Preparation technique for steel plate terrace of industrial workshop

A preparation process and technology for industrial plants, applied in the direction of floors, buildings, building structures, etc., can solve the problems of desoldering, warping, pitting, sagging, and pitting on the surface of steel plates at the end joints of steel plates, etc. Achieve the effect of fast pavement construction speed, high bearing pressure and high wear resistance coefficient requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

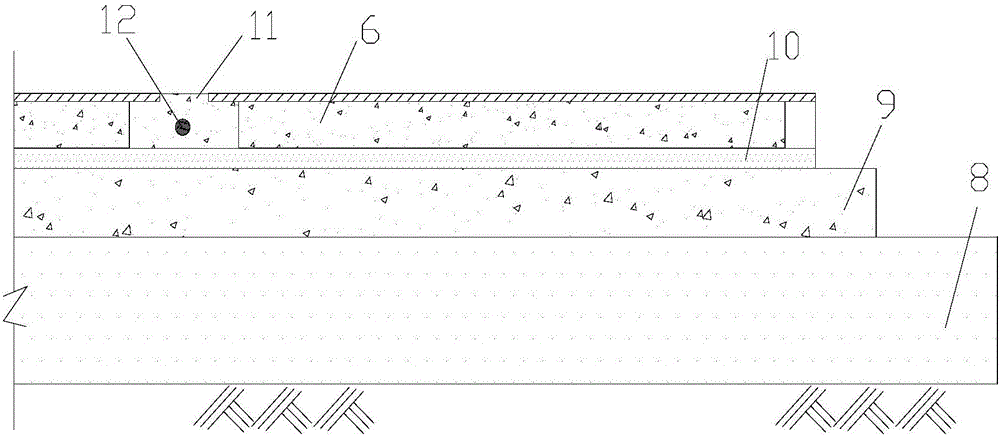

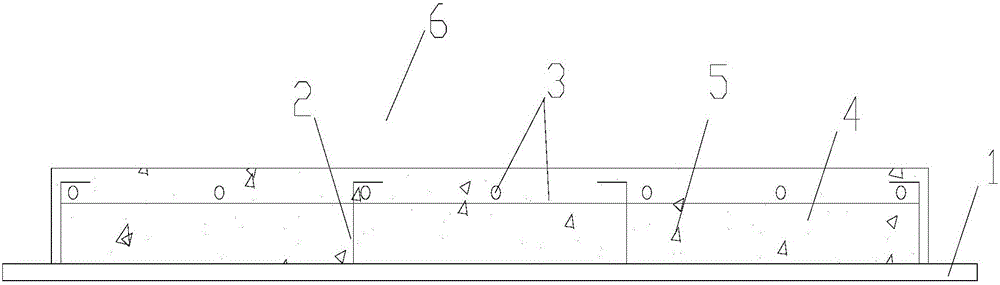

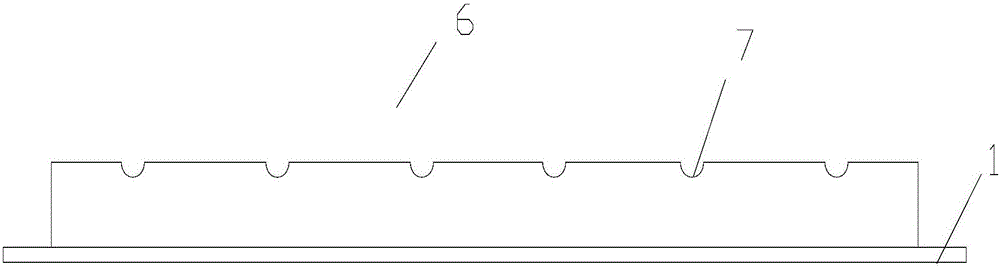

[0018] Attached below Figure 1-3 An embodiment of the present invention is described.

[0019] The preparation process for the steel plate floor of industrial workshops includes the following steps:

[0020] 1) Prefabricated steel plate concrete member 6: two-way anchor bars 2 are arranged at intervals on the back of the hot-rolled steel plate 1, and the outermost column of anchor bars 2 is indented by a certain length of the hot-rolled steel plate 1, and one end of the anchor bar 2 is connected to the hot-rolled steel plate 1 The back side is fixedly connected, the other end of the anchor bar 2 is a free end, the two-way steel mesh 3 passes through the free end of the anchor bar 2 and keeps a distance from the back of the hot-rolled steel plate 1 to form a cavity 4, fill the cavity 4 with concrete 5 and place the anchor bar 2 The free end is filled and covered to form a steel plate concrete member 6; the hot-rolled steel plate 1 adopts a 12mm thick 1000mm*1000mm steel plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com