Halogen-free high-efficiency flame retardant, flame-retardant epoxy resin and preparation method thereof

A technology of epoxy resin and solid epoxy resin, which is applied in the field of composite materials, can solve the problems of harsh reaction conditions of flame retardant epoxy resin, too high addition of flame retardant, poor heat resistance of flame retardant epoxy resin, etc. Achieve excellent transparency, good plasticization, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

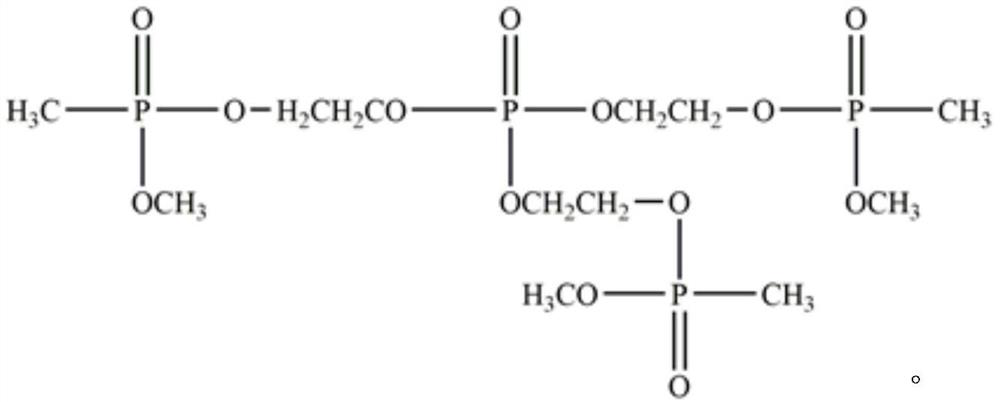

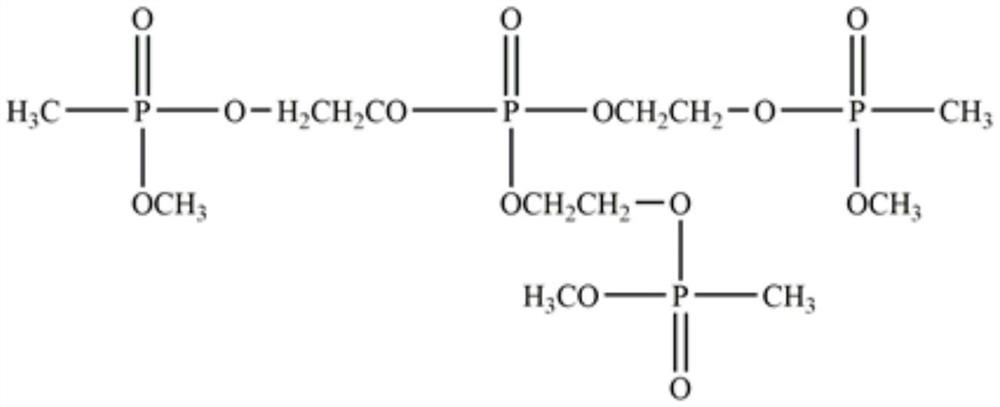

Method used

Image

Examples

Embodiment 1

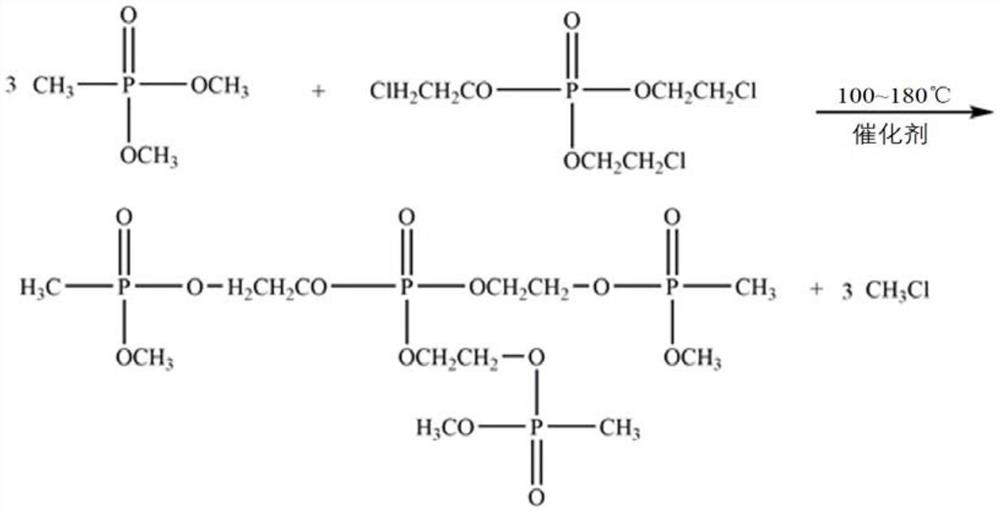

[0034]Flame retardant preparation:

[0035]In a reactor with a gas outlet, add 372g of dimethyl methylphosphonate, and at the same time add 6g of sodium carbonate as the catalyst, turn on the stirring, and start to heat up. When the temperature reaches 120°C, start to add tris(2) phosphoric acid to the reactor. -Chloroethyl) ester 285g. As the dripping progresses, there will be reaction gas methyl chloride generated. The reaction gas is condensed from the gas outlet of the reactor through the condenser and then enters the refrigerated compression unit for recovery. After the dripping is completed, continue to slowly increase the temperature to 160°C Continue the reaction and wait for almost no gas to be discharged, indicating that the reaction is basically complete, and a halogen-free high-efficiency flame retardant is obtained.

[0036]Epoxy resin formula:

[0037]

[0038]The preparation process is as follows:

[0039]In the first step, a certain amount of low-viscosity epoxy resin, halogen-free...

Embodiment 2

[0044]Flame retardant preparation:

[0045]In a reactor with a gas outlet, add 372g of dimethyl methylphosphonate, and at the same time add 6g of sodium hydroxide as a catalyst, turn on the stirring, and start to heat up. When the temperature reaches 120°C, start to add tris(phosphate) to the reactor. 300g of 2-chloroethyl) ester, as the dripping progresses, there will be reaction gas methyl chloride generated. The reaction gas is condensed from the gas outlet of the reactor through the condenser and then enters the refrigerated compression unit for recovery. After the dripping is completed, the temperature is slowly increased to 160 Continuing the reaction at ℃, and when there is basically no gas discharged, it indicates that the reaction is basically complete and a halogen-free high-efficiency flame retardant is obtained.

[0046]Epoxy resin formula:

[0047]

[0048]The preparation process is as follows:

[0049]In the first step, a certain amount of low-viscosity epoxy resin, halogen-free high...

Embodiment 3

[0054]Flame retardant preparation:

[0055]In a reactor with a gas outlet, 372g of dimethyl methylphosphonate was added, and 6g of sodium ethoxide as a catalyst was added at the same time. The stirring was turned on and the temperature started to rise. When the temperature reached 120°C, the reactor was started to drip tris(2) phosphate. -Chloroethyl ester 300g, as the dripping progresses, there will be reaction gas methyl chloride generated, the reaction gas is condensed from the gas outlet of the reactor through the condenser and then enters the refrigerating compression unit for recovery, after dripping, continue to slowly increase the temperature to 160°C Continue the reaction and wait for almost no gas to be discharged, indicating that the reaction is basically complete, and a halogen-free high-efficiency flame retardant is obtained.

[0056]Epoxy resin formula:

[0057]

[0058]The preparation process is as follows:

[0059]In the first step, a certain amount of low-viscosity epoxy resin, ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com