Alloy resin composition and preparation method thereof

A technology of alloy resin and composition, which is applied in the field of polymer composite materials and its preparation, can solve problems such as poor weather resistance, high water absorption, and insufficient low-temperature impact resistance, and achieve improved weather resistance, high gloss, and satisfactory The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) 40kg polyamide resin, 35kg styrene-maleic anhydride resin and 5kg antioxidant are put into a high-speed mixer and stirred for 5-30 minutes to obtain mixture A;

[0064] (2) Add mixture A from the main feeding port of the twin-screw extruder, mix 10kg light absorber and 10kg light stabilizer first, then add from the side feeding port of the twin-screw extruder, control the extruder The barrel temperature is 200°C, the screw speed is 400rpm, and the weather-resistant masterbatch is obtained by extruding and granulating;

[0065] (3) 40kgPA6 resin, 20kgASA rubber powder, 10kgABS-g-GMA resin, 8kg gloss modifier, 10kgAS resin, 4kg compatibilizer AS-g-MAA, 3kg nanoscale talcum powder, 0.3kg antioxidant β- Add the mixture of (4-hydroxy-3,5-di-tert-butylphenyl) n-octadecyl propionate and tris(2,4-di-tert-butylphenyl) ester into a high-speed mixer and stir for 20 minutes Rear discharge, obtain mixture B;

[0066] (4) The mixture B obtained by step (3) is added from the mai...

