Distribution type garbage treating device free of emission of low temperature pyrolysis gas

A low-temperature pyrolysis and treatment device technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of single treatment method, low resource recycling rate, and unrefined classification, and achieve enhanced preheating. Drying effect, high working efficiency, and the effect of reducing exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

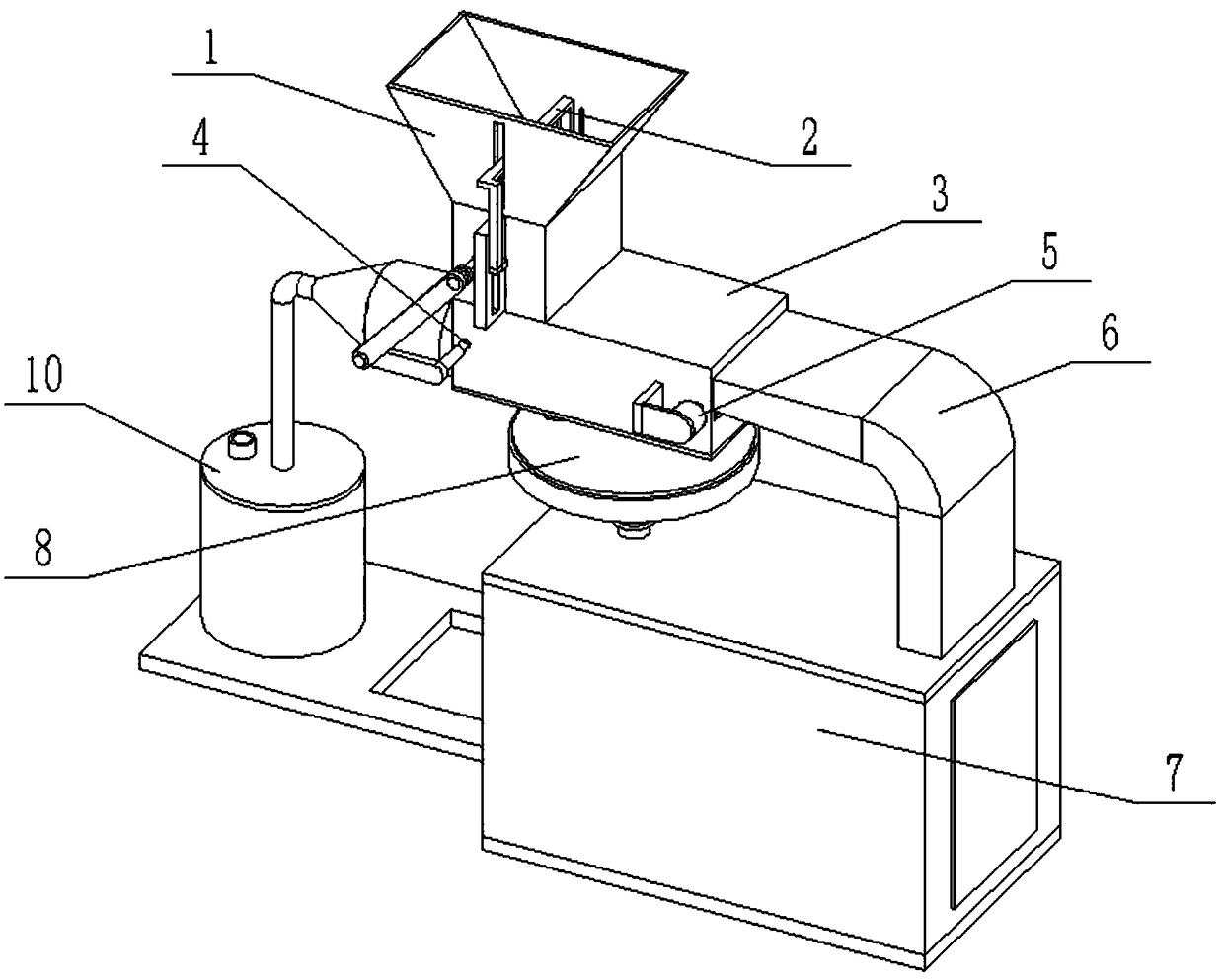

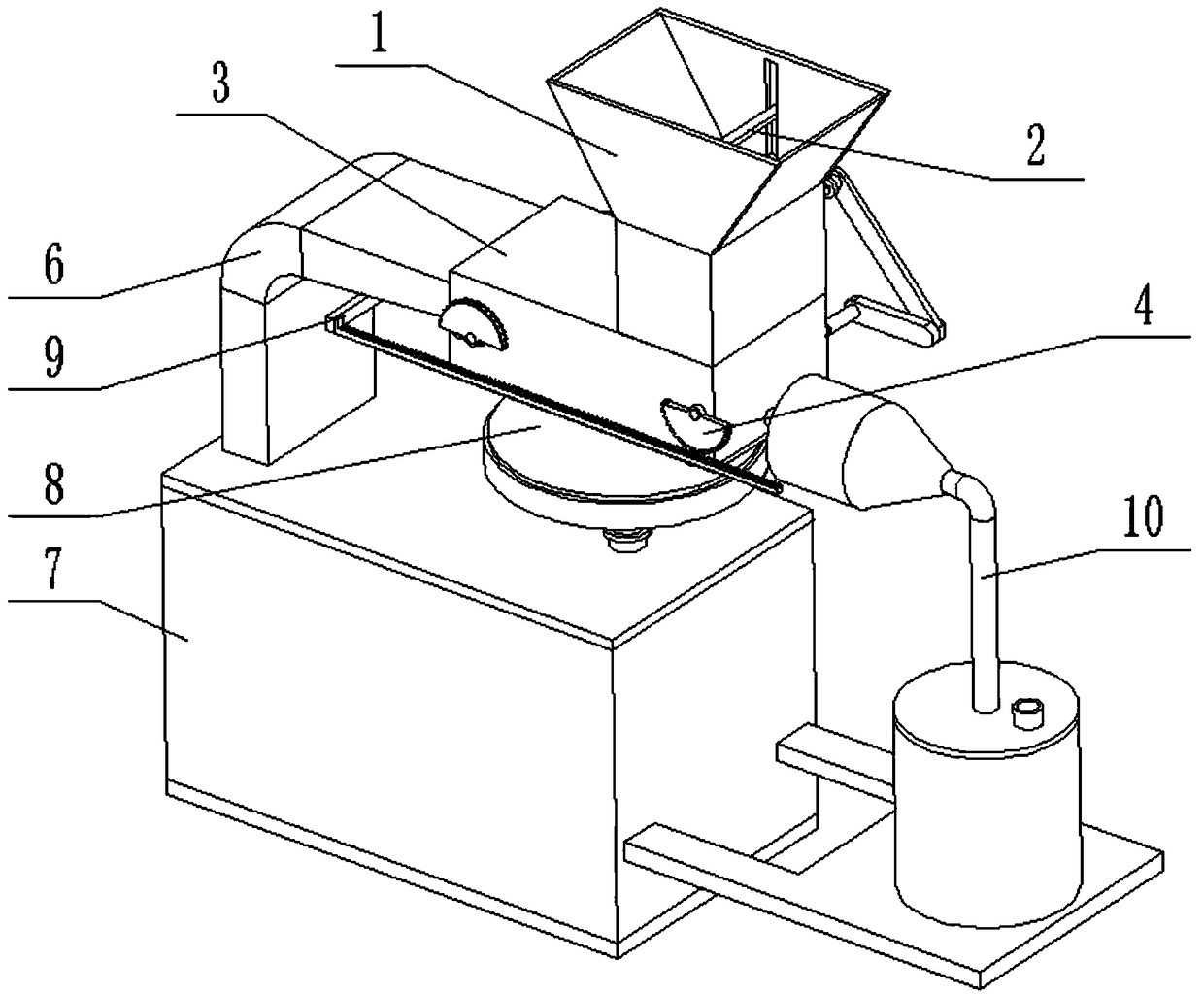

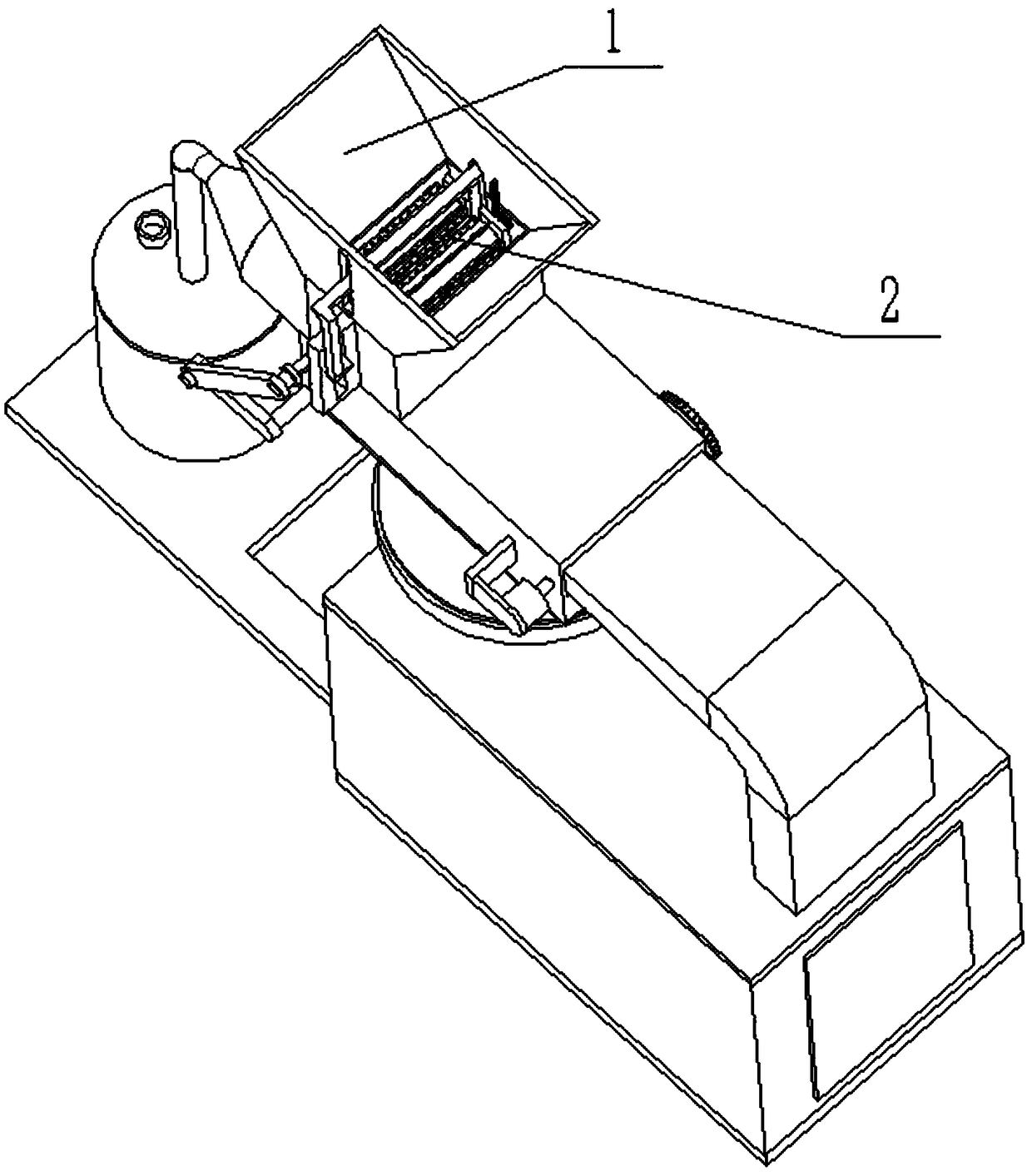

[0035] Such as Figure 1-14 As shown, the distributed garbage low-temperature pyrolysis gas emission-free treatment device includes a garbage drop box 1, a lifting garbage pressing mechanism 2, a garbage conveying preheating box 3, a garbage conveying mechanism 4, a driving motor 5, and a curved falling pipe 6. Low-temperature pyrolysis furnace 7, pyrolysis gas delivery mechanism 8, gas compression mechanism 9 and waste gas discharge treatment device 10, described garbage drop box 1 is fixedly connected and communicated with the upper end of garbage delivery preheating box 3; described garbage delivery preheating The right end of the box 3 is