Patents

Literature

41results about How to "Slow movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

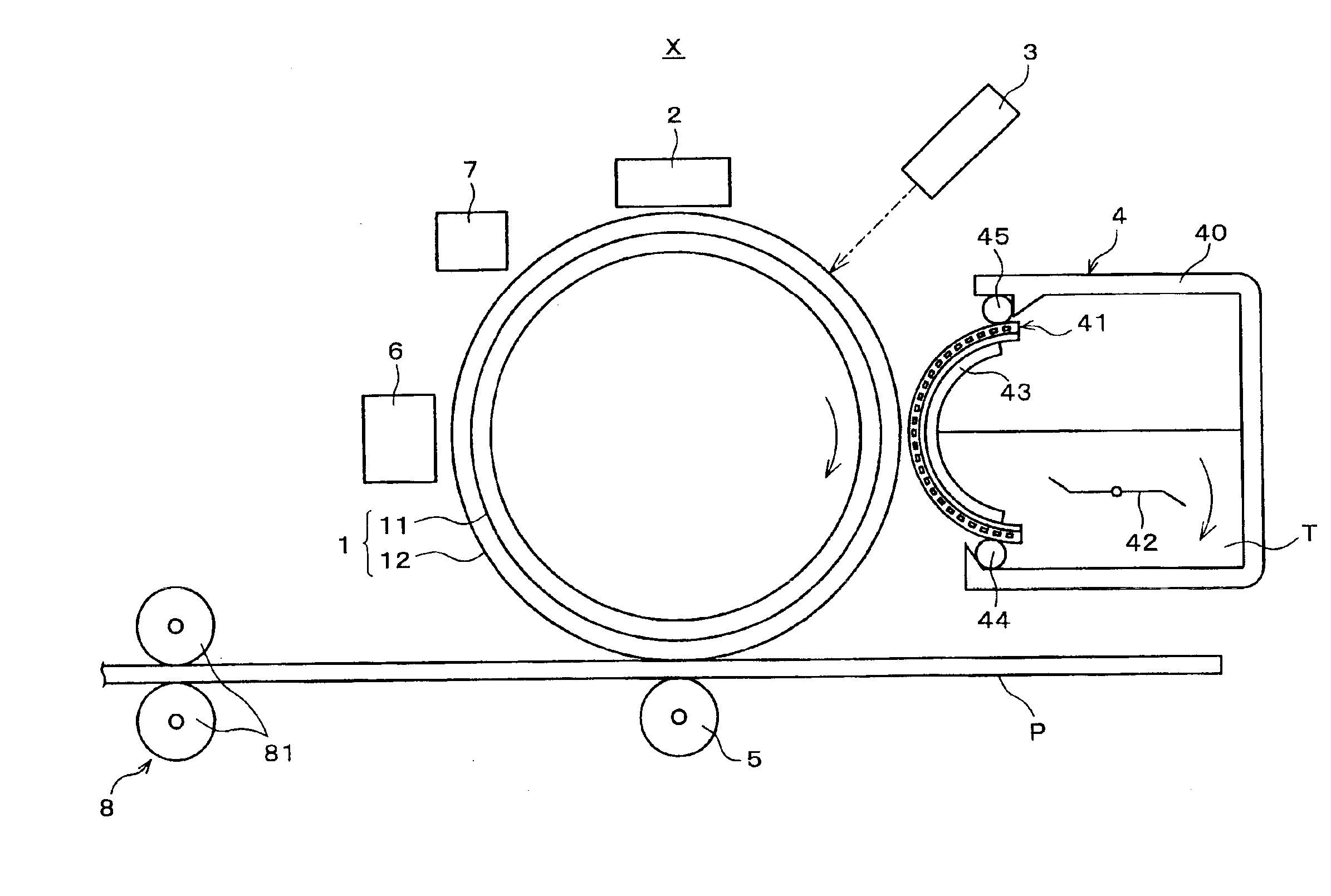

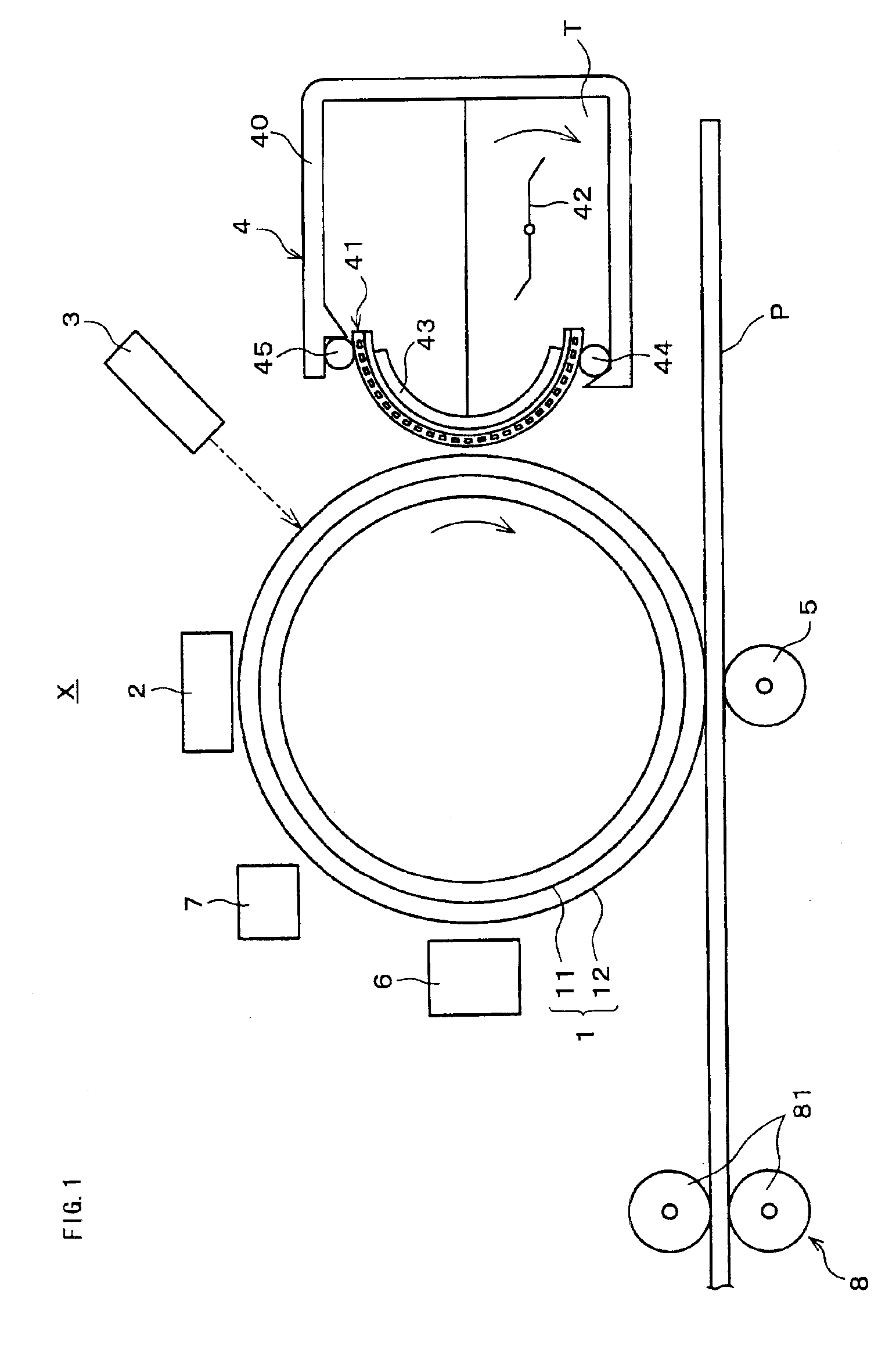

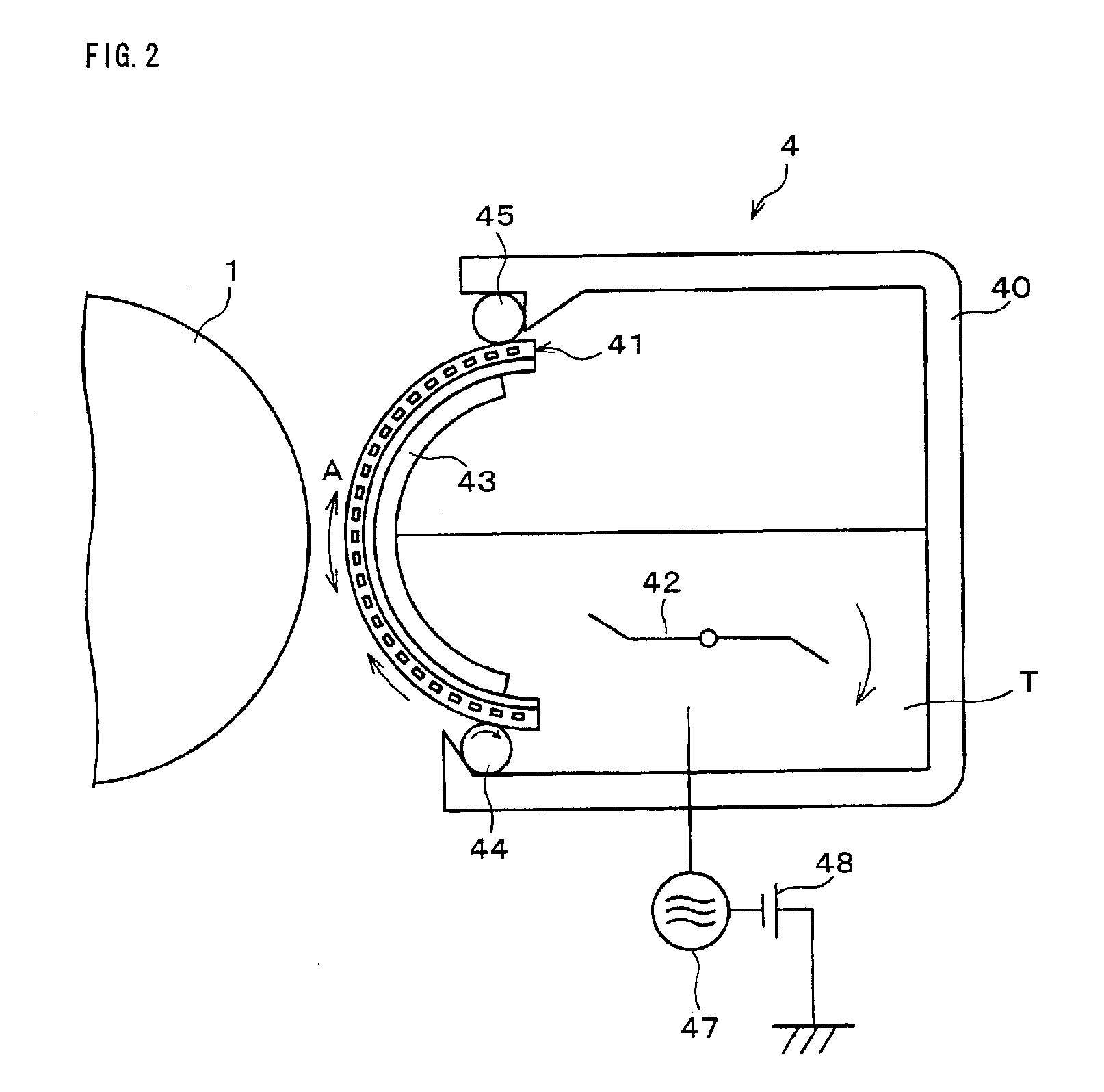

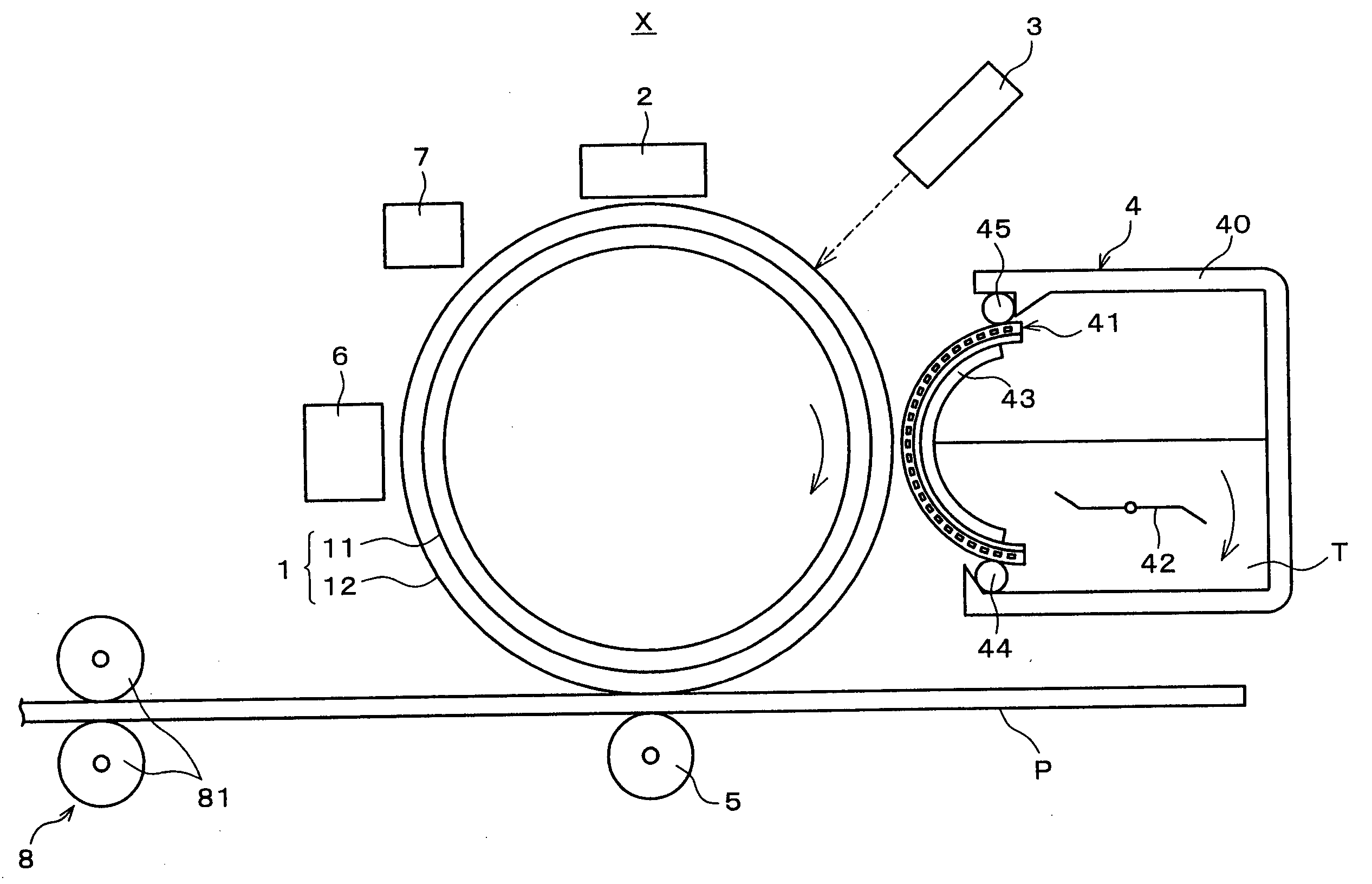

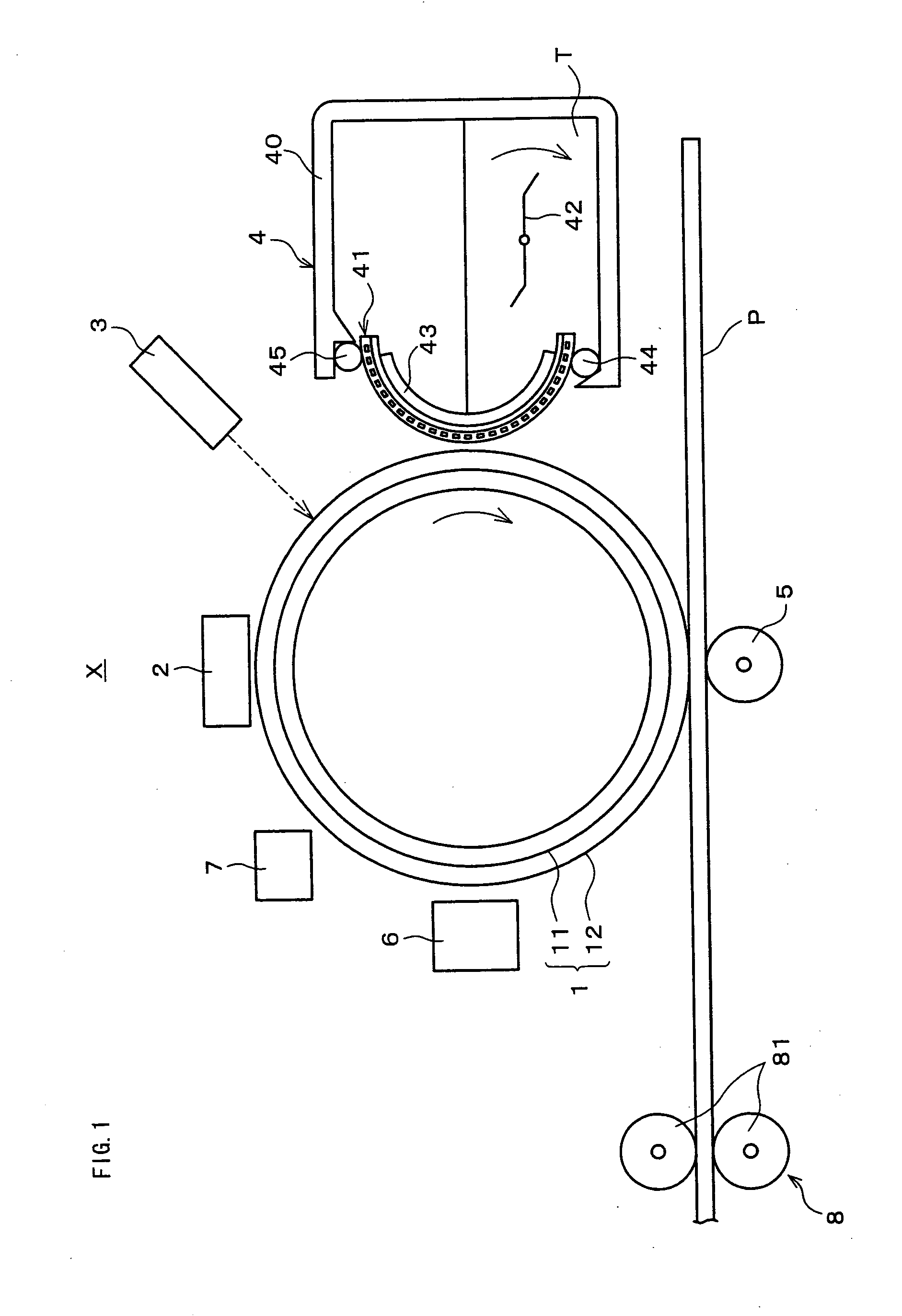

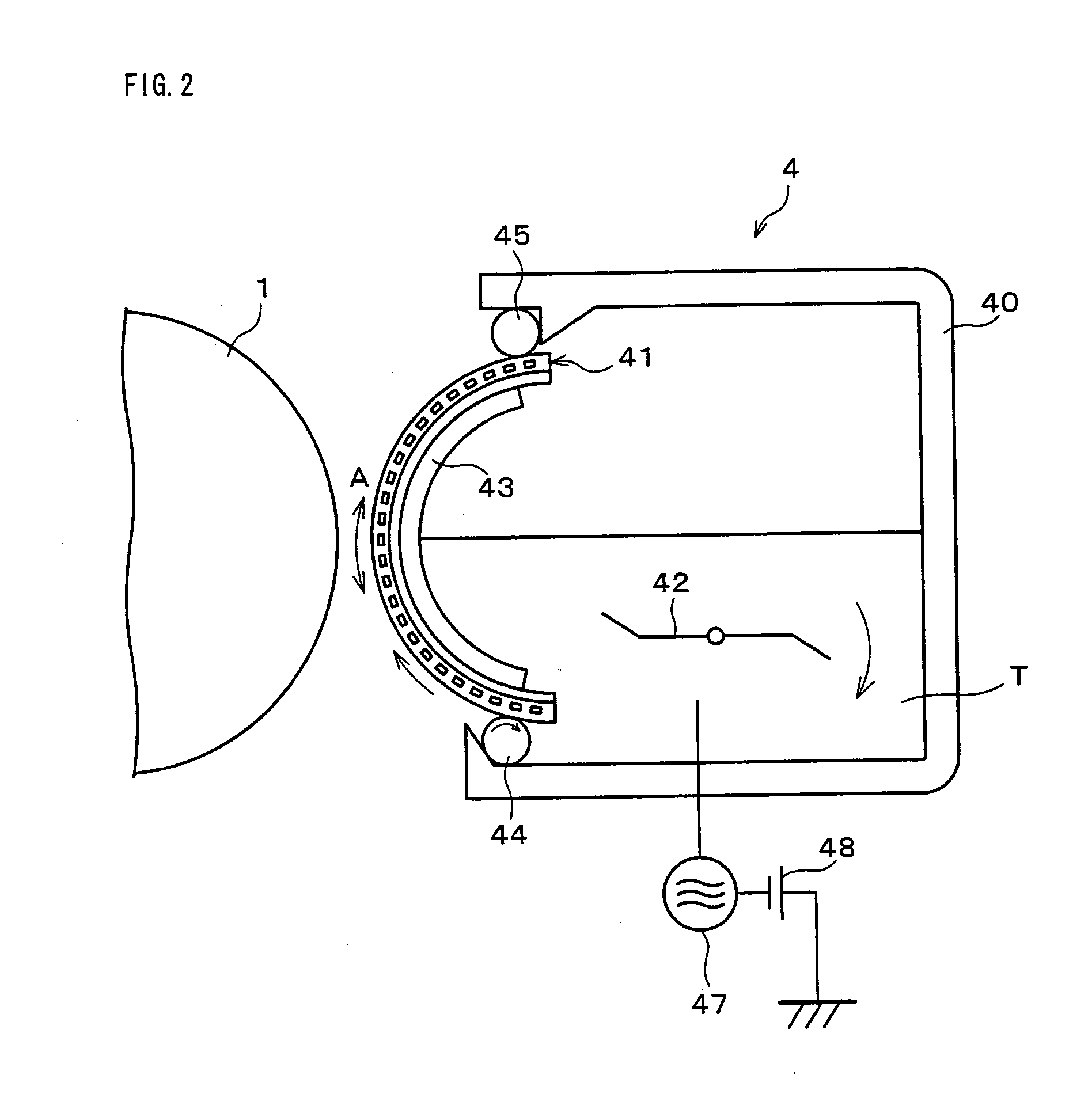

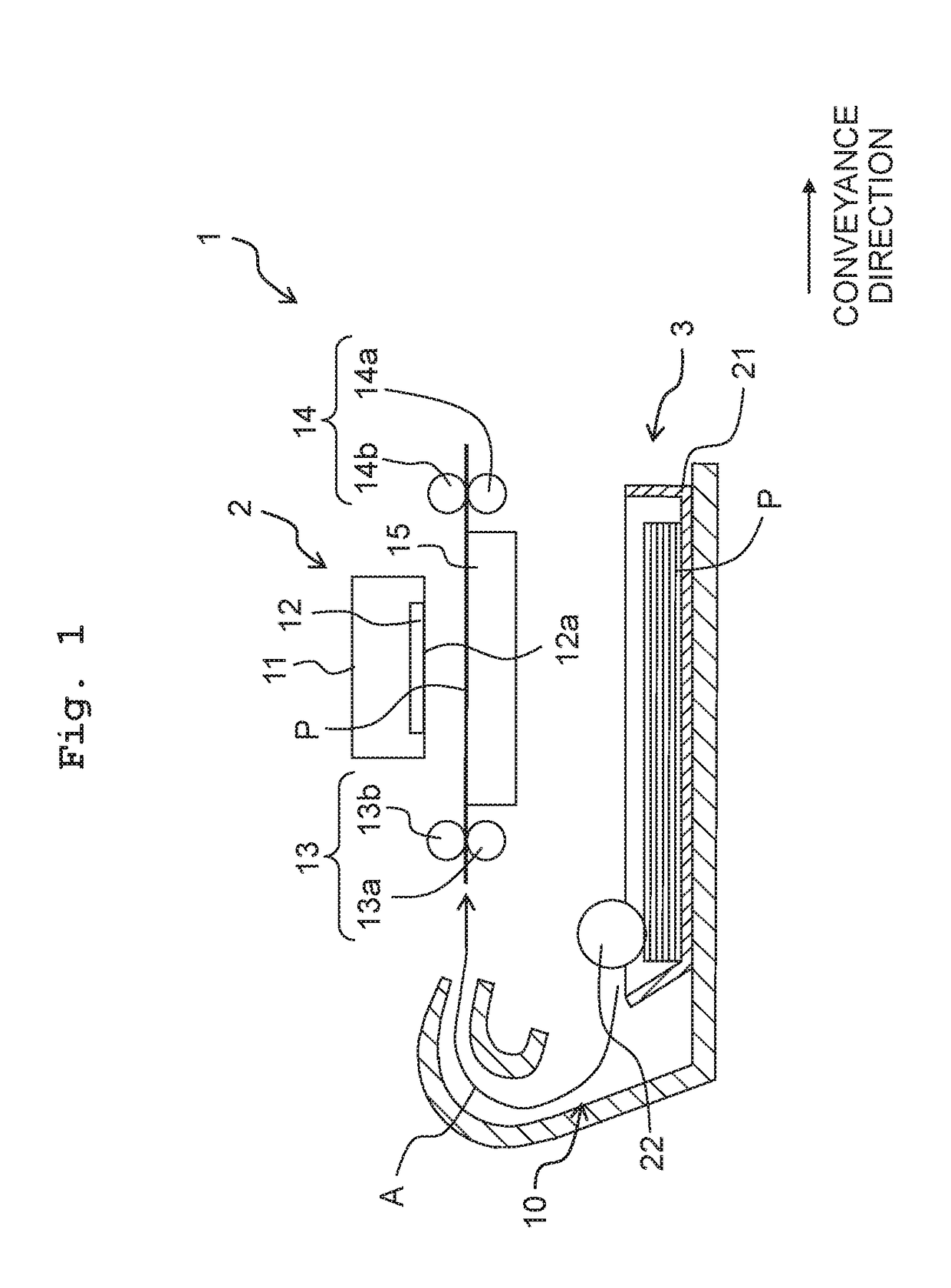

Developing device conveying toner using a traveling-wave electric field and image forming apparatus using same

InactiveUS6934496B2Reduce collision energyReduce adverse effectsElectrographic process apparatusLatent imageSoftware engineering