Embodiment 2-6

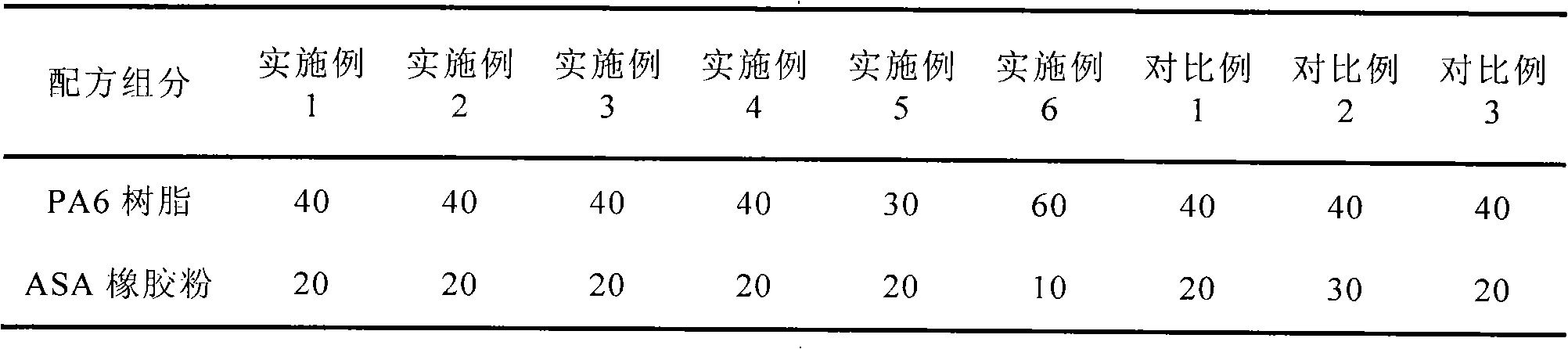

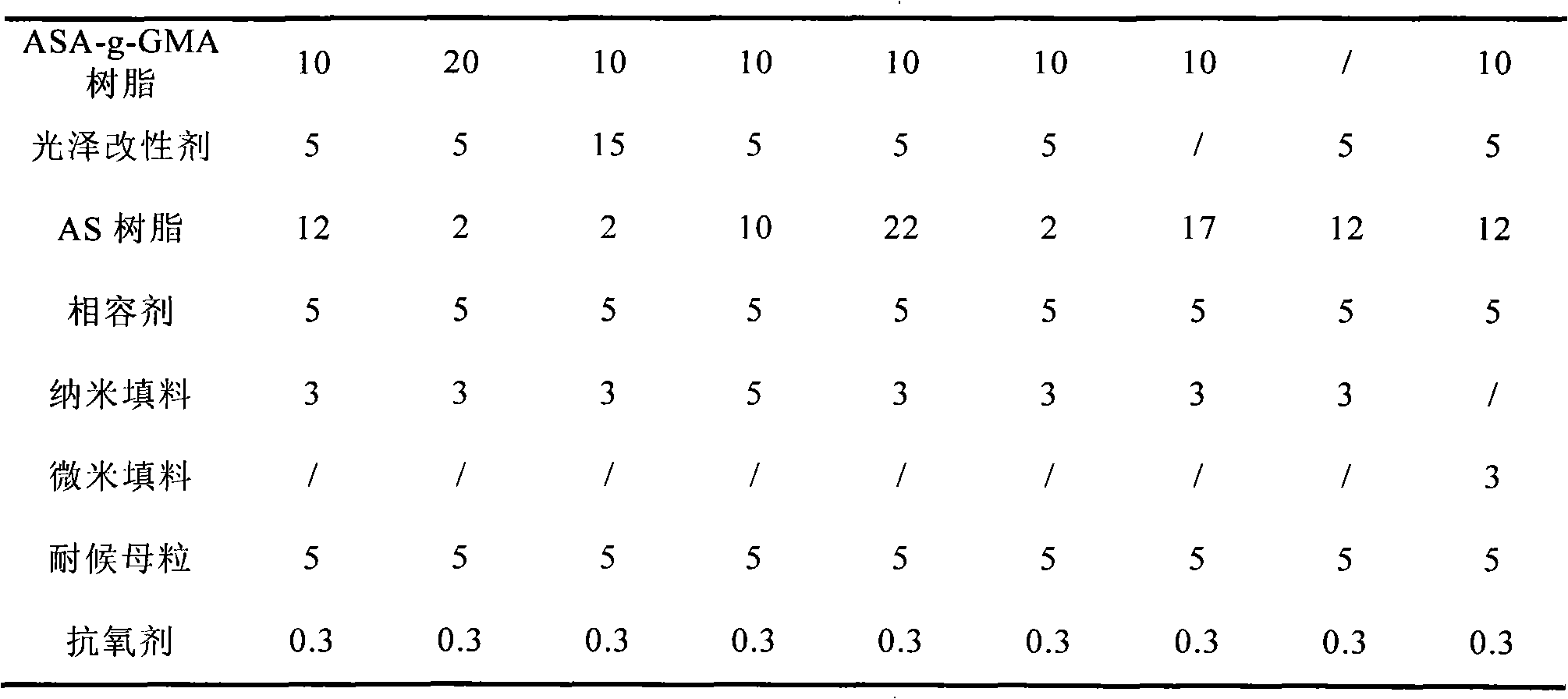

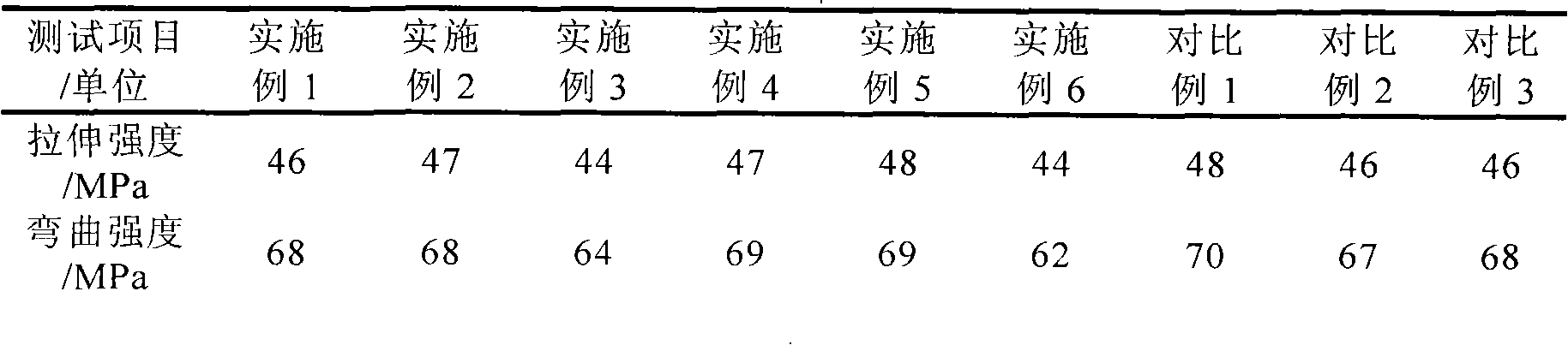

[0068] In order to better reflect the characteristics of the above-mentioned high-performance polyamide / acrylonitrile-acrylate-styrene alloy resin composition, the present invention uses Examples 2-6 to compare different ASA-g-GMA resin dosages and different gloss The influence of modifier dosage, different nanofiller dosage, and different PA6 resin dosage on product performance, the specific material formula ratio is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 7

[0089] A preparation method of an alloy resin composition, the method comprising the following steps:

[0090] (1) Preparation of weather-resistant masterbatch:

[0091] a, prepare materials according to the following components and parts by weight: polyamide resin 30kg, styrene-maleic anhydride resin 60kg, light absorber 3kg, light stabilizer 3kg, antioxidant 3kg, wherein the relative viscosity of polyamide resin is 2Pa· S, glass transition temperature is 20 DEG C, melting point is 200 DEG C, is the mixture of commercially available PA6 resin and PA66 resin, the content of maleic anhydride in the styrene-maleic anhydride resin is 15wt%, light absorber is 3, A mixture of 5-di-tert-butyl-4-hydroxybenzoic acid-2,4-di-tert-butylphenyl ester and 2-(2H-benzotriazol-2-yl) p-cresol, the light stabilizer is poly [[6-[(1,1,3,3-tetramethylbutyl)amine]-1,3,5-triazine-2,4-diyl][(2,2,6,6-tetra Methyl-4-piperidine)imine]-1,6-dihexanediyl[(2,2,6,6-tetramethyl-4-piperidine)imine]]] and seba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com