Efficient drying device for automobile interior decoration foam

A technology for drying devices and automobile interiors, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of low drying efficiency, time-consuming and labor-intensive, uneconomical, etc., achieve high drying treatment efficiency, and improve drying efficiency. Drying efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

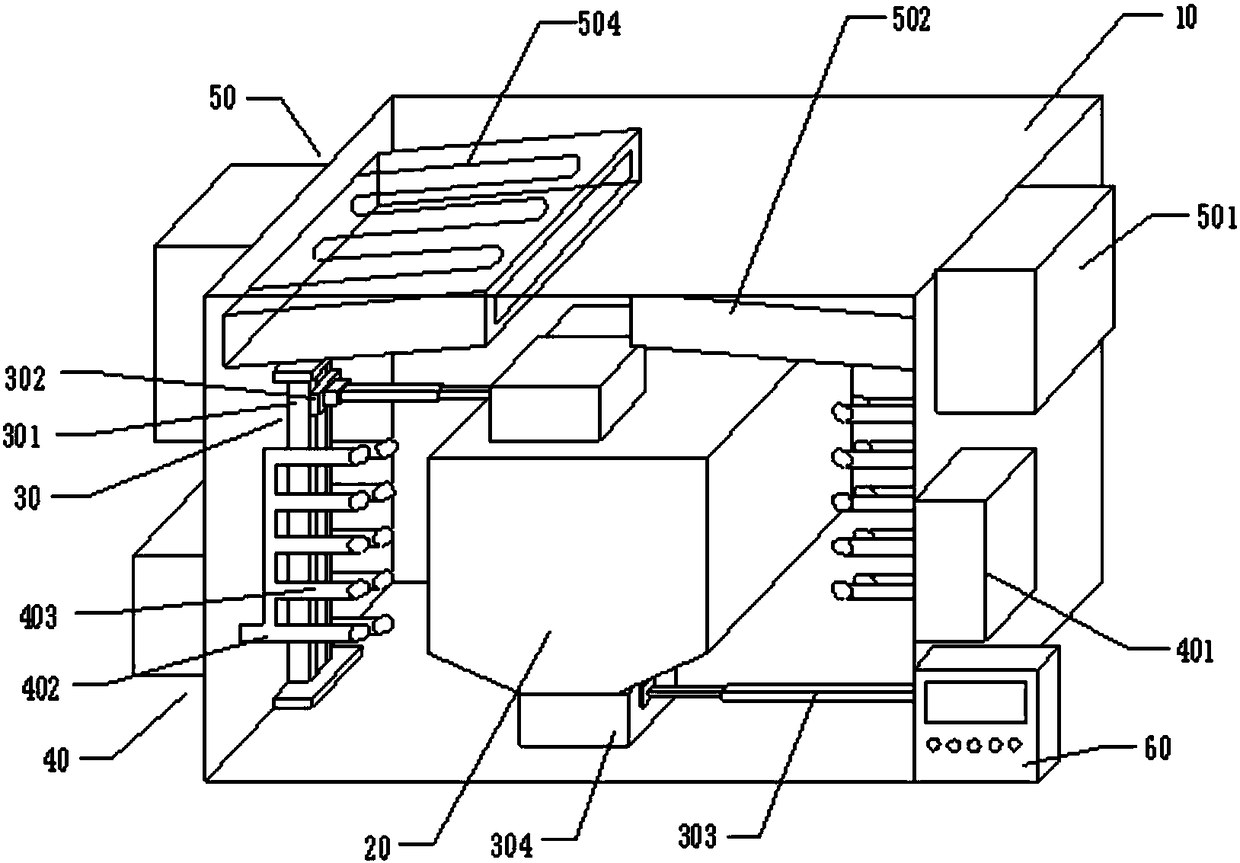

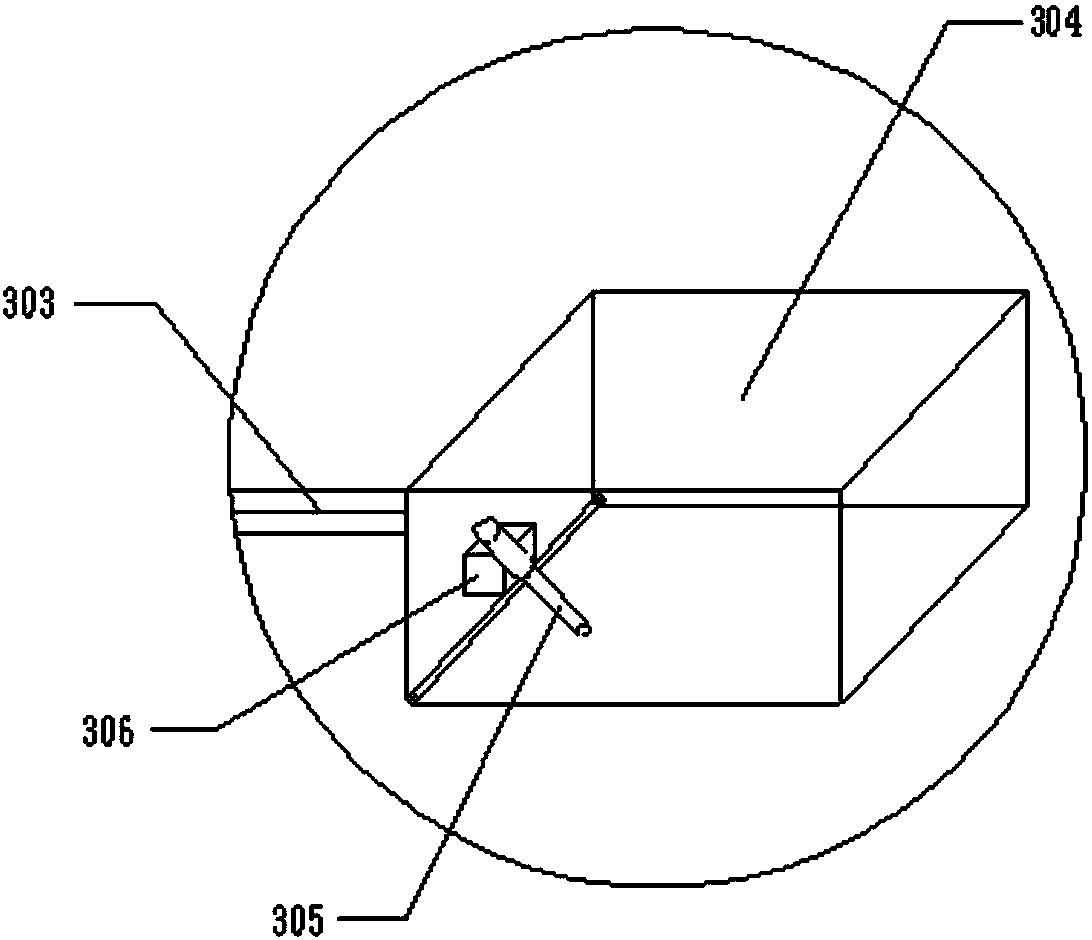