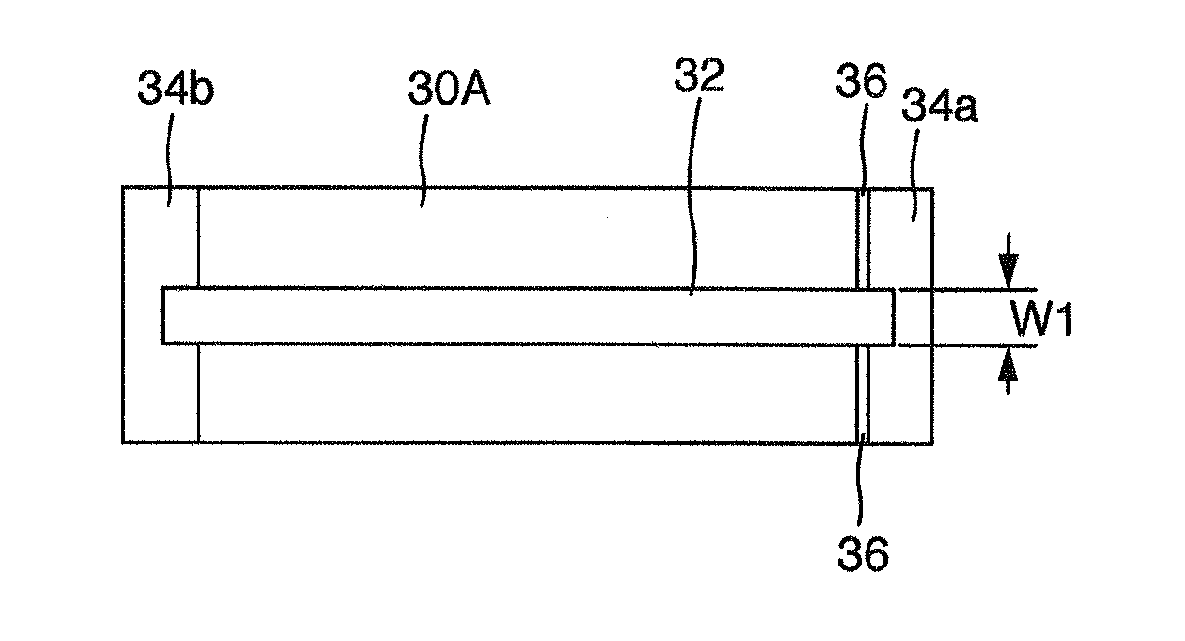

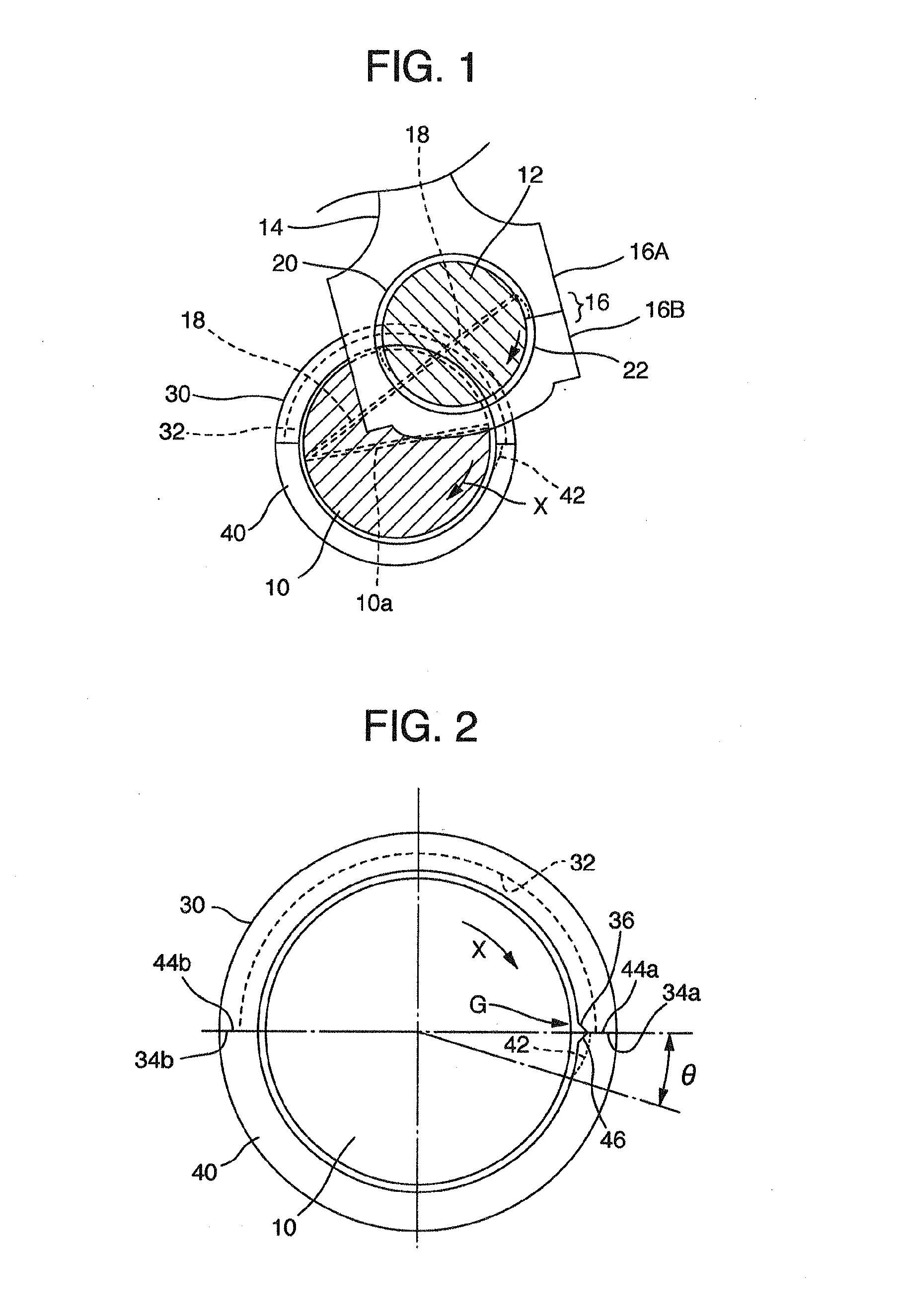

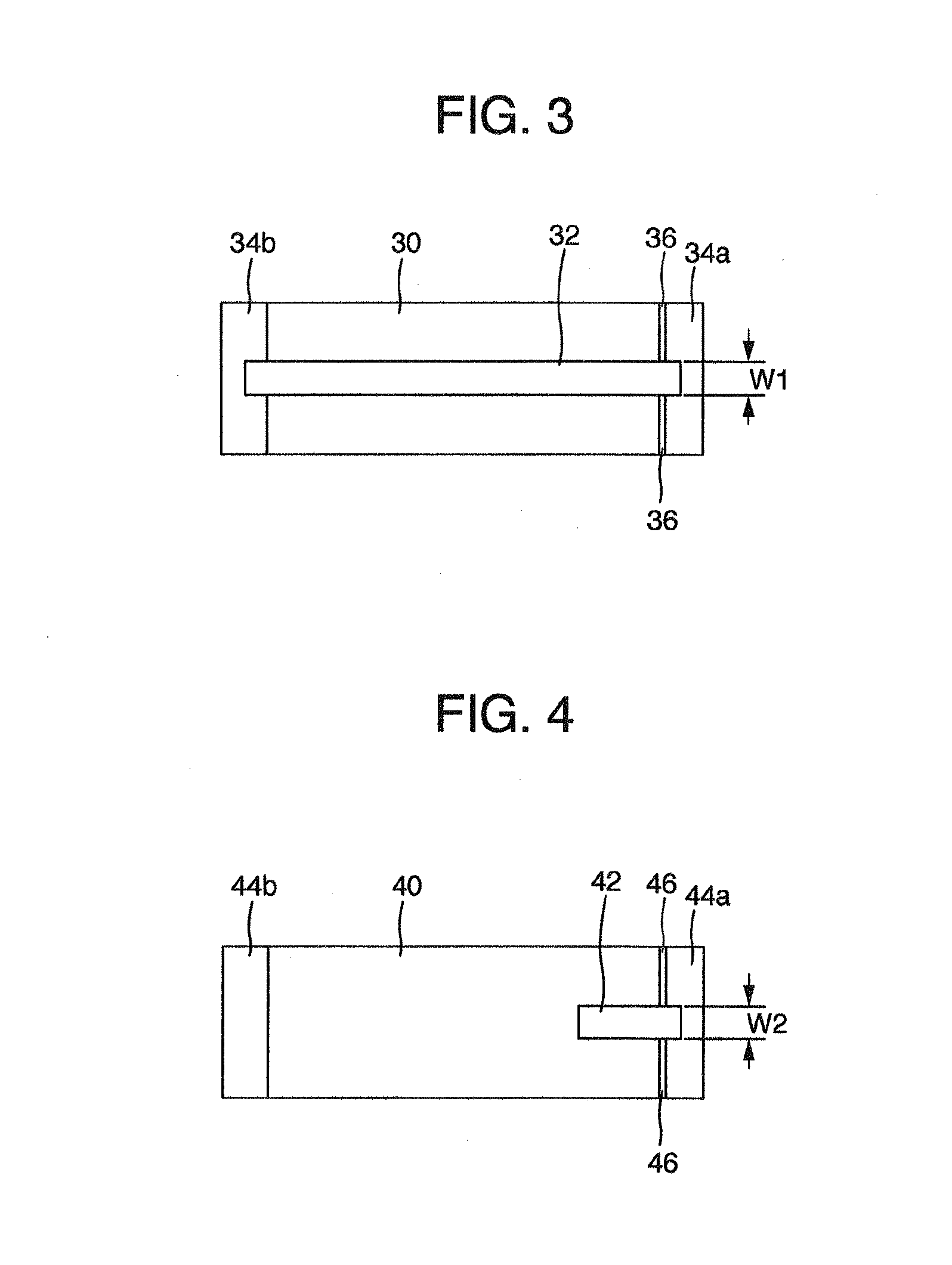

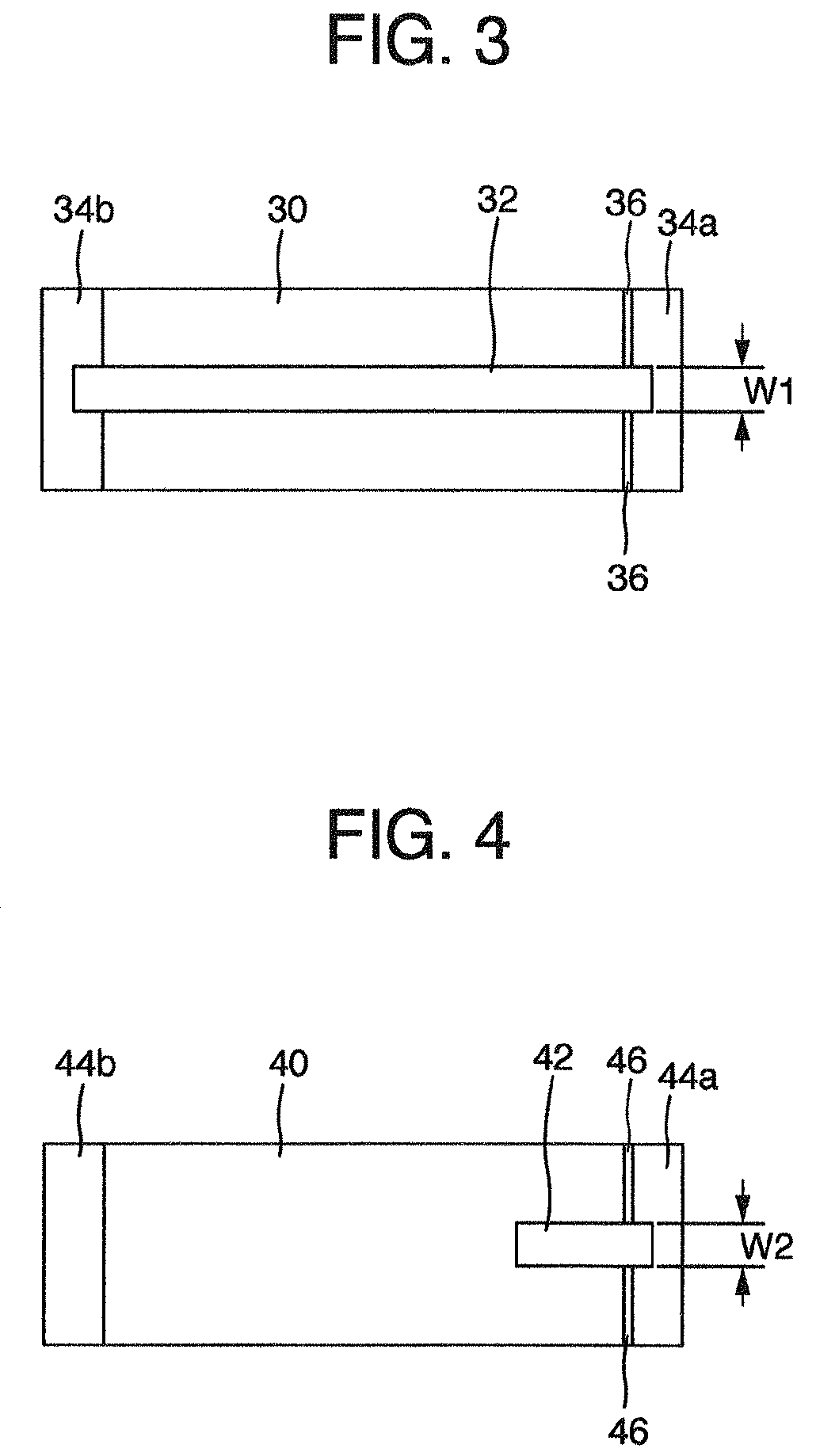

A developing device is provided with a developer conveying member in which a plurality of electrodes arranged on a substrate at a predetermined interval are coated with a surface protection layer, the developer conveying member being provided in a developing area that faces an image carrying body whose surface carries an electrostatic latent image, wherein developer is conveyed on the developer conveying member using a traveling-wave electric field that is formed by applying a polyphase voltage to the respective electrodes. The developing device is further provided with a supplying member for supplying the developer onto the developer conveying member, wherein (i) an effective electrode width Le of the respective electrodes in their width direction orthogonal to their arranging direction and (ii) a width Lt of a developer existing area on the supplying member, the width Lt being orthogonal to a direction of supplying the developer, are set so as to satisfy a relation of Lt<Le. This prevents the developer from entering wiring pattern areas outside of the electrodes on the developer conveying member, thereby surely preventing the scattering and the sticking of the developer in the areas.

Owner:SHARP KK

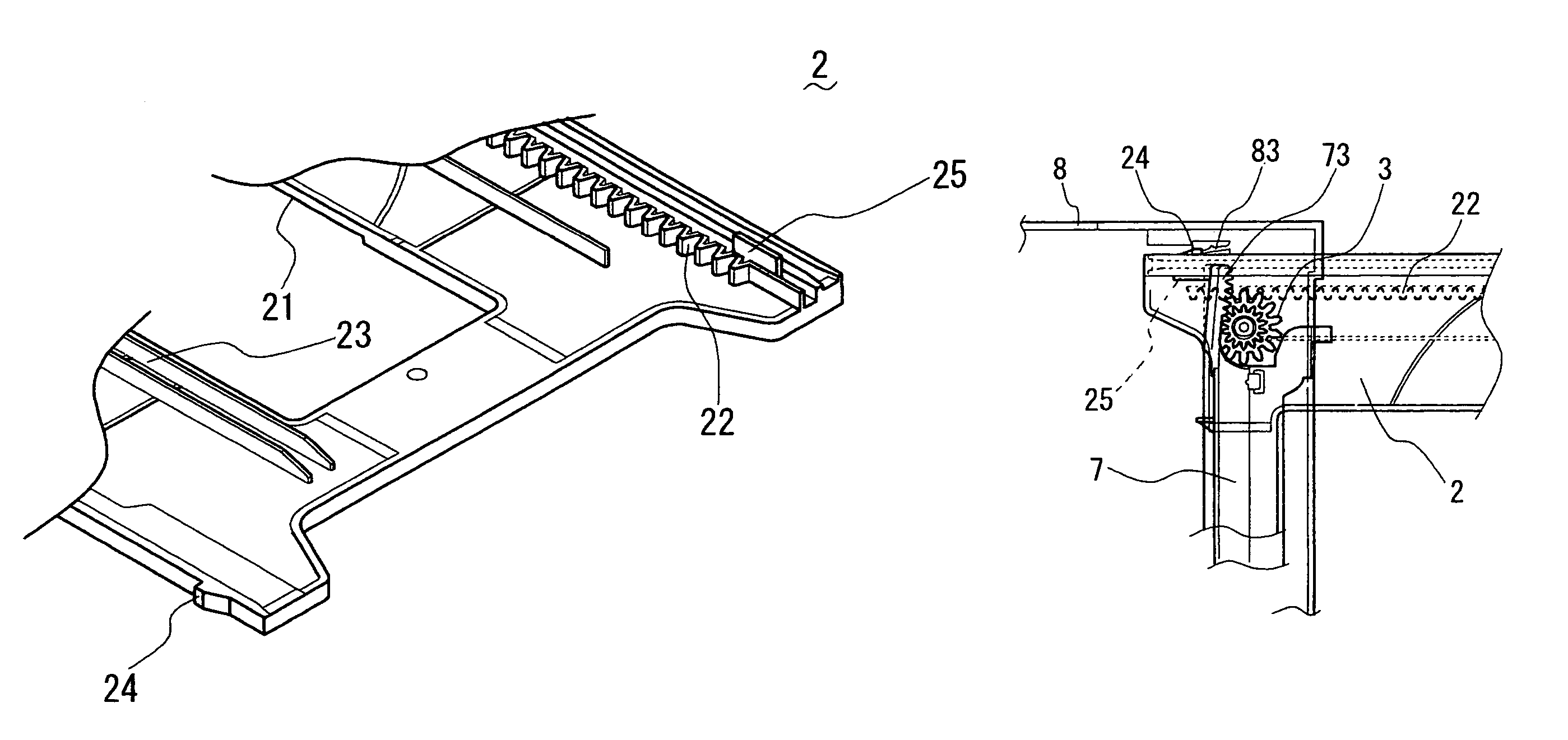

Developing device and image forming device provided with it

InactiveUS20040037593A1Reduce collision energyReduce adverse effectsElectrographic process apparatusLatent imageImage formation

A developing device is provided with a developer conveying member in which a plurality of electrodes arranged on a substrate at a predetermined interval are coated with a surface protection layer, the developer conveying member being provided in a developing area that faces an image carrying body whose surface carries an electrostatic latent image, wherein developer is conveyed on the developer conveying member using a traveling-wave electric field that is formed by applying a polyphase voltage to the respective electrodes. The developing device is further provided with a supplying member for supplying the developer onto the developer conveying member, wherein (i) an effective electrode width Le of the respective electrodes in their width direction orthogonal to their arranging direction and (ii) a width Lt of a developer existing area on the supplying member, the width Lt being orthogonal to a direction of supplying the developer, are set so as to satisfy a relation of Lt<Le. This prevents the developer from entering wiring pattern areas outside of the electrodes on the developer conveying member, thereby surely preventing the scattering and the sticking of the developer in the areas.

Owner:SHARP KK

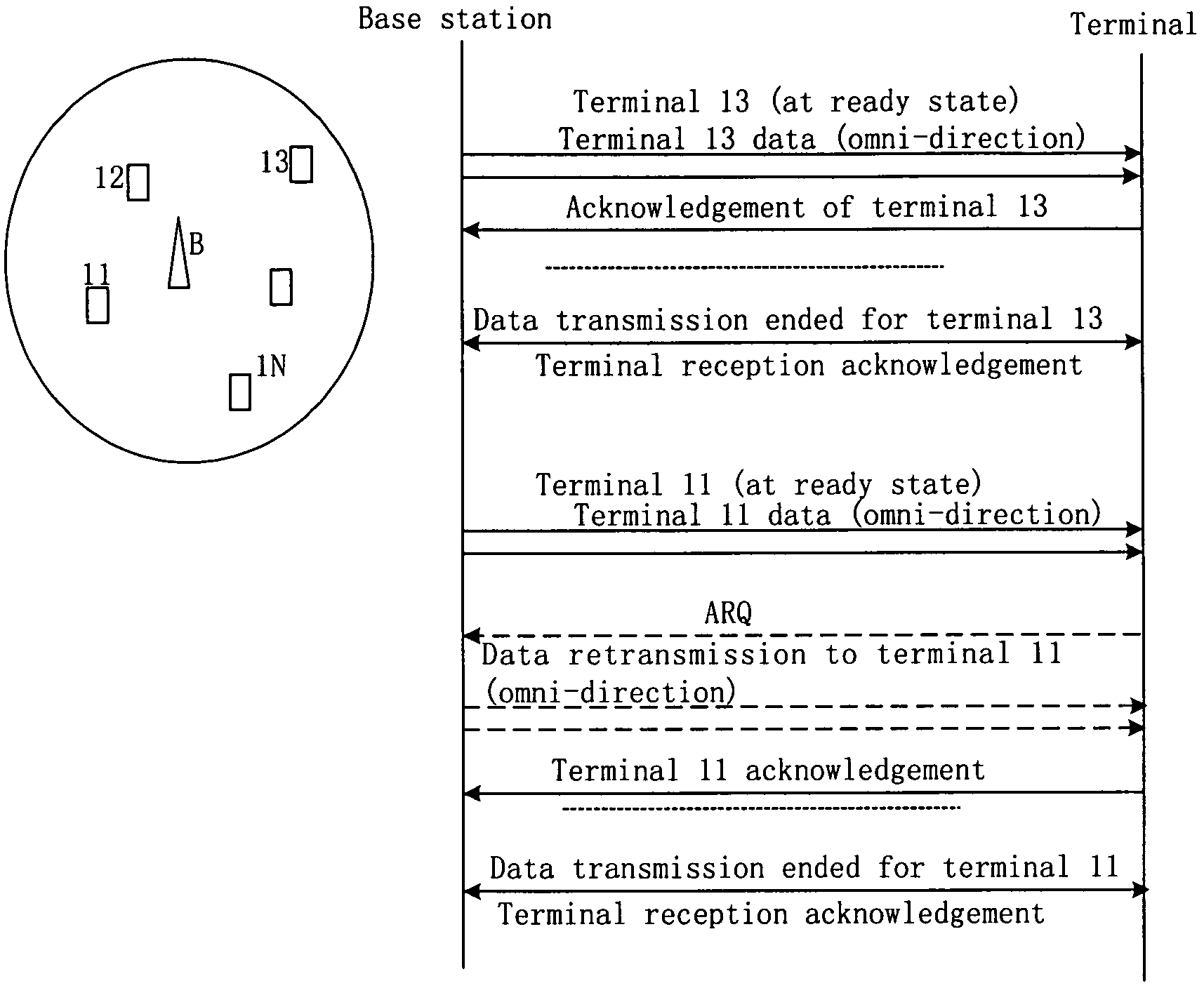

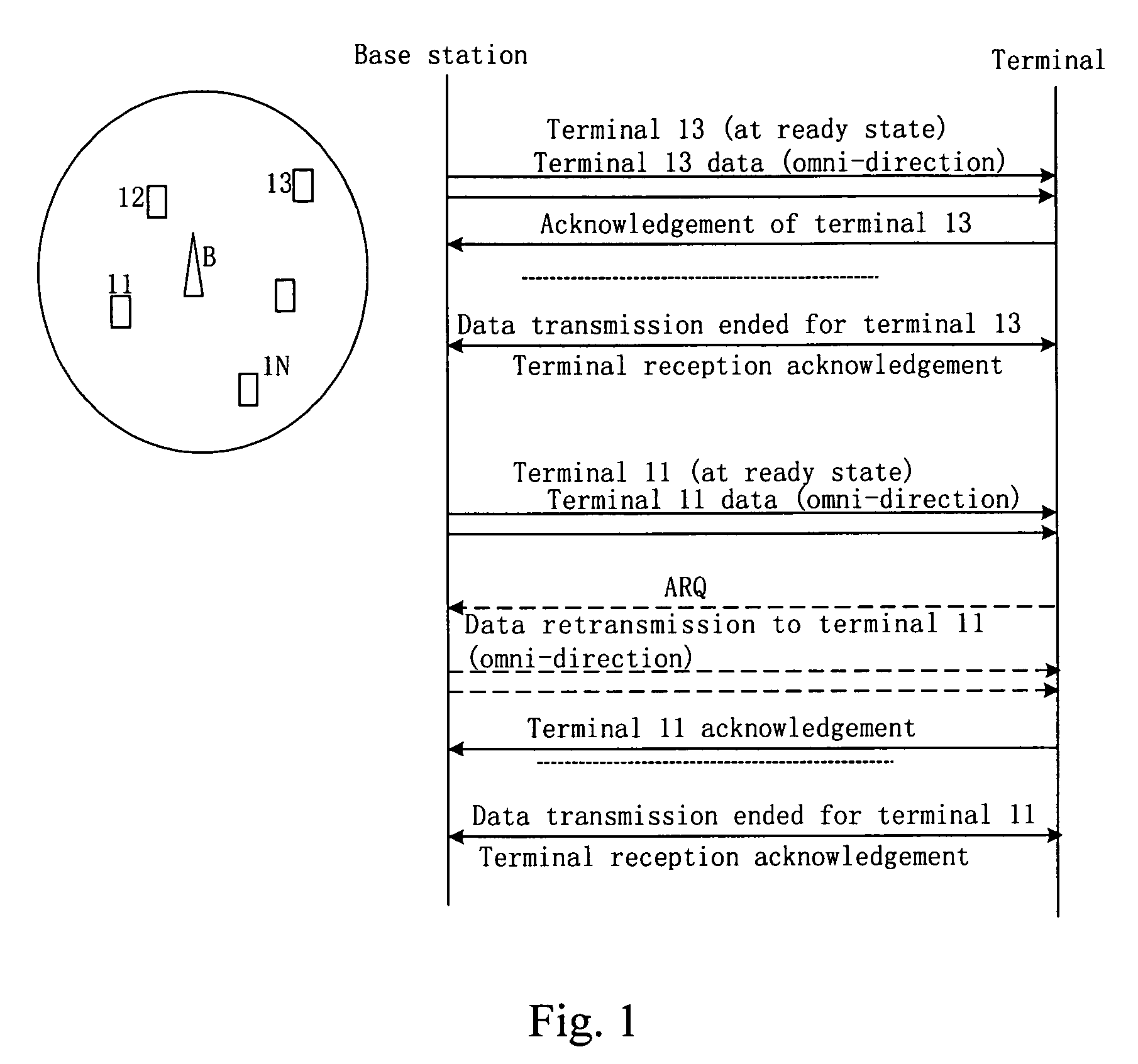

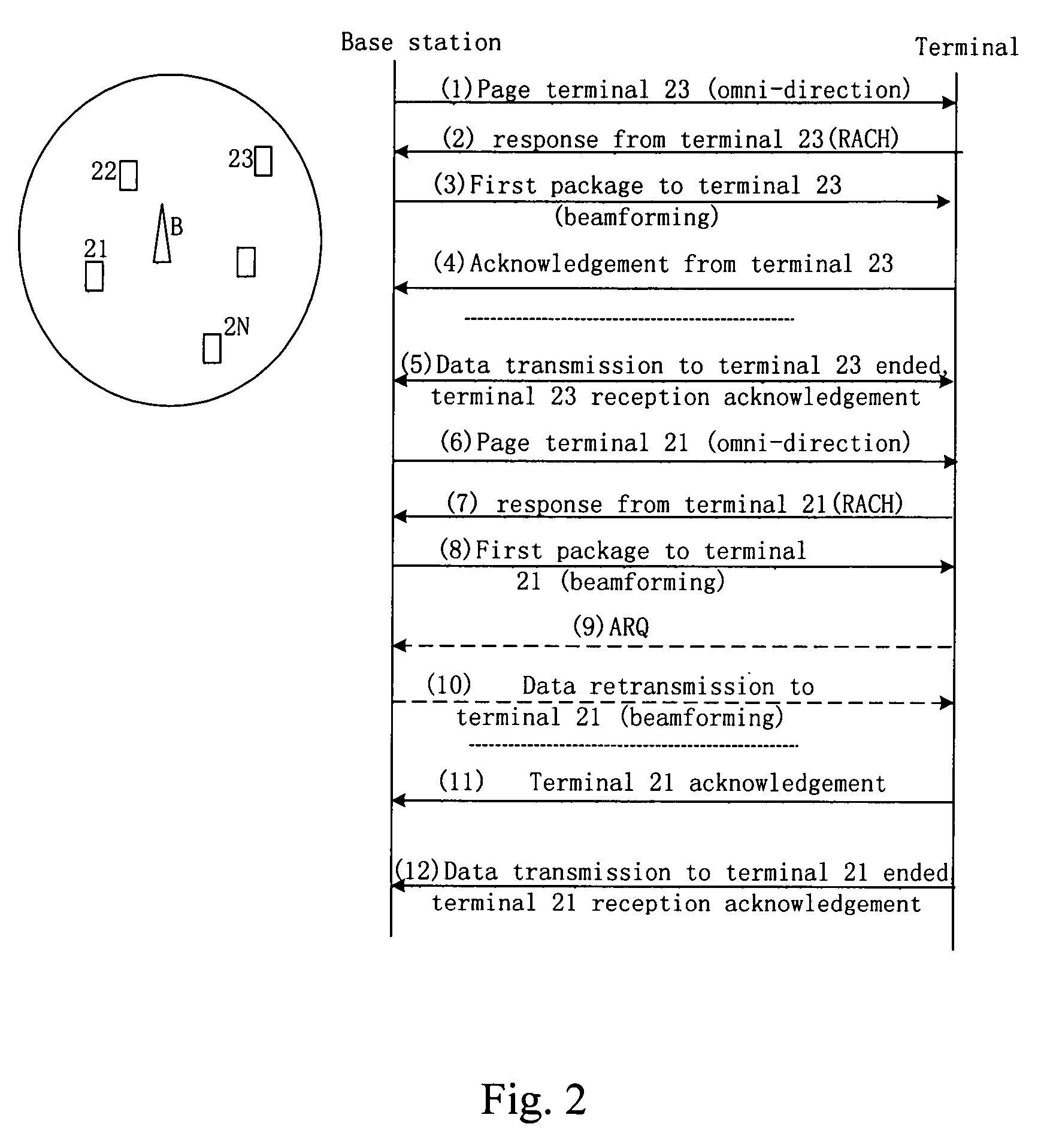

Method of mobile communication system with smart antenna

InactiveUS7319888B2Less resourcesDecreasing downlink package lengthError prevention/detection by using return channelPolarisation/directional diversityCommunications systemSmart antenna

The invention discloses a method for transmitting high-speed downlink package data in a mobile communication system with a smart antenna, which not only can take full advantage of radio beamforming of smart antenna but also can transmit downlink package data high efficiency. In this method, at the beginning of downlink package data transmission, no matter whether a subscriber terminal is at any state, a call for all ready subscriber terminal is made through a paging channel to obtain an initial DOA (direction of arrival) of every subscriber terminal, and then with this initial DOA the smart antenna transmits downlink package data to a subscriber terminal with an initial beamforming; having received one package, the subscriber terminal returns an acknowledgement message, if the downlink package is correctly received, or retransmission is required, if the received downlink package has error codes, so the system knows current position of the subscriber terminal and can use an updated beamforming to trace the subscriber terminal moving; based on received package quality, the system adaptively adjusts the length of a downlink package, and based on the moving speed of the subscriber terminal, the system adaptively adjusts the length of the downlink package too.

