Pyrolysis device and method

A technology of pyrolysis and pyrolysis products, which is applied in the heating of coke ovens, special forms of dry distillation, and the petroleum industry. It can solve the problems of collection and separation difficulties, pyrolysis products that cannot be directly sold as products, and are difficult to use. Good pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

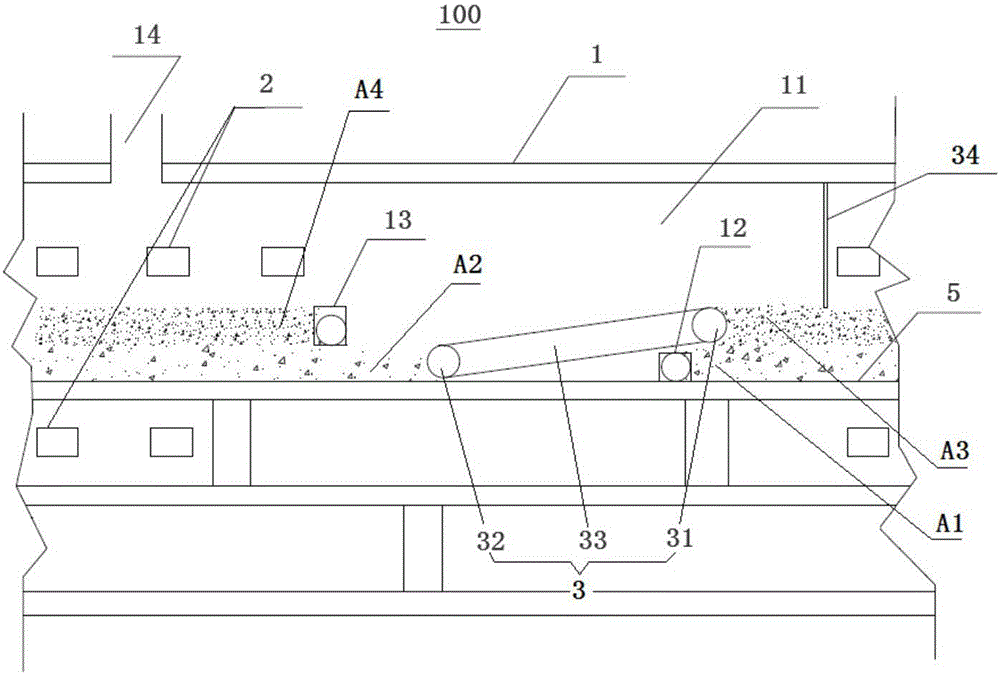

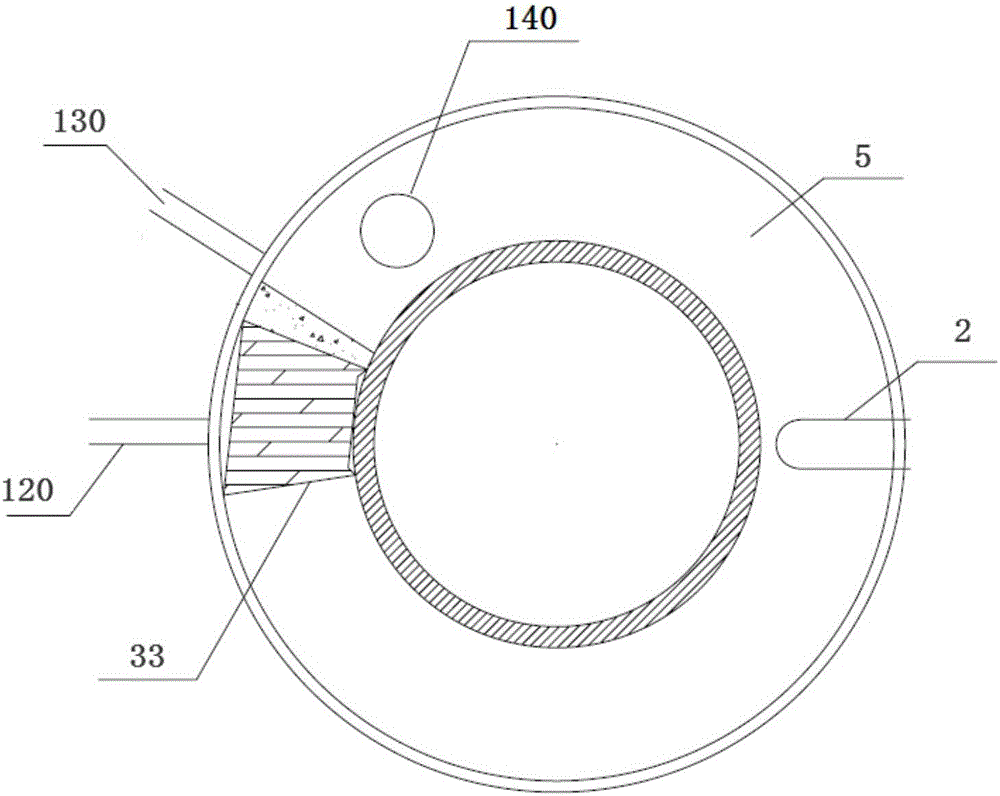

[0067] The pyrolysis device 100 of this embodiment is a radiation pyrolysis furnace, including: a furnace body 1, a feeding device 120, a discharging device 130, a gas collection pipeline 140, a material spreading plate 5, a heating device 2, and a material discharging device 3, etc.

[0068] Specifically, the furnace body 1 is generally formed as a cylinder with a circular cross-section, including: the peripheral wall of the furnace body, the peripheral wall of the furnace body, the top wall of the furnace body and the bottom wall of the furnace body, wherein the peripheral wall of the furnace body and the peripheral wall of the furnace body are formed It is cylindrical, and the peripheral wall of the furnace body is sleeved in the peripheral wall of the furnace body. The top wall of the furnace body and the bottom wall of the furnace body are both formed in a circular shape, and the top wall of the furnace body is fixedly connected to the top of the peripheral wall of the furn...

Embodiment 2

[0080] The structure of the pyrolysis device in the second embodiment is basically the same as that of the pyrolysis device 100 in the first embodiment, the difference is that the feeding device 120 in the pyrolysis device in the second embodiment is not a screw feeder but a bar feeder. Squeeze feeder.

[0081] Hereinafter, the method for pyrolyzing municipal sludge raw materials using the pyrolysis device of the second embodiment will be briefly introduced.

[0082] Specifically, this method is basically the same as the above-mentioned method of pyrolyzing straw raw materials using the pyrolysis device 100 of Embodiment 1, the difference is that: in the process of obtaining pyrolysis raw materials, municipal sludge is dried and pretreated, A pyrolysis raw material with a water content of 30% is obtained; the thickness of the pyrolysis raw material input to the laying board 5 is 50 mm; the time for the laying board 5 to rotate once is 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com