Water passage circulation structure for condensing heat exchanger

A technology of heat exchanger and circulation structure, applied in the field of water circuit circulation structure of condensing heat exchanger, can solve the problems of inconvenient maintenance, disassembly, cleaning and cleaning of residue and scale, short service life of heat exchanger, insufficient combustion of gas, etc., so as to reduce resources. Consumption, simple structure, sufficient heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

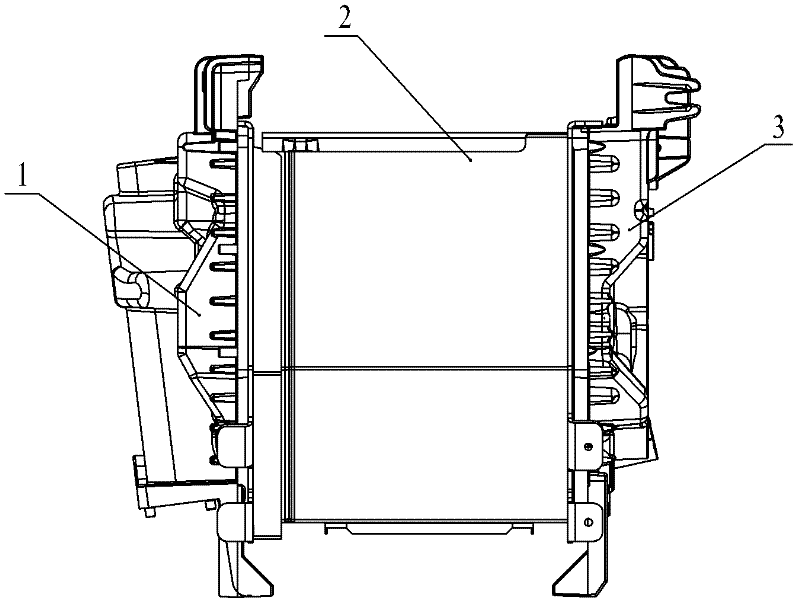

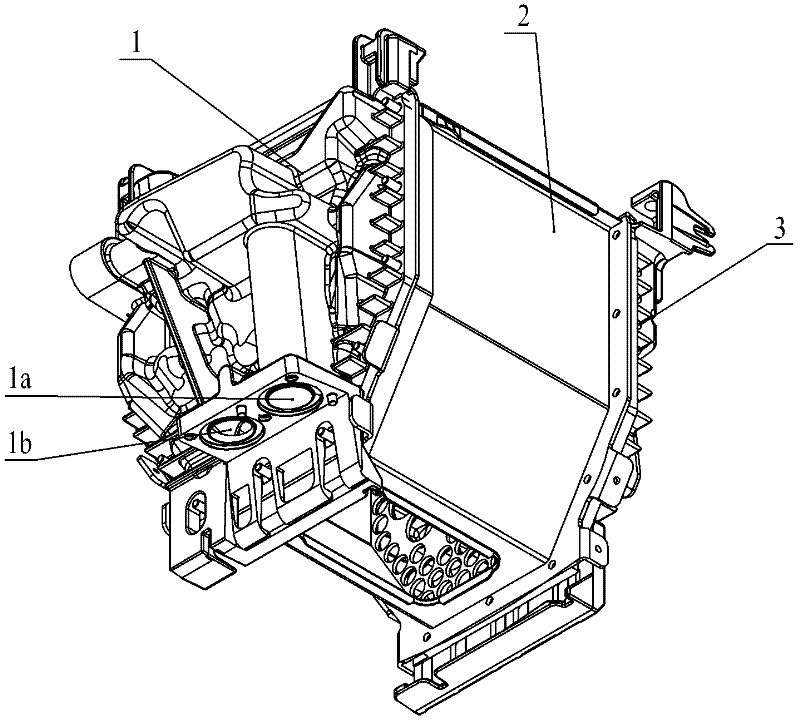

[0016] As shown in the figure: the water circulation structure of the condensing heat exchanger in the embodiment is mainly composed of a shell 2, a left cover plate 1, a right cover plate 3 and several straight-through pipes for heat dissipation.

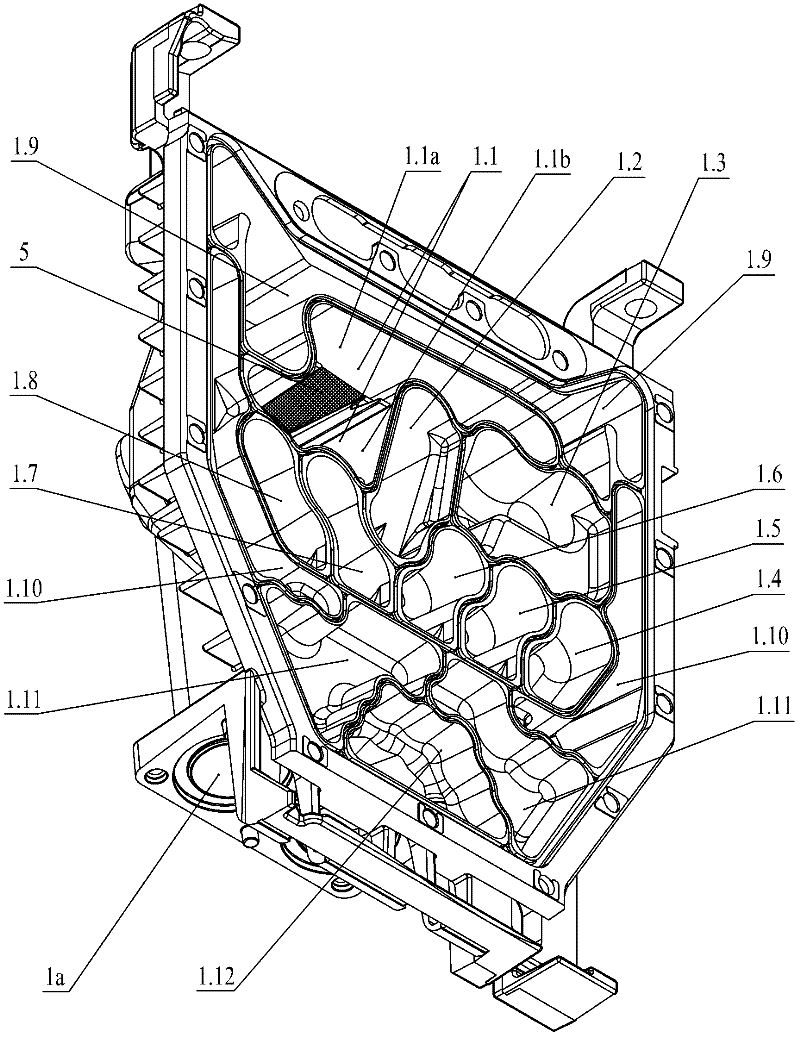

[0017] Such as Figure 1~Figure 3 As shown, the left cover plate 1 and the right cover plate 3 are installed on the left and right side walls of the housing 2, and the left cover plate 1 and the right cover plate 3 have chambers; the left cover plate 1 is provided with a water inlet 1a and Water outlet 1b, the chamber of the left cover plate 1 is divided into fourteen independent left water circulation areas by curved partitions, and the fourteen left water circulation areas are the first left water circulation area according to the order of water flow 1.1, the second left water circulation area 1.2, the third left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com