Owner:DATANG MOBILE COMM EQUIP CO LTD

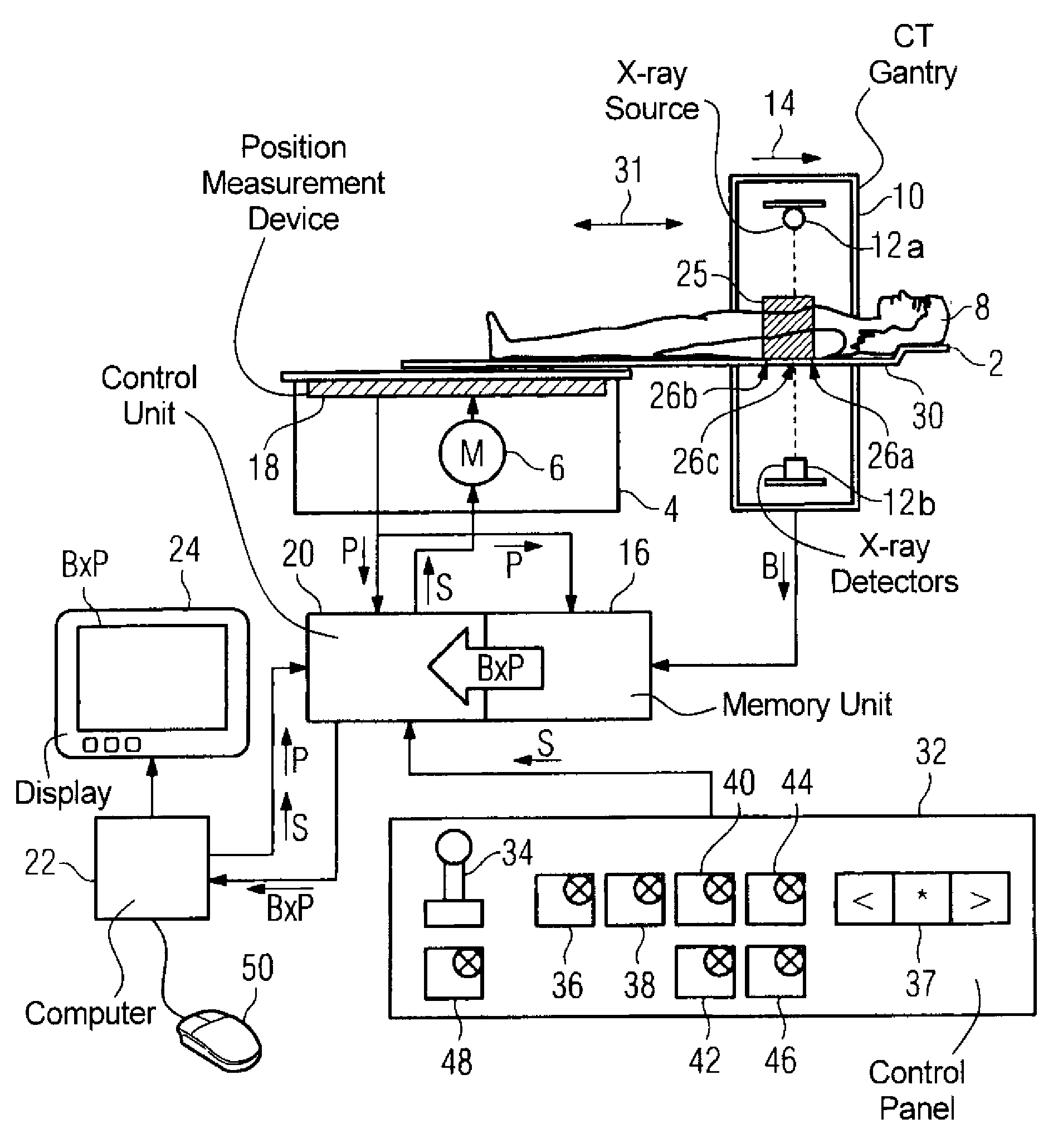

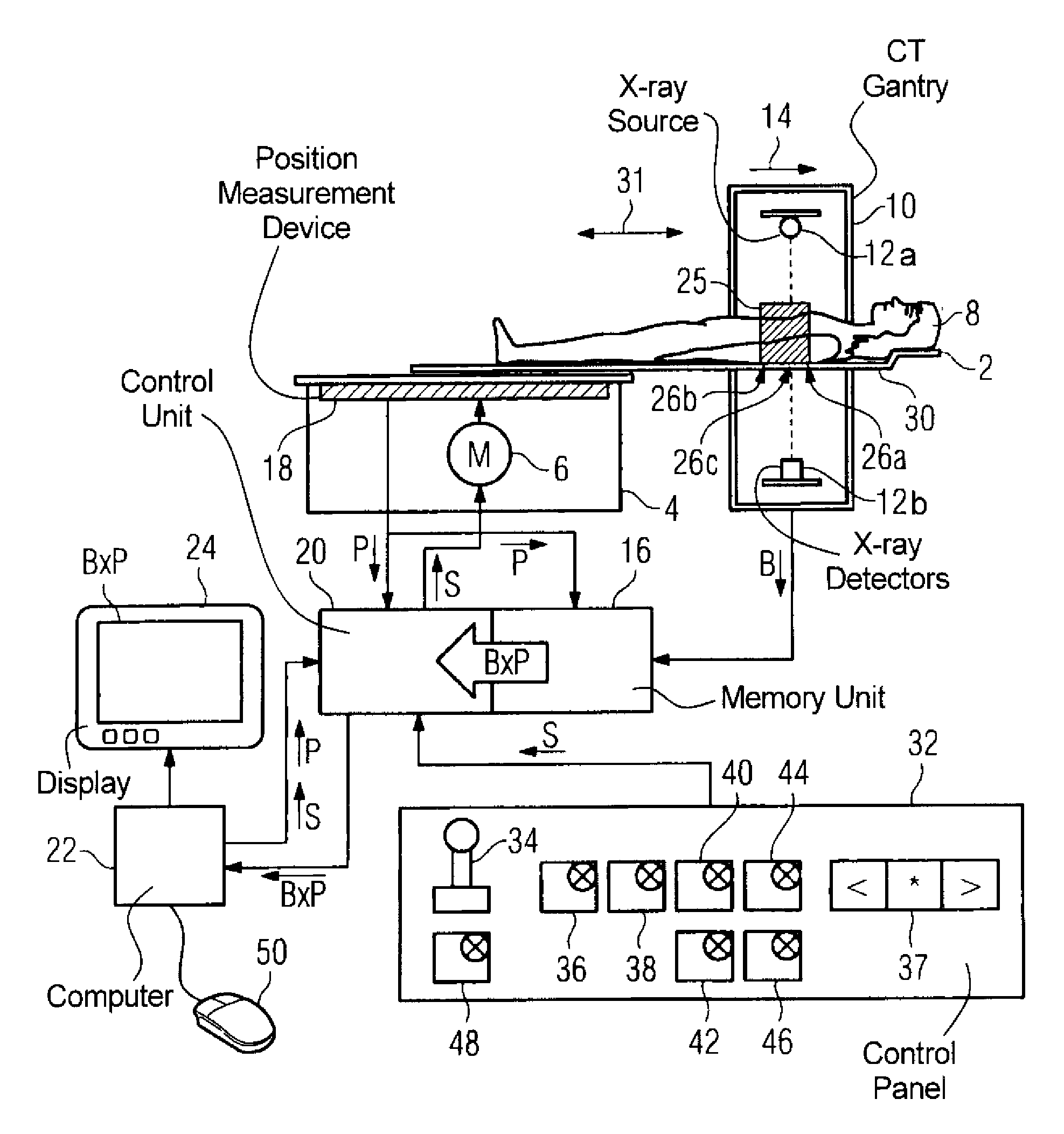

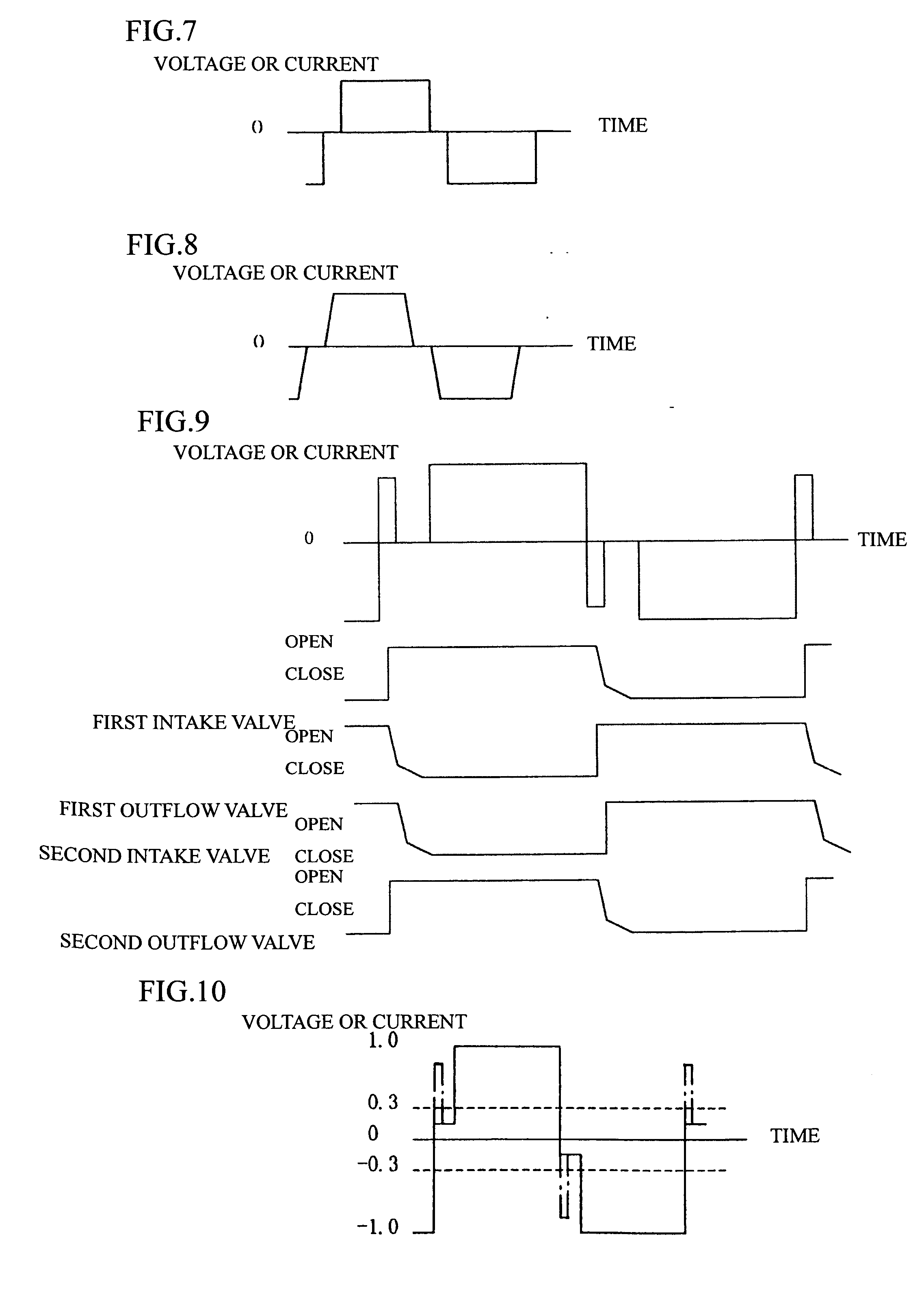

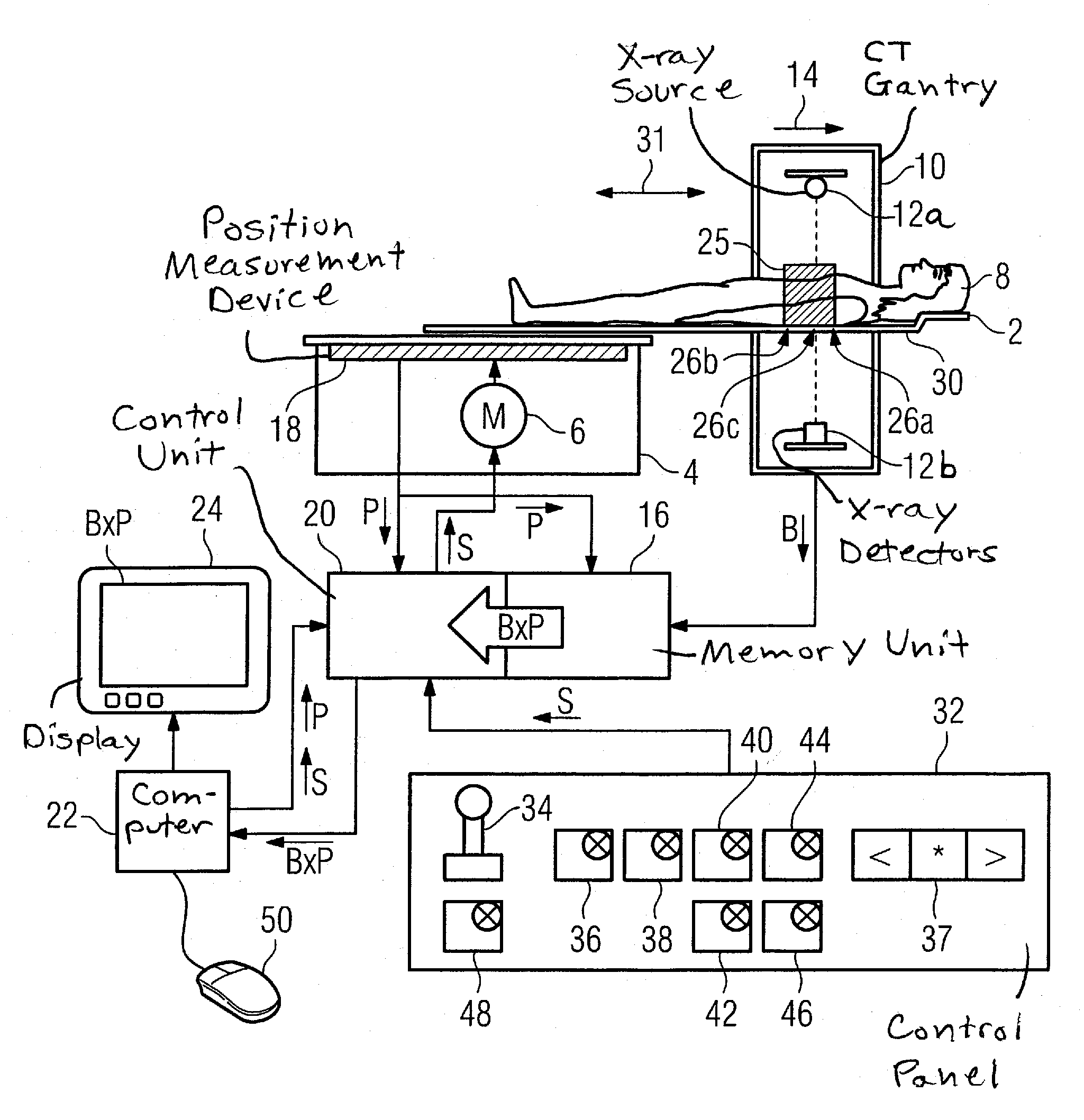

Method and patient bed for positioning a patient in a medical examination system

InactiveUS7677802B2Slow movement speedMaterial analysis using wave/particle radiationRadiation/particle handlingPatient positioningMedical screening

In a method for simplified positioning of a patient bed positioning information of a measurement position of the patient bed is recorded and retained as a forced stop position. The positioning of the patient bed between the measurement position ensues such that, given a movement of the patient bed from the withdrawn position, the positioning procedure is automatically halted upon reaching the measurement position.

Owner:SIEMENS HEALTHCARE GMBH

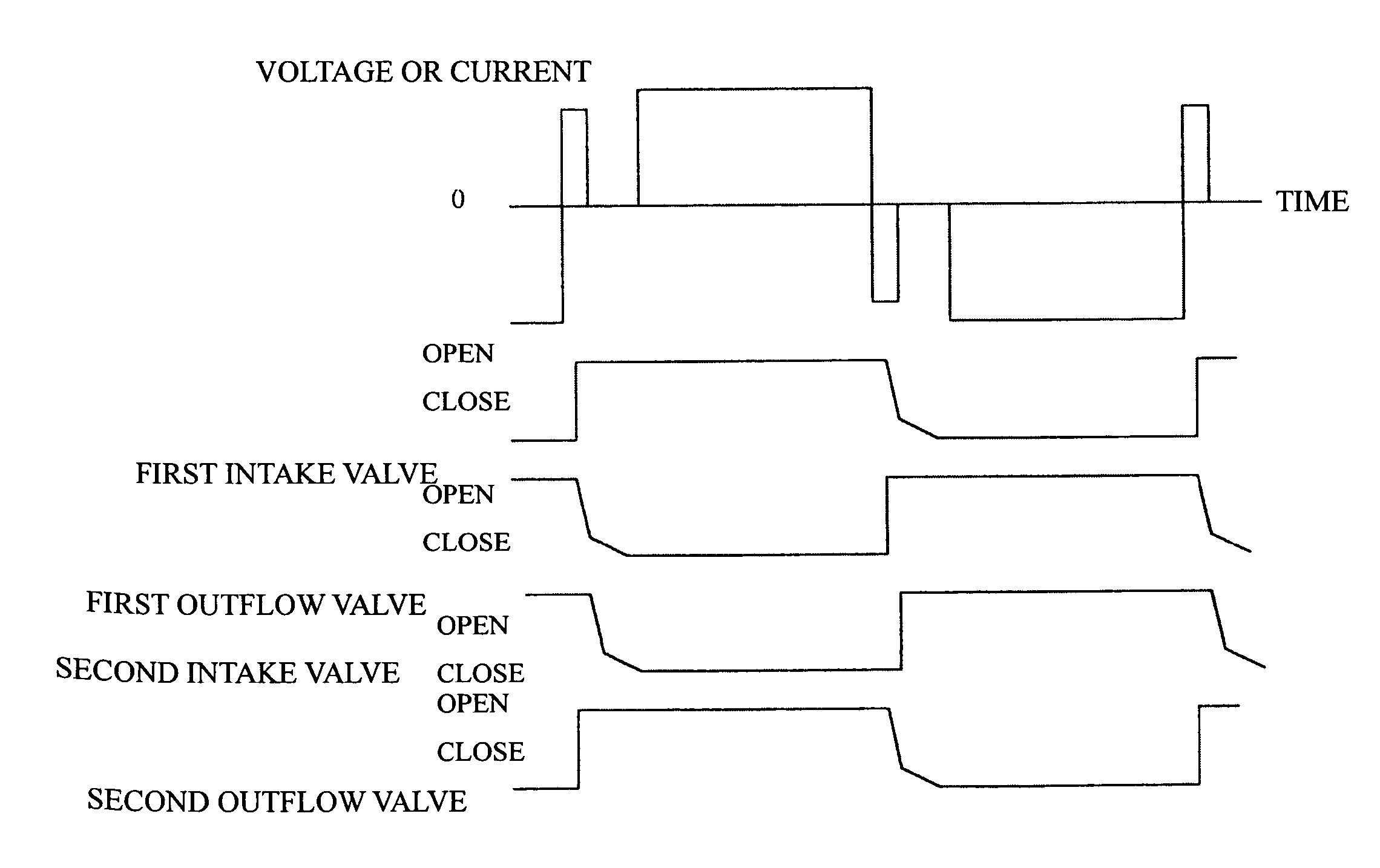

Electromagnetic pump driving method

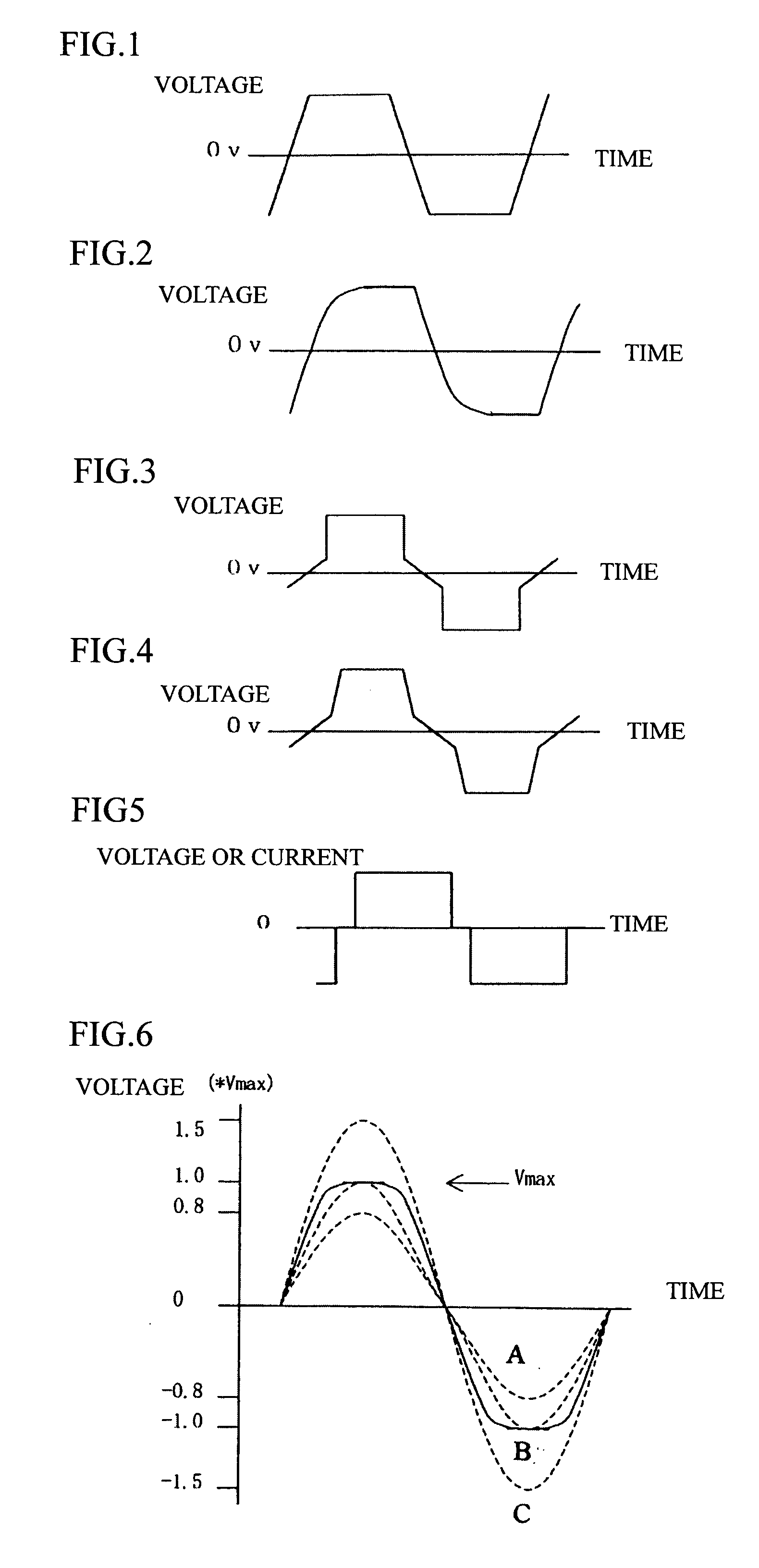

InactiveUS20070025861A1Reducing production of noiseReduce vibrationAC motor controlMotor parameterPump chamberElectrical polarity

There is provided a method of driving an electromagnetic pump where noise and vibration that accompany abrupt fluctuations in pressure inside a pump chamber are reduced. A pulse voltage is applied alternately on a positive side and a negative side to drive the electromagnetic coil such that a change in voltage that occurs when the polarity of the pulse voltage is inverted has a continuous slope at least between the positive side and the negative side.

Owner:SHINANO KENSHI

Method and patient bed for positioning a patient in a medical examination system

InactiveUS20080016620A1Maximum operating comfortSlow movement speedMaterial analysis using wave/particle radiationRadiation/particle handlingPatient positioningMedical science

In a method for simplified positioning of a patient bed positioning information of a measurement position of the patient bed is recorded and retained as a forced stop position. The positioning of the patient bed between the measurement position ensues such that, given a movement of the patient bed from the withdrawn position, the positioning procedure is automatically halted upon reaching the measurement position.

