Gasification pyrolysis system for recycling flue gas and application of gasification pyrolysis system

A pyrolysis and flue gas technology, applied in the field of pyrolysis system and gasification pyrolysis system, can solve the problem of low temperature of flue gas, and achieve the effect of improving economic benefits, improving heat exchange efficiency and improving pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

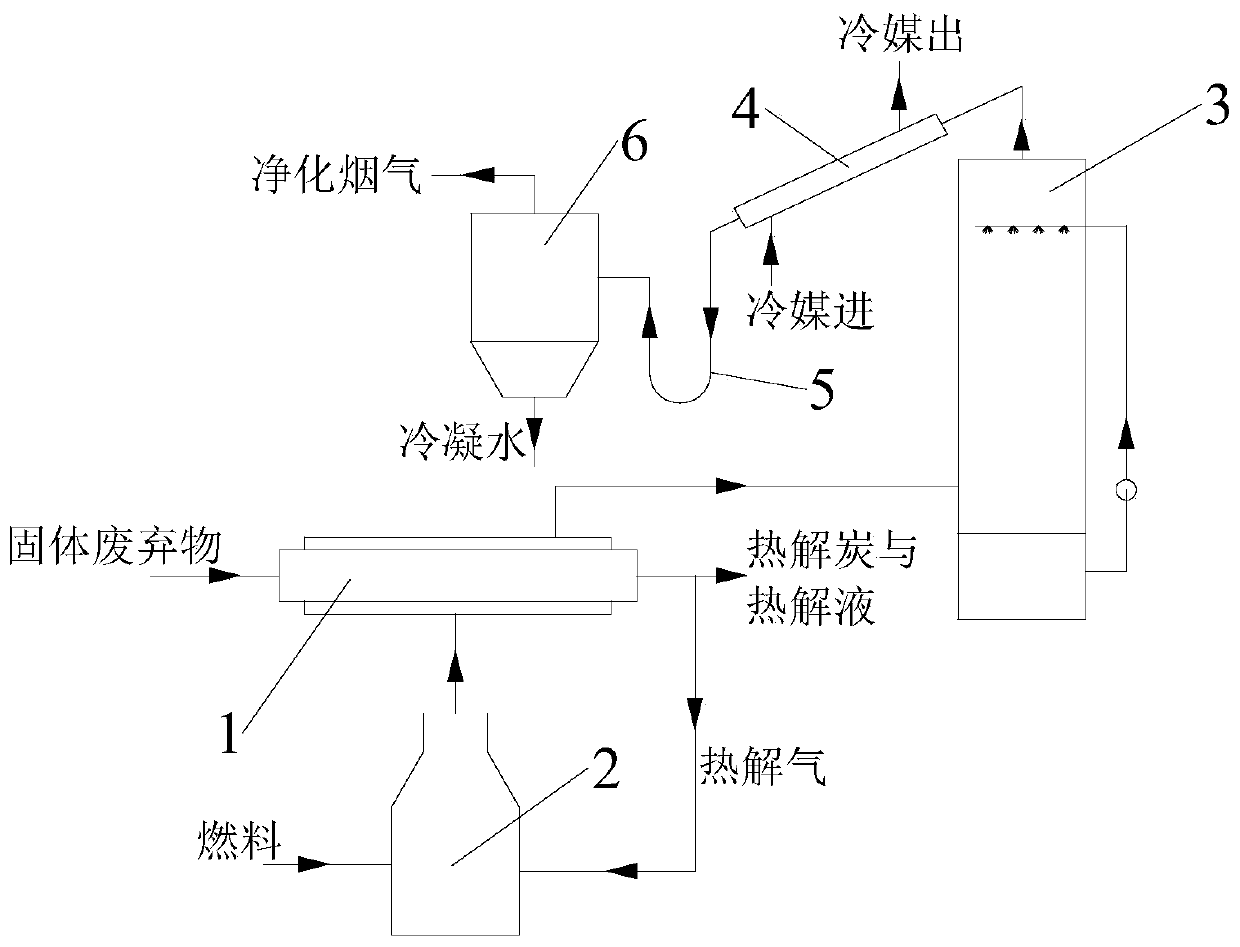

[0054] This embodiment provides a gasification and pyrolysis system for recycling flue gas, the structural schematic diagram of the gasification and pyrolysis system for recycling flue gas is as follows figure 1 As shown, it includes a pyrolysis unit, an absorption tower 3 and a condensation unit connected in sequence.

[0055] Described pyrolysis unit comprises pyrolysis furnace 1 and combustion furnace 2, and the flue gas outlet of pyrolysis furnace 1 is connected with the gas inlet of combustion furnace 2, and the flue gas outlet of combustion furnace 2 is connected with pyrolysis furnace 1, so that the combustion furnace 2 The high-temperature gas generated by combustion is used to provide the pyrolysis furnace 1 with the heat required for pyrolysis.

[0056] The condensing unit includes a shell-and-tube heat exchanger, a U-shaped tube 5 and a gas-liquid separation tank 6 connected in sequence.

[0057] The shell-and-tube heat exchanger is arranged obliquely, the higher e...

Embodiment 2

[0059] This embodiment provides a gasification and pyrolysis system for recycling flue gas. The gasification and pyrolysis system for recycling flue gas includes a pyrolysis unit, an absorption tower 3 and a condensation unit connected in sequence.

[0060] Described pyrolysis unit comprises pyrolysis furnace 1 and combustion furnace 2, and the flue gas outlet of pyrolysis furnace 1 is connected with the gas inlet of combustion furnace 2, and the flue gas outlet of combustion furnace 2 is connected with pyrolysis furnace 1, so that the combustion furnace 2 The high-temperature gas generated by combustion is used to provide the pyrolysis furnace 1 with the heat required for pyrolysis.

[0061] The condensing unit includes a shell-and-tube heat exchanger, a U-shaped tube 5 and a gas-liquid separation tank 6 connected in sequence.

[0062] The shell-and-tube heat exchanger is arranged obliquely, the higher end is connected to the gas outlet of the absorption tower 3, and the lowe...

Embodiment 3

[0064] This embodiment provides a gasification and pyrolysis system for recycling flue gas. The gasification and pyrolysis system for recycling flue gas includes a pyrolysis unit, an absorption tower 3 and a condensation unit connected in sequence.

[0065] Described pyrolysis unit comprises pyrolysis furnace 1 and combustion furnace 2, and the flue gas outlet of pyrolysis furnace 1 is connected with the gas inlet of combustion furnace 2, and the flue gas outlet of combustion furnace 2 is connected with pyrolysis furnace 1, so that the combustion furnace 2 The high-temperature gas generated by combustion is used to provide the pyrolysis furnace 1 with the heat required for pyrolysis.

[0066] The condensing unit includes a shell-and-tube heat exchanger, a U-shaped tube 5 and a gas-liquid separation tank 6 connected in sequence.

[0067] The shell-and-tube heat exchanger is arranged obliquely, the higher end is connected to the gas outlet of the absorption tower 3, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com