Fluorescence temperature measurement method suitable for ultra-wide temperature measurement range

A fluorescence temperature and fluorescence technology, applied in the field of fluorescence temperature measurement, can solve the problems of narrow fluorescence temperature measurement range and low fluorescence temperature measurement temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

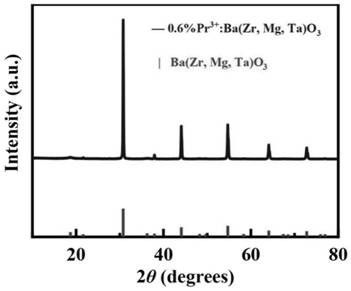

[0051] In a specific embodiment of the present invention, the Pr 3+ The preparation method of the doped oxide transparent ceramic comprises: taking main raw materials according to stoichiometric ratio, mixing them with auxiliary agents, and then performing calcination, molding and sintering; the main raw materials include carbonates or oxides of metal elements.

[0052] with Pr 3+ Doped Ba(Zr,Mg,Ta)O 3 As an example, the main raw material can be BaCO 3 , ZrO 2 , MgO, Ta 2 o 5 and Pr 6 o 11 .

[0053] In a specific embodiment of the present invention, the mixing method includes: ball milling the mixture of the main raw material and the auxiliary agent under the action of an organic solvent for 12 to 24 hours to obtain a slurry, and then removing the Organic solvents.

[0054] In actual operation, the organic solvent in the ball-milled slurry can be removed by drying, such as drying. Wherein, the drying temperature may be 40-50°C.

[0055] In a specific embodiment of th...

Embodiment 1

[0070] This embodiment provides a fluorescent temperature measurement method suitable for an ultra-wide temperature measurement range, including the following steps:

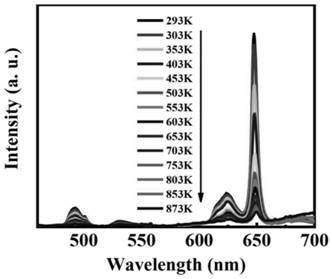

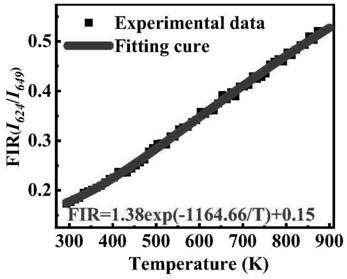

[0071] (a) Establish a fluorescent temperature sensing material at 624nm ( 3 P 1 → 3 f 2 ) and 649nm ( 3 P 0 → 3 f 2 ) Fluorescence peak intensity ratio FIR(I 624 / I 649 ) standard curve with temperature variation, the excitation wavelength is 447nm;

[0072] (b) placing the fluorescent temperature sensing material in the environment of the temperature to be measured, using 447nm wavelength excitation, measuring the fluorescence spectrum of the fluorescent temperature sensing material, and calculating the corresponding 624nm ( 3 P 1 → 3 f 2 ) and 649nm ( 3 P 0 → 3 f 2 ) Fluorescence peak intensity ratio FIR(I 624 / I 649 ), into the standard curve of step (a), to calculate the measured temperature of the environment to be tested.

[0073] Wherein, the fluorescent temperature sensing material is...

Embodiment 2

[0082] This embodiment refers to the fluorescence temperature measurement method of Embodiment 1, the only difference is that the fluorescent temperature sensing materials are different.

[0083] The fluorescent temperature sensing material of the present embodiment is 0.2% Pr 3+ : Ba(Zr 0.16 Mg 0.28 Ta 0.56 )O 3 , its preparation method refers to the 0.6% Pr of Example 1 3+ : Ba(Zr 0.16 Mg 0.28 Ta 0.56 )O 3 The only difference is that in step (1), BaCO is weighed according to the molar ratio of Ba, Zr, Mg, Ta and Pr as 1:0.16:0.28:0.56:0.002 3 , ZrO 2 , MgO, Ta 2 o 5 and Pr 6 o 11 Powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com