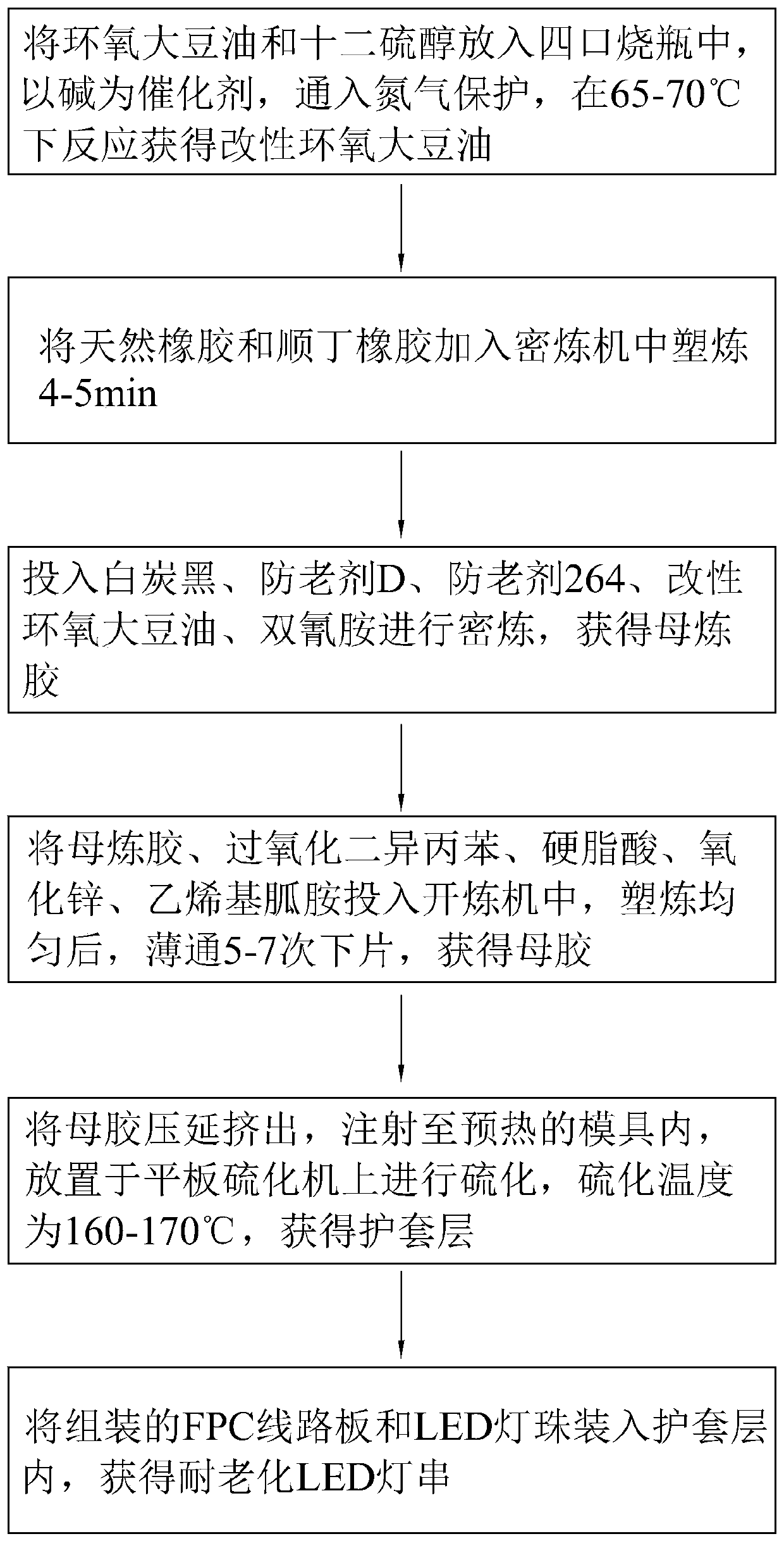

[0056] like figure 1 As shown, the preparation method of the aging-resistant LED lamp string comprises the following steps:

[0057] S1, putting epoxidized soybean oil and dodecyl mercaptan into a four-necked flask, using alkali as a catalyst, introducing nitrogen protection, and reacting at 65-70°C to obtain modified epoxidized soybean oil;

[0058] S2, adding natural rubber and butadiene rubber into the internal mixer for mastication for 4-5min;

[0059] S3, put in white carbon black, anti-aging agent D, anti-aging ...

Embodiment 2

[0064] An aging-resistant LED lamp string, comprising an FPC circuit board, a plurality of LED lamp beads electrically connected to the FPC circuit board, a sheath layer wrapped on the outside of the FPC circuit board and the LED lamp beads, and the sheath layer is calculated in parts by weight. The raw material composition of the layer is shown in Table 1.

[0065] Wherein, the antiaging agent adopts the mixture of antiaging agent D and antiaging agent 264.

[0066] The preparation method of the aging-resistant LED lamp string comprises the following steps:

[0067] S1, putting epoxidized soybean oil and dodecyl mercaptan into a four-necked flask, using alkali as a catalyst, introducing nitrogen protection, and reacting at 65-70°C to obtain modified epoxidized soybean oil;

[0068] S2, adding natural rubber and butadiene rubber into the internal mixer for mastication for 4-5min;

[0069] S3, put in white carbon black, anti-aging agent D, anti-aging agent 264, modified epoxy...

Embodiment 3

[0074] An aging-resistant LED lamp string, comprising an FPC circuit board, a plurality of LED lamp beads electrically connected to the FPC circuit board, a sheath layer wrapped on the outside of the FPC circuit board and the LED lamp beads, and the sheath layer is calculated in parts by weight. The raw material composition of the layer is shown in Table 1.

[0075] Wherein, the antiaging agent adopts the mixture of antiaging agent D and antiaging agent 264.

[0076] The preparation method of the aging-resistant LED lamp string comprises the following steps:

[0077] S1, putting epoxidized soybean oil and dodecyl mercaptan into a four-necked flask, using alkali as a catalyst, introducing nitrogen protection, and reacting at 65-70°C to obtain modified epoxidized soybean oil;

[0078] S2, adding natural rubber and butadiene rubber into the internal mixer for mastication for 4-5min;

[0079] S3, put in white carbon black, anti-aging agent D, anti-aging agent 264, modified epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com