Stainless steel electrolytic polishing solution and electrolytic polishing method

An electrolytic polishing, stainless steel technology, applied in the electrolytic process, electrolytic components, etc., can solve problems such as unfavorable application, pollution, toxicity, etc., and achieve the effects of cost control, improved electrical conductivity, and reduced failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

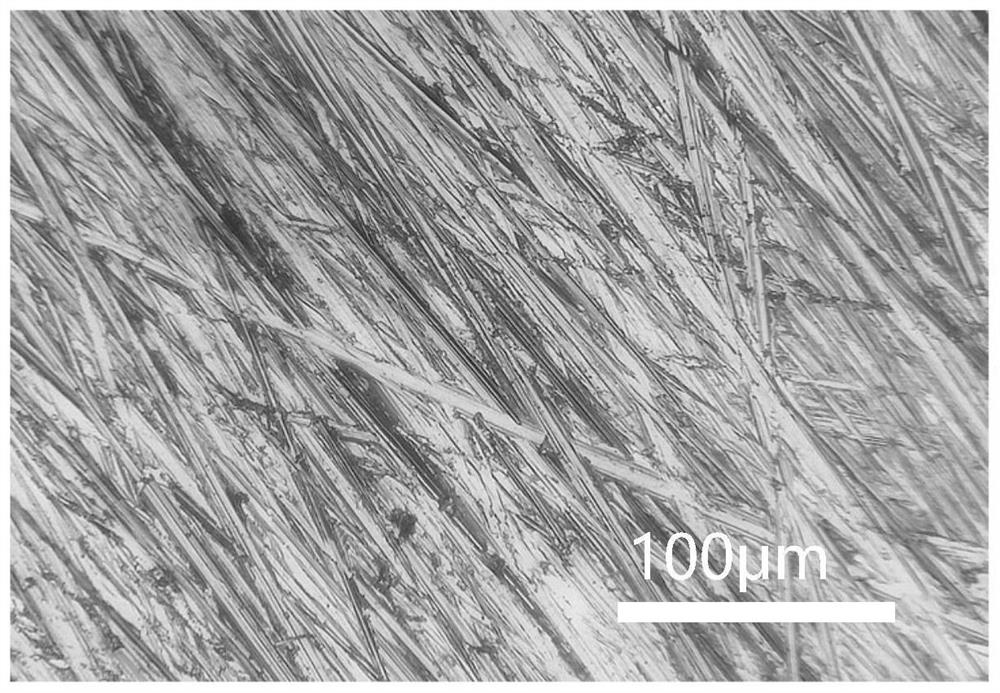

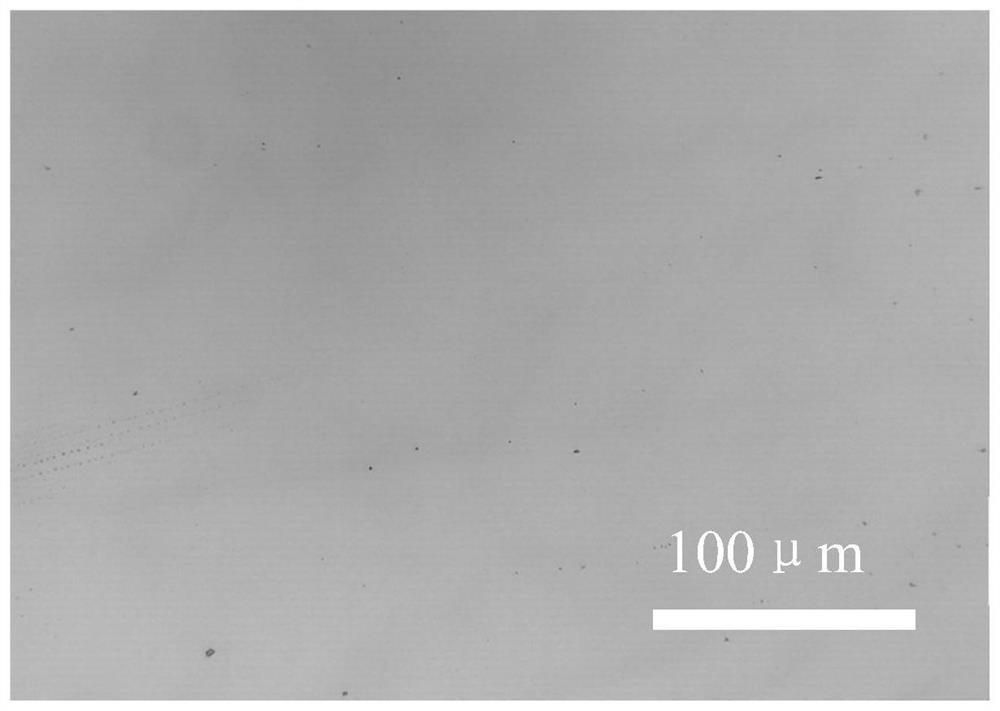

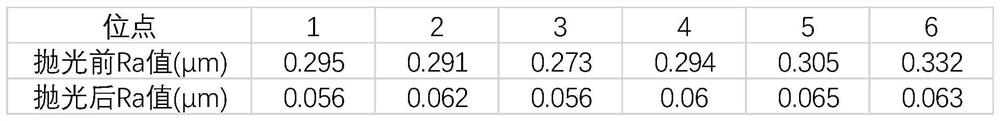

Image

Examples

Embodiment 1

[0034] The raw materials used and their contents by weight are as follows: 35 parts of sulfuric acid, 57 parts of phosphoric acid, 2.5 parts of brightener gelatin, 5.5 parts of auxiliary brightener op emulsifier, and 2.5 parts of conductive agent ammonium sulfate.

[0035] The electrolytic polishing method is carried out according to the following steps:

[0036] (1) Stainless steel pretreatment: Ultrasonic cleaning with degreasing agent and deionized water for 30 seconds.

[0037] (2) Electropolishing: Put the pretreated stainless steel into the stainless steel electrolytic polishing solution for electropolishing; wherein the pretreated stainless steel is the anode, and the copper plate is the cathode;

[0038] (3) Cleaning and drying: Ultrasonic cleaning with deionized water followed by ultrasonic cleaning with ethanol solution for 30 seconds. Dry the liquid components on the surface with a hair dryer or an oven, and dry the residual liquid components on the surface.

[003...

Embodiment 2

[0044] The raw materials used and their contents by weight are as follows: 35 parts of sulfuric acid, 57 parts of phosphoric acid, 3 parts of brightener gelatin, 5.5 parts of auxiliary brightener op emulsifier, and 2.5 parts of conductive agent ammonium sulfate.