Owner:SIEMENS HEALTHCARE GMBH

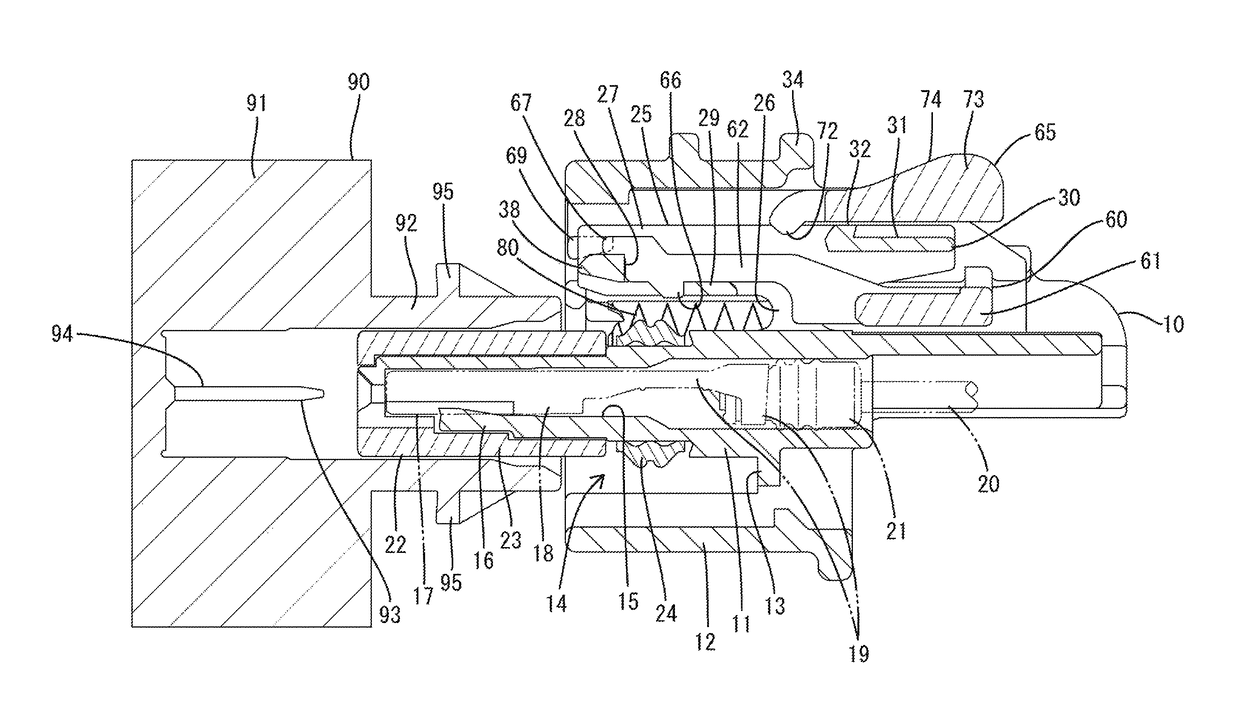

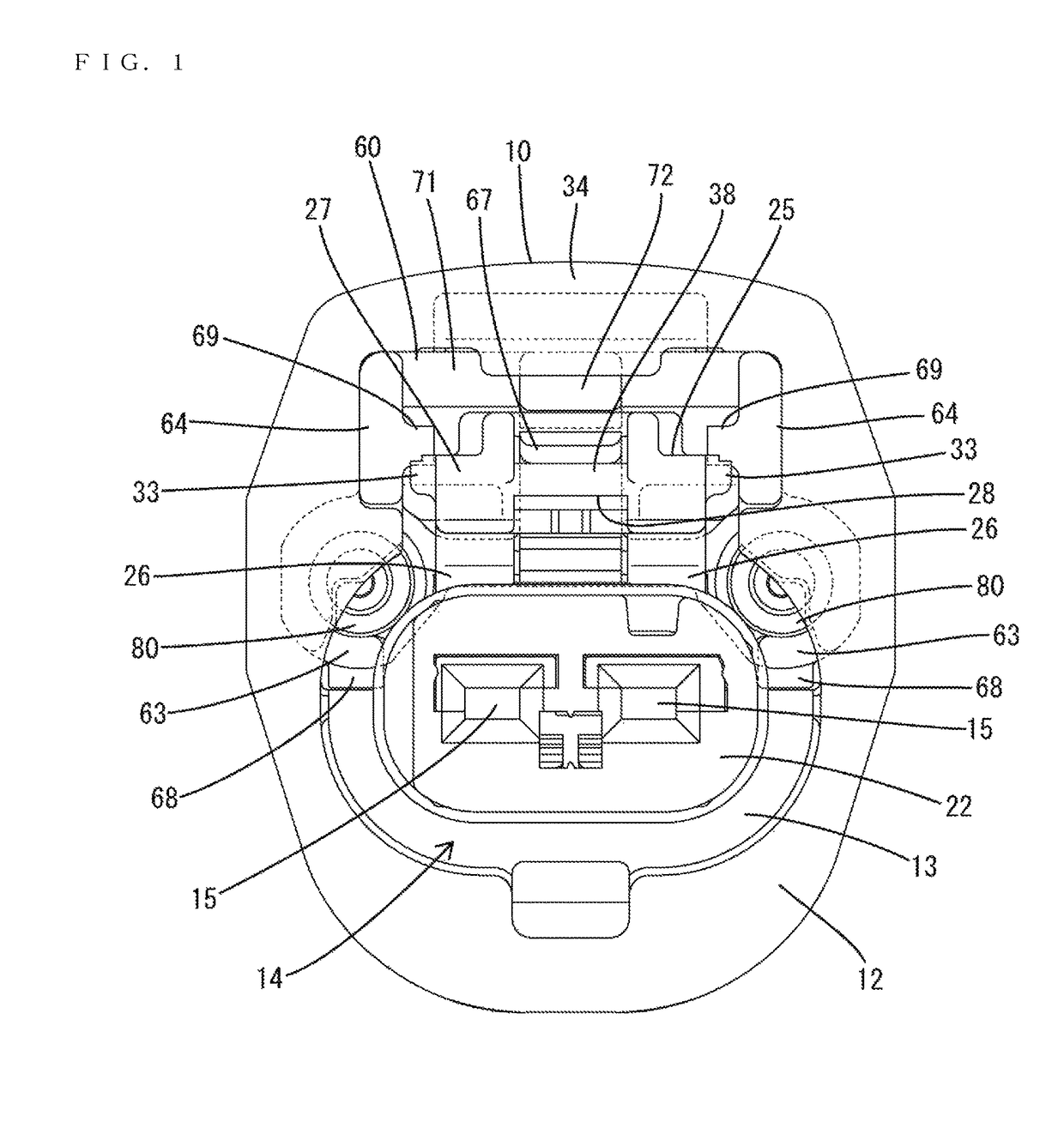

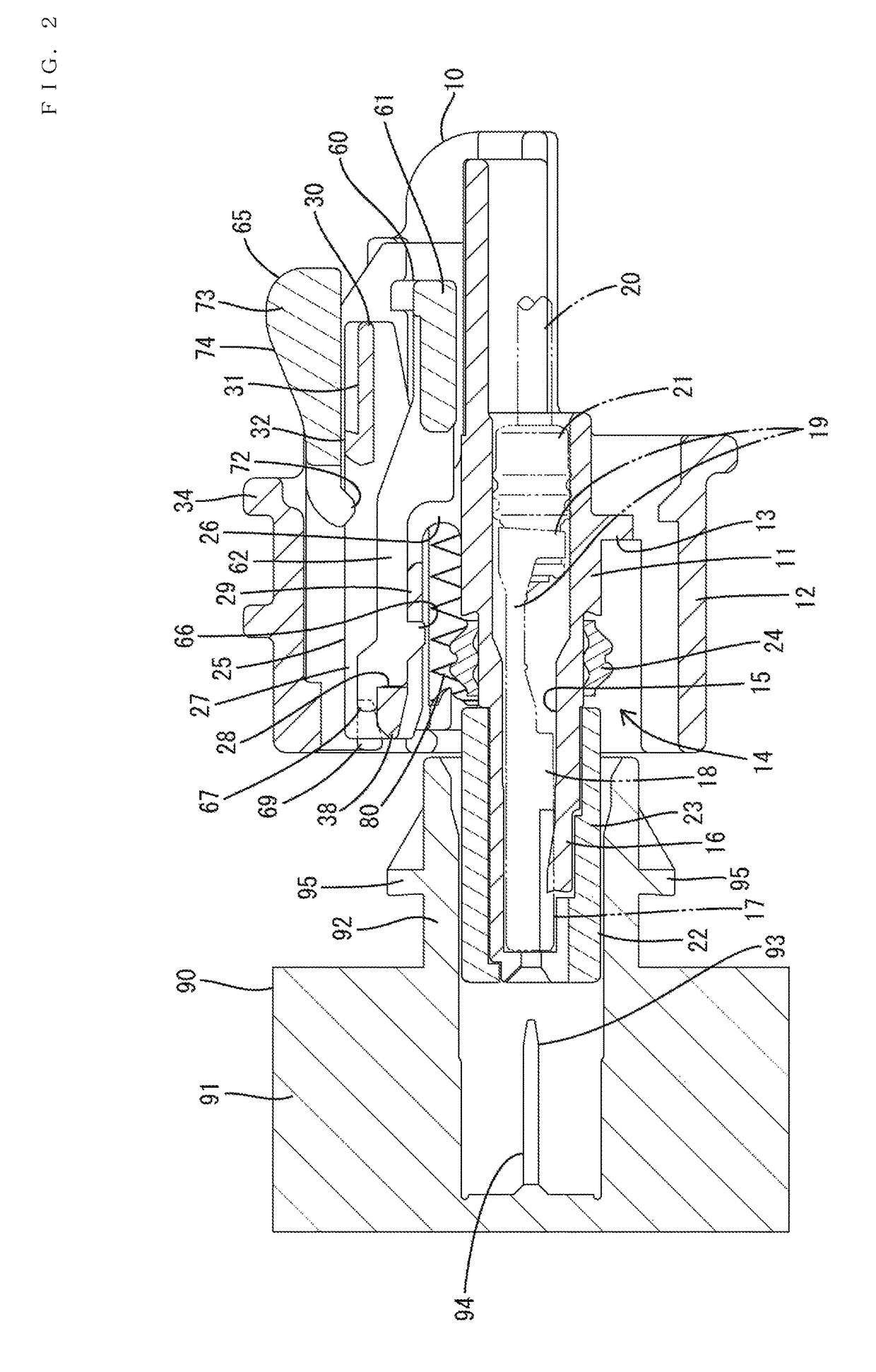

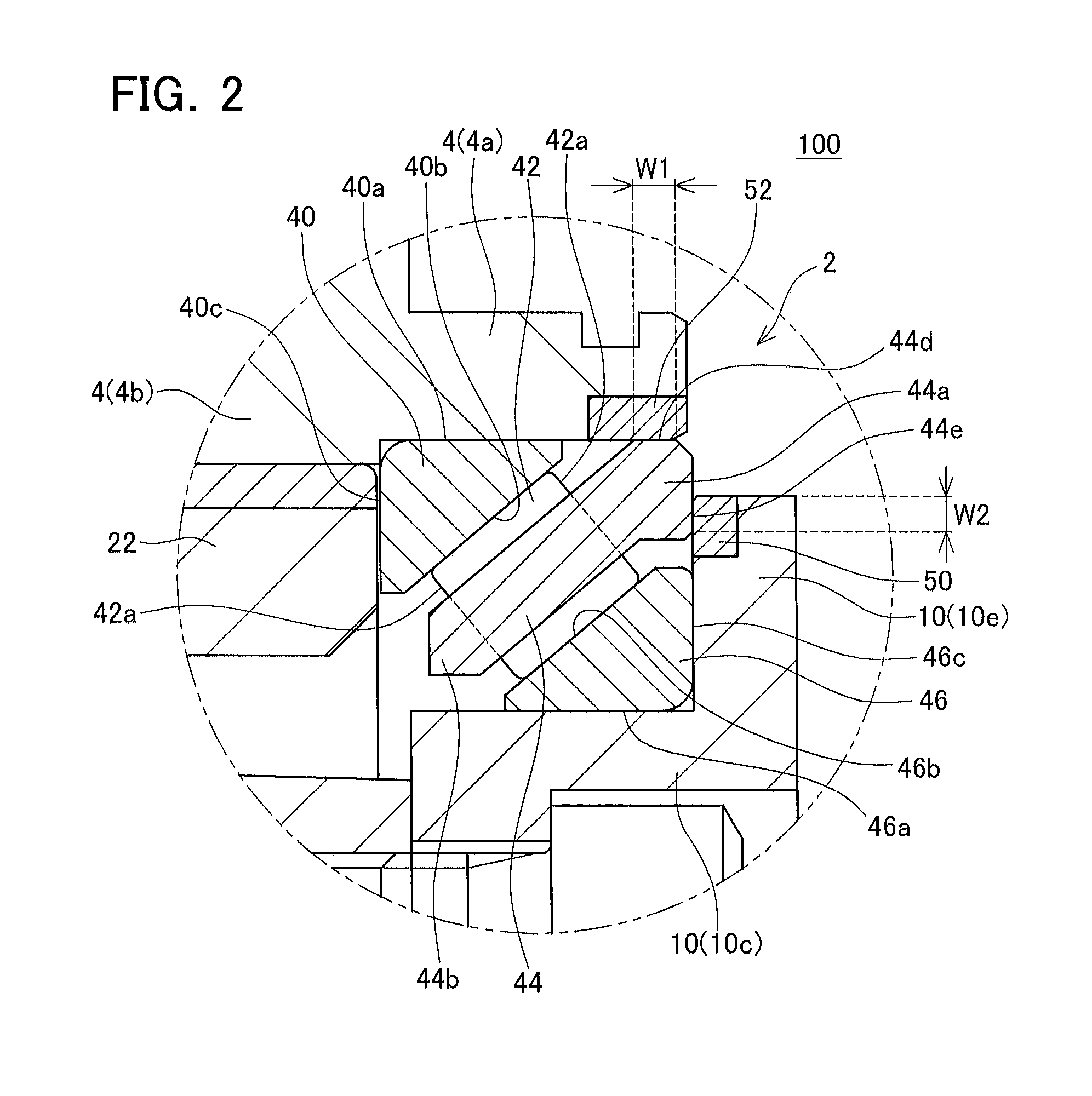

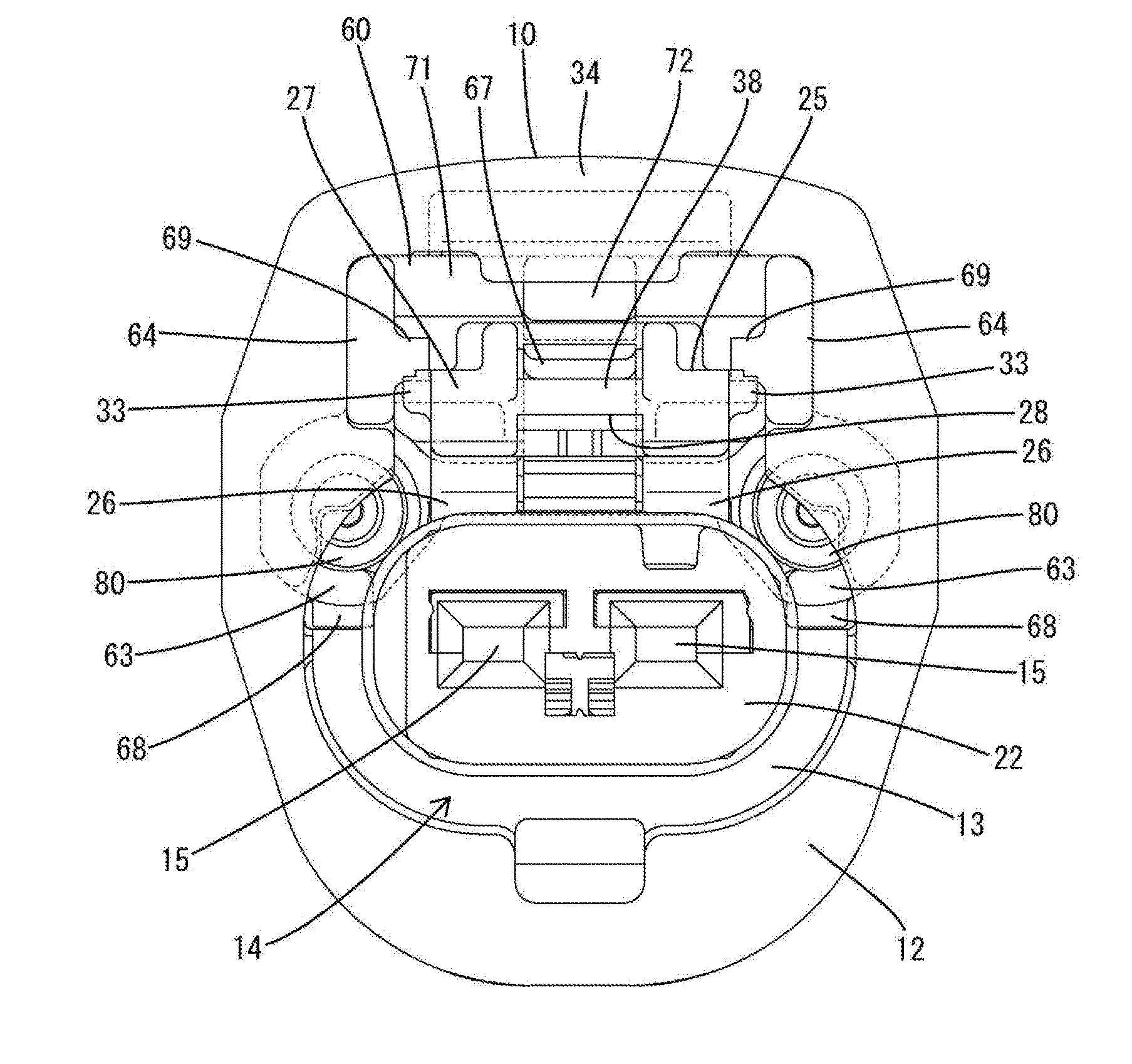

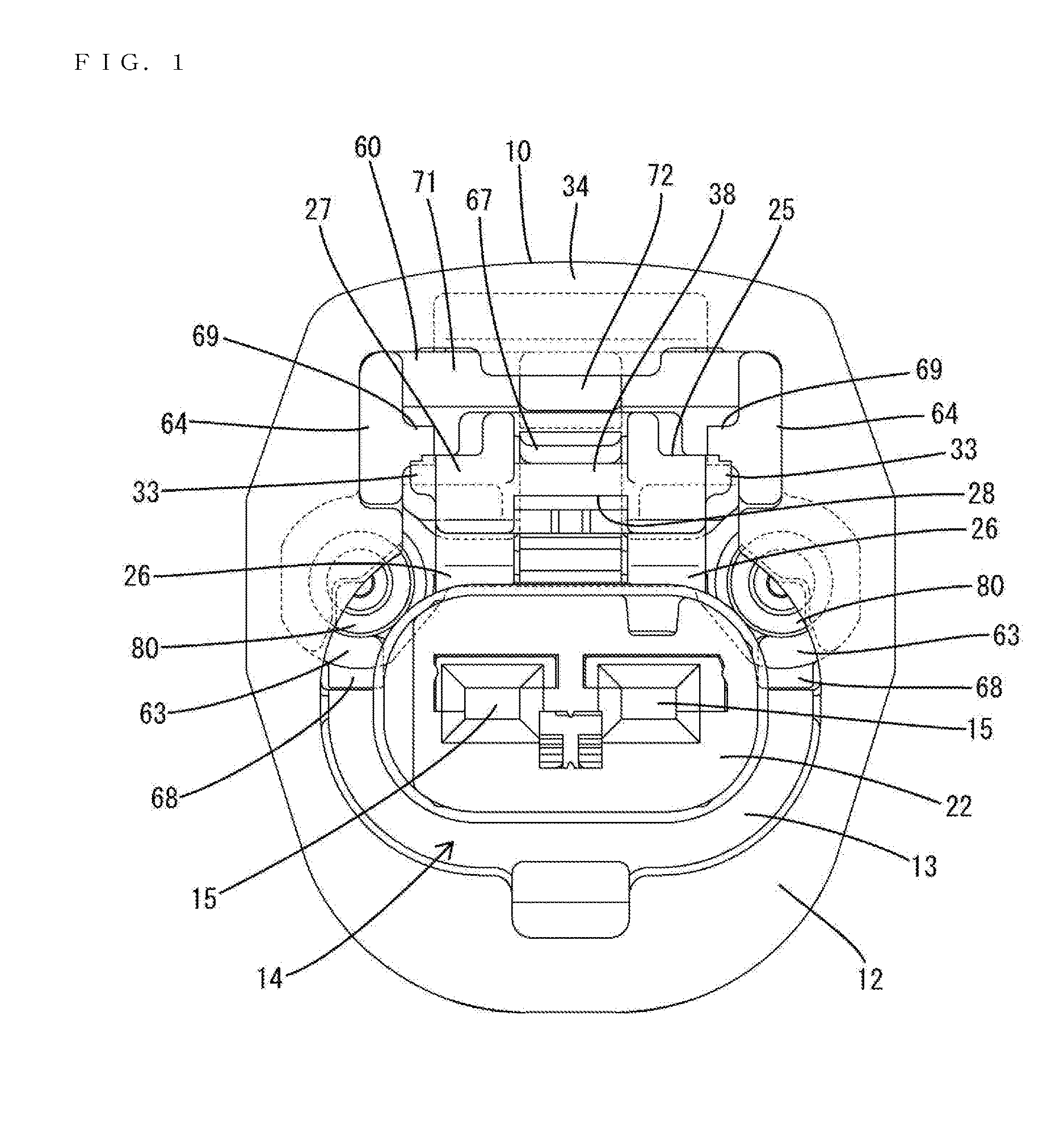

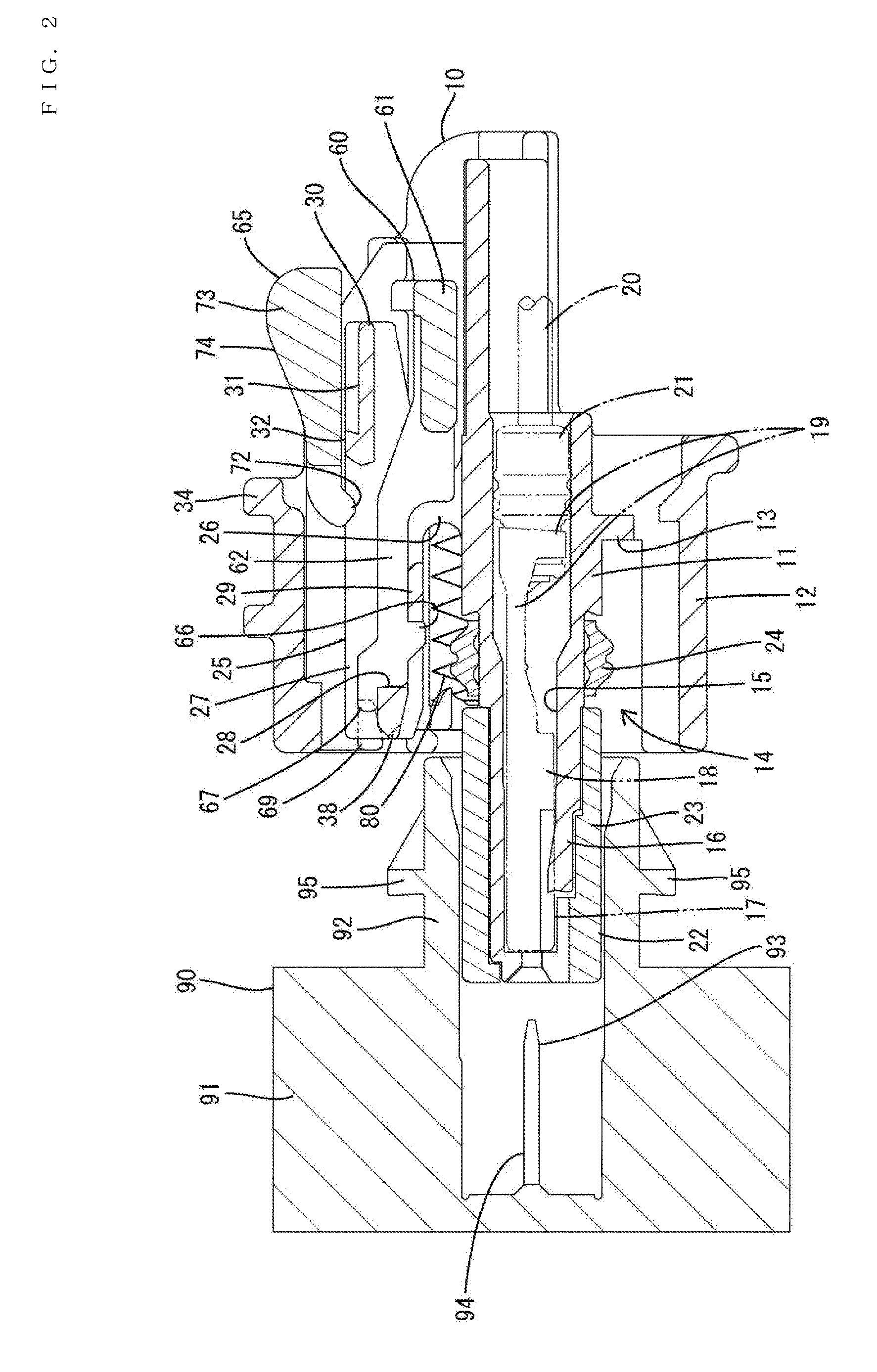

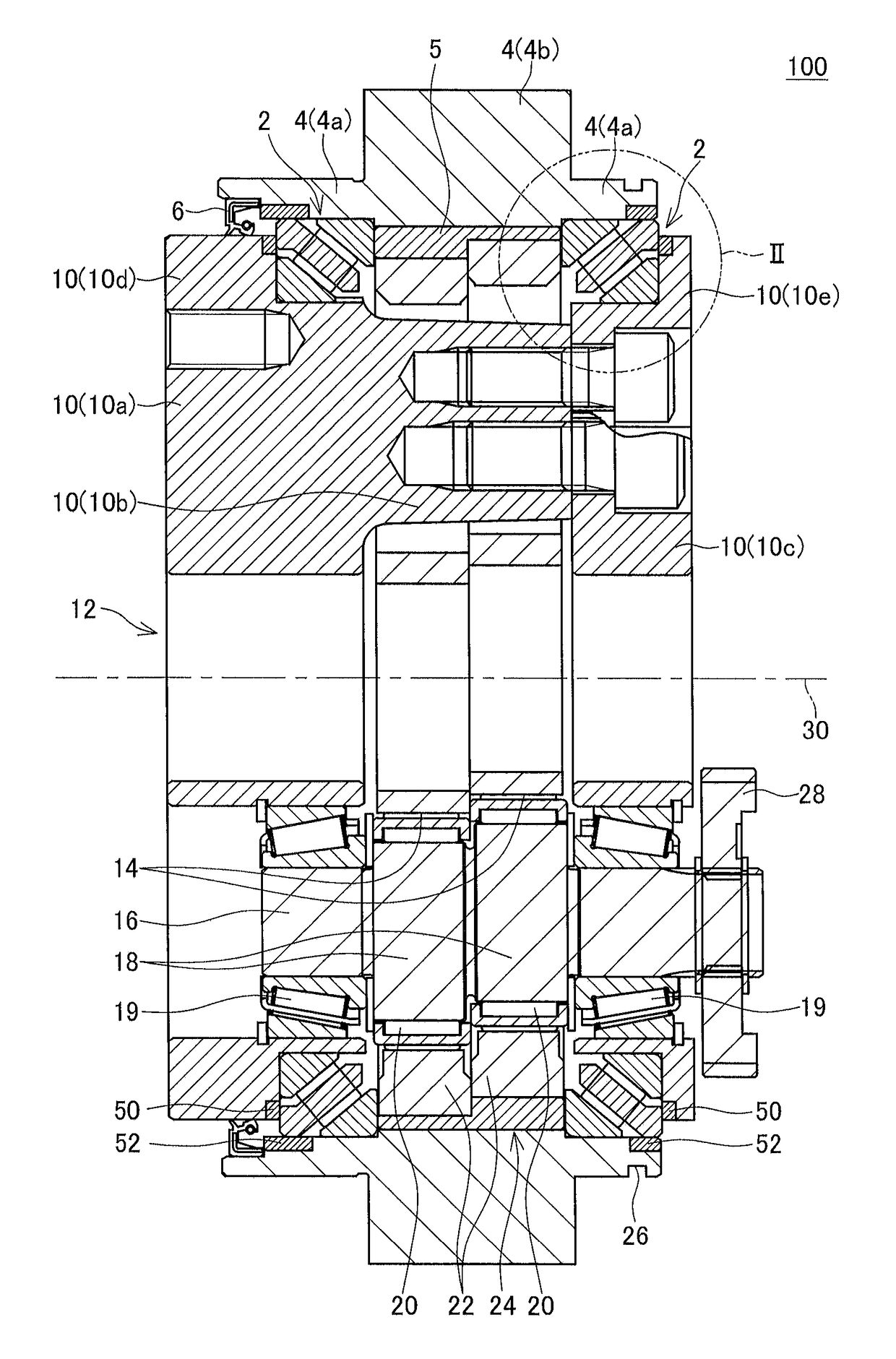

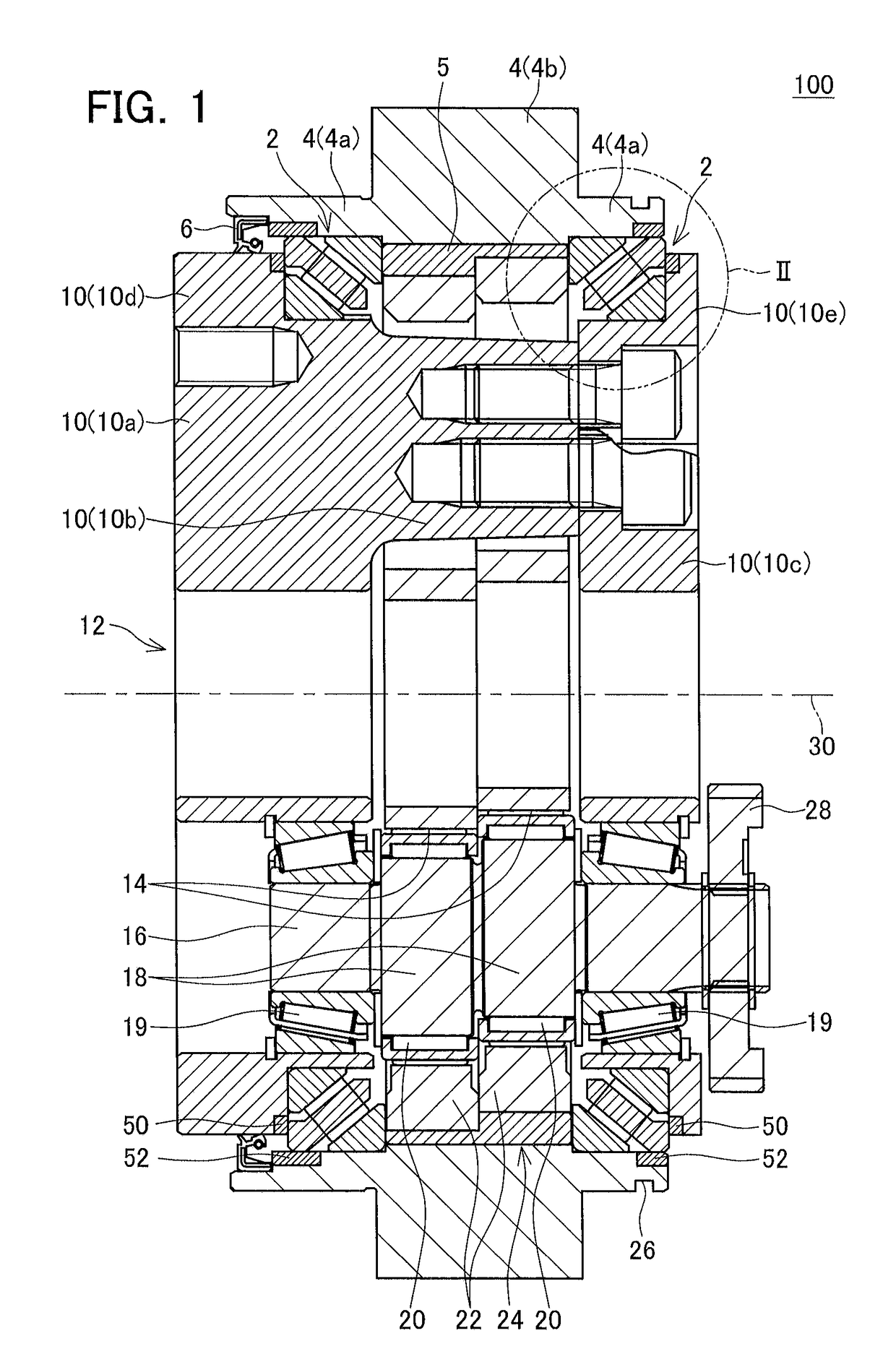

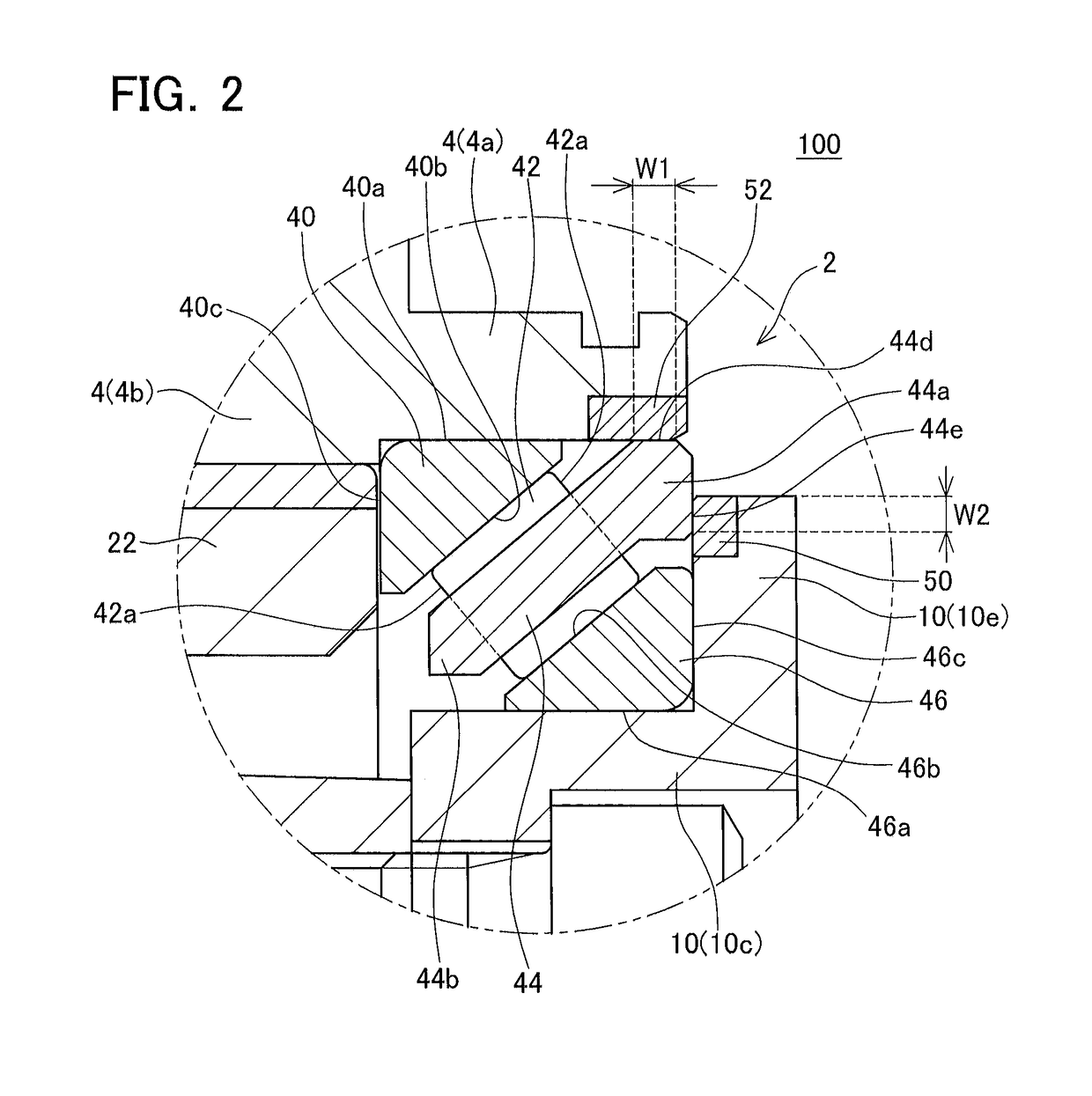

Connector

ActiveUS9666989B2Reduce impactSlow movement speedIncorrect coupling preventionCouplings bases/casesEngineeringMechanical engineering

A connector includes a detector (60) movable to a standby position and a detection position with respect to a housing (10). The detector (60) is kept at the standby position in the process of connecting two housings (10, 90) and is biased by biasing members (80) and brought to the detection position when the two housings (10, 90) are properly connected. The detector (60) includes a resilient arm (65) configured to slide on a sliding surface (32) of the housing (10) while being resiliently deformed in the process of reaching the detection position.

