Pyrolysis device for waste plastic oil-production processing

A technology for waste plastics and oil production, which is applied in the petroleum industry, processing hydrocarbon oil, preparation of liquid hydrocarbon mixtures, etc., and can solve problems such as poor pyrolysis efficiency of plastic raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

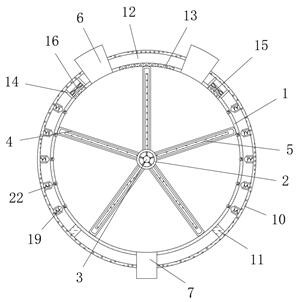

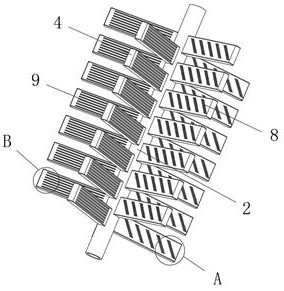

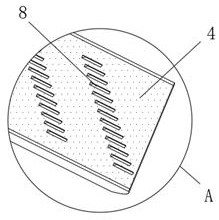

[0030] refer to Figure 1-4 , a pyrolysis device for processing waste plastics into oil, comprising a pyrolysis tank 1, the pyrolysis tank 1 is arranged in a horizontally placed cylindrical structure, and both ends of the pyrolysis tank 1 are provided with sealing covers, and the thermal The middle position between the inner walls of the two ends of the pyrolysis tank 1 is rotatably connected with a fixed pipe 2, and one end of the fixed pipe 2 is connected with a drive motor, and the inner wall of the end of the pyrolysis tank 1 away from the drive motor is fixed at a position corresponding to the fixed pipe 2. A heating element 3, the outer wall of the fixed pipe 2 is fixed with a plurality of dispersing elements 4, and the inside of the dispersing element 4 is provided with a mounting groove, the inner wall of the mounting groove is fixed with a second heating element 5, and the top two of the outer wall of the pyrolysis tank 1 are A feed pipe 6 is fixed on both sides, and ...

Embodiment 2

[0035] refer to Figure 1-6 , a pyrolysis device for waste plastic oil processing, a plurality of fixed cylinders 17 are fixed on both sides of the inner wall of the thermal insulation shell 10, and the end of the fixed cylinder 17 away from the thermal insulation shell 10 and the outer wall of the pyrolysis tank 1 There is a gap between them, the end of the inner wall of the fixed cylinder 17 close to the pyrolysis tank 1 is slidably connected with a hemispherical block 19, and the end of the block 19 away from the pyrolysis tank 1 is connected with the inner wall of the heat preservation shell 10. A spring 18, a chute 20 is provided at the position corresponding to the inner wall of the pyrolysis tank 1 and the block 19, and the inner wall of the chute 20 is slidably connected with a dispersing block 22, and one end of the dispersing block 22 is connected to the inner wall of the chute 20 There is a second spring 21, and the end of the dispersion block 22 away from the pyrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com