Sludge biochar soil conditioner production device

A technology of soil improver and production equipment, applied in pyrolysis treatment of sludge, mixer with rotating stirring device, transportation and packaging, etc., can solve the problems of reducing heat conduction efficiency, adhesion, and pyrolysis effect, etc. To achieve the effect of improving pyrolysis effect, uniform heating and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

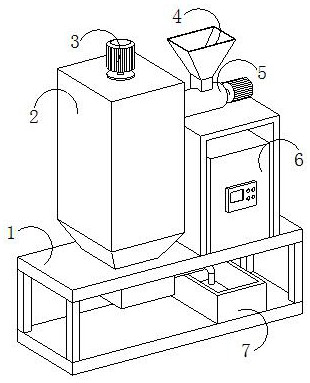

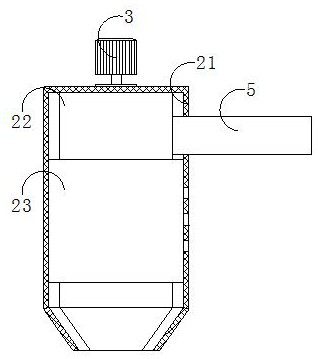

[0022] as attached figure 1 To attach Figure 5 Shown:

[0023] A kind of sludge biochar soil improvement agent production device of the present invention, its structure comprises support platform 1, pyrolysis device 2, motor 3, hopper 4, feed pipe 5, heater 6, collection box 7, described support platform 1 A pyrolysis device 2 is fixedly installed on the upper end surface of the left side, and a motor 3 is fixedly installed on the top of the pyrolysis device 2. The hopper 4 is arranged on the right end of the feed pipe 5, and the left end of the feed pipe 5 is arranged on the upper right side of the pyrolysis device 2. end and communicate with each other, the heater 6 is fixedly installed on the upper end surface of the right side of the support platform 1, and the heater 6 is connected to the right side of the pyrolysis device 2, and the collection box 7 is arranged at the lower end of the right side of the support platform 1, so The pyrolysis device 2 includes a pyrolysis...

Embodiment 2

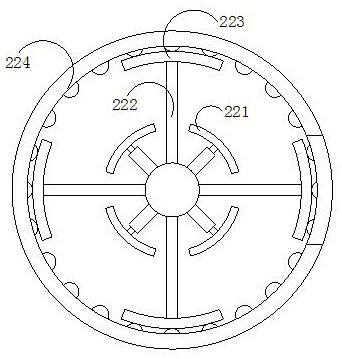

[0030] as attached Image 6 To attach Figure 7 Shown:

[0031] Wherein, the conduction mechanism 23 includes a heat insulation layer 231, a conduction pipe 232, a heat collection pipe 233, a sub-duct 234, and a transfer mechanism 235. The inside is embedded with a conduction pipe 232, and the conduction pipe 232 communicates with the heat collection pipe 233. The heat collection pipe 233 is located outside the heat preservation liner 24a, and the inside of the heat collection pipe 233 is provided with a branch pipe 234. Conduit 234 communicates with transfer mechanism 235, and the inner end of said transfer mechanism 235 is in conflict with the outer surface of heat preservation liner 24a, and said sub-conduit 234 and transfer mechanism 235 are provided with twenty-four, and twenty-four transfer mechanisms 235 conducts conduction connection through twenty-four sub-ducts 234, and the twenty-four transmission mechanisms 235 are evenly distributed on the outer side of the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com