Owner:SUMITOMO WIRING SYST LTD

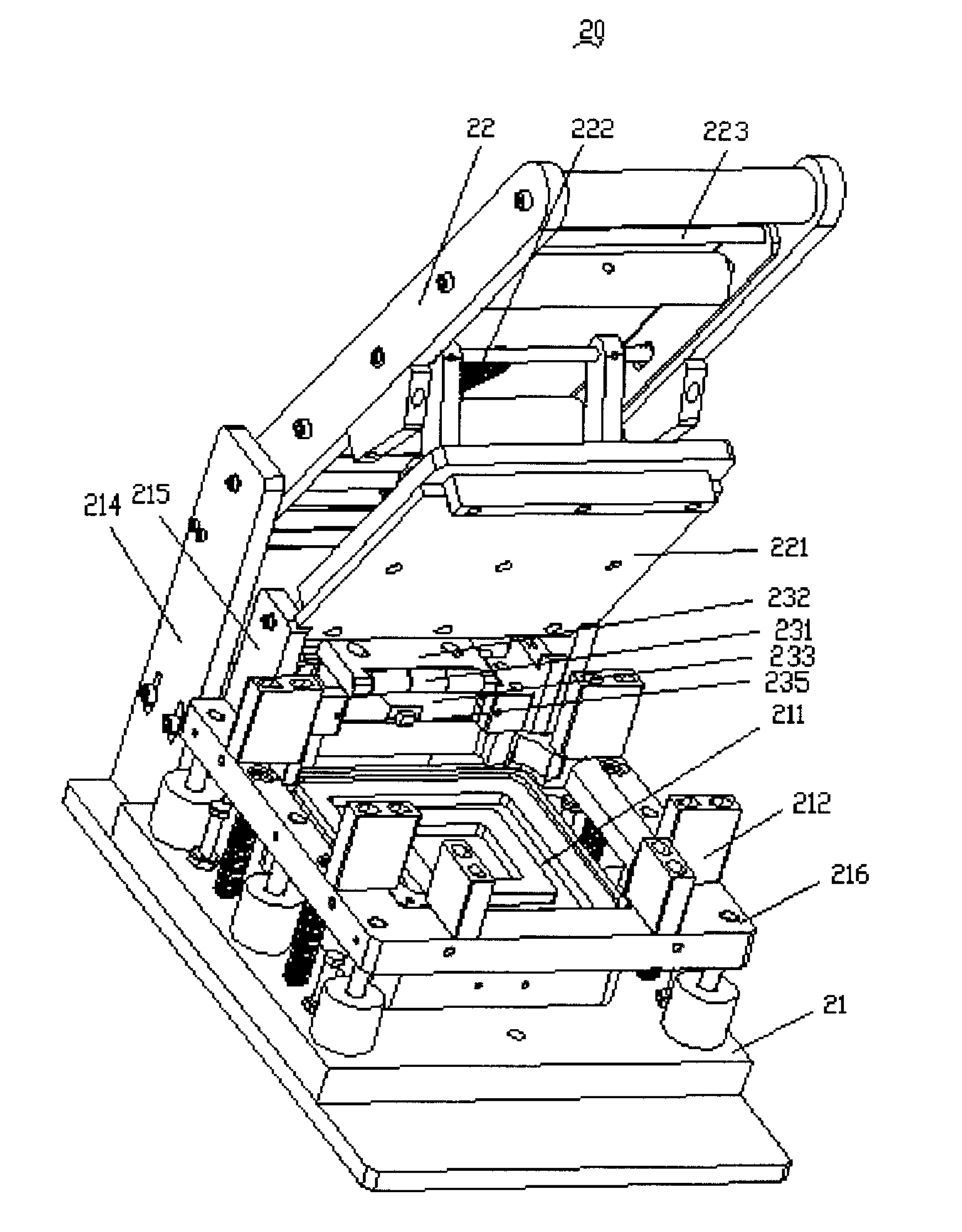

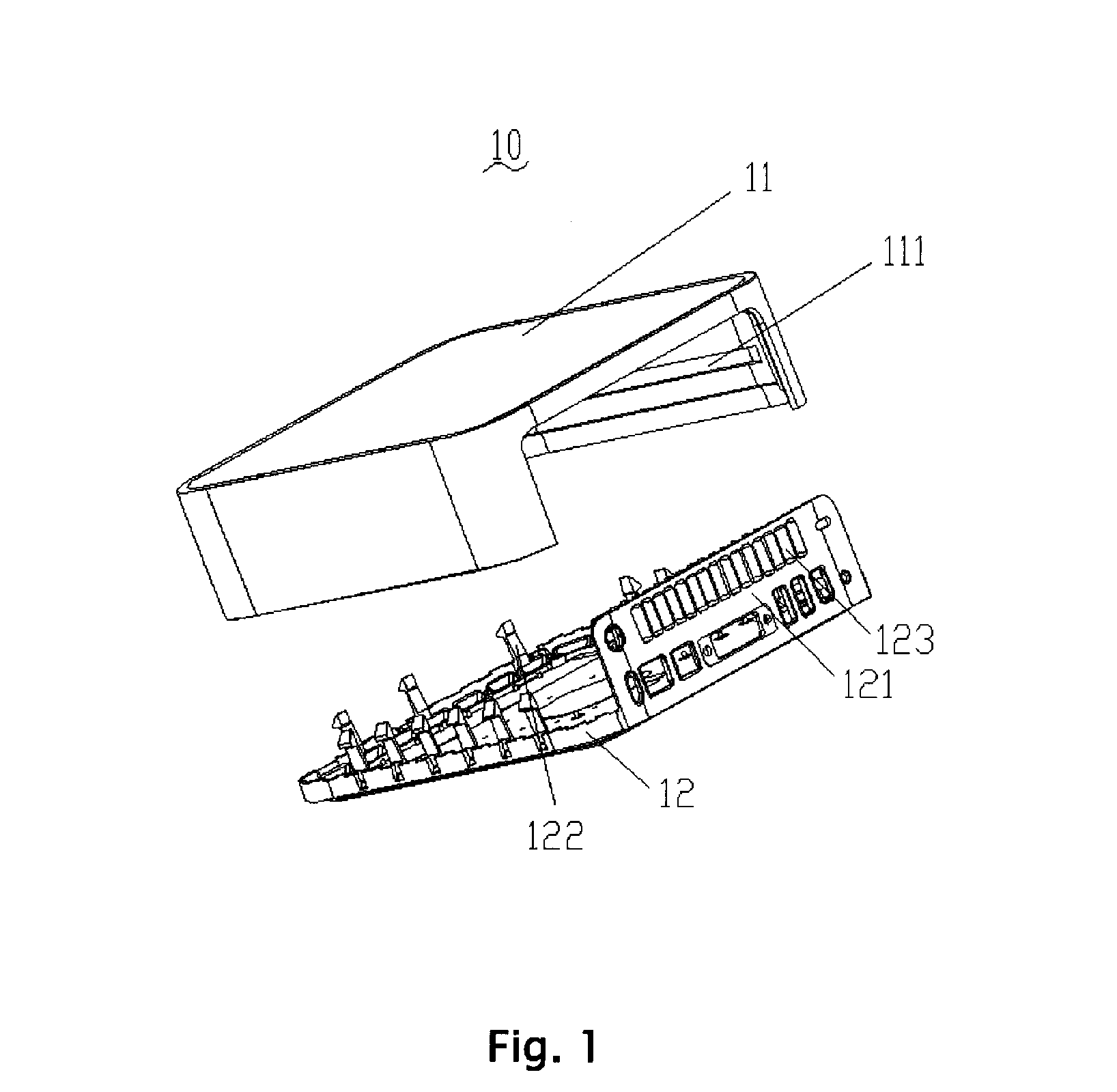

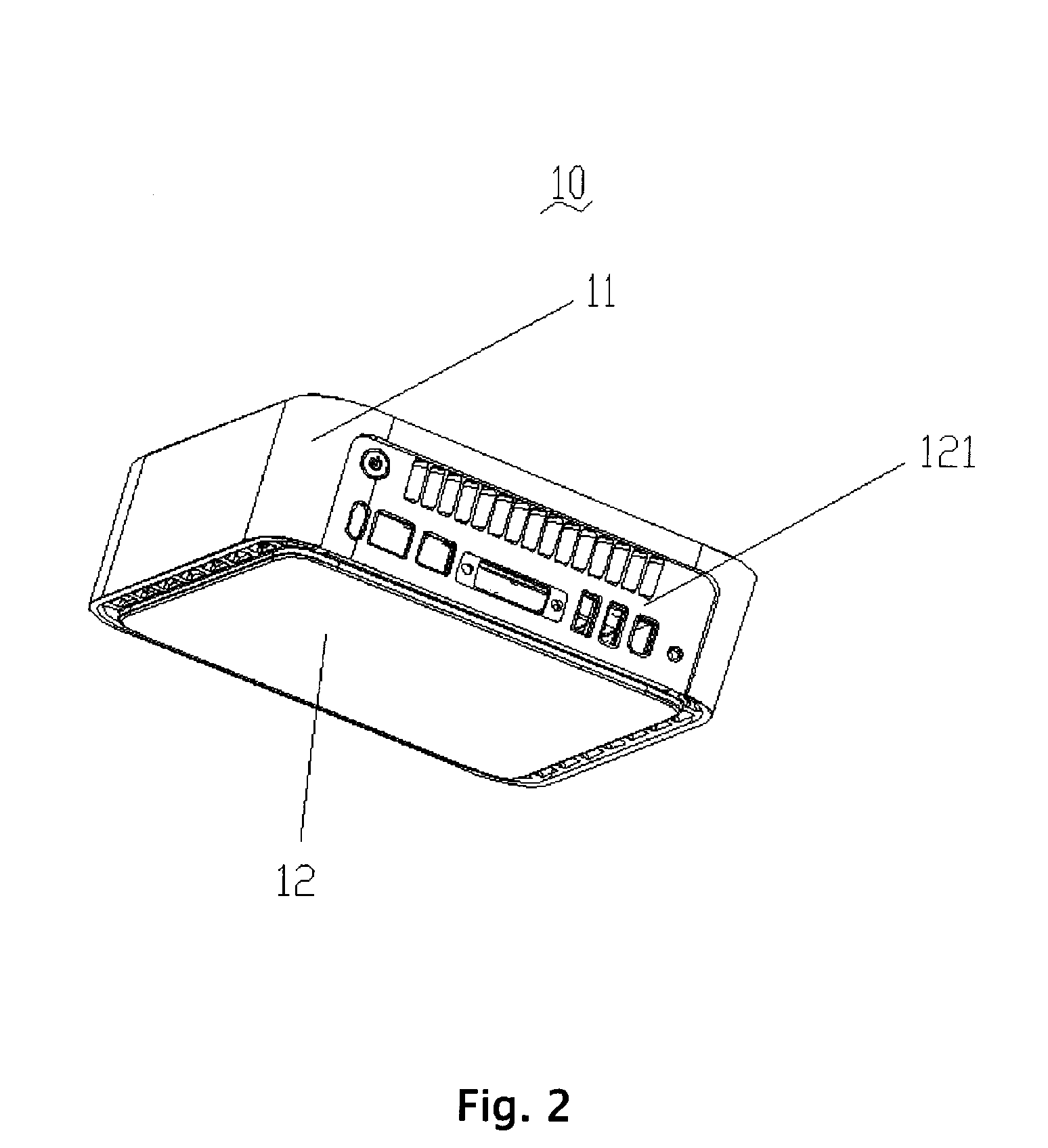

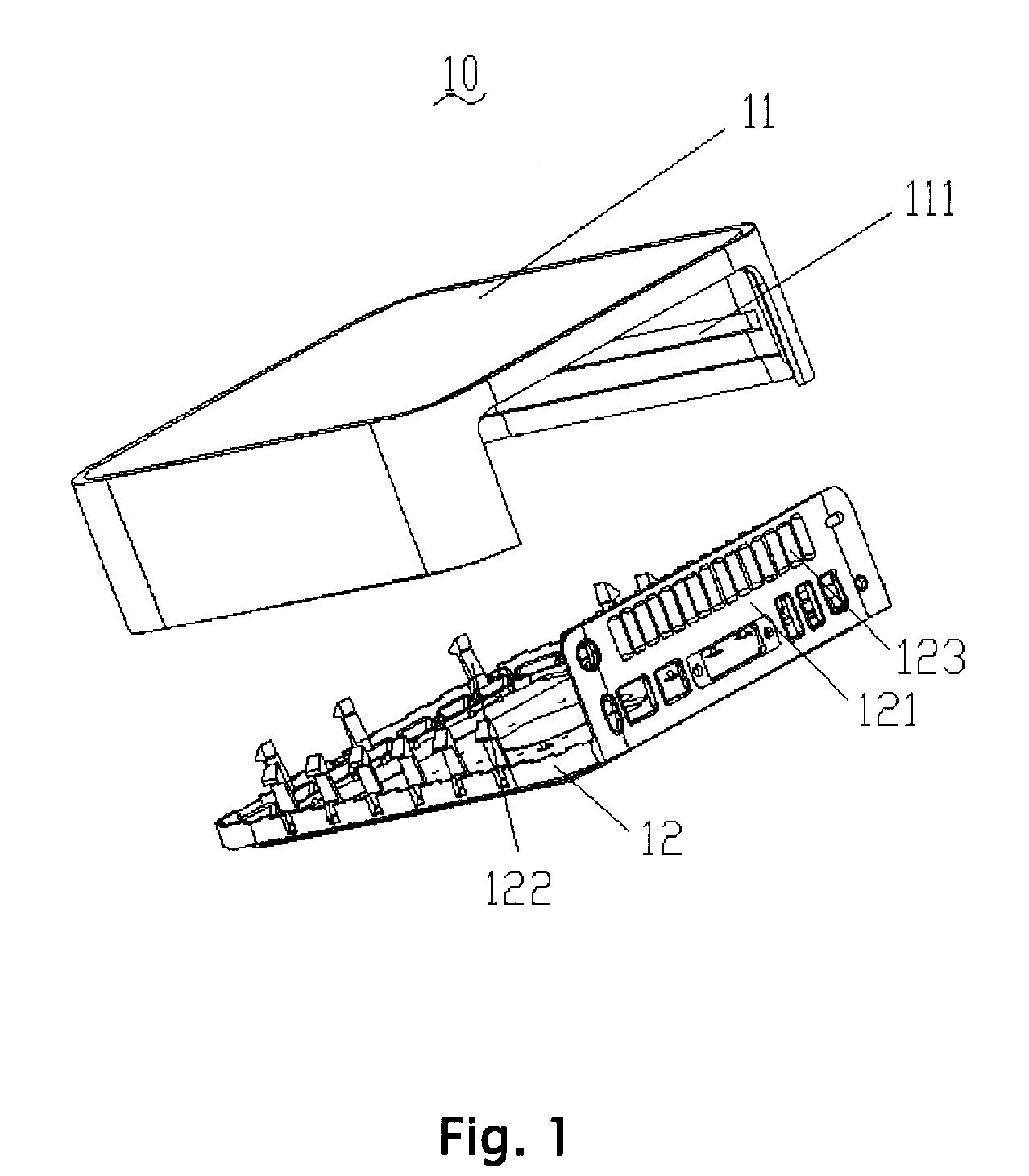

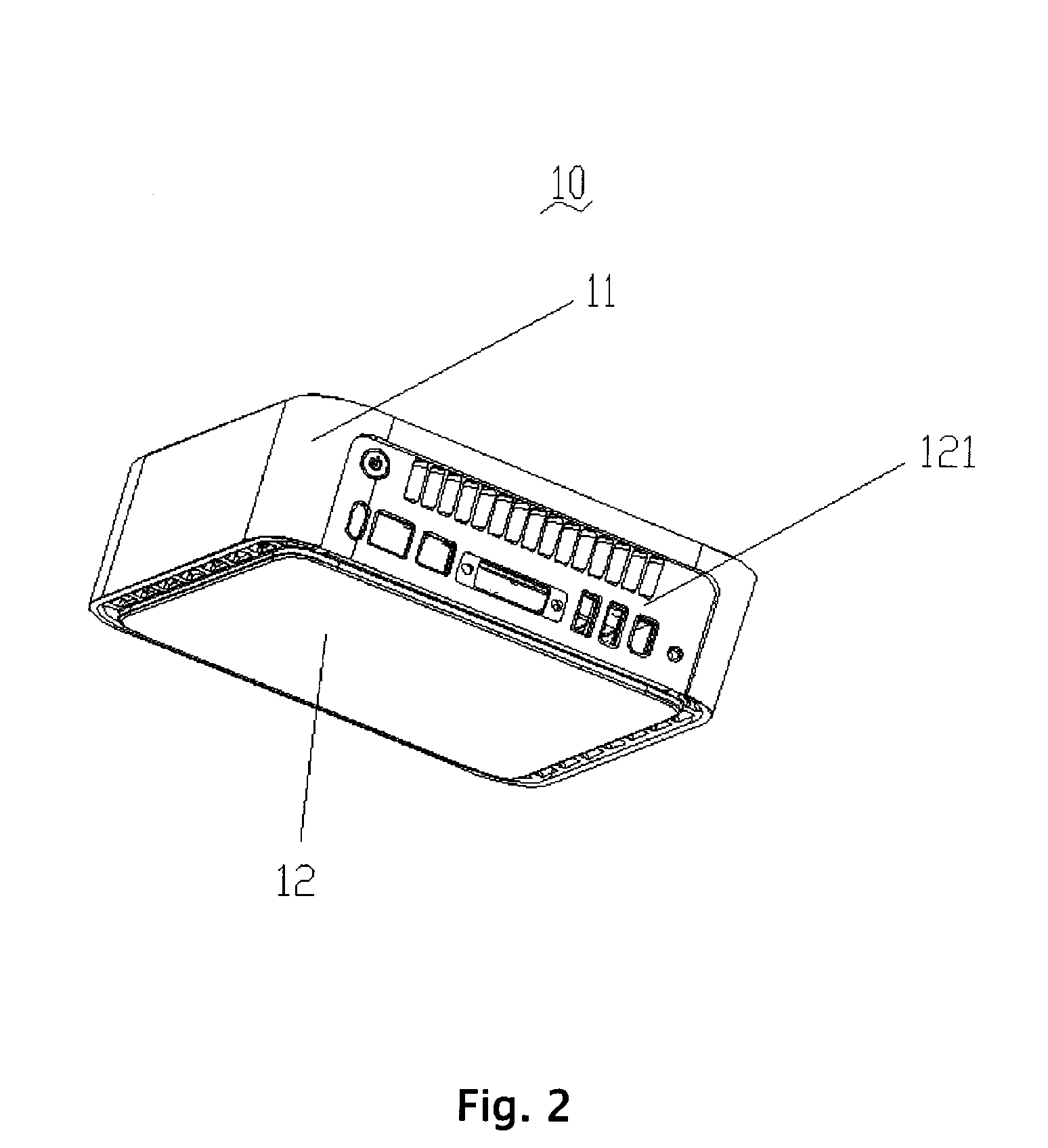

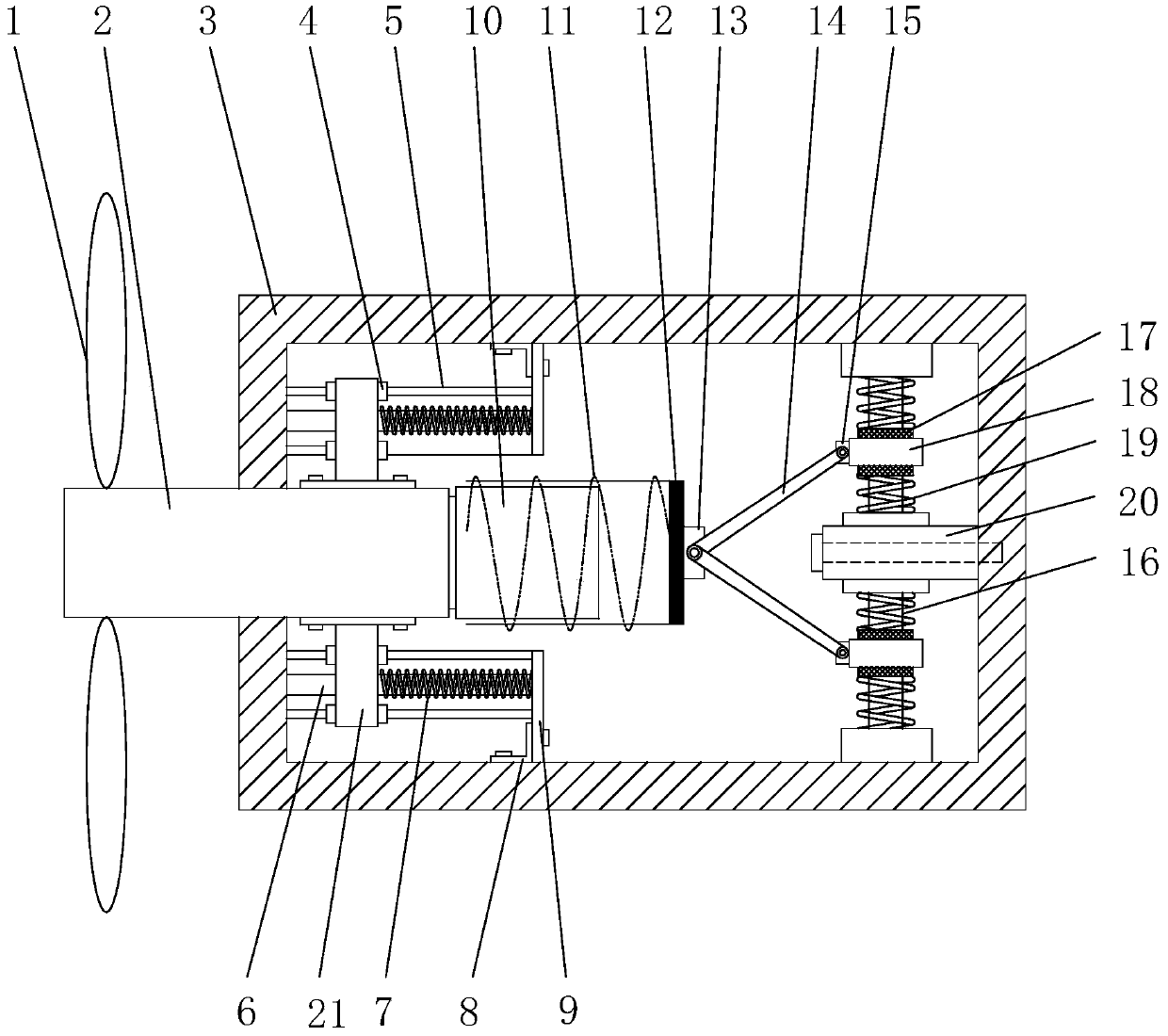

Press-fit assembling device

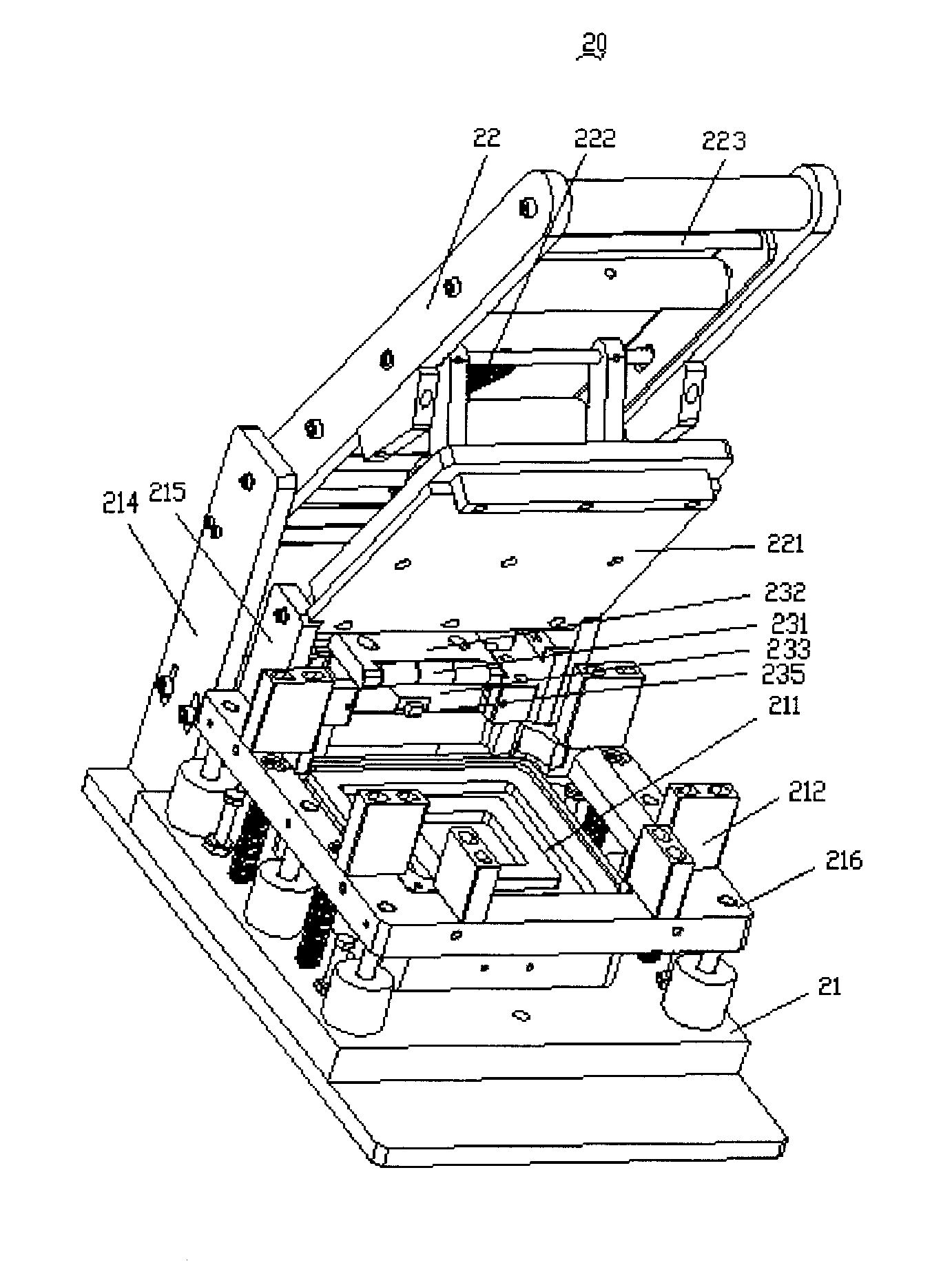

InactiveUS20060248711A1Slow movement speedIncrease ratingsEngagement/disengagement of coupling partsClosed casingsEngineeringElectrical and Electronics engineering

A press-fit assembling device is provided to assemble enclosures including a chassis and a housing. The press-fit assembling device includes a base and a driver. The base includes a platform defined with a locating channel to secure the chassis located thereon. The driver is pivotally connected to one end of the base and is formed with a press plate. The press plate moves down under the control of the driver to press fit the housing and the chassis located on the platform. A plurality of stop blocks is arranged on the platform, and is used to prevent damage to the enclosure. The driver is also formed with a linkage set. When the press plate is lifted up, an aft part of the linkage set abuts against a cross rod and keeps the press plate from dropping down while the operator positions the chassis and housing for press-fitting.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

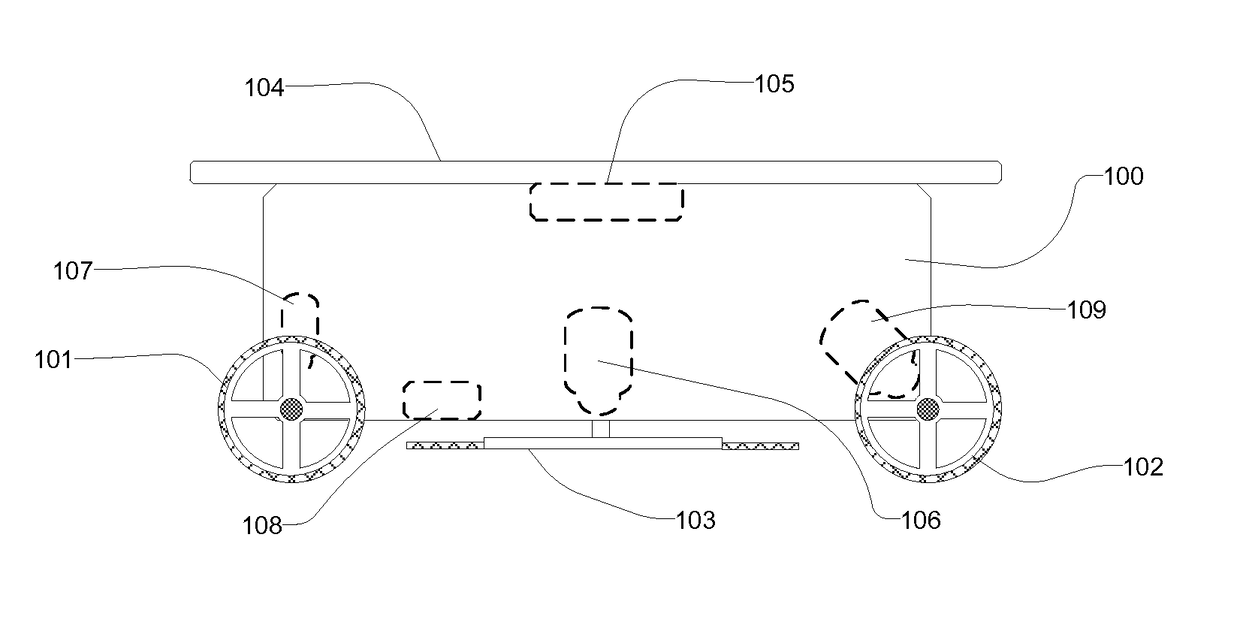

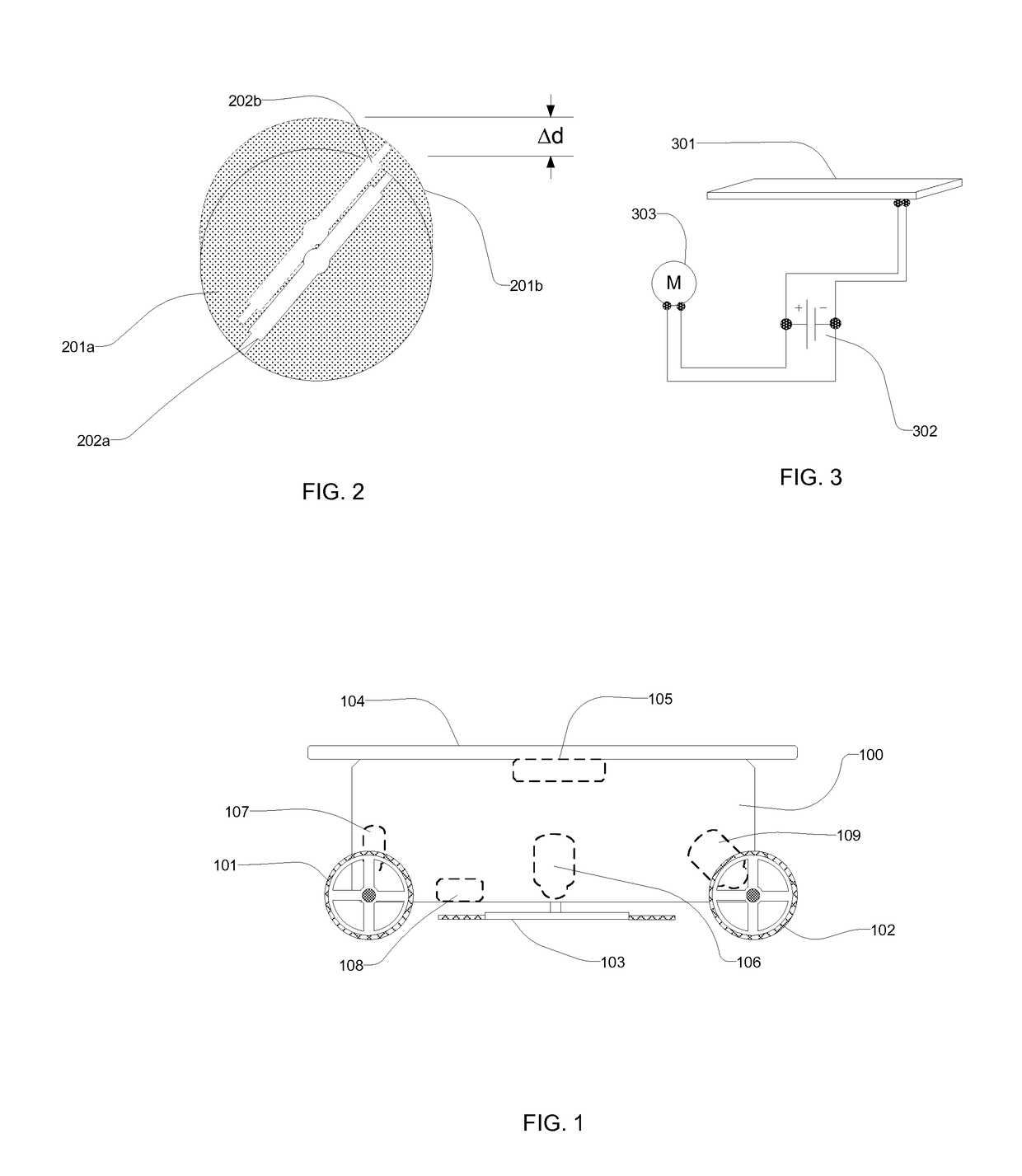

Crawl speed lawnmower operable using solar energy as sole power source

InactiveUS20170240041A1Manufacturing cost be increaseLower costAuxillary drivesRenewable energy machinesMowerSpecific time

Owner:JONG CHIOU MUH

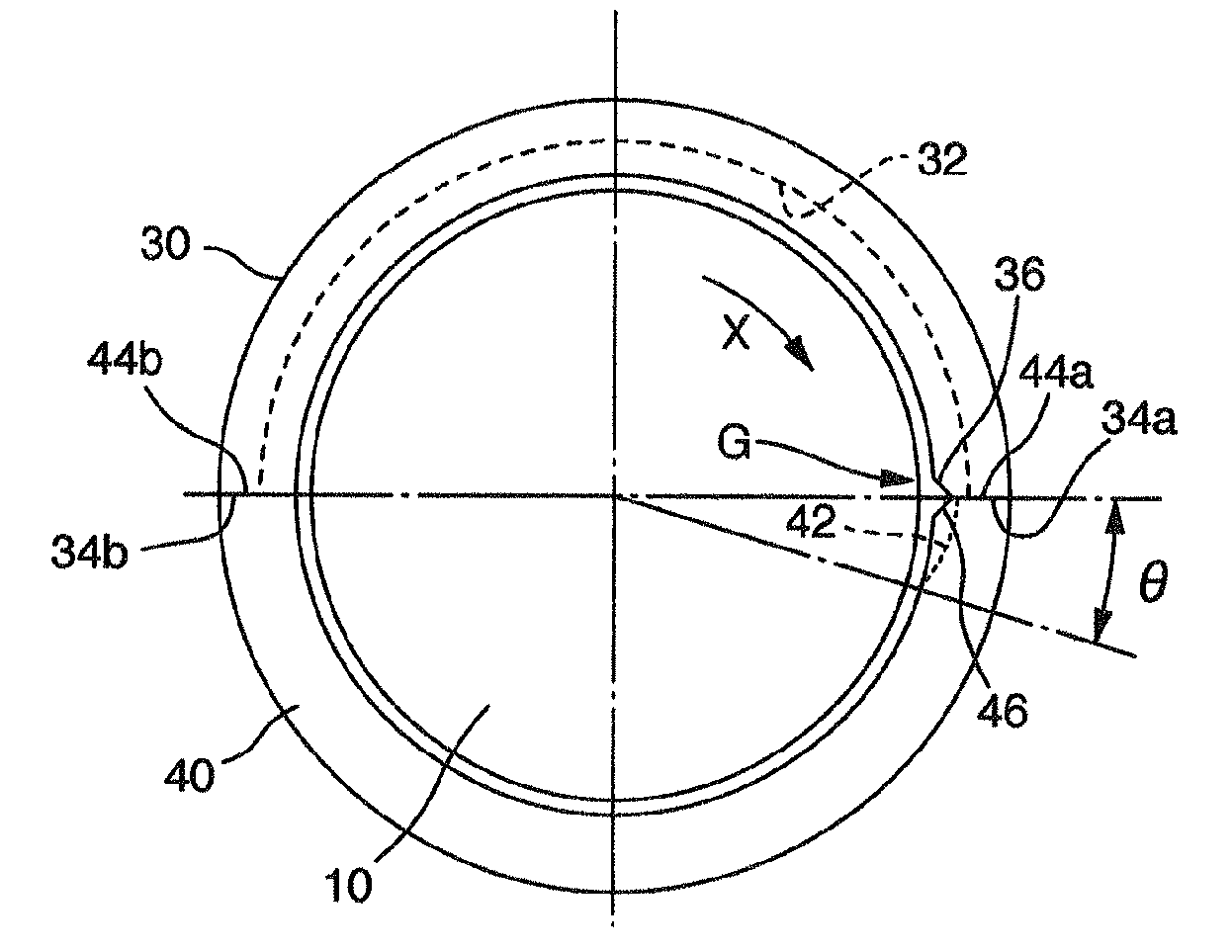

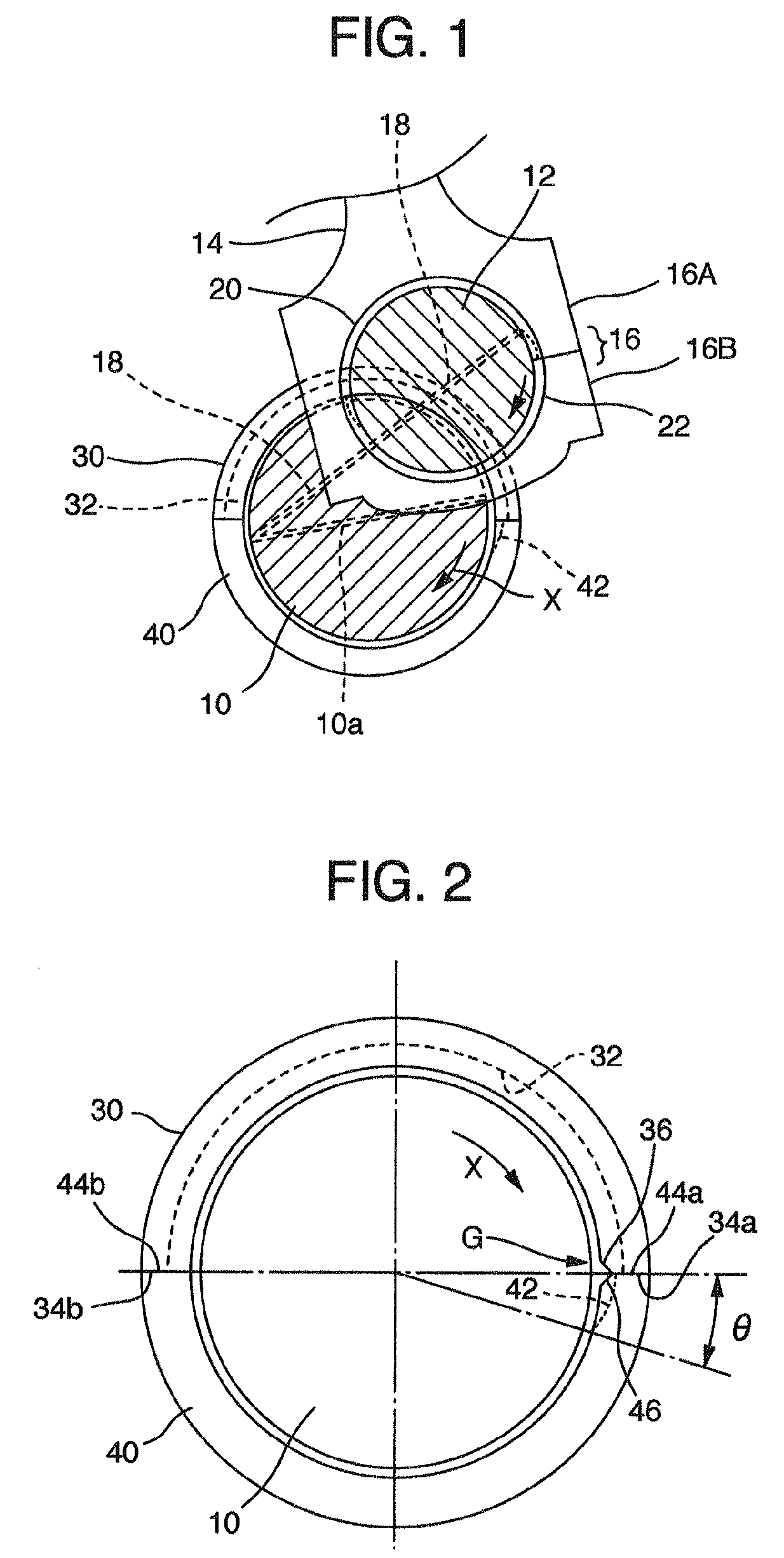

Sliding bearing for internal combustion engines

ActiveUS20110243486A1Improve the lubrication effectEasy accessCrankshaft bearingsBearing componentsCombustionEngineering

Disclosed is a sliding bearing for supporting a crankshaft journal portion of an internal combustion engine. One of the semi-cylindrical bearings is provided with a circumferential oil groove on its inner circumferential surface, and has two circumferential ends. The circumferential oil groove has an open groove end at at least one of the two circumferential ends, which one is a first circumferential end being directed to the same direction as a relative rotational direction of a crankshaft. The other semi-cylindrical bearing is provided with at least one circumferential local groove on its inner circumferential surface, and has two circumferential ends. The circumferential local groove has an open groove end at one of the two circumferential ends, which one is a second circumferential end being directed to the opposite direction to the relative rotational direction of the crankshaft. The circumferential oil groove and the local circumferential groove are in fluid communication with each other. At a region of the fluid communication, a groove bottom of the local circumferential groove is deviated toward an axis of the sliding bearing from another groove bottom of the circumferential oil groove. An axial groove is formed along a contact interface between the first and second circumferential ends.

