Thickened oil emulsifying viscosity reducer, emulsified thickened oil and preparation method of emulsified thickened oil

A technology for emulsification and viscosity reduction and heavy oil, which is used in mechanical equipment, petroleum industry, refined hydrocarbon oil, etc. It can solve the problems of heat energy loss, limited source of dilution oil, and increase in cost, and achieve the effect of reducing the moving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

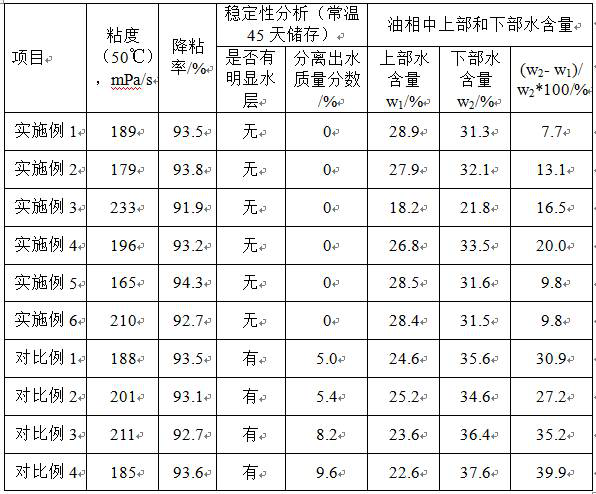

[0047] In parts by weight, take 150 parts of normal temperature water and add 0.5 part of water-soluble starch, stir to make it fully mixed, slowly heat to 60 ° C, then add 0.25 part of Tween 80, 0.25 part of Span 80 and 0.25 part of Twelve Sodium alkyl benzene sulfonate, stir to make it fully mixed to obtain emulsified viscosity reducer; take 350 parts of heavy viscous oil, add 10 parts of bio-based heavy oil, and mechanically stir at 100 ° C to fully mix to obtain oil phase material. The oil phase material and the emulsified viscosity reducer were added to the colloid mill for emulsification treatment to obtain an emulsified heavy oil. The properties of the emulsified heavy oil are shown in Table 1.

Embodiment 2

[0049] In parts by weight, take 150 parts of normal temperature water and add 0.5 part of water-soluble starch, stir to make it fully mixed, slowly heat to 60 ° C, then add 0.5 part of OP-10, 0.25 part of sodium dodecylbenzene sulfonate in turn , stir to make it fully mixed to obtain emulsified viscosity reducer; take 350 parts of heavy heavy oil, add 10 parts of bio-based heavy oil, mechanically stir at 100 ° C to fully mix to obtain oil phase material. The oil phase material and the emulsified viscosity reducer were added to the colloid mill for emulsification treatment to obtain an emulsified heavy oil. The properties of the emulsified heavy oil are shown in Table 1.

Embodiment 3

[0051] In parts by weight, take 100 parts of normal temperature water and add 0.5 part of water-soluble starch, stir to make it fully mixed, slowly heat to 60 ° C, then add 0.25 part of Tween 80, 0.25 part of Span 80 and 0.25 part of Twelve Sodium alkyl benzene sulfonate, stir to make it fully mixed to obtain emulsified viscosity reducer; take 400 parts of heavy heavy oil, add 10 parts of bio-based heavy fractions, and mechanically stir at 100 ° C to fully mix to obtain oil phase material. The oil phase material and the emulsified viscosity reducer were added to the colloid mill for emulsification treatment to obtain an emulsified heavy oil. The properties of the emulsified heavy oil are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com