A pyrolysis reactor

A technology of pyrolysis reactor and body, which is applied in the direction of direct heating dry distillation, petroleum industry, coke oven, etc., can solve the problems of high production cost, hidden safety hazards, anti-channeling and other problems of premixing devices, achieve the reduction of air tightness level, solve the Anti-channeling and pressure-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

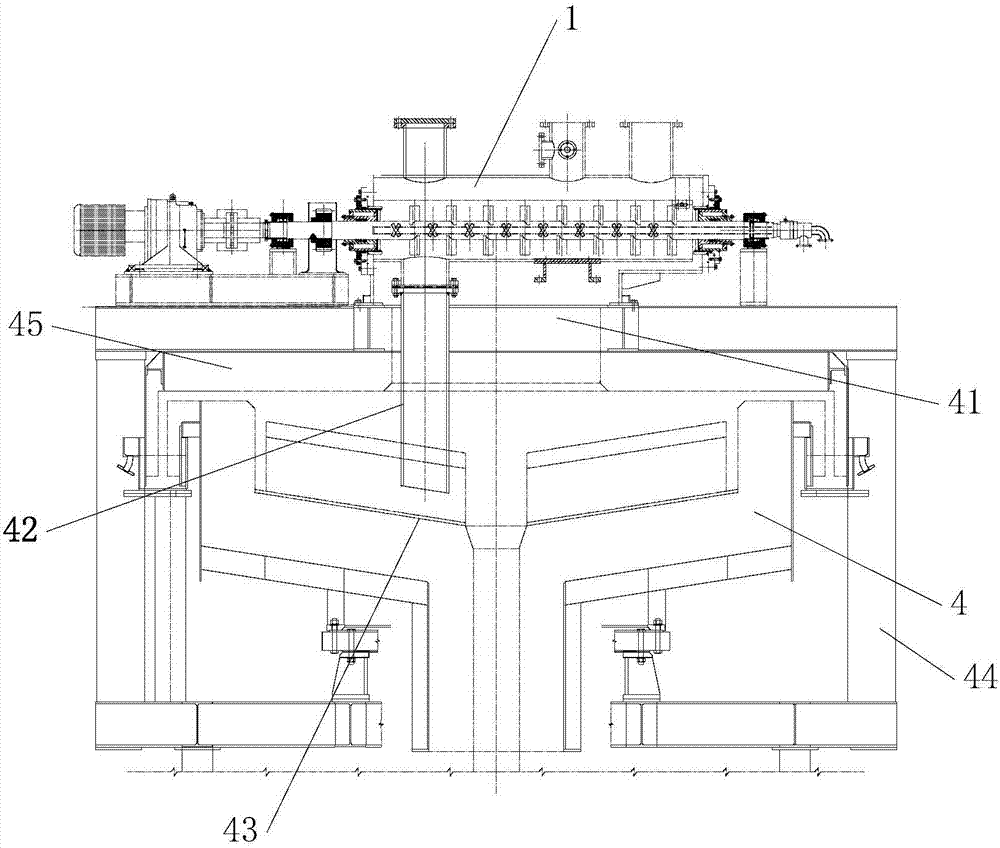

[0047] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

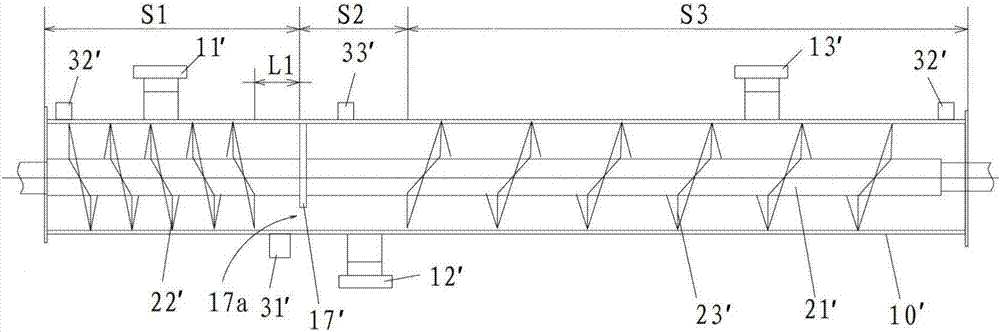

[0048] In the present invention, in the absence of a contrary statement, the used orientation words "upper and lower" generally refer to those defined in the normal use of the pyrolysis reactor provided by the present invention, and together with the attached image 3 in the same direction as shown. These orientation words are used to facilitate the understanding of the present invention, and thus should not be construed as limiting the protection scope of the present invention.

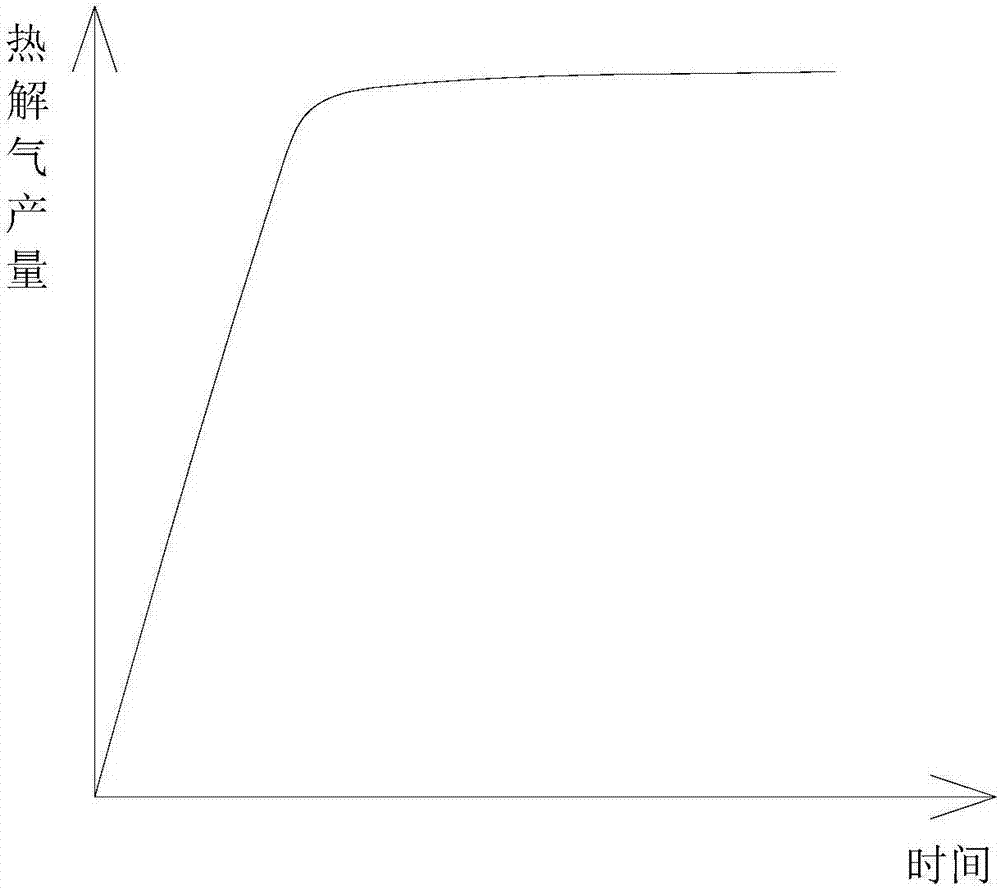

[0049] First of all, it should be noted that the present invention aims to provide a pyrolysis reactor, by setting a premixing device with a flow space for gas flow inside, and combining the flow space in the premixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com