Owner:DAIDO METAL CO LTD

Press-fit assembling device

InactiveUS7214077B2Slow movement speedIncrease ratingsEngagement/disengagement of coupling partsClosed casingsEngineeringElectrical and Electronics engineering

A press-fit assembling device is provided to assemble enclosures including a chassis and a housing. The press-fit assembling device includes a base and a driver. The base includes a platform defined with a locating channel to secure the chassis located thereon. The driver is pivotally connected to one end of the base and is formed with a press plate. The press plate moves down under the control of the driver to press fit the housing and the chassis located on the platform. A plurality of stop blocks is arranged on the platform, and is used to prevent damage to the enclosure. The driver is also formed with a linkage set. When the press plate is lifted up, an aft part of the linkage set abuts against a cross rod and keeps the press plate from dropping down while the operator positions the chassis and housing for press-fitting.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method of inhibiting growth of lithium dendrites through organic compound coating

ActiveCN110581310AGrowth inhibitionEffective adjustment distributionSecondary cells servicing/maintenanceOrganic electrolytesSimple Organic CompoundsIon distribution

The invention discloses a method of inhibiting growth of lithium dendrites through organic compound coating. The method comprises the following specific steps of: coating an organic compound on the surface of metal lithium to serve as a protective layer, and directly applying the protective layer to a battery negative electrode. On one hand, the organic compound is rich in Lewis acid functional groups and can interact with anions in an electrolyte, the moving speed of the anions is decreased, and the influence of space charges on the surface of a negative electrode is relieved, so that dendrite growth is inhibited, and on the other hand, lithium ion distribution can be adjusted due to rich lithium-philic elements, the phenomenon that the local lithium ion concentration is too high is reduced, and dendrite growth is inhibited. Therefore, when the coated lithium metal is used in the lithium battery, the coulombic efficiency and the discharge capacity of the battery can be effectively improved, the polarization of the lithium battery is reduced, and the service life of the lithium secondary battery is prolonged.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

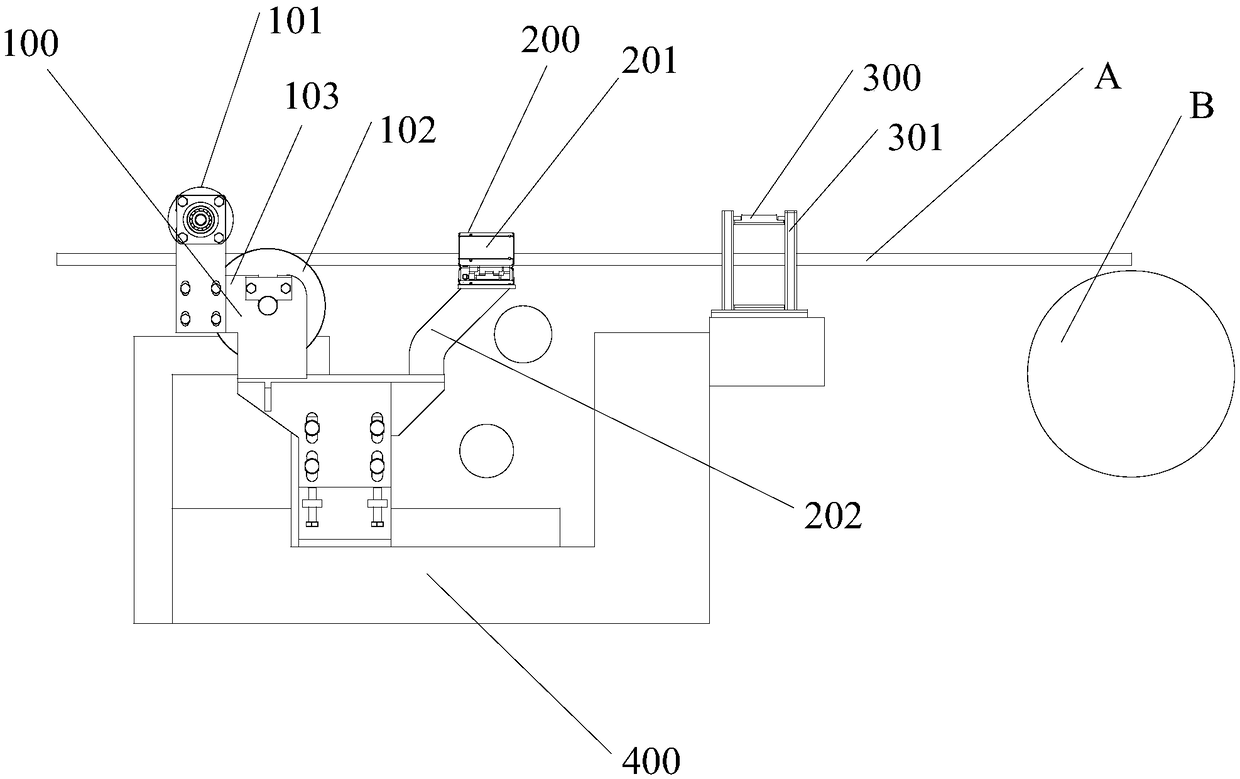

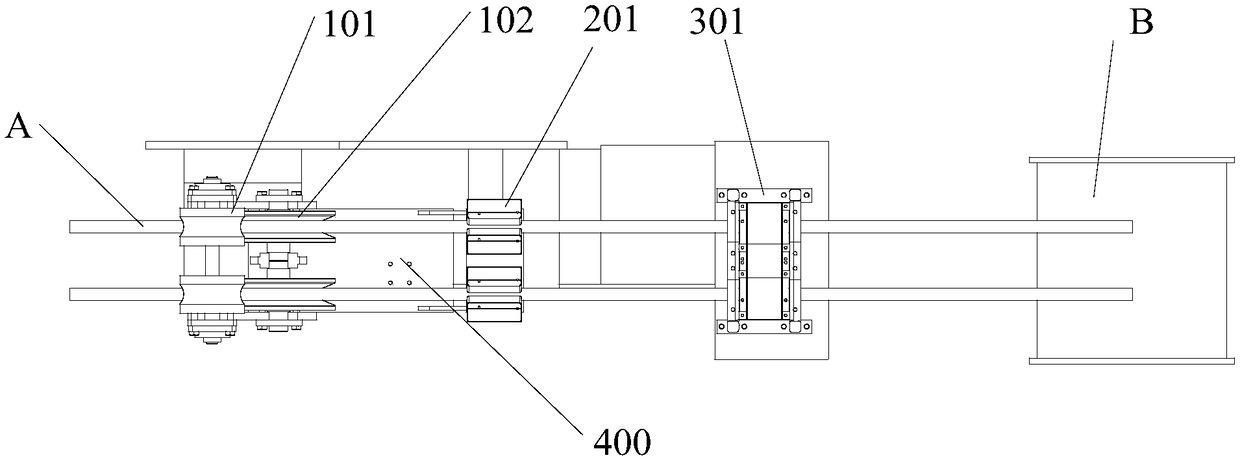

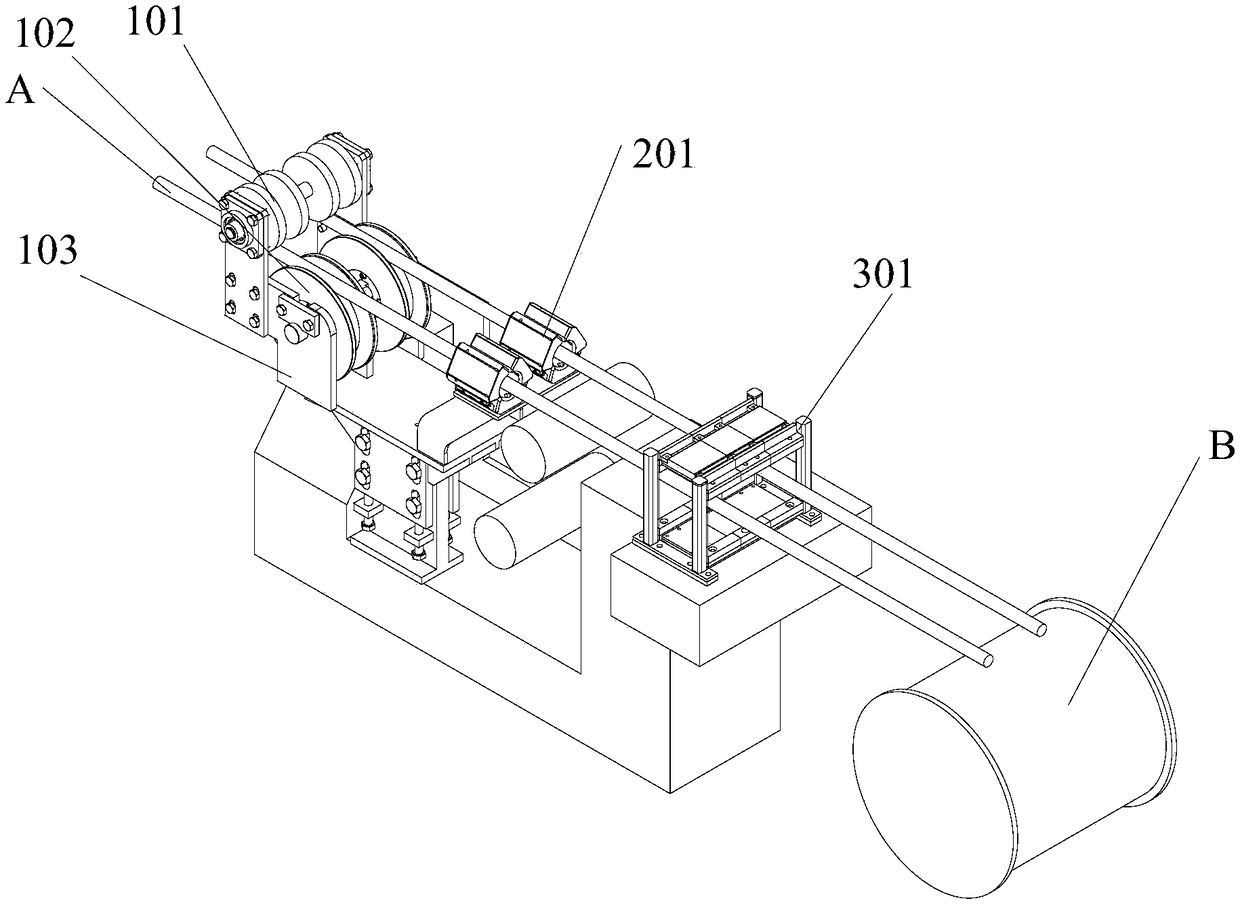

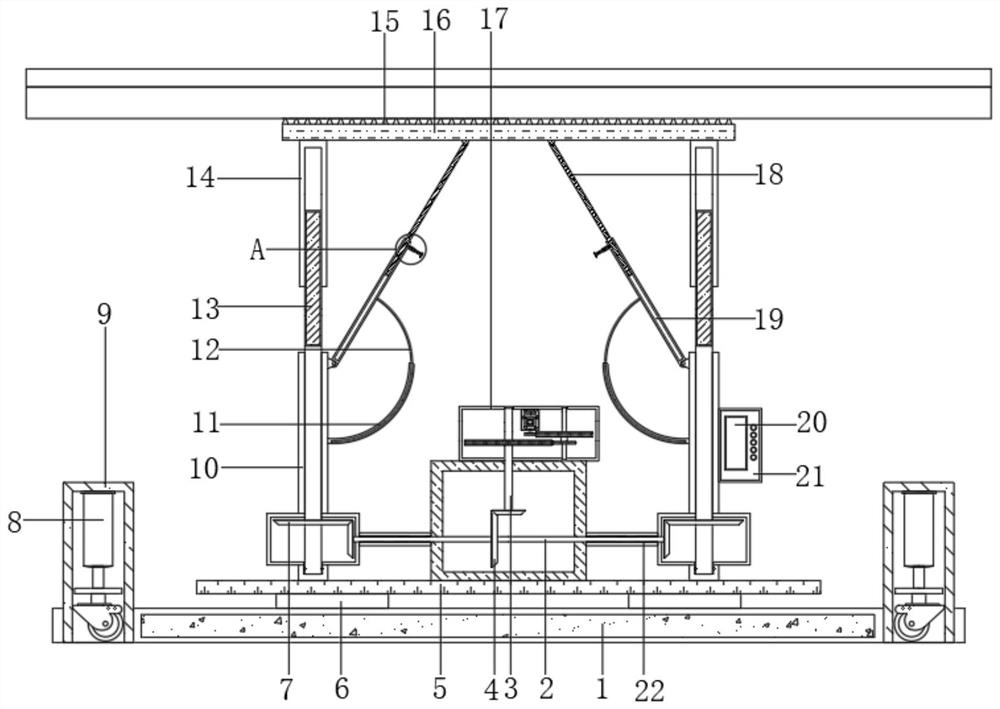

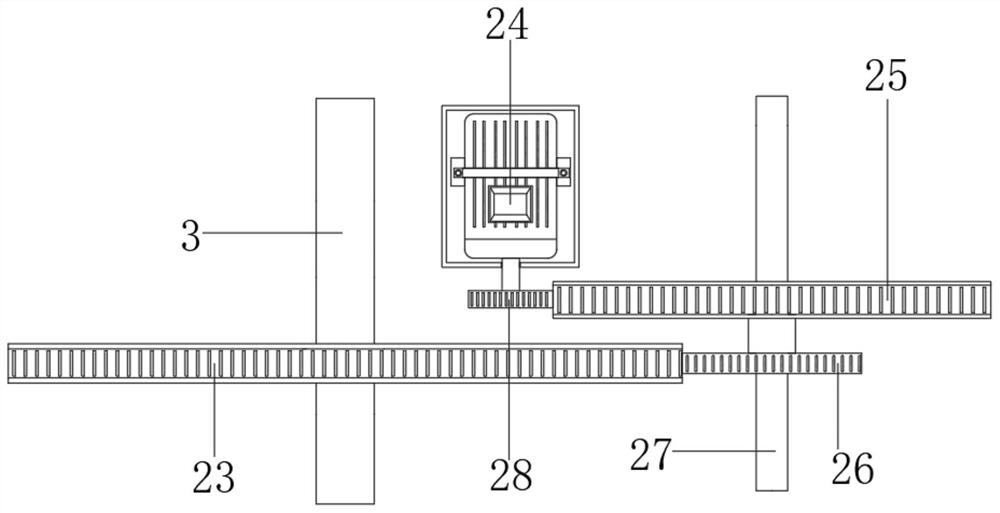

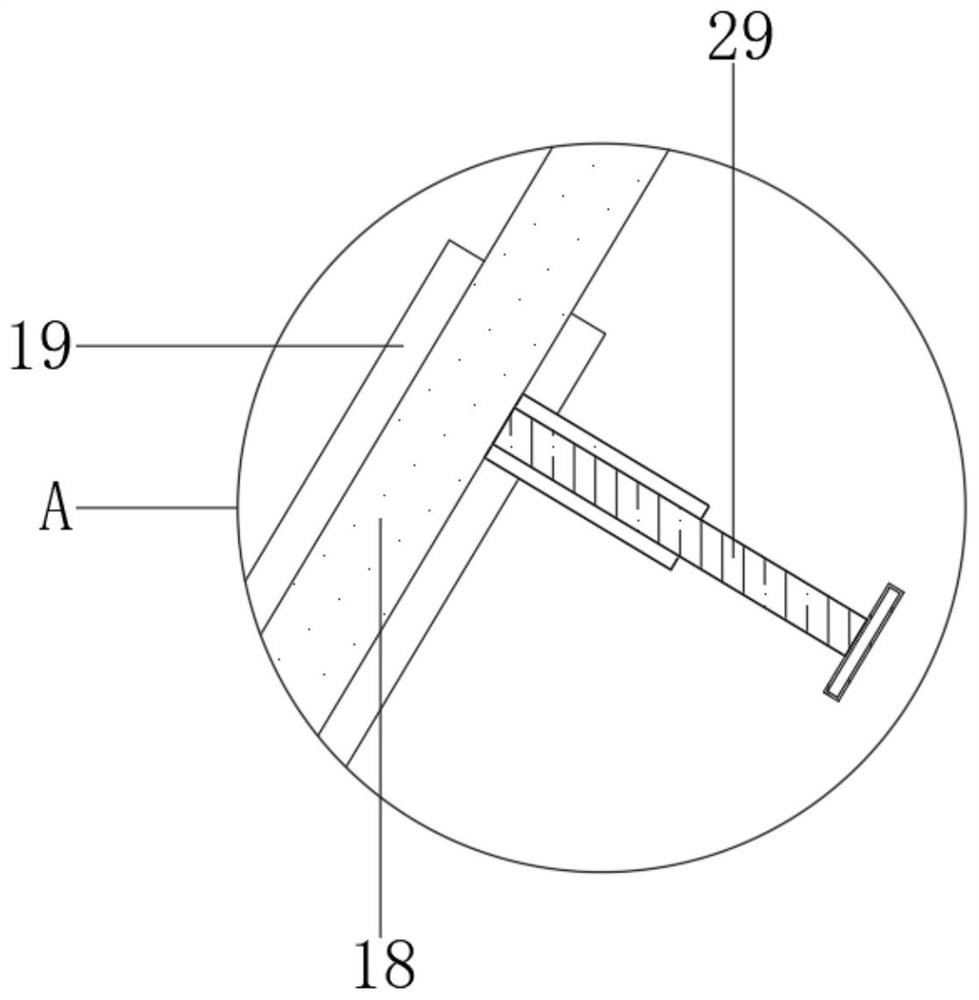

Steel wire rope detection steady-state limiting device

InactiveCN109001295AGuaranteed accuracyReduce vibrationMaterial magnetic variablesEngineeringSteady state

The invention discloses a steel wire rope detection steady-state limiting device. The steel wire rope detection steady-state limiting device comprises clamping devices, a detection device, a fixed loading device and a mounting platform, wherein the clamping devices and the detection device are both fixedly connected to the surface of the mounting platform; the fixed loading device is fixedly connected behind the mounting platform; each group of the clamping devices is provided with an upper clamping wheel, a lower clamping wheel and a supporting arm; the detection device comprises at least onedetection sensor and a detection support arm; and the detection device comprises a weak magnetic detection sensor, a strong magnetic detection sensor, an all-magnetic detection sensor and other various electromagnetic detection sensors. By virtue of the steel wire rope detection steady-state limiting device, the accuracy of the steel wire rope detection data is guaranteed, and damage to equipmentcaused by strong vibration of the steel wire rope is avoided.

Owner:LUO YANG WIRE ROPE INSPECTION TECH CO LTD

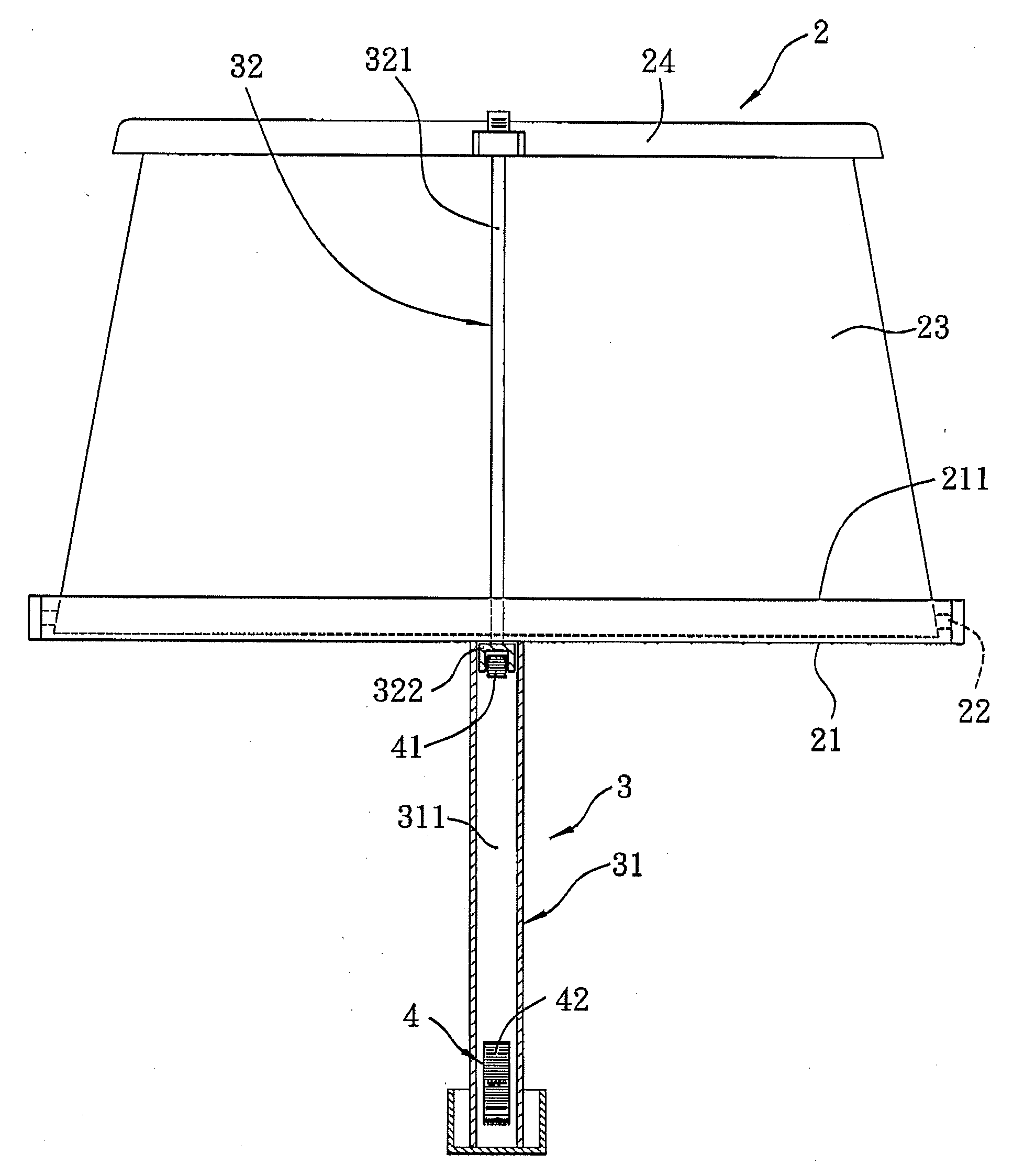

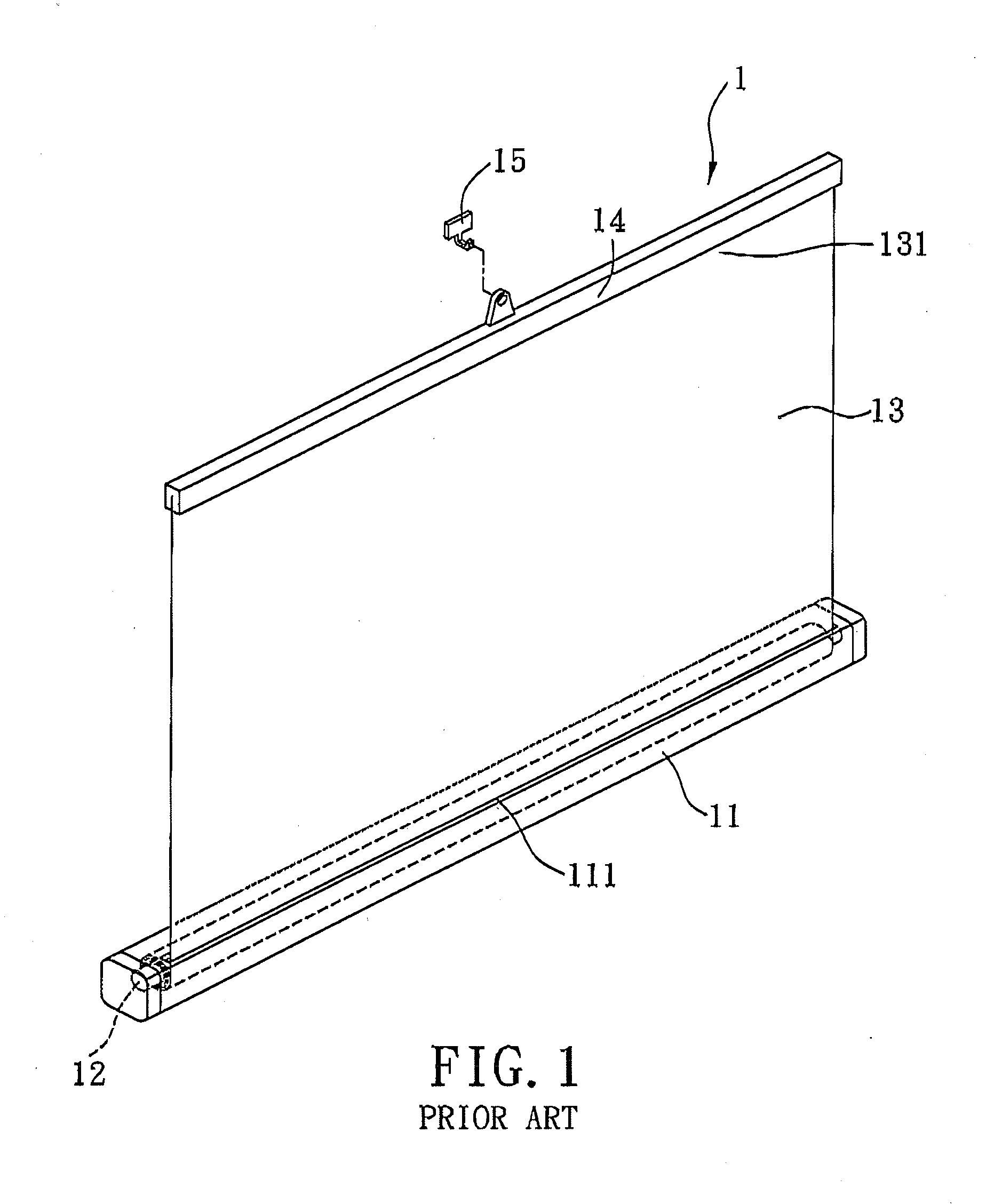

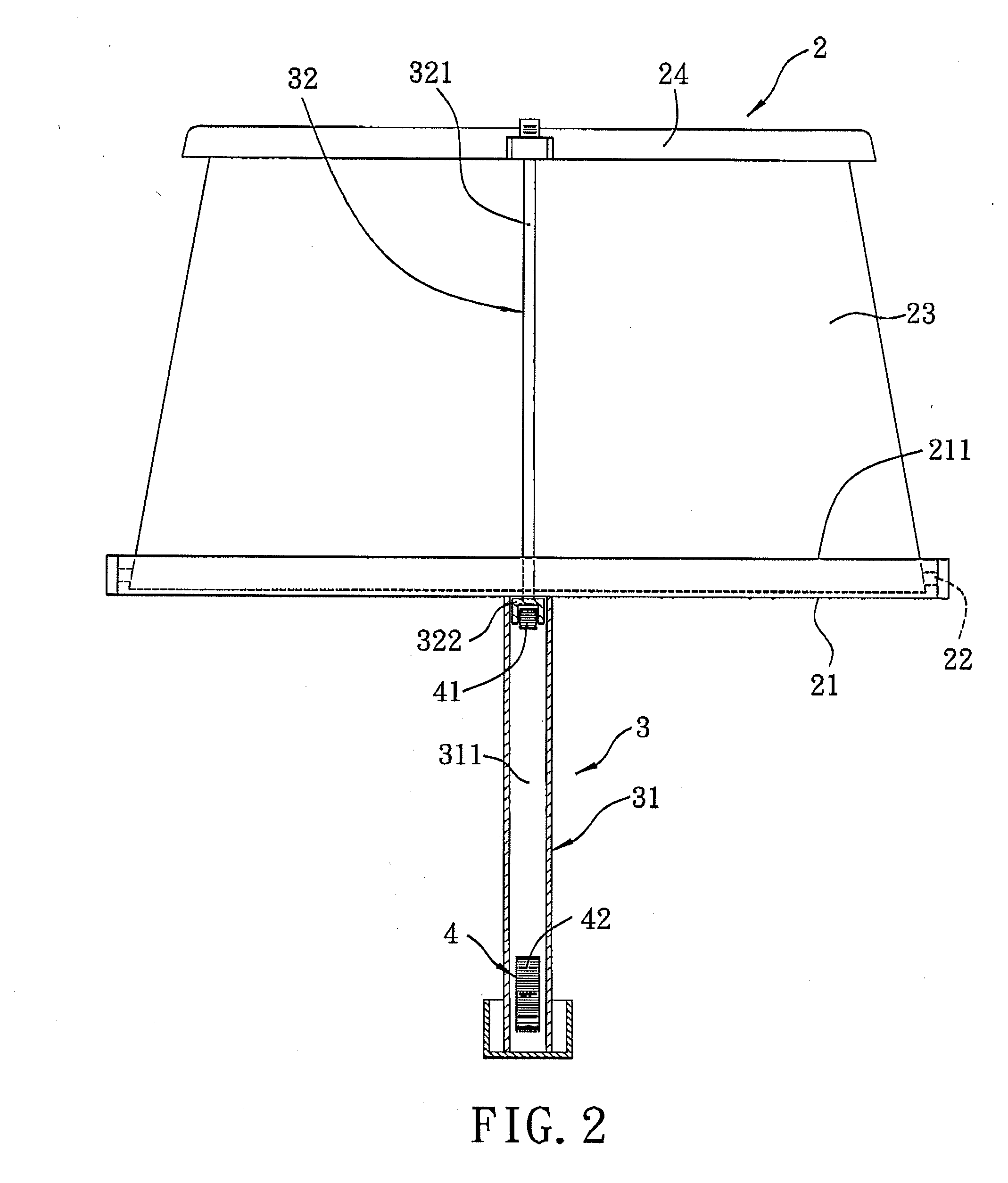

Sunshade Assembly Having a Buffer Unit

InactiveUS20120193934A1Prevent production of noise and vibrationReduce wind speedWindowsAntiglare equipmentWind speedMechanical engineering

A sunshade assembly includes a housing having a top opening, a winding shaft mounted rotatably in the housing, a sunshade cloth wound around the winding shaft, a pull rod connected to one end of the sunshade cloth and disposed external to the top opening, and a guide unit including a tubular casing mounted below the housing, and a guide rod extending downward from the pull rod and slidable in the tubular casing. A buffer unit includes a driven member mounted to the guide rod, and a buffer mounted to the tubular casing. When the sunshade cloth is moved by the winding shaft to a wound position from a stretched position, the guide rod is moved downward along with the pull rod until the driven member contacts the buffer, thereby retarding a downward movement speed of the guide rod to reduce a winding speed of the sunshade cloth.

Owner:MACAUTO IND CO LTD

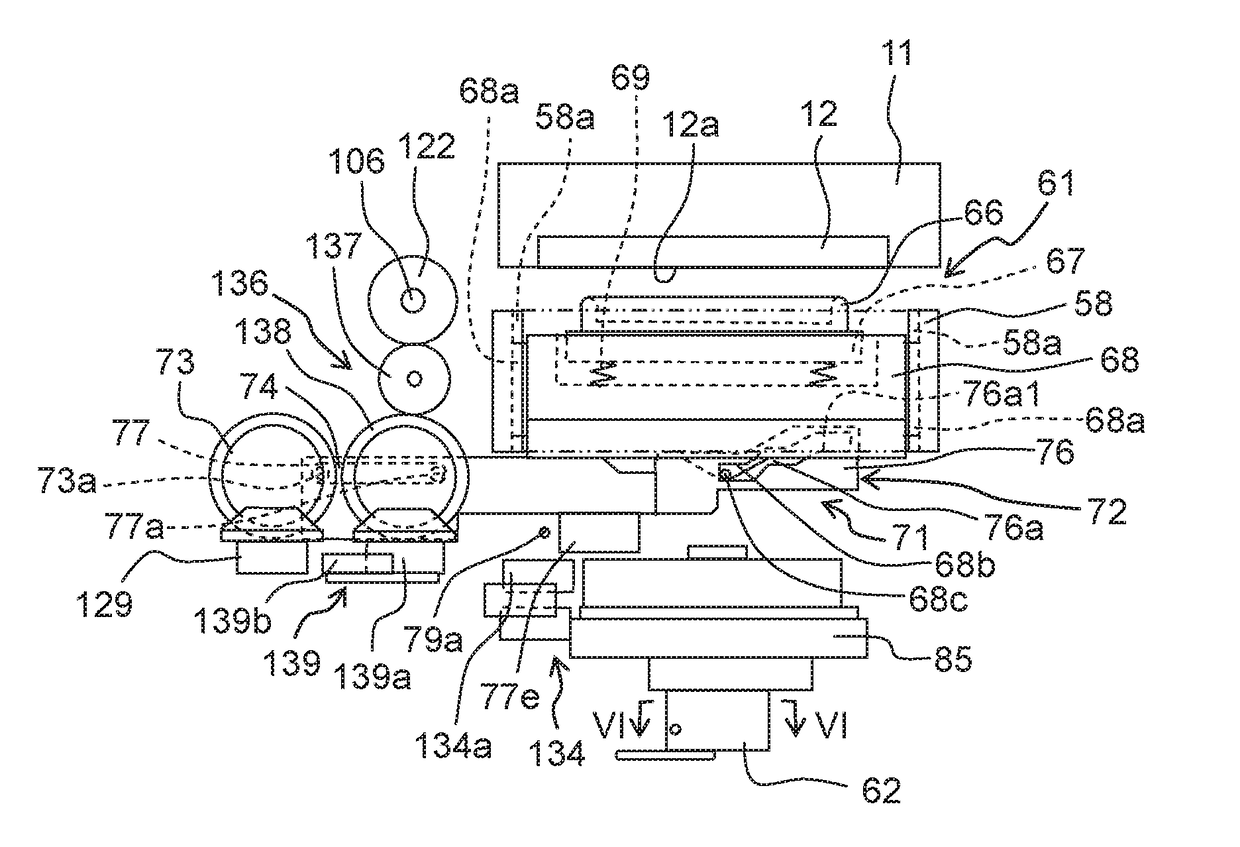

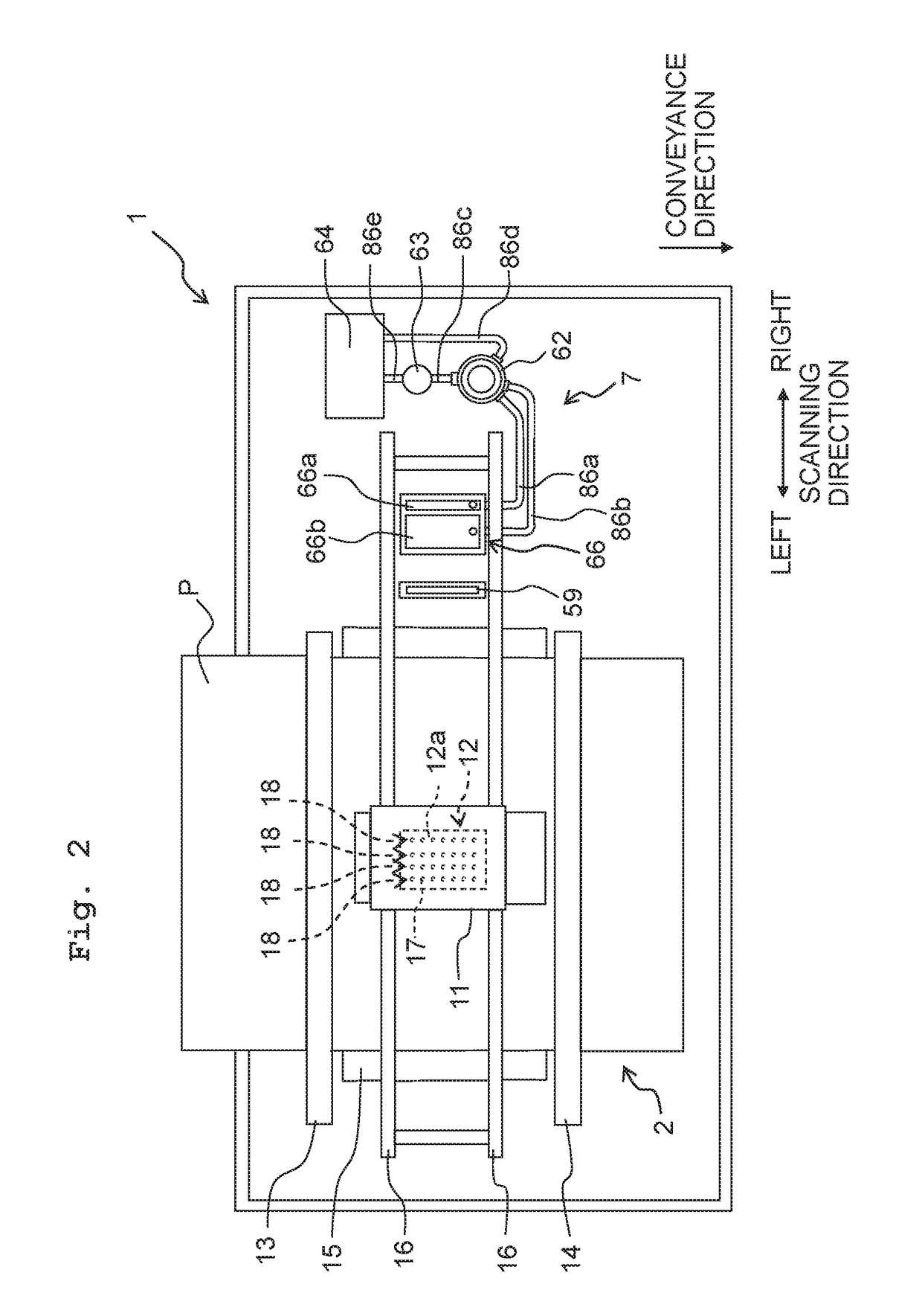

Liquid jetting apparatus

A liquid jetting apparatus includes: a head unit including nozzles; a cap which covers the nozzles in a state of being in contact with the head unit at a capping position; and a cap movement device including a cam having a slide surface and a cam follower which is slid on the slide surface. One of the cam and the cam follower is provided integrally with the cap, and the other of the cam and the cam follower is moved in a slide direction. The slide surface includes a first inclined surface inclined by a first angle relative to the slide direction and a second inclined surface inclined by a second angle greater than the first angle relative to the slide direction.

