Plastic base paper composite pipe

A composite pipe and base paper technology, applied in the field of composite pipes, can solve the problems of rising production costs, low production efficiency, long curing time, etc., and achieve the effects of high pipeline bearing pressure, low production cost and great practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples, but the scope of protection required by the present invention is not limited to the scope described in the specific examples.

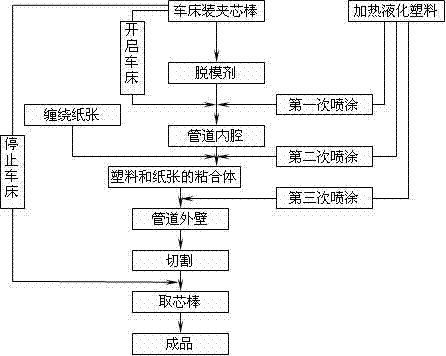

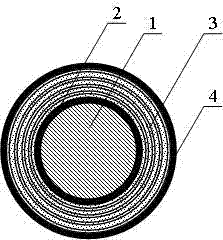

[0018] Such as figure 1 , figure 2 As shown, a plastic-based paper composite pipe is disclosed, which includes a pipe inner cavity 2, a plastic and paper bonded body 3, and a pipe outer wall 4, and is characterized in that there is a plastic and paper bonded body 3 outside the pipe inner cavity 2 , the adhesive body 3 of plastics and paper has the pipe outer wall 4 outside, during production, one end of the slender mandrel mold 1 is clamped on the chuck of the lathe, and the movable thimble of the tailstock of the lathe is pushed against the other end of the mandrel 1 mould. One end, then coat release agent on the mandrel mold 1, install the spray port of the spraying equipment on the tool rest of the lathe, after turning on the lathe, spray the heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com