[0045] The electrolytic polishing method is carried out according to the following steps:

[0046] (1) Stainless steel pretreatment: Ultrasonic cleaning with degreasing agent and ultrasonic cleaning with deionized water for 30 seconds.

[0047] (2) Electropolishing: Put the pretreated stainless steel into the stainless steel electrolytic polishing solution for electropolishing; wherein the pretreated stainless steel is the anode, and the lead plate is the cathode;

[0048] (3) Cleaning and drying: Ultrasonic cleaning with deionized water followed by ultrasonic cleaning with ethanol solution for 30 seconds. Dry the liquid components on the surface with a hair dryer or an oven, and dry the residual liquid components on...

Embodiment 3

[0053] The raw materials used and their parts by weight are as follows: 35 parts of sulfuric acid, 57 parts of phosphoric acid, 4 parts of brightener glycerin, 5.5 parts of auxiliary brightener sodium lauryl sulfate, and 2.5 parts of conductive agent ammonium phosphate.

[0054] The electrolytic polishing method is carried out according to the following steps:

[0055] (1) Stainless steel pretreatment: Ultrasonic cleaning with degreasing agent and ultrasonic cleaning with deionized water for 30 seconds.

[0056](2) Electropolishing: Put the pretreated stainless steel into the stainless steel electrolytic polishing solution for electropolishing; wherein the pretreated stainless steel is the anode, and the copper plate is the cathode;

[0057] (3) Cleaning and drying: Ultrasonic cleaning with deionized water followed by ultrasonic cleaning with ethanol solution for 30 seconds. Dry the liquid components on the surface with a hair dryer or an oven, and dry the residual liquid comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com