Owner:BROTHER KOGYO KK

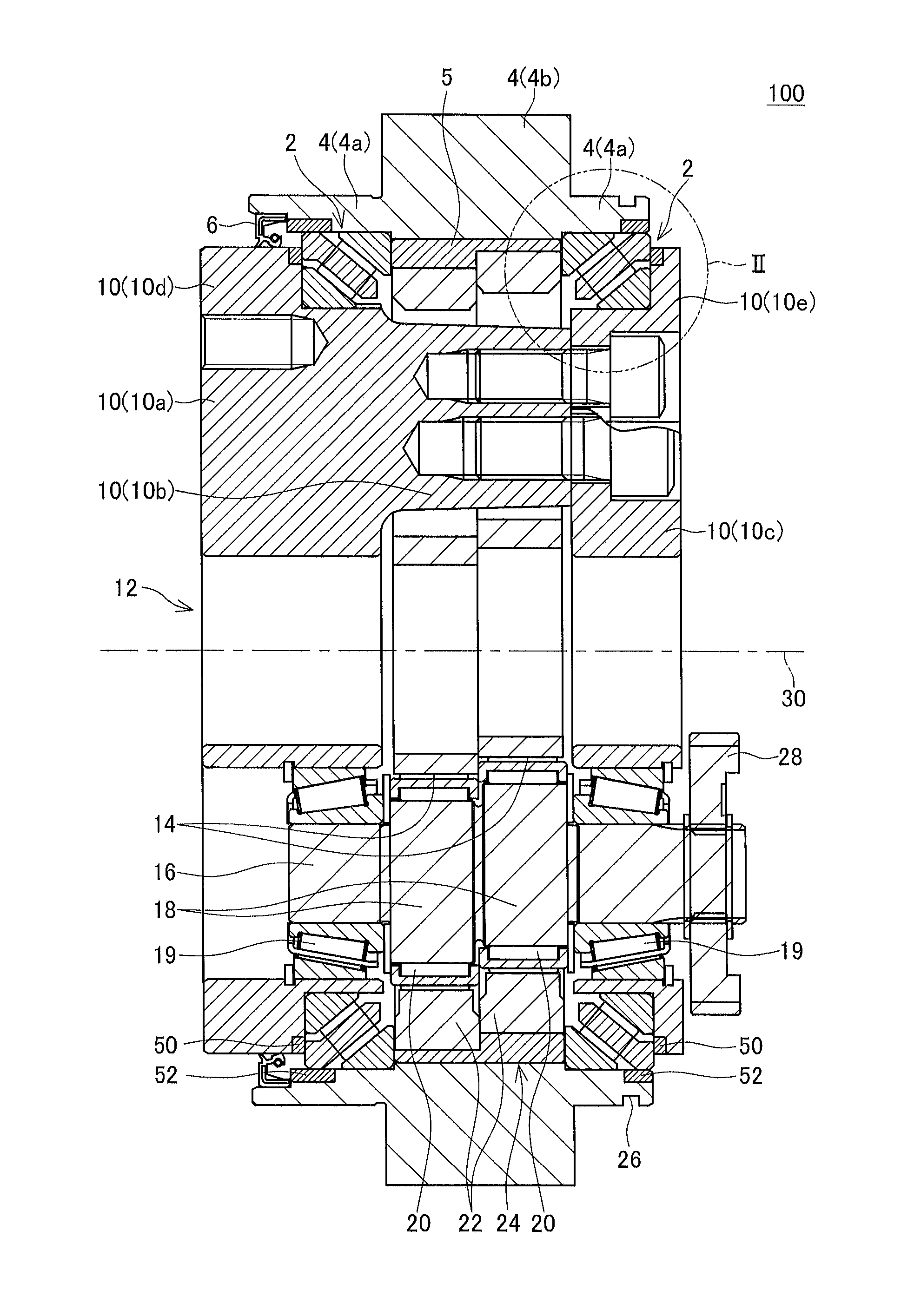

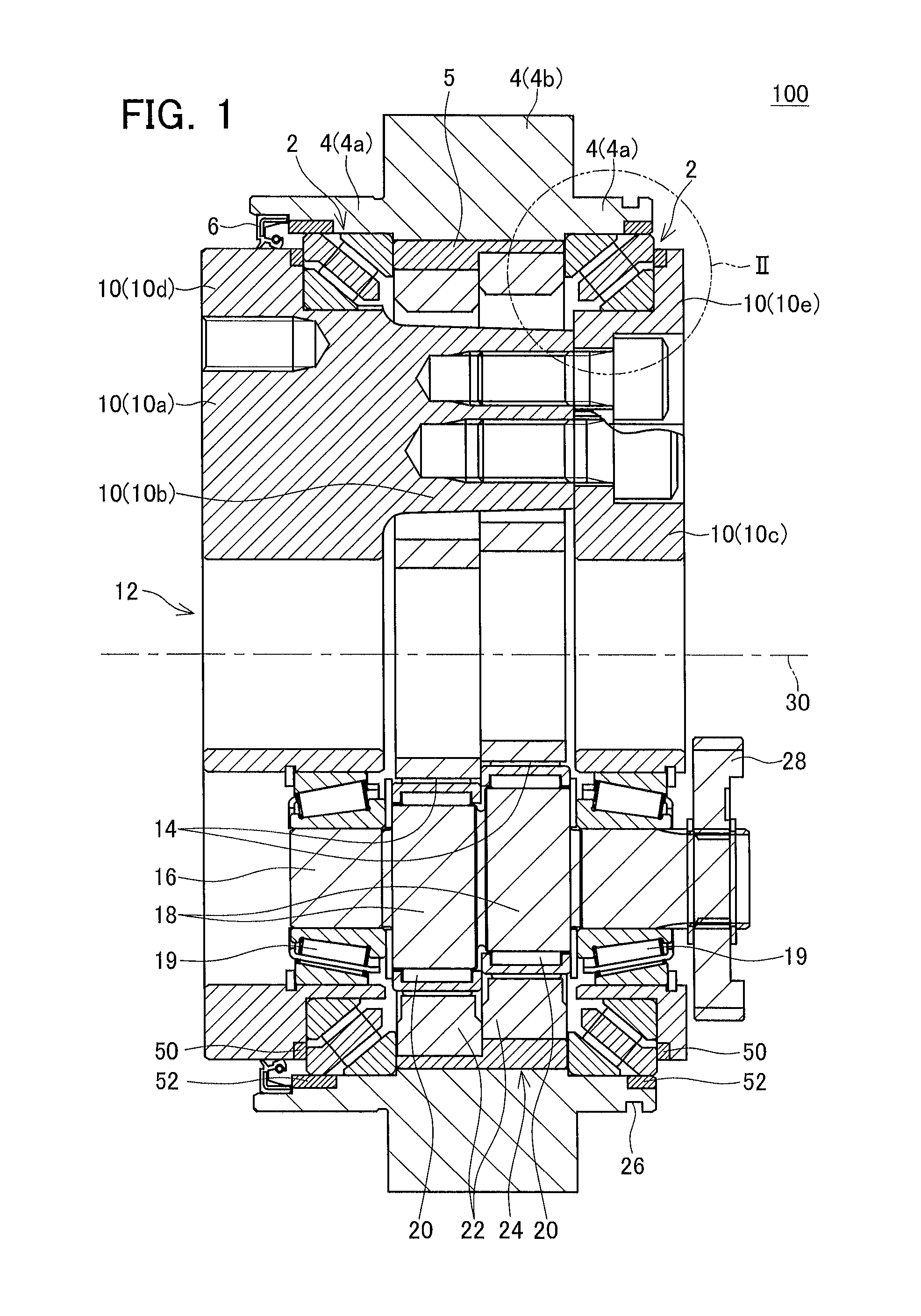

Gear transmission

ActiveUS20160047418A1Inhibit deteriorationCarrier occurs more readilyRoller bearingsToothed gearingsEngineeringGear transmission

A carrier is supported by a case via a bearing. The bearing comprises an inner race, an outer race, rollers, and a retainer. The inner race has a tapered outer peripheral surface, and is fixed to a carrier. The outer race has a tapered inner peripheral surface facing the outer peripheral surface of the inner race, and is fixed to the case. The rollers is disposed between the inner race and the outer race. An end part of the retainer having a larger diameter makes contact with the case via a first member. The larger diameter end part of the retainer makes contact with the case via a second member. By the retainer making contact with the case and the carrier via the first member and the second member, the retainer can reduce friction compared to when making direct contact with the case and the carrier.

Owner:NABLESCO CORP

Connector

ActiveUS20170025792A1Reduce impactSlow movement speedIncorrect coupling preventionCouplings bases/casesEngineeringMechanical engineering

A connector includes a detector (60) movable to a standby position and a detection position with respect to a housing (10). The detector (60) is kept at the standby position in the process of connecting two housings (10, 90) and is biased by biasing members (80) and brought to the detection position when the two housings (10, 90) are properly connected. The detector (60) includes a resilient arm (65) configured to slide on a sliding surface (32) of the housing (10) while being resiliently deformed in the process of reaching the detection position.

Owner:SUMITOMO WIRING SYST LTD

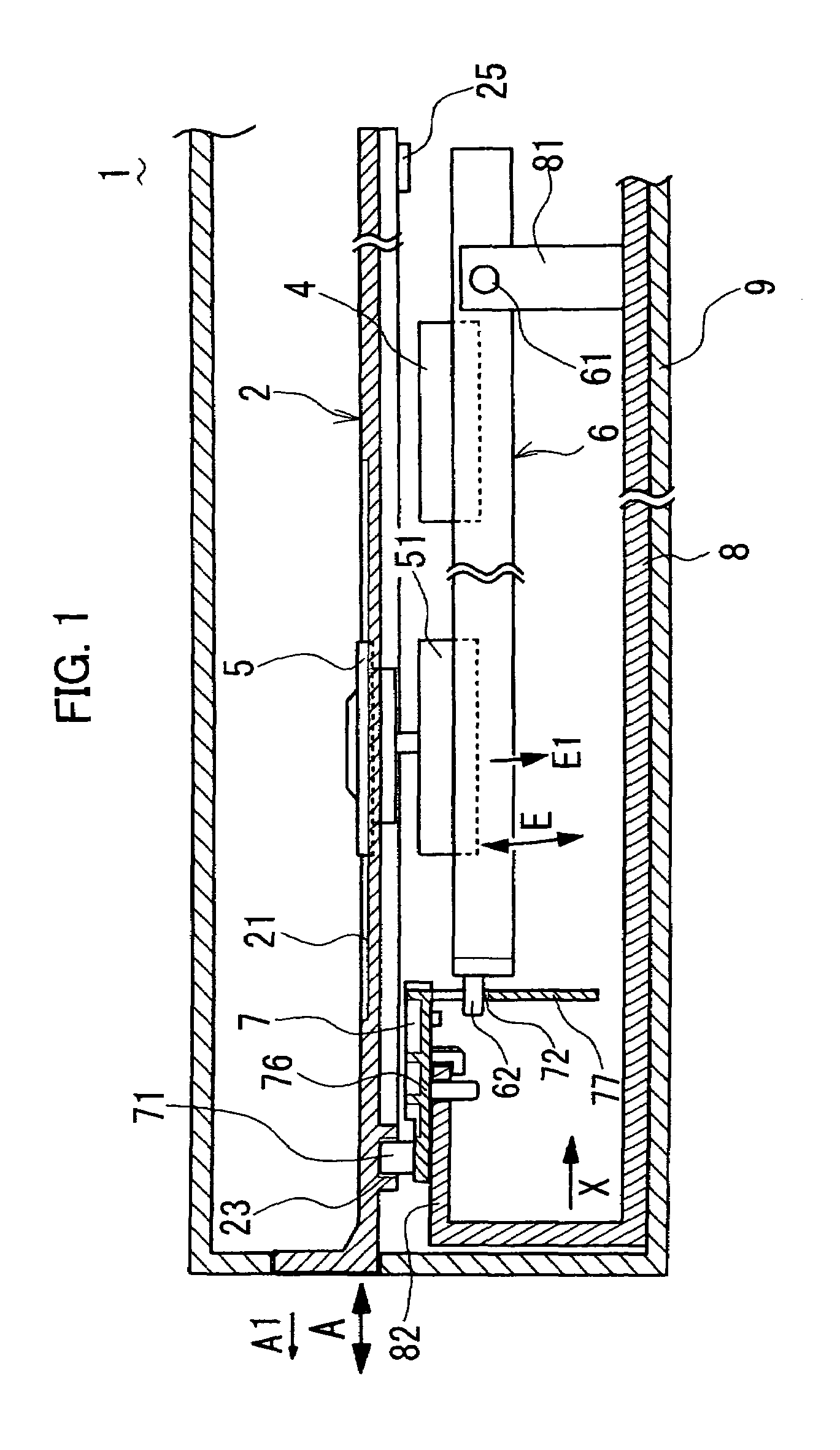

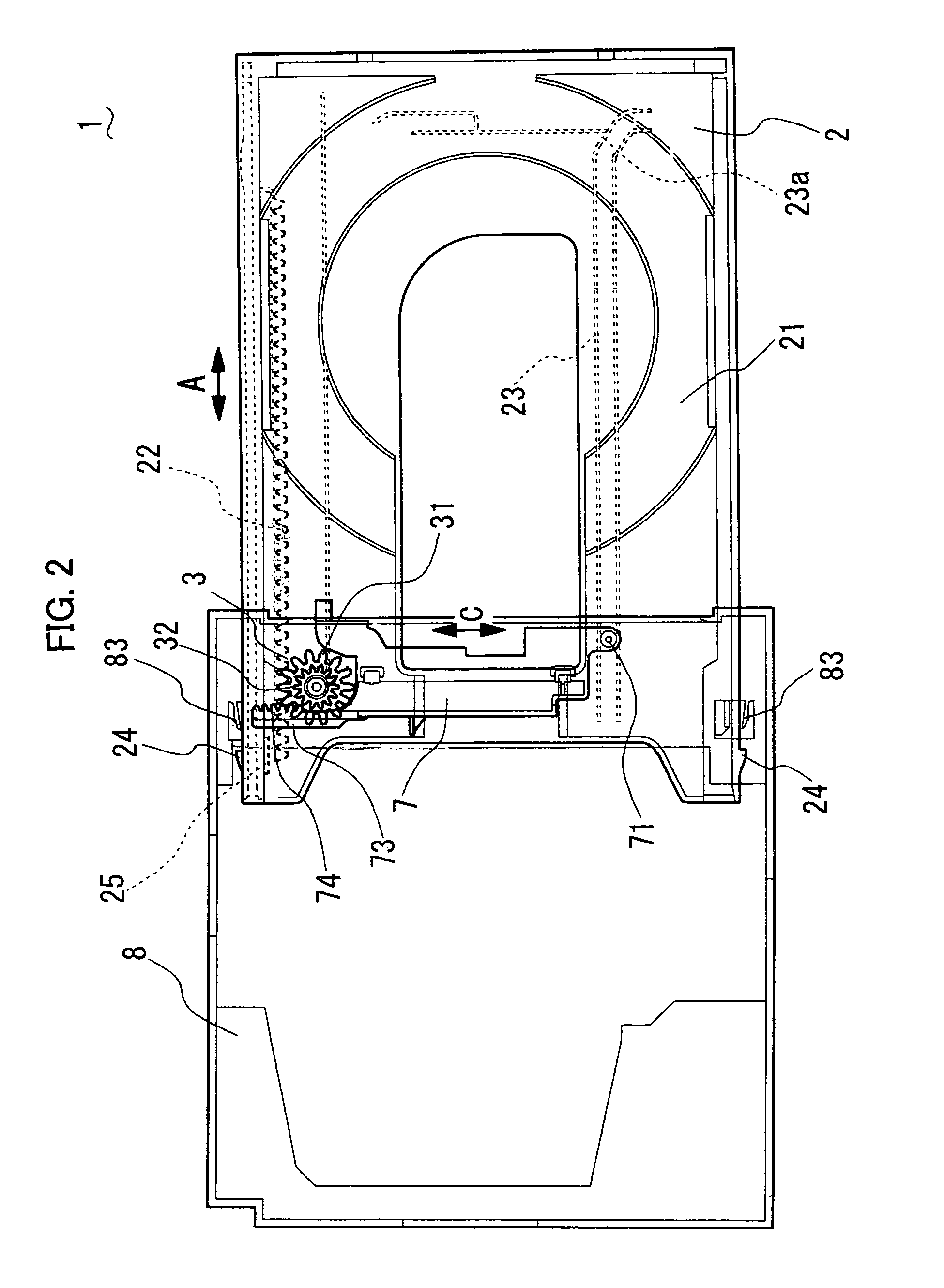

Optical disc apparatus

InactiveUS7334239B2Slow movement speedImprove wear resistanceRecord information storageRecord carrier contruction detailsEngineeringCam

Owner:FUNAI ELECTRIC CO LTD

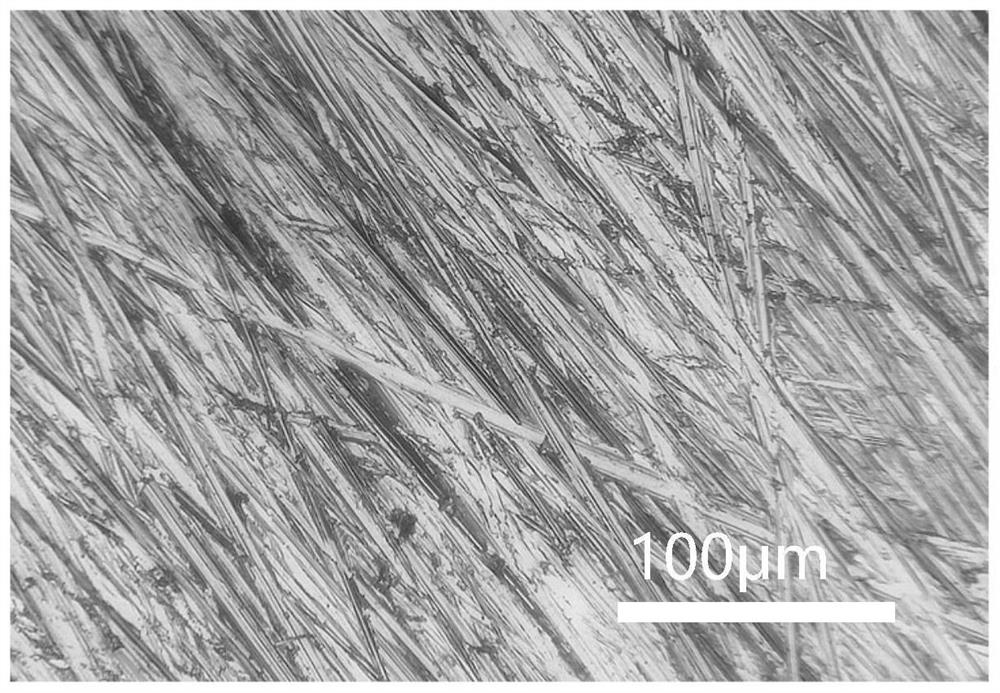

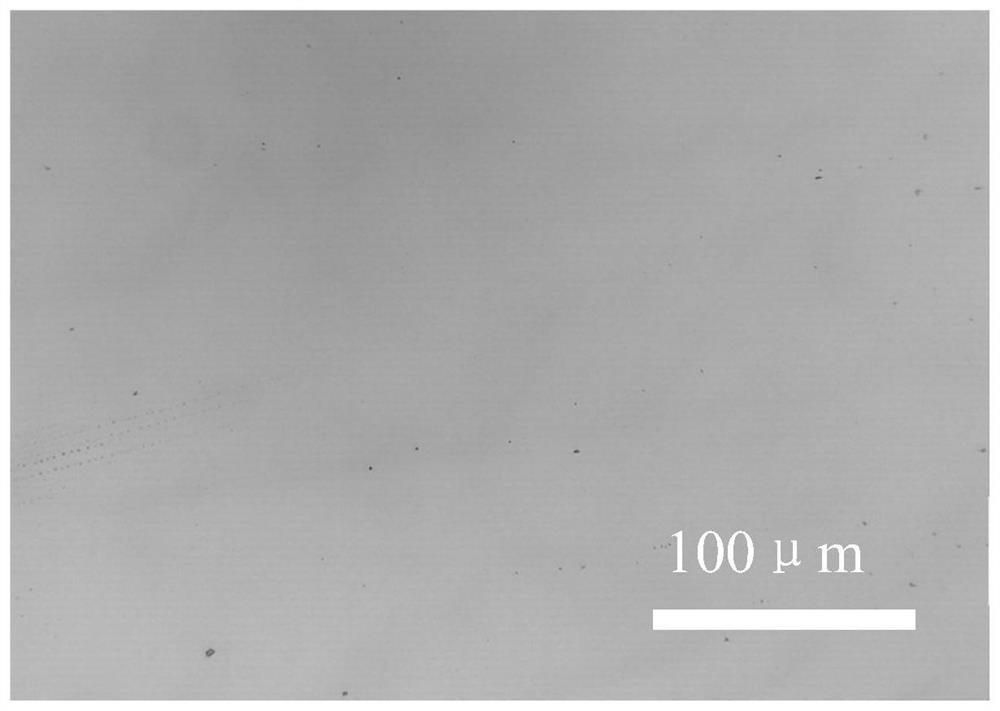

Stainless steel electrolytic polishing solution and electrolytic polishing method

InactiveCN113481585AReduce failure rateExtended service lifeElectrolysis componentsElectrolytic agentO-Phosphoric Acid

The invention relates to a stainless steel electrolytic polishing solution and an electrolytic polishing method. The stainless steel electrolytic polishing solution comprises the following components in parts by weight: 20-50 parts of sulfuric acid, 50-80 parts of phosphoric acid, 2-6 parts of a brightener, 3-7 parts of an auxiliary brightener and 2-3 parts of a conductive agent. The stainless steel electrolytic polishing method comprises the steps that stainless steel is pretreated, the stainless steel is put into the stainless steel electrolytic polishing solution to be subjected to electrolytic polishing, the pretreated stainless steel serves as an anode, a copper plate or a lead plate serves as a cathode, meanwhile, a magnetic stirring device is started to achieve dispersion of the electrolyte, the electrolytic polishing time is 1-5 minutes, and cleaning and drying are conducted. Compared with the prior art, according to the technical scheme, the cost is controllable, the electrolytic polishing time is short, the method can be carried out under the medium-low temperature condition, compared with a traditional electrolytic polishing solution, the efficiency is greatly improved, the production difficulty is reduced, and the method is widely applied to the field of stainless steel electrolytic polishing.

Owner:SHANGHAI INST OF TECH

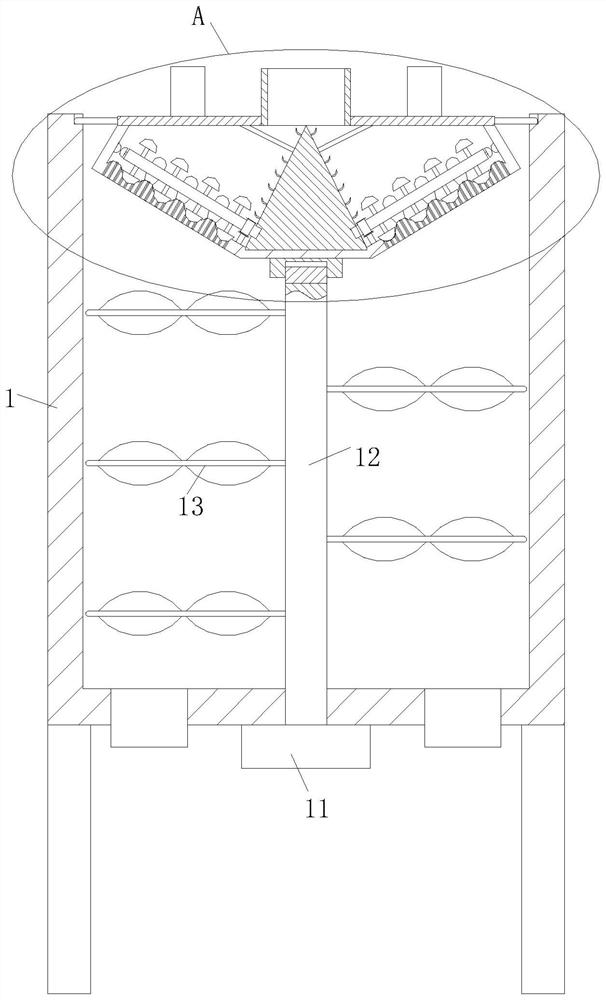

Non-stop feeding assembly for workpiece cleaning equipment

ActiveCN111086853ASmooth feedingImprove cleaning efficiencyConveyor partsControl engineeringElectric machinery

The invention relates to a non-stop feeding assembly for workpiece cleaning equipment. The non-stop feeding assembly comprises a rack, a rotating disc horizontally rotating relative to the rack, and arotating disc motor for driving the rotating disc to rotate; the rotating disc is provided with a transmission groove; a return seat and a feeding arm are further included; and a synchronous swing mechanism is arranged between a swing end and the side face of the rotating disc, a reset piece and a limiting piece are arranged between the return seat and the feeding arm, and a feeding seat is provided with a material controlling mechanism and a guiding mechanism. In the feeding process of the feeding arm, the swing end synchronously swings along with the rotating disc through the synchronous swing mechanism, the material controlling mechanism and the guiding mechanism are stably kept to be aligned with the transmission groove in the synchronous swing process of the swing end, and thus non-stop stable feeding is achieved; and after feeding is completed, the synchronous swing mechanism relieves synchronous swing of the swing end and the rotating disc, and the reset piece makes the swing end reset towards the return seat until reaching an initial position, and waits for next feeding. By adopting the non-stop feeding assembly for the workpiece cleaning equipment, the cleaning efficiencyis improved.

Owner:WENZHOU POLYTECHNIC

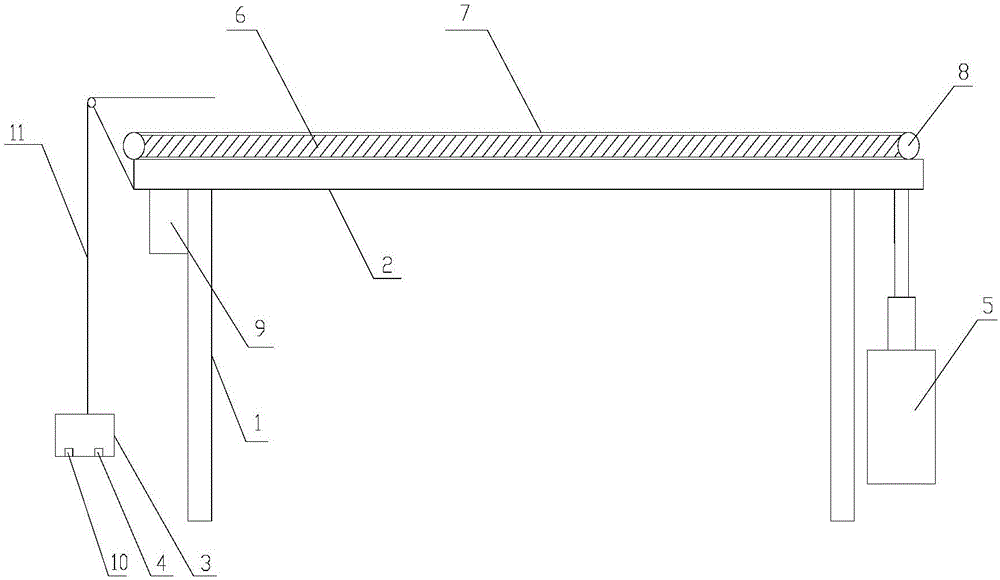

An assembled laminated plate support device

The present invention belongs to the technical field of construction, in particular to an assembly-type laminated slab support device. Aiming at the problem that most traditional laminated slab support devices have relatively simple structures and are generally supported by steel columns, and the size of the support force at different positions varies greatly, the present invention proposes The following scheme includes a base, the four corners of the top outer wall of the base are fixed with pressure sensors by screws, and the top of the pressure sensor is fixedly installed with a mounting plate, and both sides of the top of the mounting plate are welded with fixed tubes, and the fixed tubes The inner walls of each are connected with threaded columns through bearing rotation. In the present invention, through the provided storage tube and sliding rod, after the adjustment of the supporting board is completed, the sliding rod can be squeezed and locked by rotating the screw thread against the bolt, thereby effectively improving the stability of the supporting board and ensuring the stability of the laminated board. Support effect; through the mutual cooperation between the set arc rod and the arc tube, it plays a good role in limiting the storage tube and improves the stability of the storage tube.