fixedly connected and communicated with the upper end of the curved falling pipeline 6, and the lower end of the curved falling pipeline 6 is fixedly connected and communicated with the low-temperature pyrolysis furnace 7; the low-temperature pyrolysis furnace 7 is fixedly connected and communicated with the pyrolysis gas delivery mechanis...

specific Embodiment approach 2

[0040] Such as Figure 1-14 As shown, the garbage conveying mechanism 4 includes a driving shaft 4-1, a driving roller 4-2, a driving gear 4-3, a driven gear 4-4, a gear shaft 4-5, a return half gear 4-6, a compression Half gear 4-7, driven shaft 4-8, driven roller 4-9, conveying belt 4-10, linkage shaft 4-11 and rotating connecting plate 4-12; both ends of the driving shaft 4-1 pass through The bearing with seat is rotatably connected to the rectangular box 3-1, and the front end of the driving shaft 4-1 is connected to the output shaft of the drive motor 5 through a coupling; the rear end of the driving shaft 4-1 is fixedly connected to the driving gear 4-3 , the driving gear 4-3 meshes with the driven gear 4-4, the driven gear 4-4 is fixedly connected to the gear shaft 4-5, and the gear shaft 4-5 is rotatably connected to the rectangular box body 3-1 through a bearing with seat; The return half gear 4-6 is fixedly connected to the gear shaft 4-5; the driving roller 4-2 is ...

specific Embodiment approach 3

[0042] Such as Figure 1-14 As shown, the gas compression mechanism 9 includes a linkage rack 9-1, a linkage plate 9-2, a push-pull rod 9-3 and a compression plate 9-4; the linkage rack 9-1 is fixedly connected to the linkage plate 9-2 One end of the linkage plate 9-2 is fixedly connected to one end of the push-pull rod 9-3, and the other end of the push-pull rod 9-3 is fixedly connected to the compression plate 9-4; the push-pull rod 9-3 is slidably connected to the On the right side of the combustion chamber 3-5; the compression plate 9-4 is connected with clearance fit to the inside of the combustion chamber 3-5; the linkage rack 9-1 is meshed with the compression half gear 4-7 or the return half gear 4 -6; when the compression half gear 4-7 is engaged with the linkage rack 9-1, the return half gear 4-6 is separated from the linkage rack 9-1; the return half gear 4-6 is engaged with the linkage gear When the bar 9-1 is used, the compression half gear 4-7 is separated from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com