Environment-friendly pleuripotent garbage pyrolysis device

A garbage and environmental protection technology, applied in the field of environmental protection and multi-energy garbage pyrolysis device, can solve the problems of hot air acquisition and transportation, high maintenance and operation cost of garbage pyrolysis device, difficulty in continuous and stable compliance of garbage pyrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

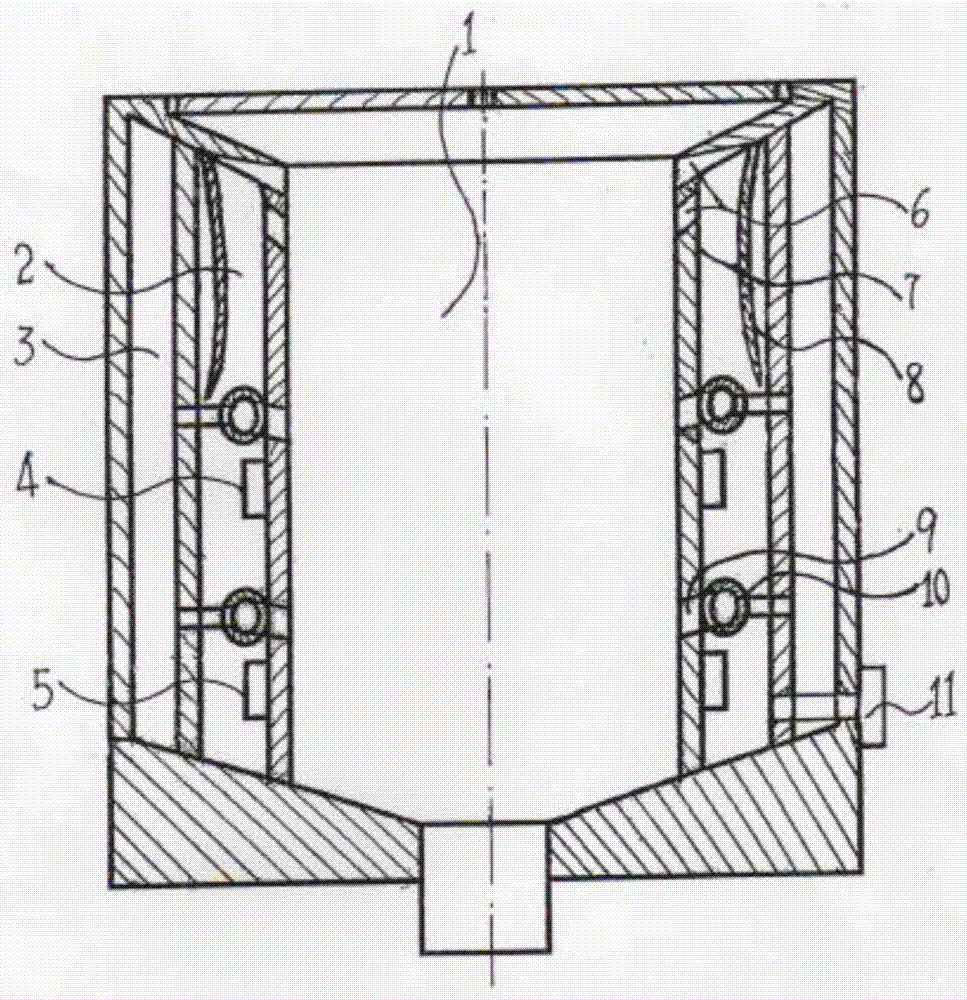

[0017] Such as figure 1 As shown, this environment-friendly multi-energy garbage pyrolysis device has an incineration chamber 1, a flue gas chamber 2 and a hot gas chamber 3 are arranged outside the incineration chamber 1, and an evaporation mechanism 4, a drying chamber 3, and an evaporation mechanism 4 are installed in the flue gas chamber 2. Drying mechanism 5, the evaporation mechanism 4 is connected with the sedimentation water conveying mechanism after the garbage water is precipitated, the drying mechanism 5 is connected with the sedimentation slag conveying mechanism after the garbage water is precipitated, the hot air chamber 3 is connected with the air conveying mechanism, The hot gas chamber 3 communicates with the incineration chamber 1 through the gas delivery pipe 10 , the gas delivery pipe 10 is arranged around the flue gas chamber 2 , and the gas delivery pipe 10 communicates with the incineration chamber 1 through the gas delivery channel 9 of the partition wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com