Waste pyrolysis extrusion sewage environmental protection treatment device

A technology for environmental protection and waste disposal, applied in lighting and heating equipment, combustion types, combustion methods, etc., can solve problems that affect the continuous and stable pyrolysis of waste, difficulty in pyrolysis of waste, and increased processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

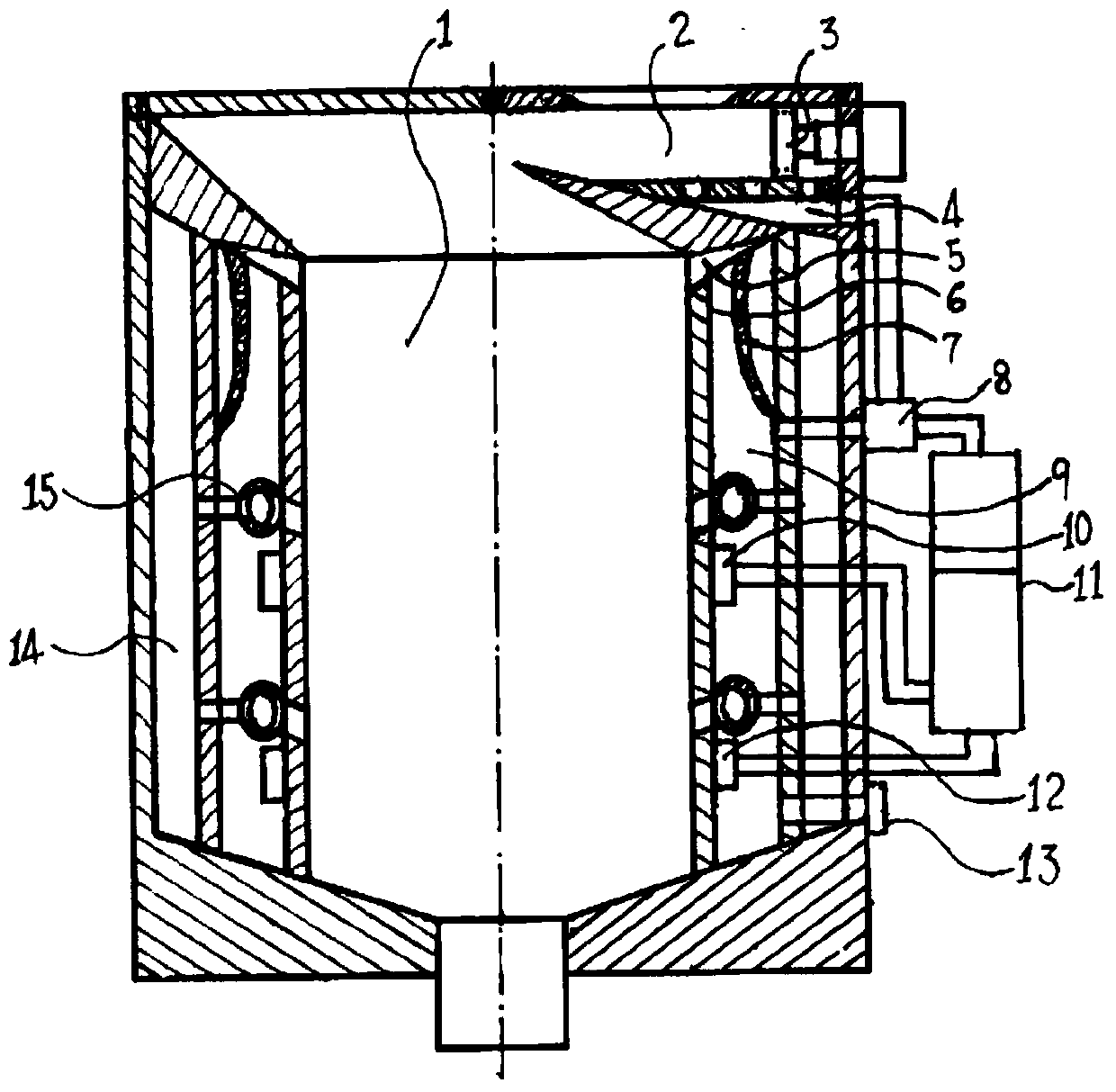

[0017] as it should figure 1 As shown, the garbage pyrolysis extrusion sewage environmental protection treatment device includes a sewage collection and transportation mechanism 8, and the sewage collection and transportation mechanism 8 is respectively connected with the garbage extrusion liquid diversion mechanism 4, the flue gas chamber 9, and the rotation sedimentation tank 11, The rotating sedimentation tank 11 is respectively connected with the evaporation mechanism 10 and the drying mechanism 12. The evaporation mechanism 10 is connected with the rotating sedimentation tank 11 through the sedimentation water delivery mechanism after the garbage water is deposited, and the drying mechanism 12 is deposited through the garbage water. The final sedimentation slag conveying mechanism is connected with the rotation sedimentation tank 11, the evaporation mechanism 10 and the drying mechanism 12 are arranged in the flue gas chamber 9, and the flue gas chamber 9 is arranged outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com