Two-stage drying and pyrolysis sludge disposal, heat energy utilization method and device system

A technology for sludge disposal and sludge, which is applied in pyrolysis sludge treatment, dehydration/drying/concentration sludge treatment, by-product vaporization, etc., can solve the problems of increasing sales costs and achieve increased calorific value and huge social benefits , The effect of solving the problem of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

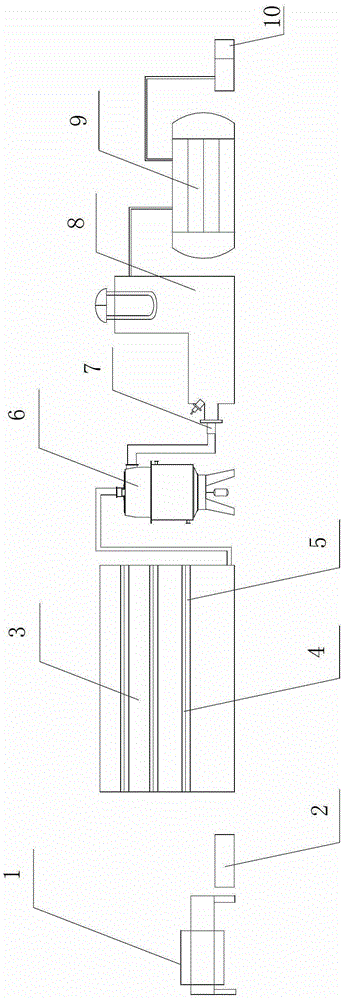

[0030] See figure 1

[0031] The two-stage drying and pyrolysis sludge disposal and heat energy utilization device system are arranged in sequence, including filter press 1, crusher 2, low-temperature and high-speed air-dried sludge drying room 3, and pyrolysis reactor 6, which is a vertical pyrolysis reactor , a combustion chamber 8, a steam generator 9, a waste heat utilization device 10, wherein the discharge port of the low-temperature high-speed air-dried sludge drying room 3 is connected with the feed port of the pyrolysis reactor 6, and the gas outlet on the upper part of the pyrolysis reactor 6 is connected to the The air inlets of the combustion chamber 8 are connected, and the front end of the combustion chamber 8 is provided with a burner 7 . The filter press 1 is a plate-and-frame diaphragm filter press, and a directional air circulation unit is installed on the top of the low-temperature and high-speed air-dried sludge drying room 3 to provide high-speed circulat...

Embodiment 2)

[0039] See figure 1

[0040] The two-stage drying and pyrolysis sludge disposal and heat energy utilization device system are arranged in sequence including filter press 1, crusher 2, low-temperature and high-speed air-dried sludge drying room 3, vertical pyrolysis reactor 6, combustion chamber 8, A steam generator 9 and a waste heat utilization device 10, wherein the outlet of the low-temperature high-speed air-dried sludge drying room 3 is connected to the inlet of the pyrolysis reactor 6, and the gas outlet on the upper part of the pyrolysis reactor 6 is connected to the inlet of the combustion chamber 8. The gas ports are connected, and the front end of the combustion chamber 8 is provided with a burner 7 . The filter press 1 is a plate-and-frame diaphragm filter press, and a directional air circulation unit is installed on the top of the low-temperature and high-speed air-dried sludge drying room 3 to provide high-speed circulating air. There are three layers of laminate...

Embodiment 3)

[0048] See figure 1

[0049] The two-stage drying and pyrolysis sludge disposal and heat energy utilization device system are arranged in sequence including filter press 1, crusher 2, low-temperature and high-speed air-dried sludge drying room 3, vertical pyrolysis reactor 6, combustion chamber 8, A steam generator 9 and a waste heat utilization device 10, wherein the outlet of the low-temperature high-speed air-dried sludge drying room 3 is connected to the inlet of the pyrolysis reactor 6, and the gas outlet on the upper part of the pyrolysis reactor 6 is connected to the inlet of the combustion chamber 8. The gas ports are connected, and the front end of the combustion chamber 8 is provided with a burner 7 . The filter press 1 is a plate-and-frame diaphragm filter press, and a directional air circulation unit is installed on the top of the low-temperature and high-speed air-dried sludge drying room 3 to provide high-speed circulating air. There are three layers of laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com