A kind of composite flexible graphite sealing material and sealing gasket manufacturing method

A flexible graphite and sealing material technology, applied in the production of modified graphite sealing materials and gaskets, the production method and product of composite flexible graphite sealing materials, and the production of packing rings, can solve the problems of high temperature resistance, poor ultra-high pressure, etc., to avoid The effect of denaturation, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

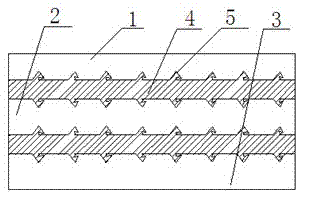

[0026] A method for manufacturing a flexible graphite sealing composite material, which adopts a multi-layer flexible graphite superposition and combination method to make the sealing material, and is characterized in that a layer of metal mesh with barbs on both sides is laid between every two layers of flexible graphite, The mesh is rapidly heated by electromagnetic heating, and when the metal mesh is heated to 850-950°C, the composite layer of flexible graphite and metal mesh is pressurized, and the pressure ratio can be 200KG / CM 2 up to 500 KG / CM 2 Choose between them, so that the barbs on the metal mesh hook the flexible graphite layer close to the surface of the metal mesh to form a whole sealing material, and then let the whole sealing material cool naturally to room temperature, that is, a multi-layer flexible graphite superimposed composite seal is made. Material.

[0027] A flexible graphite sealing composite material proposed according to the above method is as fol...

Embodiment 2

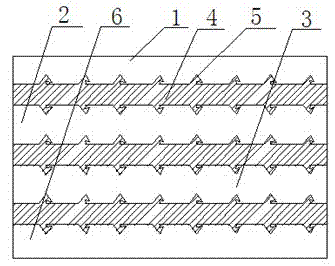

[0029] The preparation method of embodiment two is the same as embodiment one, just as attached figure 2 Shown, the flexible graphite layer that adopts is five layers, has increased one deck 6 on the basis of embodiment one, is spread the metal mesh 4 that has barb on both sides equally between every two layers of flexible graphite layers, and metal The barbs 5 on both sides of the net 4 are respectively hooked in the surface layers of the flexible graphite layer on both sides, so that the flexible graphite layer and the metal net become an integral body.

Embodiment 3

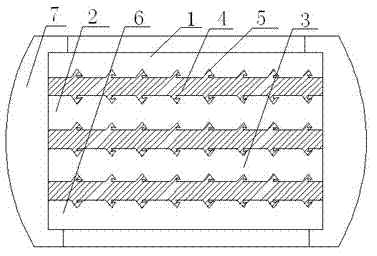

[0031] Embodiment 3 is a method for making a sealing gasket using the material made by the above method. The material used for the sealing gasket is made in the same way as in Example 2. The flexible graphite layer used is five layers, as shown in the attached image 3 As shown, a layer 6 is added on the basis of Embodiment 1, and a metal mesh 4 with barbs on both sides is laid between every two layers of flexible graphite, and the barbs 5 on both sides of the metal mesh 4 are respectively hooked. In the surface layers of the flexible graphite layer on both sides, the flexible graphite layer and the metal mesh are integrated. After the material is prepared, the sealing gasket is made; the making of the sealing gasket at least includes the following steps:

[0032] 1) Making sealing material: Make a sealing material with a suitable thickness according to the above method, then place it under the punching machine, and punch out a cake-shaped sealing pad as required;

[0033] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com