Calcium carbide furnace and method for preparing calcium carbide

A technology of calcium carbide furnace and calcium carbide, which is applied in the direction of carbide, calcium carbide, etc., can solve the problems that calcium carbide needs to be improved, and achieve the effect of improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

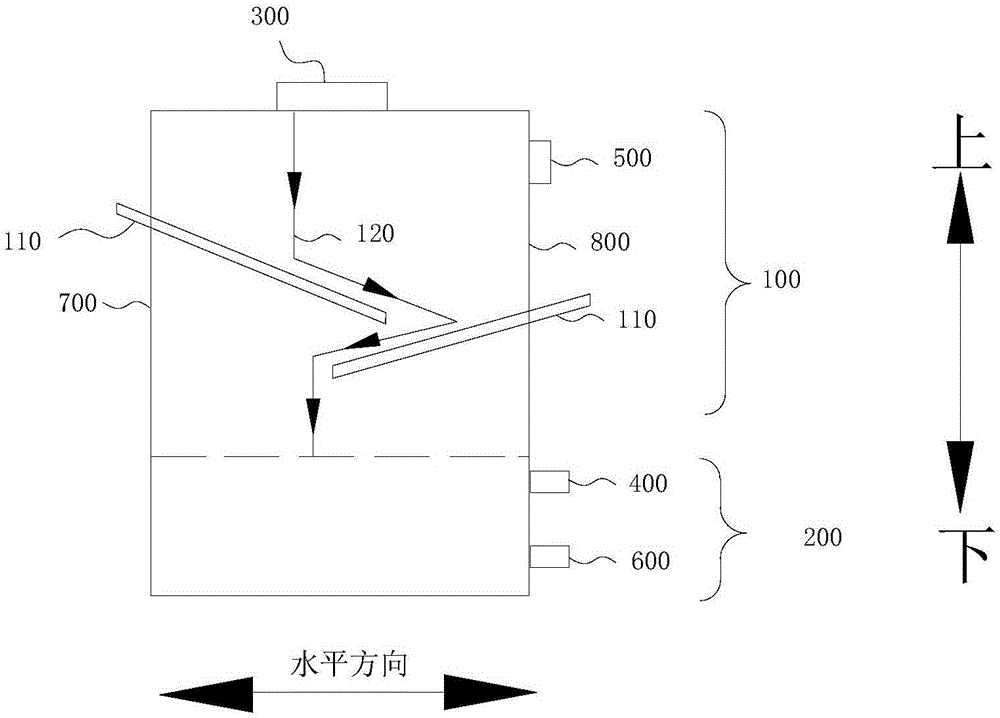

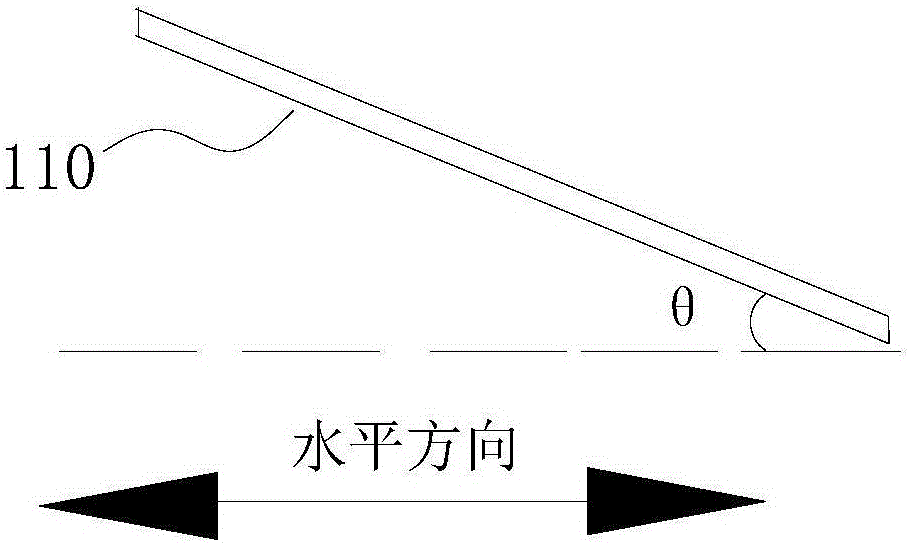

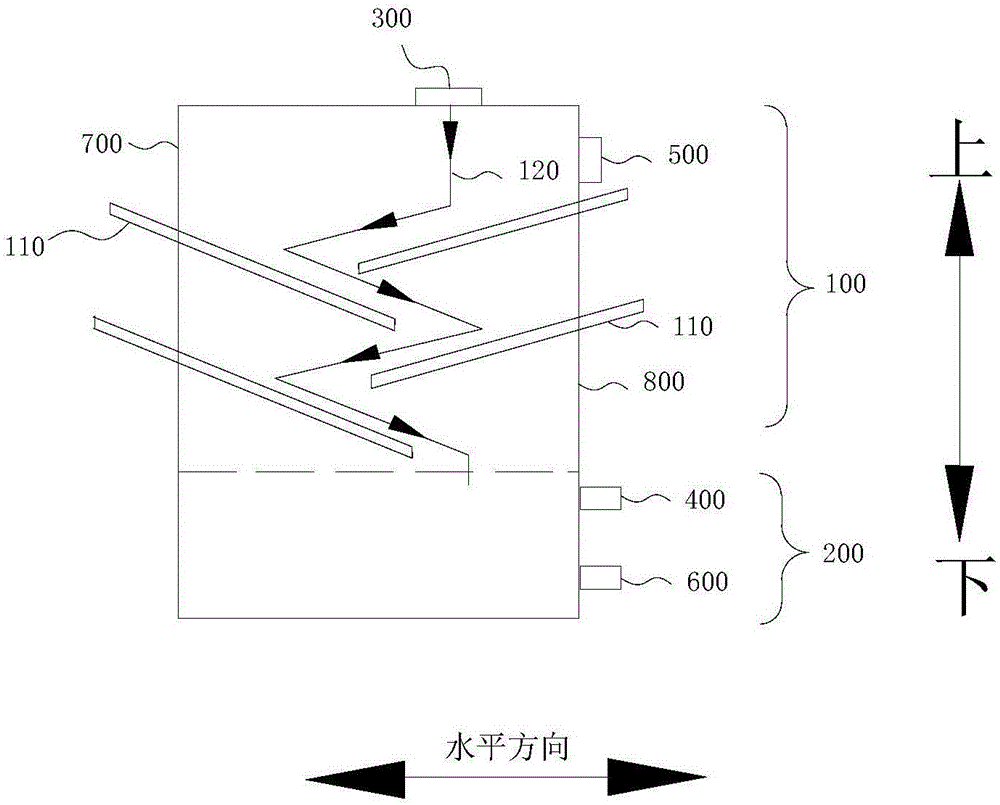

[0067] There are 15 sets of electric heating plates in the calcium carbide furnace, the heating plates are inclined at 15 degrees relative to the ground, and the maximum working temperature of the heating plates is 1000 degrees Celsius.

[0068] Carbon-based raw materials: Taking a medium and low-rank raw coal as an example, its main properties are shown in Table 1.

[0069] Table 1 Main properties of carbon-based raw materials

[0070] project

unit

value

Remark

whole water

wt%

13.7

Receive base

wt%

54.1

Volatile matter

wt%

39.4

Ash

wt%

6.5

[0071] Calcium-based raw material: it can be one or a mixture of lime, limestone, slaked lime or carbide slag. In this embodiment, the calcium-based material fed into the calcium carbide furnace is lime with a CaO content of 92.4%.

[0072] Raw material particle size: 0.6mm.

[0073] Carbon-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com