Chemical looping conversion recovery of non-magnetic metal oxides and co-production hydrogen system and process

A non-magnetic metal and oxide technology, applied in the direction of titanium oxide/hydroxide, oxide/hydroxide preparation, zinc oxide/zinc hydroxide, etc., can solve the problem of not being able to achieve harmless paint residue, etc. problems, to achieve significant overall economic efficiency and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

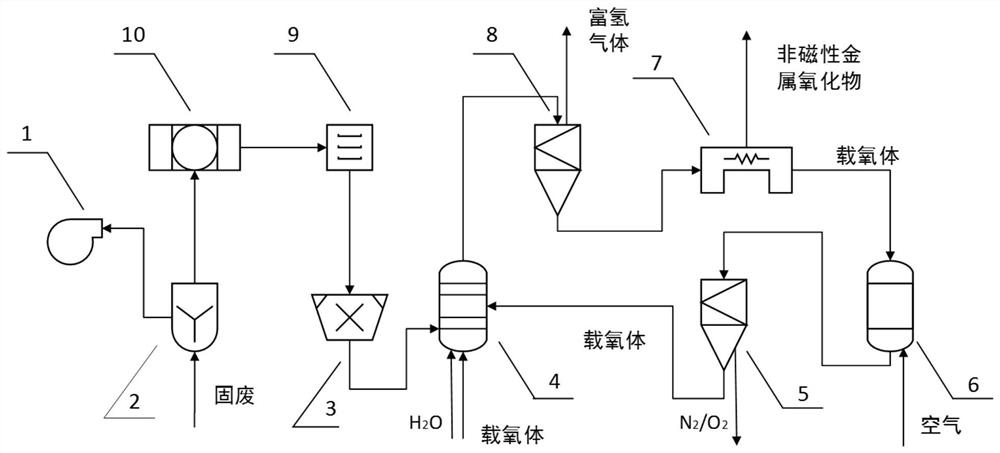

[0042] A recovery process for titanium-containing paint waste, comprising the following steps:

[0043] 1 Clean the titanium-containing paint waste residue and clean water in a certain proportion in the reaction kettle 2. At the same time, the reaction kettle 2 is connected with the centrifugal fan 1, and the exhaust gas in the titanium-containing paint waste residue is separated through the centrifugal fan. Carry out cleaning and deodorization operations.

[0044] 2. The waste titanium-containing paint slag cleaned by the reaction kettle 2 is sent to the solid-liquid separation device 10 for dehydration, and then sent to the dryer 9 for drying treatment after dehydration.

[0045] 3. The dehydrated and deodorized titanium-containing waste paint slag is sent to the mill 3 for grinding to obtain titanium-containing waste paint slag particles.

[0046] 4 Pass titanium-containing waste paint slag particles, oxygen carrier and water into the combustion reactor 4 according to the ...

Embodiment 2

[0052] A recovery process for zinc-containing paint waste, comprising the following steps:

[0053] 1 Clean the zinc-containing paint waste and clean water in a certain proportion in the reaction kettle 2. At the same time, the reaction kettle 2 is connected with the centrifugal fan 1, and the waste gas in the zinc-containing paint waste is separated through the centrifugal fan, and the zinc-containing paint waste Carry out cleaning and deodorization operations.

[0054] 2 The zinc-containing waste paint slag cleaned by the reaction kettle 2 is sent to the solid-liquid separation device 10 for dehydration, and then sent to the dryer 9 for drying treatment after dehydration.

[0055] 3. The dehydrated and deodorized zinc-containing waste paint slag is sent to the mill 3 for grinding to obtain zinc-containing waste paint slag particles.

[0056] 4 Pass the zinc-containing waste paint slag particles, oxygen carrier and water into the combustion reactor 4 according to the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com