Moving bed system for preparing low-carbon olefin through dehydrogenation of low-carbon alkane

A technology of low-carbon olefins and low-carbon alkanes, applied in the field of moving bed systems, to achieve the effects of good load adjustment operability, improved economic benefits, and optimized product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

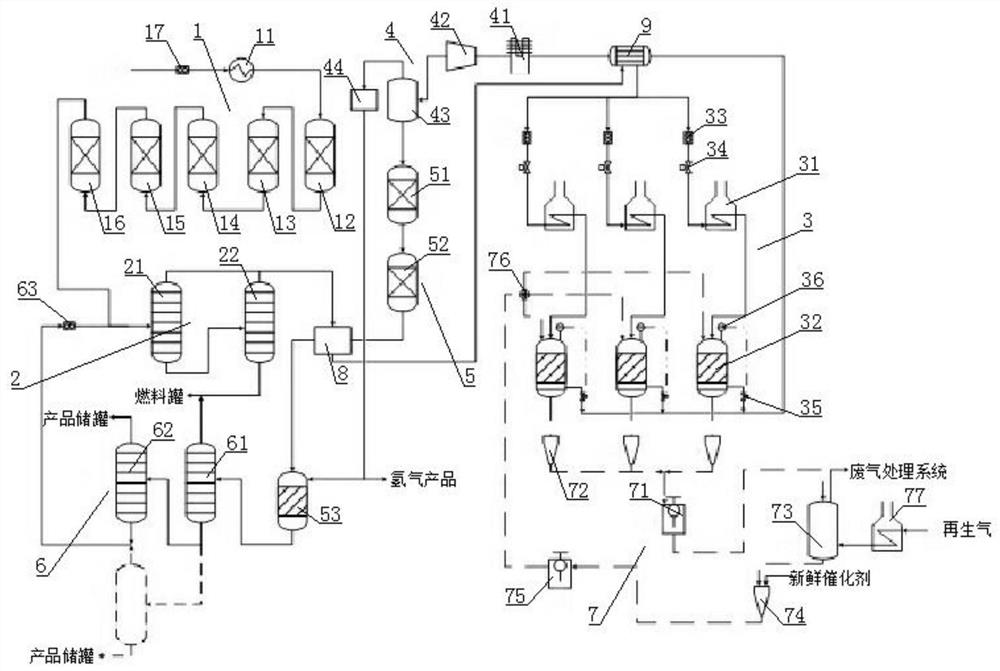

[0029] Such as figure 1 As shown, the present embodiment is propane dehydrogenated propylene. The material sequentially passes through the raw material pretreatment unit 1, the fuel separation unit 2, the cold tank 8, the material product heat exchanger 9, the moving bed reaction unit 3, the feedstock heat exchanger 9, hydrogen separation unit 4, product purification unit 5, cold box 8. The product separation purification unit 6. The catalyst cycle between the moving bed reaction unit 3 and the catalyst regeneration unit 7.

[0030] The specific operation is as follows, and the raw propane is measured by the fresh raw material flow meter 17, first conveyed to the raw material heater 11, warmed to 40 ° C, and the pressure was controlled at 2.5 to 3.0 MPa. Sequentially by the desulfurization tower 12, a dehydrated protective column 13, a dry tower 14, a dehydrated arsenic protection tower 15, a dephosphorized protective column 16, an inorganic or organic sulfide, alkaline nitride, a...

Embodiment 2

[0033] Such as figure 1 As shown, the present embodiment is isobutylene dehydrogenation. The material sequentially passes through the raw material pretreatment unit 1, the fuel separation unit 2, the cold tank 8, the material product heat exchanger 9, the moving bed reaction unit 3, the feedstock heat exchanger 9, hydrogen separation unit 4, product purification unit 5, cold box 8. The product separation purification unit 6. The catalyst cycle between the moving bed reaction unit 3 and the catalyst regeneration unit 7.

[0034] The specific operation is as follows, and the raw material isobutane is metered from the fresh raw material flowmeter 17, first conveyed to the raw material heater 11, warmed to 40 ° C, and the pressure control is controlled at 2.0 to 2.5 MPa, sequentially through the desulfurization tower 12, demurd protection column 13. , Dry tower 14, dehydration tower 15, dephosphorized protective column 16, inorganic or organic sulfide, basic nitride, alkaline nitride,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com