Coal gasification spray gun

A coal gasification and spray gun technology, applied in electrical components, plasma and other directions, can solve the problems of loose cathode, easy leakage of cooling water, displacement and sealing of cathode, etc., to meet application requirements and improve the effect of pyrolysis capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

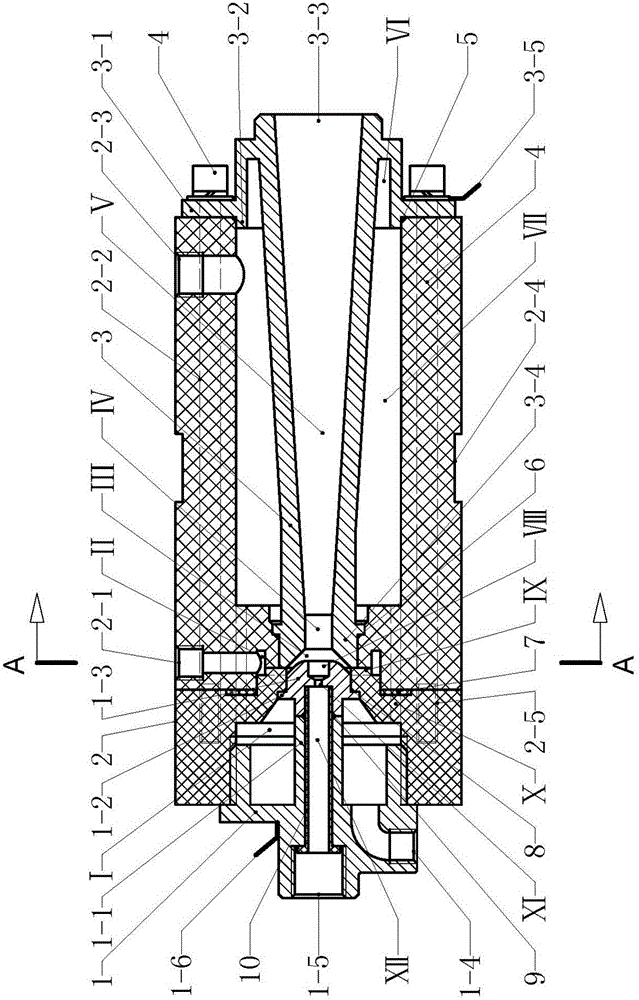

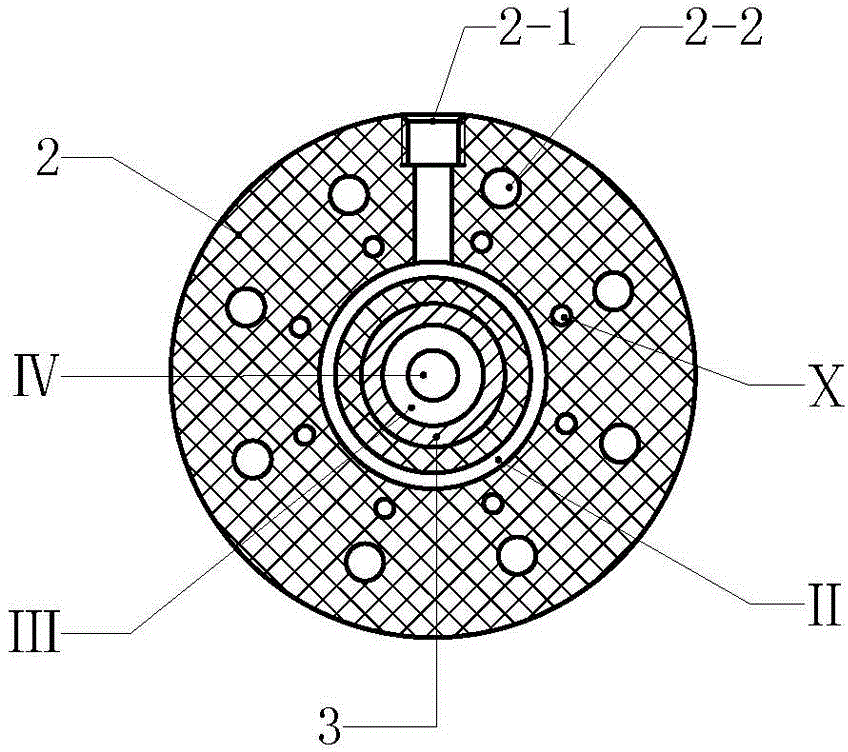

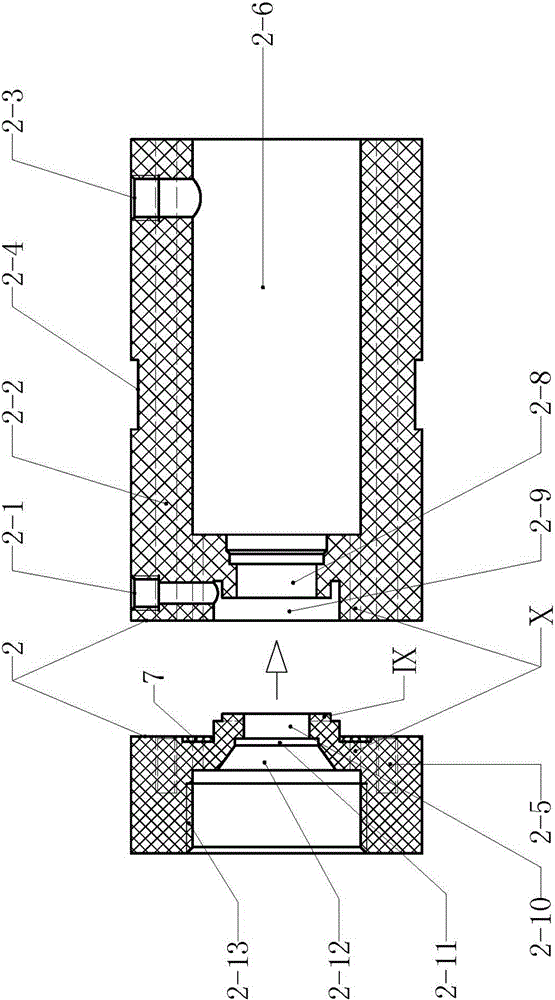

[0021] Example 1 figure 1 with image 3 In the illustrated embodiment, a coal gasification spray gun is composed of an insulating gun frame 2, a cathode 1 and an anode 3. The insulating gun frame 2 is a hollow rotary structure, and the hollow rotary body of the insulating gun frame 2 has a rear cavity 2- 12. The middle cavity 2-9 and the front cavity 2-6, the rear cavity 2-12, the middle cavity 2-9 and the front cavity 2-6 are arranged in sequence from the back to the front, and the back cavity 2-12 and the middle cavity 2-9 There is a sealing groove 2-11 and a via hole 2-10 between them, there is a tangential air groove Ⅸ on the front wall of the via hole 2-10, and there is a socket hole between the middle cavity 2-9 and the front cavity 2-6 2-8; there is a hollow connecting rod 1-1 on the cathode 1, and the inner space of the hollow connecting rod 1-1 constitutes the material channel Ⅻ, and the material channel Ⅻ is connected to the raw material input interface 1-5, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com