Formula and preparation process of anti-crack concrete

A preparation process and concrete technology, which are applied in clay preparation devices, mixing operation control, mixing operation control devices, etc., can solve the problems of reducing the durability and service life of concrete, and high cracking rate, so as to slow down the movement rate, ensure uniformity, The effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

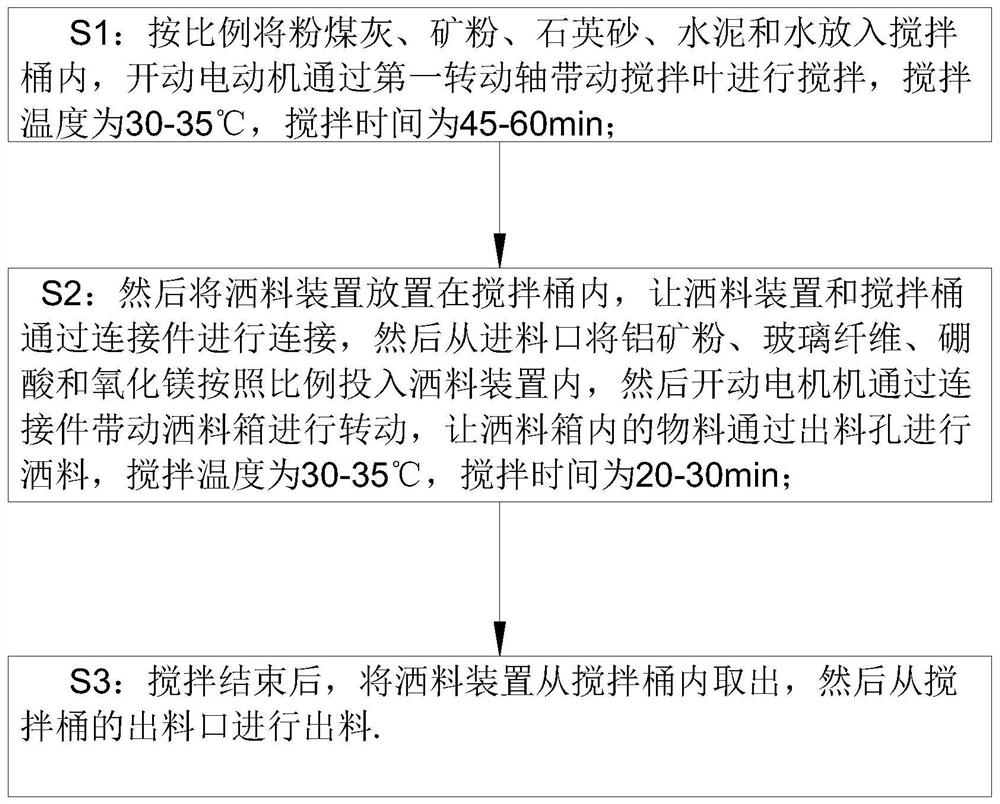

[0046] Take 10-15 parts of fly ash, 8-10 parts of mineral powder, 20-30 parts of quartz sand, 40-50 parts of cement and 20-25 parts of water; the raw materials are produced according to the preparation process, and then a 2m*2m foundation is selected , lay it, and check the cracking of the concrete.

Embodiment 2

[0048] Take 10-15 parts of fly ash, 8-10 parts of mineral powder, 20-30 parts of quartz sand, 40-50 parts of cement, 20-25 parts of water and 5-8 parts of anti-cracking agent; among them, bauxite in anti-cracking agent 4-6 parts of powder, 8-10 parts of glass fiber, 10-12 parts of boric acid and 5-6 parts of magnesium oxide, each raw material is produced according to the preparation process, and then a 2m*2m foundation is selected and laid, and the cracked concrete is detected. Happening.

[0049] Crack rate of concrete Example 1 0.05-0.08% Example 2 0.01-0.02%

[0050] Table 1

[0051] It can be seen from the implementation of 1-2 that after adding the anti-cracking agent to the original concrete formula, the cracking of the concrete can be greatly reduced, which proves that the formula of the present invention is reasonable, and the service life and use effect of the concrete can be effectively improved.

[0052] A crack-resistant concrete formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com