Production process of PMMA monomer copolymerized organic glass

A plexiglass and production process technology, applied in the field of PMMA monomer copolymerization plexiglass production process, can solve the problems of affecting transparency, easy to accumulate charges, easy migration of antistatic agents, etc., achieve excellent antistatic performance and broad application prospects , Improve the effect of solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

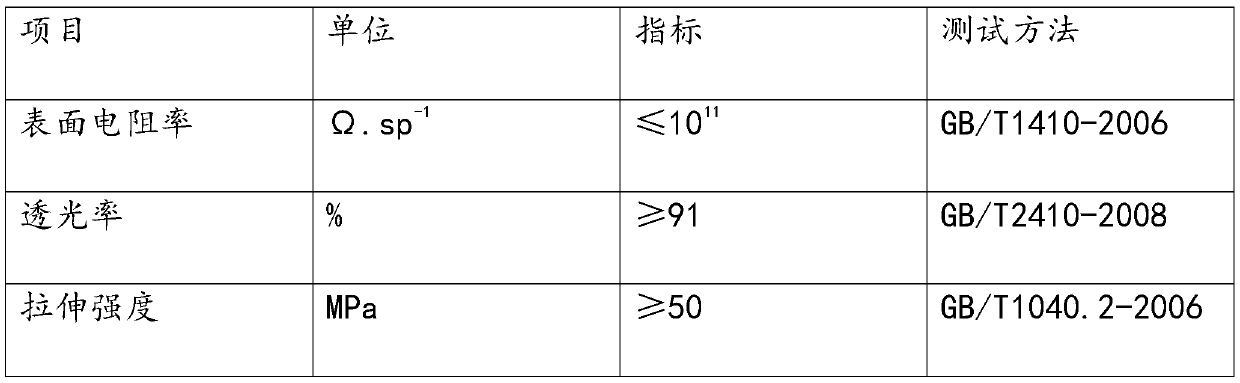

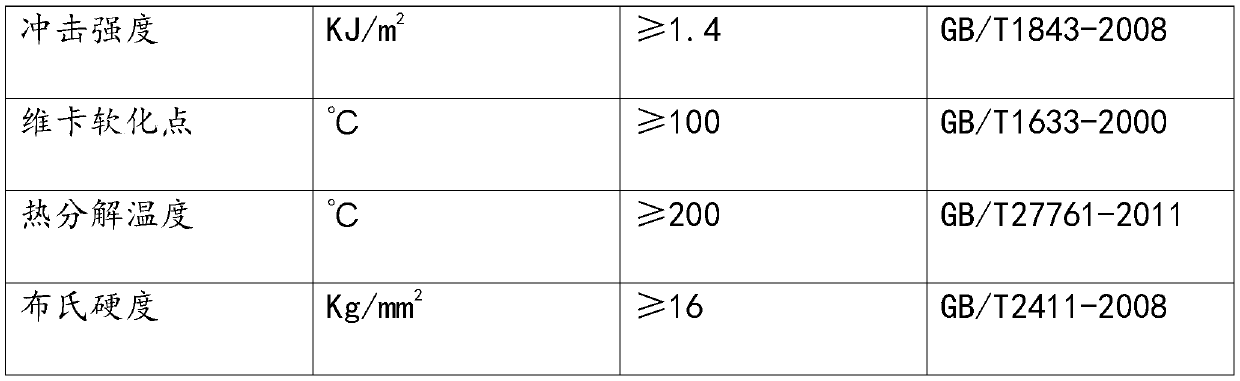

Image

Examples

Embodiment 1

[0022] The invention provides a kind of PMMA monomer copolymerization organic glass production process, comprises the following steps:

[0023] 1), its raw materials are composed of the following components in mass percentage: 79-85% of methyl methacrylate, 5-10% of antistatic agent, 5-10% of intermediate monomer, and 1-3% of initiator;

[0024] 2), take raw material in proportion, add methyl methacrylate and initiator together in the dissolving device in step 1), after mutual dissolution reaction, stand-by;

[0025] 3), weigh the raw materials in proportion, add the double bond-containing antistatic agent and the intermediate monomer into the high-temperature dispersion device in step 1), and dissolve the double bond-containing antistatic agent in the intermediate monomer by ultrasonic, stand-by;

[0026] 4), each of step 2) and step 3) are added together into the prepolymerization reactor and stirred for reaction, then fully cured through high temperature prepolymerization-...

Embodiment 2

[0036] The invention provides a kind of PMMA monomer copolymerization organic glass production process, comprises the following steps:

[0037] 1), its raw material is composed of the following components in mass percentage: methyl methacrylate 70-80%, antistatic agent 5-10%, intermediate monomer 15-20%, initiator 1-3%;

[0038] 2), take raw material in proportion, add methyl methacrylate and initiator together in the dissolving device in step 1), after mutual dissolution reaction, stand-by;

[0039] 3), weigh the raw materials in proportion, add the double bond-containing antistatic agent and the intermediate monomer into the high-temperature dispersion device in step 1), and dissolve the double bond-containing antistatic agent in the intermediate monomer by ultrasonic, stand-by;

[0040] 4), each of step 2) and step 3) are added together into the prepolymerization reactor and stirred for reaction, then fully cured through high temperature prepolymerization-low temperature c...

Embodiment 3

[0056] 1), its raw materials are composed of the following components in mass percentage: 60-70% of methyl methacrylate, 5-10% of antistatic agent, 5-10% of intermediate monomer, 1-3% of initiator, mixed salt 0.1-0.3%, crosslinking agent 1-4%, comonomer 8-10%, dimethylaminoethyl methacrylate 0.2-0.3%, methacrylic acid 0.2-0.3%, rubber particles 3-6%, nano Titanium dioxide 1-3%, lauric acid 7-13%, dioctyl phthalate 3-6%, anti-fog additive 5-10%;

[0057] 2), methyl methacrylate and initiator are added together in the dissolving device in step 1), after mutual dissolution reaction, stand-by;

[0058] 3) Add the material to be used in step 2) into the reaction kettle, add lauric acid and dioctyl phthalate in step 1) in turn during the stirring and mixing process, keep the temperature in the reaction kettle at 70-80°C, stir for 10 After -20min, ultrasonic treatment for 3-8min, take out for use;

[0059] 4), add the to-be-used in step 3) into the heating kettle, add dimethylamino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com