Solid waste pyrolysis treatment equipment

A technology for solid waste and treatment equipment, applied in grain treatment, lighting and heating equipment, combustion methods, etc. problems, to achieve the effect of improving heating efficiency, shortening working time, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

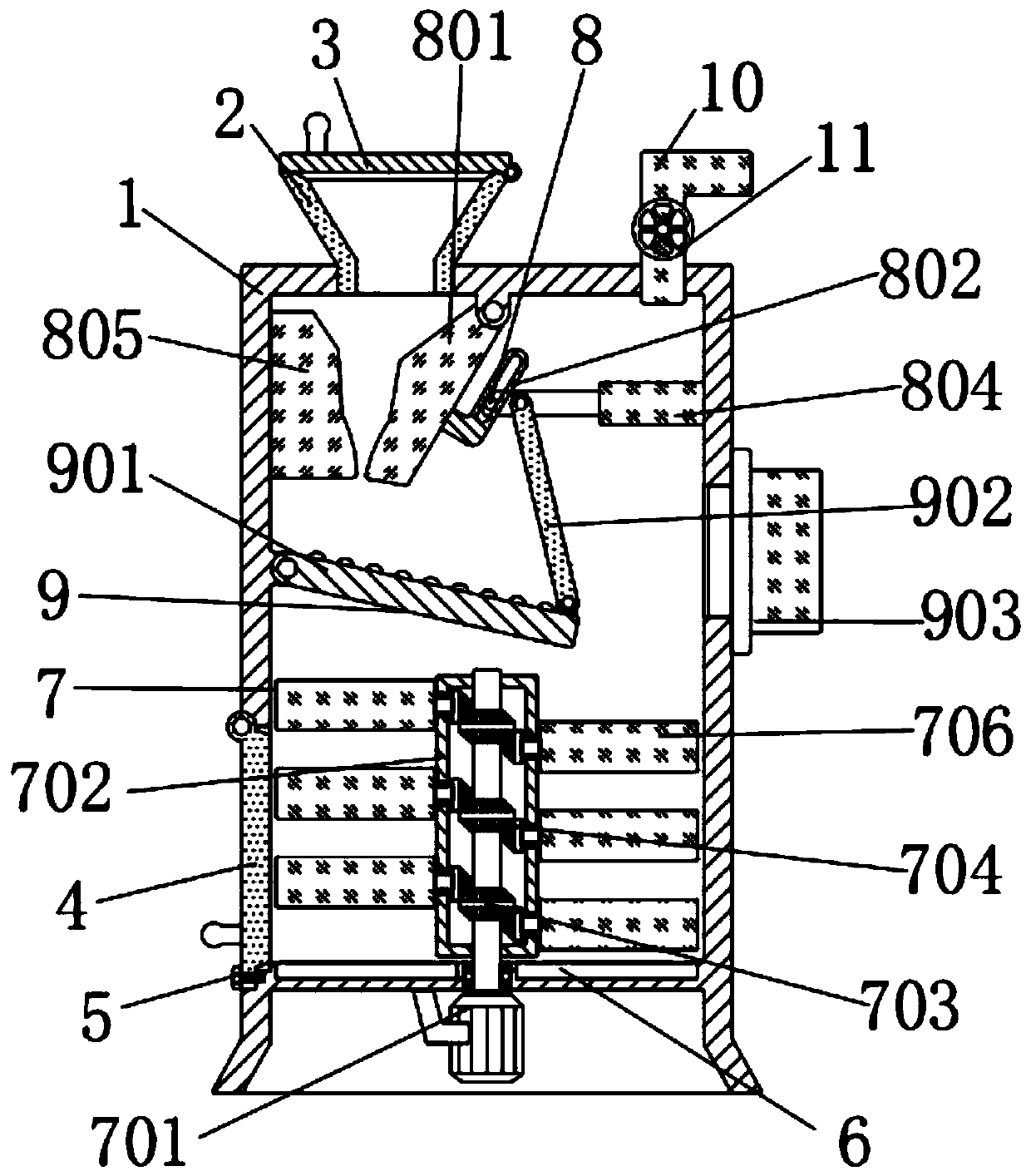

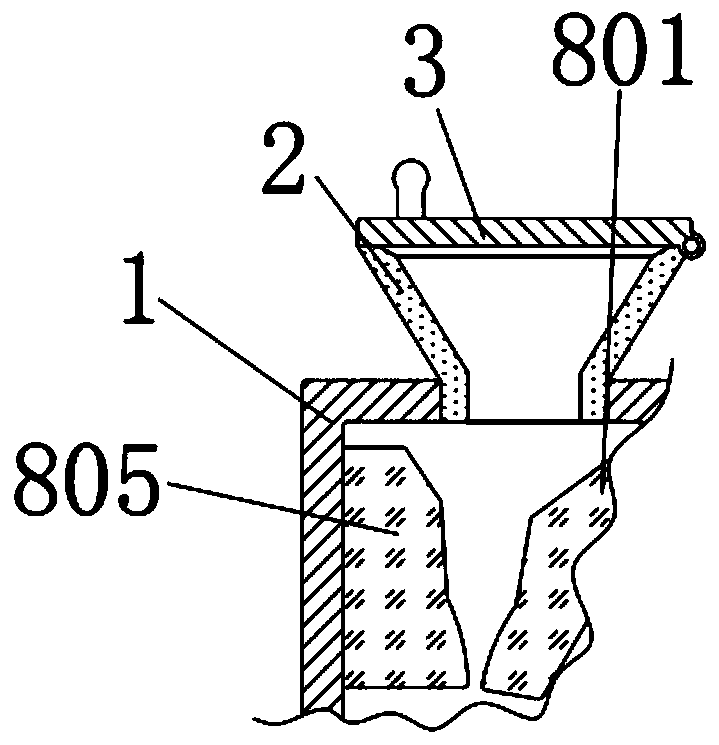

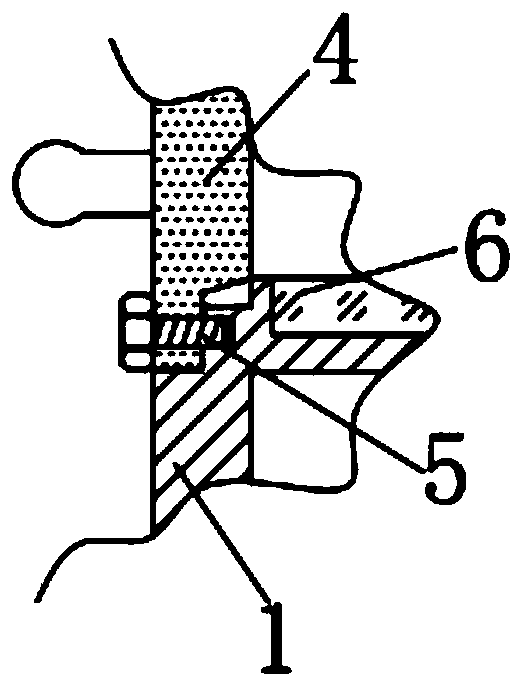

[0031] Example 1: Please refer to Figure 1-6 , the present invention provides a technical solution: a solid waste pyrolysis treatment equipment, including a box body 1, a feed hopper 2 is fixedly connected to the top of the box body 1, and a cover plate 3 is rotatably connected to the top of the feed hopper 2, The outer wall of the cover plate 3 is fixed with a rubber sleeve, and then the feed hopper 2 is sealed, and the bottom of the left end of the box body 1 is rotatably connected with a baffle 4, and the outer wall of the baffle 4 is fixed with a rubber sleeve for sealing the baffle 4. For sealing, the bottom of the baffle 4 is screwed to the left end of the box body 1 through the bolt 5, and the bolt 5 acts as a limit to the baffle 4, and the bottom of the inner wall of the box 1 is fixed with a heating plate 6, the model of the heating plate 6 It is bc-1, the top of the box body 1 is connected with a curved pipe 10, which is used to collect pyrolysis gas or connect to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com