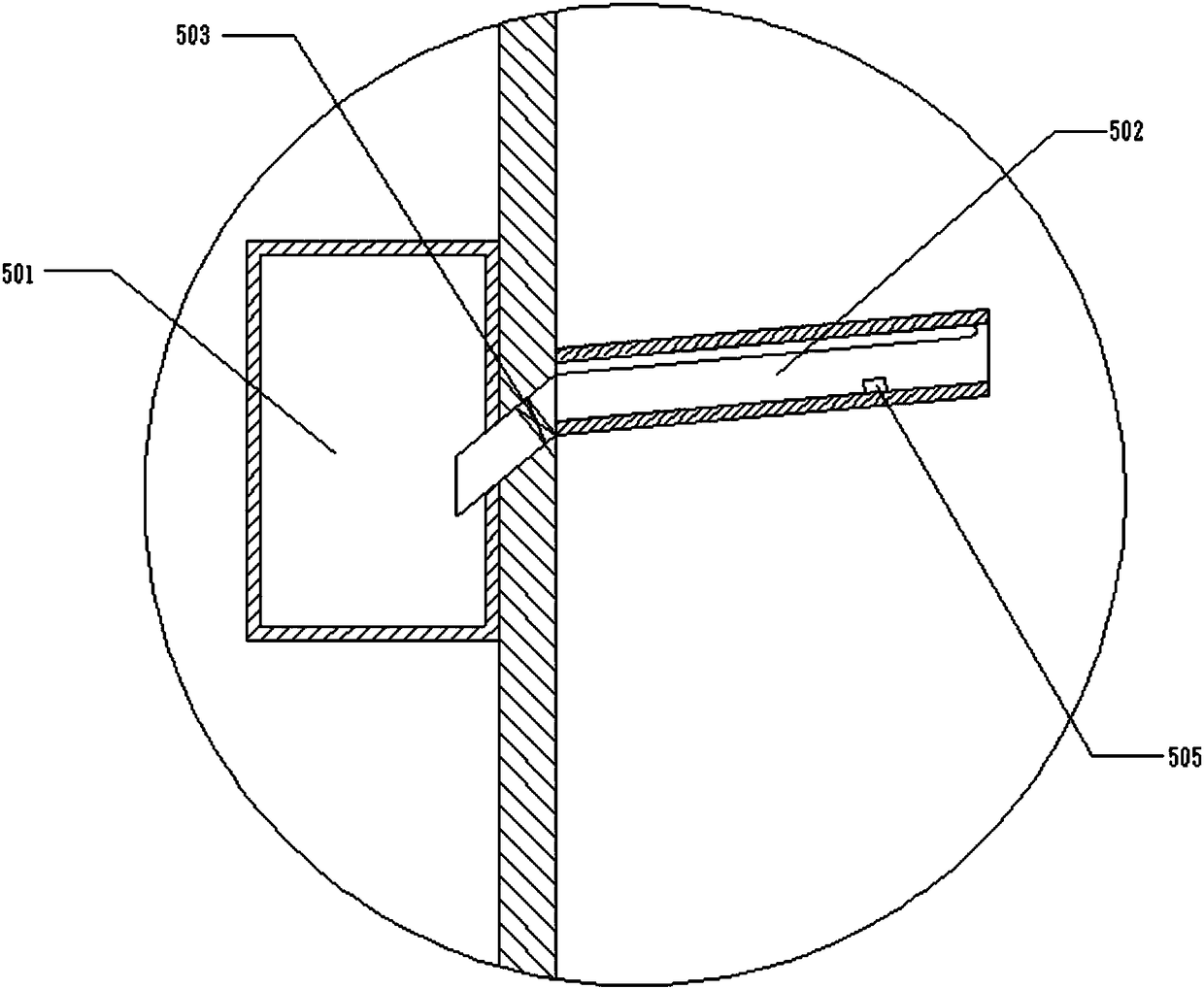

[0026] Such as Figure 1-Figure 3 As shown, a high-efficiency drying device for automotive interior foam, including a drying device body 10, a foam drying bucket 20, a material delivery part 30, a dryer 40, a steam collection part 50 and a controller 60, the drying device The center of the inner cavity of the main body 10 is provided with a foam drying bucket 20, and the material delivery part 30 is set as a first material delivery part and a second material delivery part, and the first material delivery part and the second material delivery part are respectively arranged in the drying area. On the left and right walls of the inner cavity of the device body 10, the material delivery part 30 realizes multiple drying of the foam to ensure a good drying effect. The dryer 40 is configured to include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com