Owner:中嘉建盛建工集团有限公司

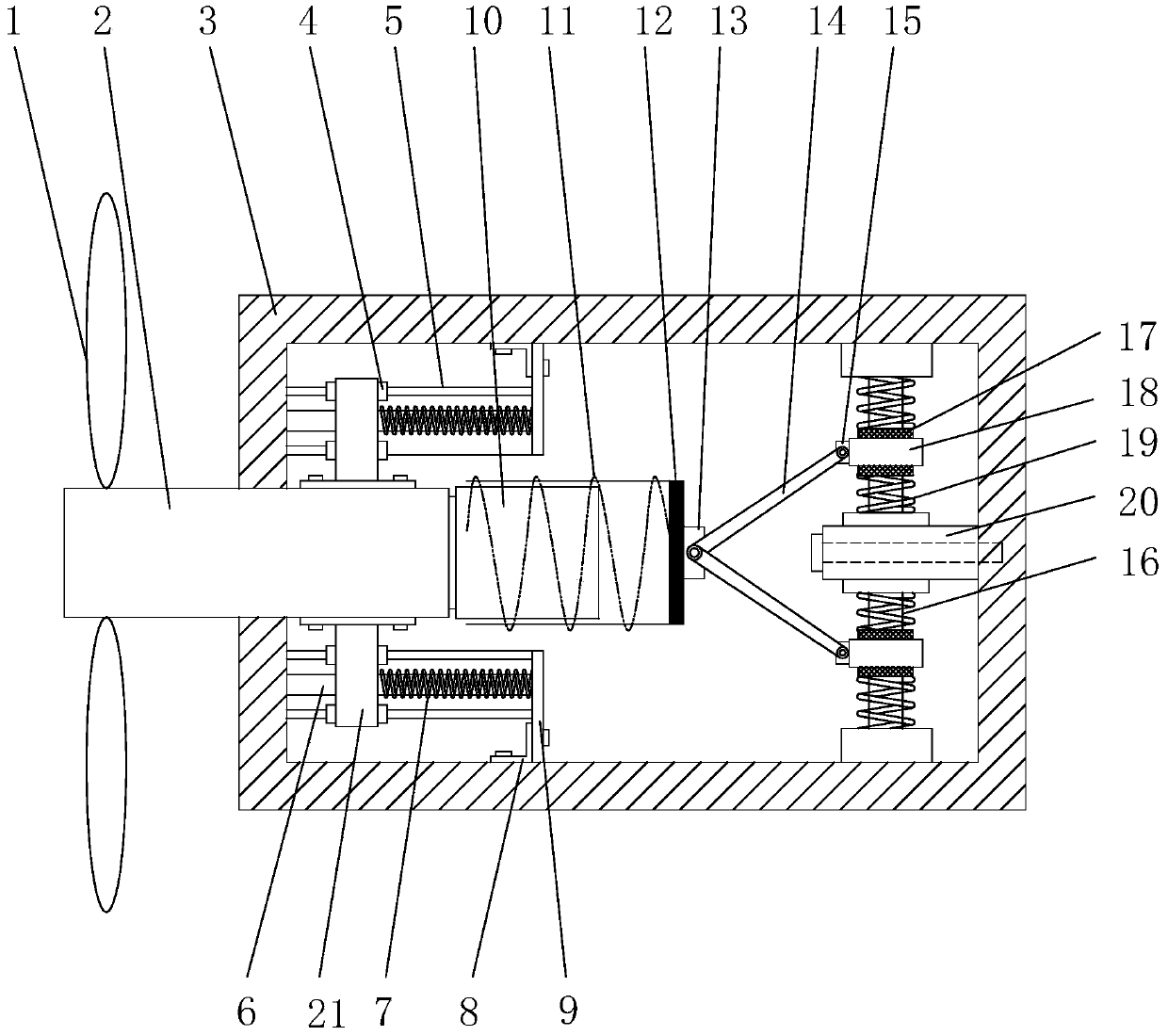

Wind turbine blade damping device capable of resisting strong wind

PendingCN111173674AExtended service lifeIncreased operating lifeNon-rotating vibration suppressionMachines/enginesTurbine bladeClassical mechanics

The invention provides a wind turbine blade damping device capable of resisting strong wind. The device comprises a connecting shaft arranged on a main shaft, blades arranged on the connecting shaft,primary damping mechanisms and a secondary damping mechanism, wherein the primary damping mechanisms and the secondary damping mechanism are used for realizing damping of the connecting shaft, the primary damping mechanisms are arranged on two sides of the connecting shaft, the secondary damping mechanism is arranged at the tail end of the connecting shaft, the primary damping mechanisms are in contact type damping, and the secondary damping mechanism is non-contact type damping. According to the device, under the effects of variable turbulent wind and strong wind, the damping protection effect can be carried out on a wind turbine blade, automatic unloading is achieved through an internal connection mode combining with a contact type and a non-contact type, the over-fatigue phenomenon of the wind turbine blade under various operating conditions is avoided, an important role of prolonging the operating life of the wind turbine blade is played, and the probability of accidents is reduced.

Owner:INNER MONGOLIA UNIV OF TECH

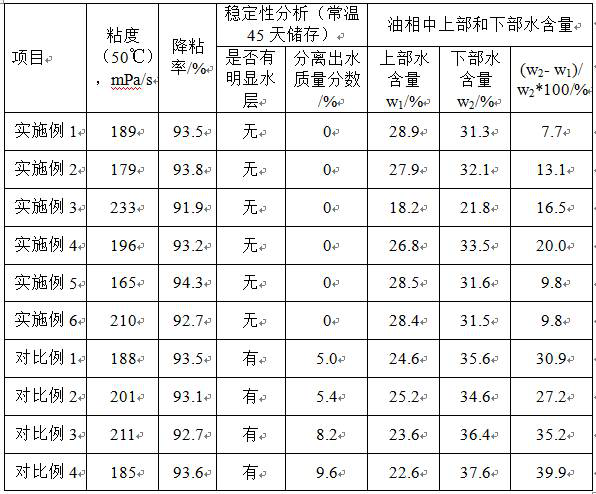

Thickened oil emulsifying viscosity reducer, emulsified thickened oil and preparation method of emulsified thickened oil

PendingCN114763481AGood miscibilitySlow movement speedPipeline systemsHydrocarbon oils refiningEmulsionActive agent

The invention provides a thick oil emulsification viscosity reducer, emulsified thick oil and a preparation method of the emulsified thick oil, and the emulsified viscosity reducer comprises the following components in parts by weight: 0.1-10 parts of a nonionic surfactant; 0.1 to 10 parts of an anionic surfactant; 0.01 to 5 parts of an auxiliary agent; and 100 to 5000 parts of water. The emulsified heavy oil comprises the emulsified viscosity reducer, thickened oil and bio-base oil. Compared with the existing emulsifying viscosity reducer, the emulsifying viscosity reducer provided by the invention has the advantage that the stability of an emulsion system is greatly improved on the premise that the emulsifying viscosity reduction effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sliding bearing for internal combustion engines

ActiveUS8672551B2Reduce lubricationIncrease the areaCrankshaft bearingsBearing componentsCombustionEngineering

A sliding bearing supporting a crankshaft journal portion of an internal combustion engine includes a semi-cylindrical bearing half provided with a circumferential oil groove on its inner surface. The circumferential oil groove has an open groove end at least at one of its two circumferential ends, one end being in the rotational direction of the crankshaft. The other cylindrical bearing half has at least one circumferential local groove on its inner circumferential surface with an open groove end at a second circumferential end directed in the opposite direction to the relative rotational direction of the crankshaft. The circumferential oil groove and the local circumferential groove are in fluid communication at a region where groove bottom of the local circumferential groove deviates toward the sliding bearing from another groove bottom of the circumferential groove. An axial groove is formed along a contact interface between the first and second circumferential ends.

Owner:DAIDO METAL CO LTD

Gear transmission

ActiveUS9689430B2Inhibit deteriorationCarrier occurs more readilyRoller bearingsToothed gearingsGear transmissionElectrical and Electronics engineering

A carrier is supported by a case via a bearing. The bearing comprises an inner race, an outer race, rollers, and a retainer. The inner race has a tapered outer peripheral surface, and is fixed to a carrier. The outer race has a tapered inner peripheral surface facing the outer peripheral surface of the inner race, and is fixed to the case. The rollers is disposed between the inner race and the outer race. An end part of the retainer having a larger diameter makes contact with the case via a first member. The larger diameter end part of the retainer makes contact with the case via a second member. By the retainer making contact with the case and the carrier via the first member and the second member, the retainer can reduce friction compared to when making direct contact with the case and the carrier.

Owner:NABLESCO CORP

Automatic bed capable of preventing flooring of traction weight

ActiveCN106264823AIncrease frictionSlow movement speedNervous disorderAntipyreticSurface layerEngineering

The invention discloses an automatic bed capable of preventing flooring of a traction weight. The automatic bed comprises a bed body, wherein a bed plate is arranged on the bed body; the bed body is also provided with a traction hammer; a pressure sensor is arranged on the bottom surface of the traction hammer; a driving mechanism is arranged on the bed body and is used for driving the bed plate to incline; a bed mattress is arranged on the bed plate, and comprises a mattress layer and a surface layer; the surface layer is an annular belt body, the mattress layer is arranged at the center of the annular belt body, rotary shafts are arranged on two ends of the annular belt body, and a driving motor is arranged on at least one rotary shaft. The automatic bed capable of preventing the flooring of the traction weight has the advantages that the state of the traction hammer can be automatically detected, and a patient is automatically moved to the proper position.

Owner:ZHUJIANG HOSPITAL SOUTHERN MEDICAL UNIV

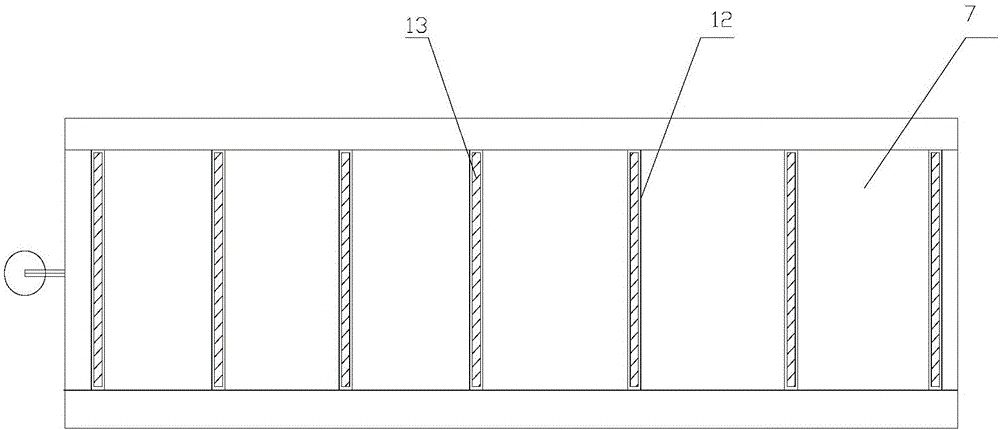

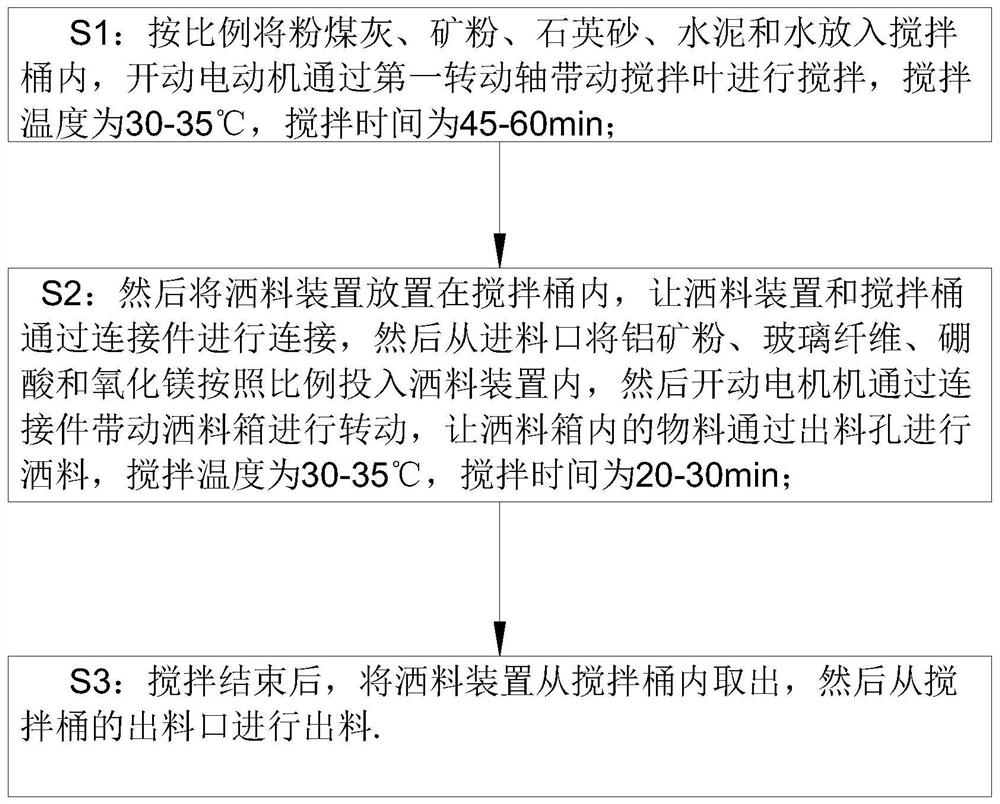

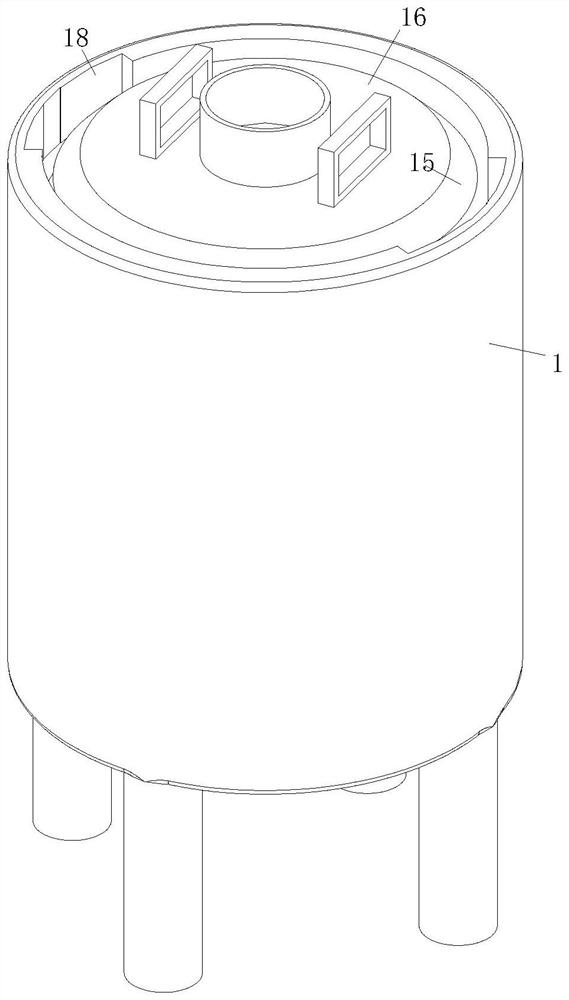

Formula and preparation process of anti-crack concrete

ActiveCN114716190AGuaranteed uniformitySlow movement speedSolid waste managementMixing operation control apparatusGlass fiberHazardous substance

The invention belongs to the technical field of concrete production, and particularly relates to an anti-crack concrete formula and a preparation process, S1, fly ash, mineral powder, quartz sand, cement and water are put into a stirring barrel in proportion, a motor is started to drive stirring blades to stir through a first rotating shaft, the stirring temperature is 30-35 DEG C, and the stirring time is 45-60 min; s2, placing a material spraying device in a stirring barrel, connecting the material spraying device with the stirring barrel through a connecting piece, proportionally adding aluminum ore powder, glass fibers, boric acid and magnesium oxide into the material spraying device from a feeding hole, starting a motor to drive a material spraying box to rotate through the connecting piece, and stirring uniformly; the materials in the material spraying box are sprayed through the discharging holes, the stirring temperature ranges from 30 DEG C to 35 DEG C, and the stirring time ranges from 20 min to 30 min; the problems that in concrete engineering use, the cracking rate of concrete solidification is high, external harmful substances easily invade into concrete, the durability of the concrete is reduced, and the service life of the concrete is prolonged are solved.

Owner:慈利鼎盛建材有限责任公司

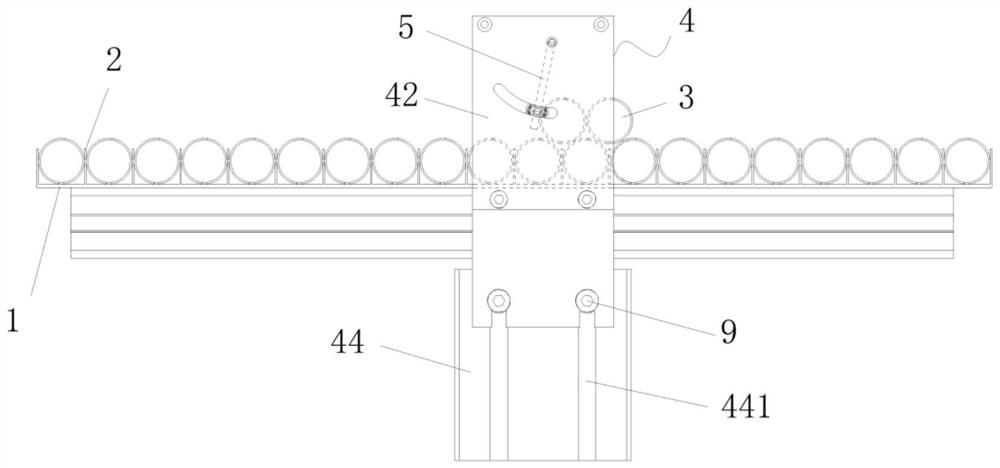

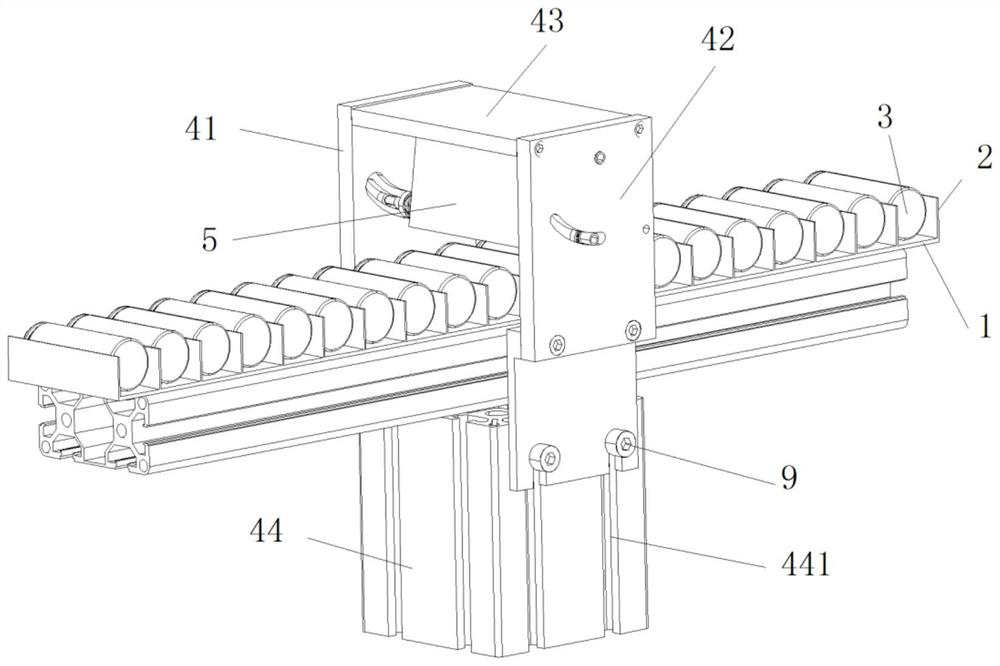

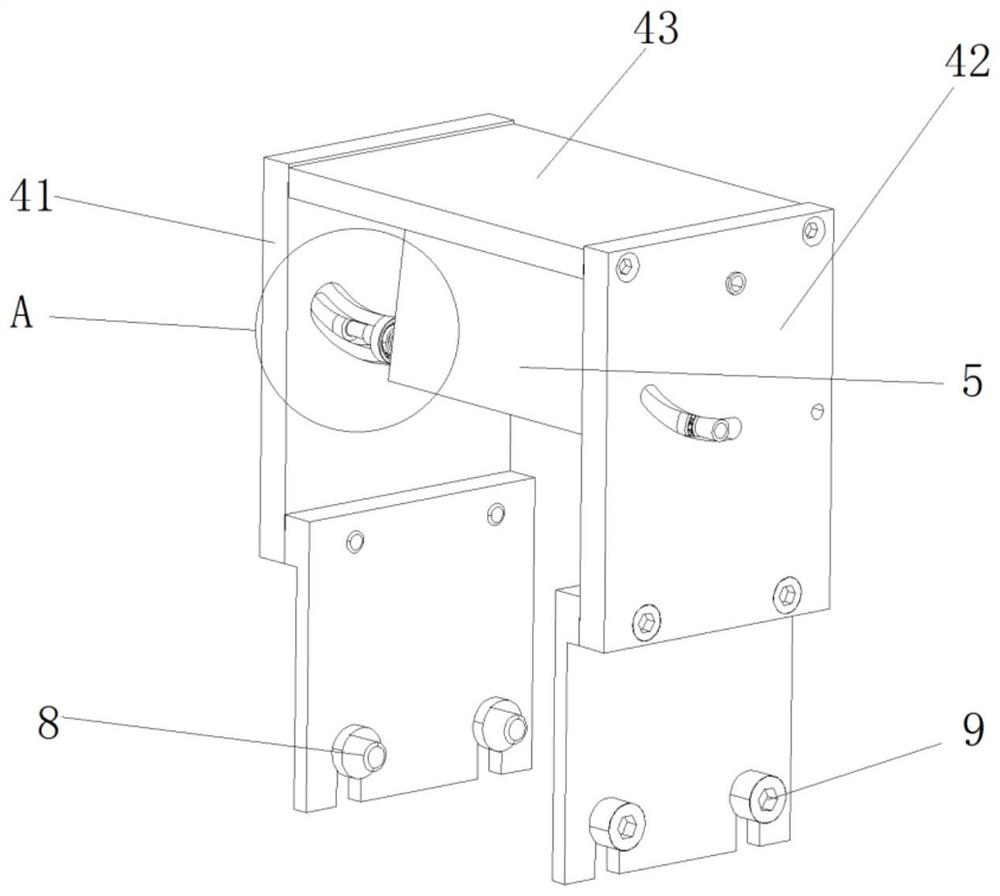

Conveying and blocking device and feeding device for cylindrical steel shell batteries

PendingCN114524227AIncrease the number ofReduce in quantityConveyorsConveyor partsEngineeringStructural engineering

The invention relates to the technical field of lithium battery generation equipment, and provides a conveying and material blocking device and a feeding device for cylindrical steel shell batteries. The conveying and material blocking device for the cylindrical steel shell batteries comprises a support and a material blocking plate; one end of the striker plate is rotationally connected with the bracket, and the other end of the striker plate extends to the conveying surface of the conveyor belt; a plurality of conveying positions are arranged on the conveying face of the conveying belt and arranged in the moving direction of the conveying belt. Under the condition that the cylindrical steel shell battery is located at the conveying position, a preset gap is formed between the outer side wall of the cylindrical steel shell battery and the other end of the material blocking plate, and the preset gap is smaller than the diameter of the cylindrical steel shell battery; and the axis of the cylindrical steel shell battery located at the conveying position is parallel to the material blocking plate. The striker plate provided by the invention can prevent the cylindrical steel shell batteries from being stacked at a fault device.

Owner:DALIAN CBAK POWER BATTERY CO LTD

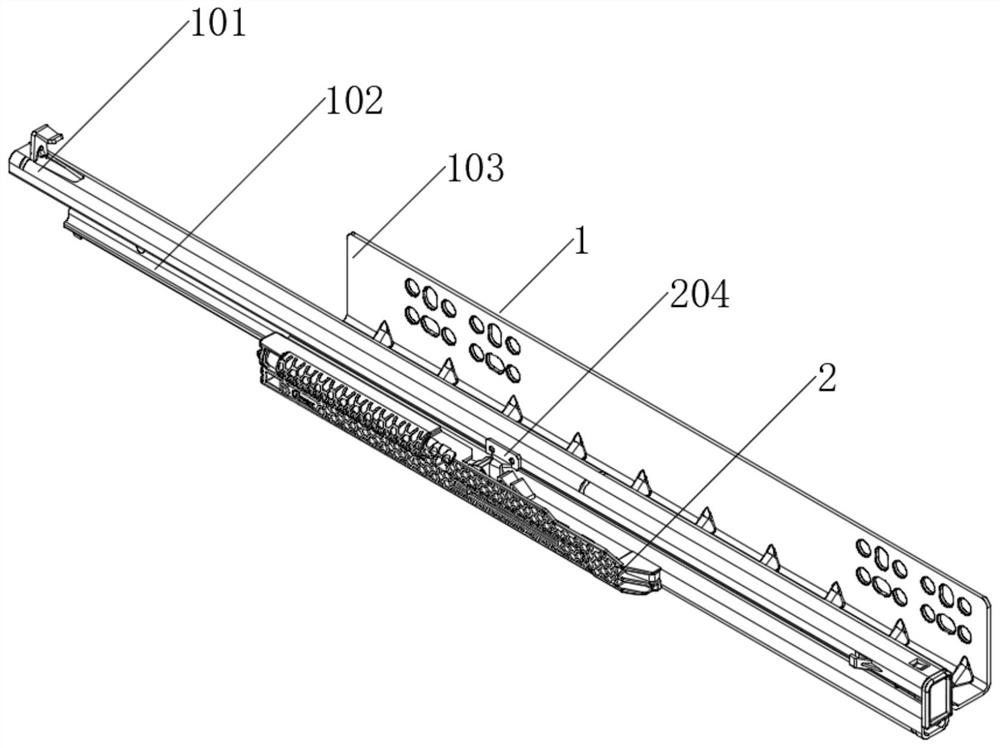

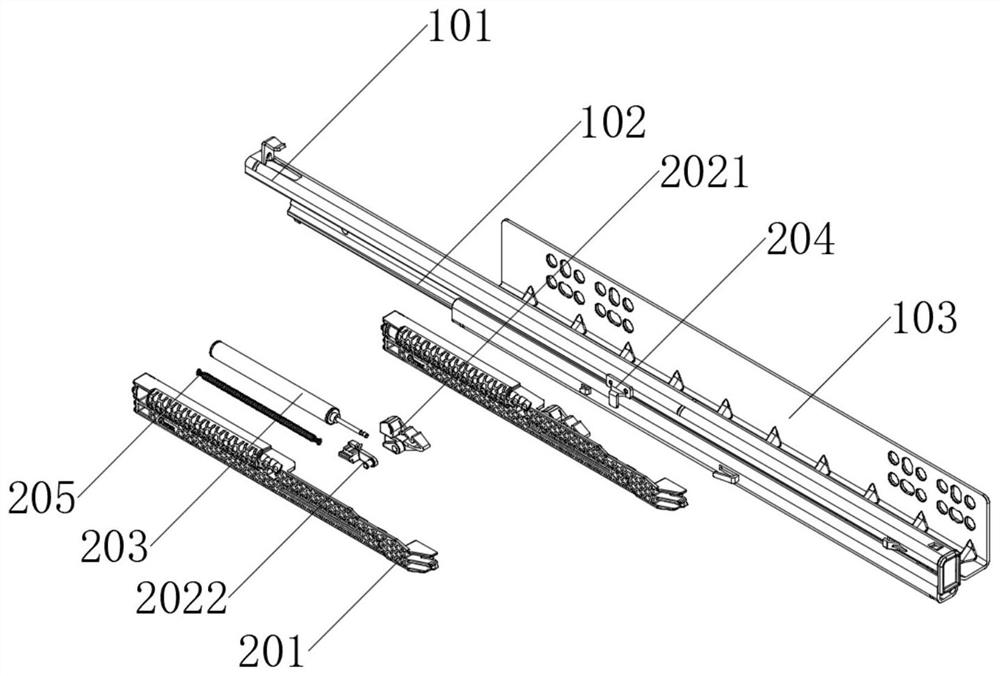

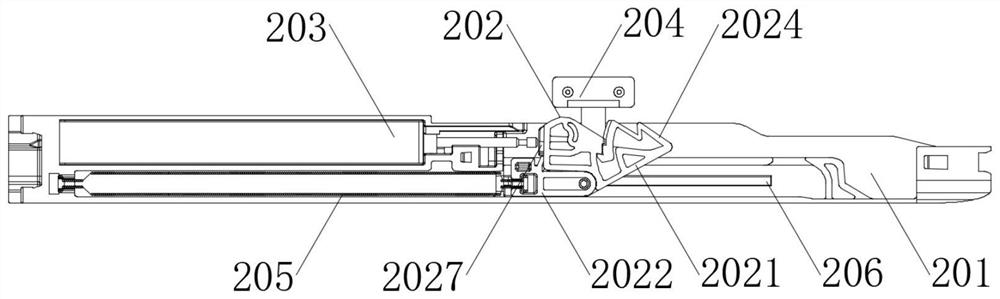

Pop-up buffer system with auxiliary system

PendingCN113854754ASlow movement speedReduce movement speedDrawersControl theoryMechanical engineering

The invention discloses a pop-up buffer system with an auxiliary system, which comprises a sliding rail assembly and a buffer device, the sliding rail assembly comprises a movable rail, a middle rail and a fixed rail, the middle rail is installed on the surface of the fixed rail, the movable rail is installed at the upper end of the middle rail, and the buffer device comprises a buffer frame, a sliding block assembly, a pop-up buffer and a shifting block. The buffer frame is fixedly connected to one side of the fixed rail, the sliding block assembly is installed on the surface of the buffer frame, the pop-up buffer is installed in the buffer frame, one end of the pop-up buffer makes contact with the sliding block assembly, and the shifting block is rotationally connected to the surface of the movable rail. By arranging the buffer device, when a worker pushes the movable rail, the movable rail drives the shifting block to make contact with the damping elastic piece, the damping elastic piece can reduce the moving speed of the shifting block, sound generated by collision between the shifting block and the main sliding block can be effectively reduced, and therefore the good mute effect is achieved.

Owner:GUANGDONG GMAX HARDWARE CO LTD

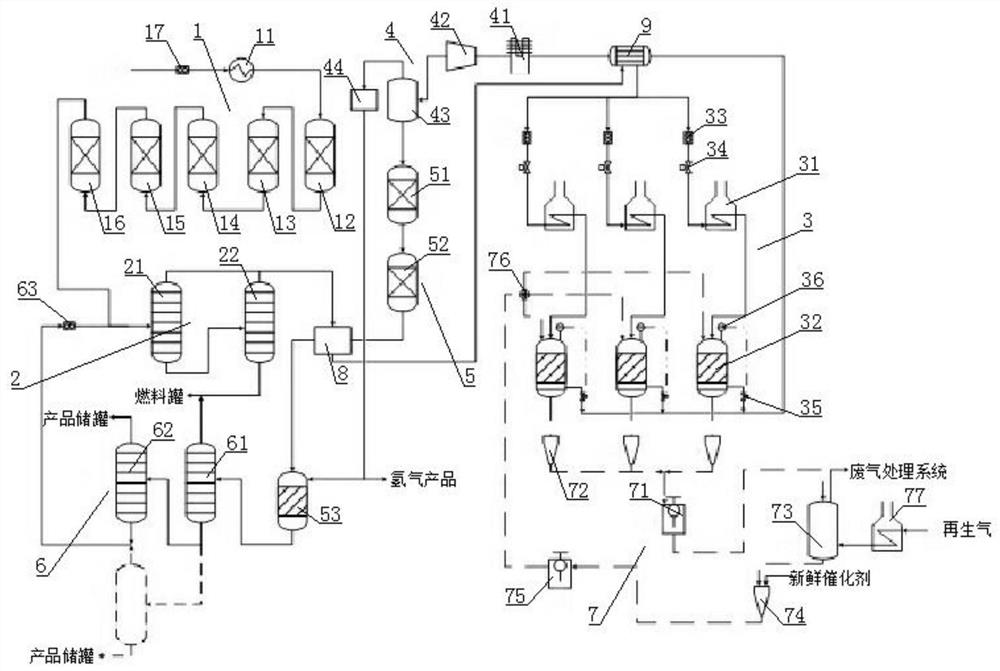

Moving bed system for preparing low-carbon olefin through dehydrogenation of low-carbon alkane

InactiveCN112569872AAccelerate carbon depositionGood load adjustment operabilityHydrocarbon purification/separationHydrocarbonsAlkanePtru catalyst

The invention belongs to the technical field of moving bed systems, and particularly relates to a moving bed system for preparing low-carbon olefin through dehydrogenation of low-carbon alkane. According to the technical scheme, the moving bed system for preparing the low-carbon olefin through dehydrogenation of the low-carbon alkane comprises a raw material pretreatment unit, a fuel separation unit, a moving bed reaction unit, a hydrogen separation unit, a product purification unit, a product separation and purification unit and a catalyst regeneration unit which are sequentially connected through pipelines; and the moving bed reaction unit comprises a plurality of reaction pipelines which are arranged in parallel, and a heating furnace and a reactor are arranged on the reaction pipelines. The invention provides the moving bed system for preparing the low-carbon olefin through dehydrogenation of the low-carbon alkane by independently adjusting each reactor.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com