An assembled laminated plate support device

A support device and a technology of laminated panels, which are applied in the preparation of pillars and building components on site, and construction, can solve problems such as poor support effect, damage to laminated panels, and inability to ensure pressure, so as to improve the connection support effect and slow down the movement. The effect of speed, good anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

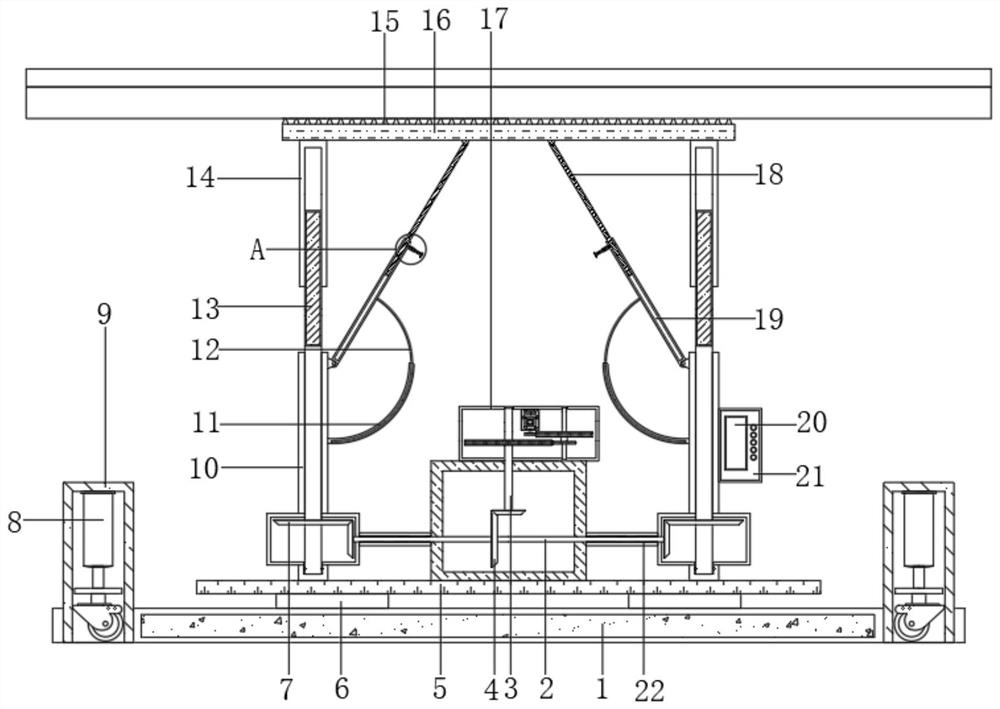

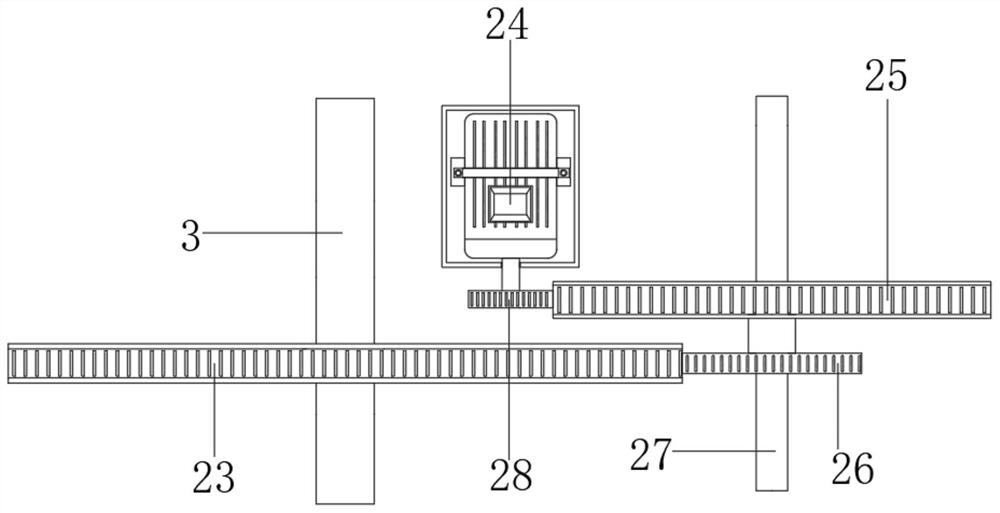

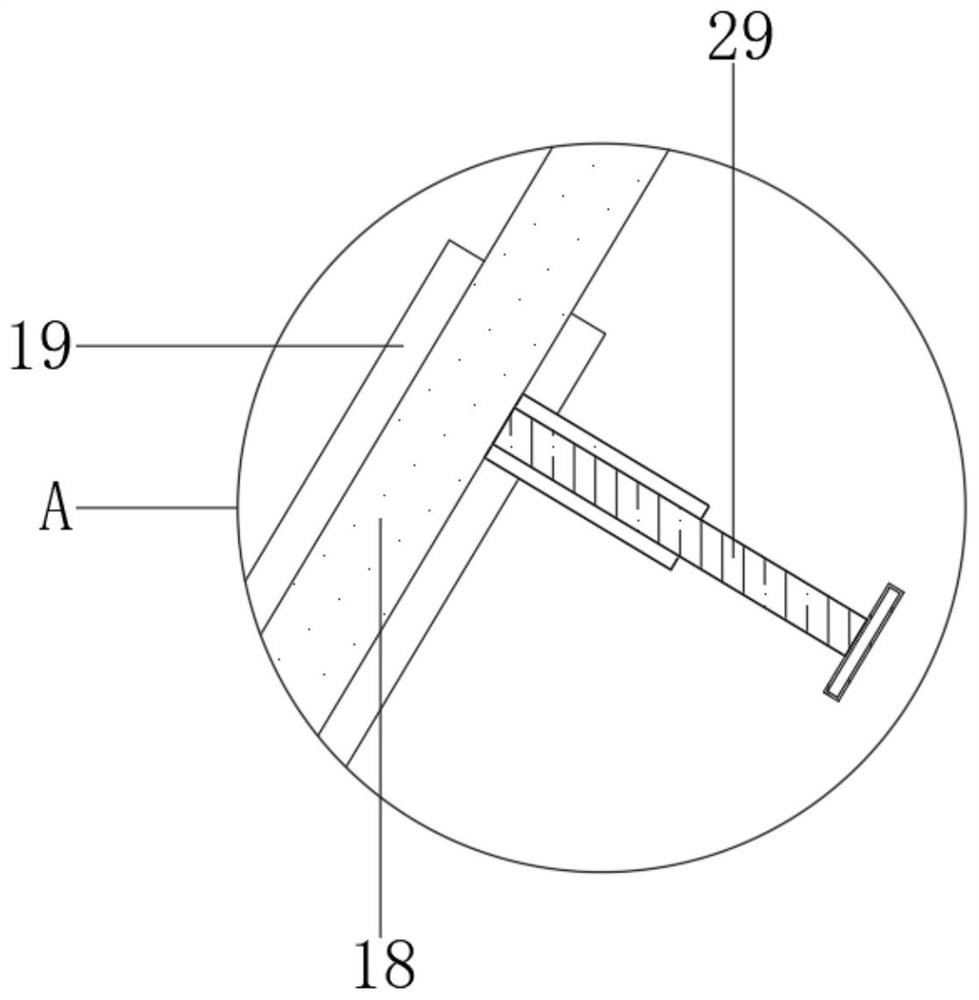

[0030] refer to Figure 1-5 , a prefabricated laminated plate support device, comprising a base 1, the four corners of the top outer wall of the base 1 are fixed with a pressure sensor 6 by screws, and the top of the pressure sensor 6 is fixedly installed with a mounting plate 5, and both sides of the top of the mounting plate 5 are welded There is a fixed tube 10, and the inner wall of the fixed tube 10 is connected with a threaded column 13 through bearing rotation, and the top of the threaded column 13 is connected with a threaded tube 14 through threads, and the top of the threaded tube 14 is fixed with the same support by bolts. Plate 16, the top outer wall of the support plate 16 is welded with protruding rods 15 distributed equidistantly, and the top outer wall of the protruding rods 15 is welded with claw-shaped convex strips 30 distributed equidistantly, to fix the opposite side of the tube tube 10 and the support plate 16 The storage tube 19 and the sliding rod 18 sl...

Embodiment 2

[0041] refer to figure 1 and Figure 4 , an assembly-type laminated plate support device, compared with Embodiment 1, this embodiment also includes a strengthening connecting pipe 22 welded to the opposite side of the square box and the transmission box, and the strengthening connecting pipe 22 is connected to the transmission rod 2 through the bearing Turn to connect.

[0042] When the present invention is in use, the setting of the reinforcing connecting pipe 22 can, on the one hand, play a good role in covering and protecting the transmission rod 2, and on the other hand, effectively strengthen the connection between the square box and the transmission box, so as to increase the structural strength of the device .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com