Garbage air drying treatment system and method

A treatment system and a technology of garbage wind, which are applied in the directions of garbage drying, combustion method, drying, etc., to achieve the effect of facilitating promotion, improving the environment of garbage dumps, and facilitating garbage storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

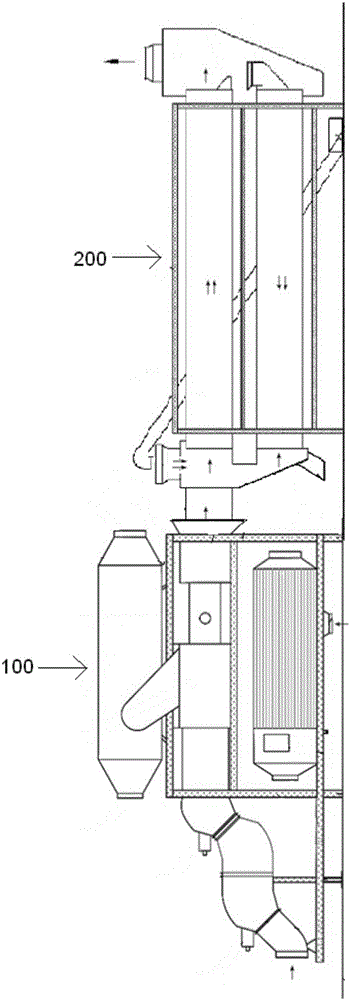

[0042]Refer to attached figure 1 As shown, the garbage air-drying treatment system of the present invention includes a low-temperature dry air production device 100 and a garbage air-drying treatment device 200 connected thereto.

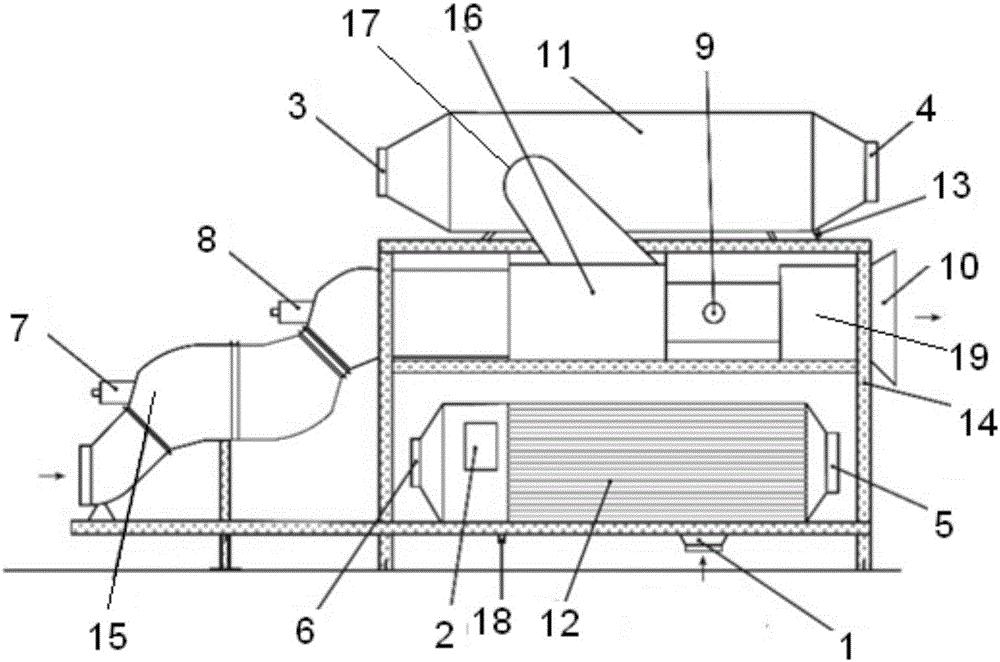

[0043] Refer to attached figure 2 As shown, the low-temperature dry air production device 100 includes a cold and hot air exchange mechanism 11 and an air distribution mechanism.

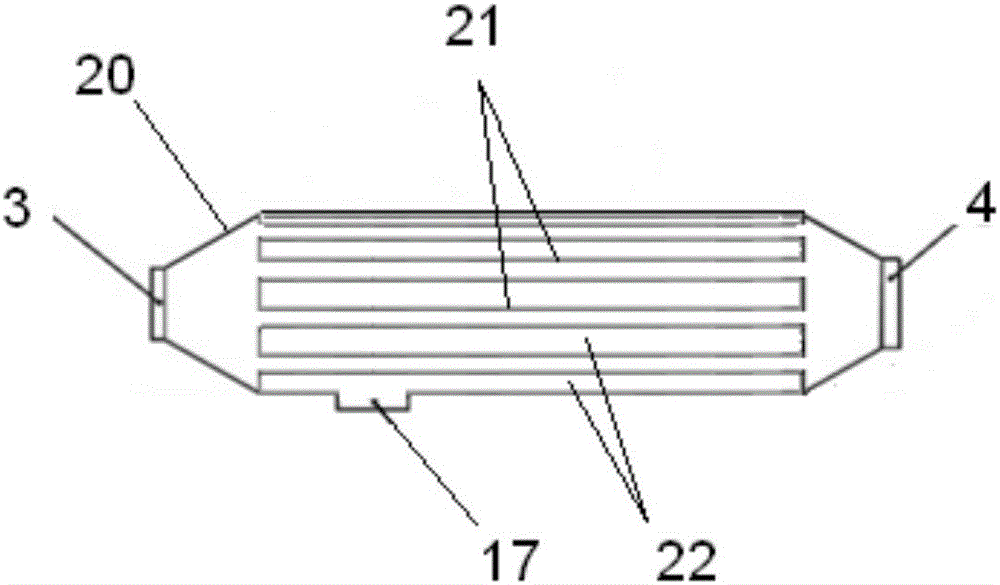

[0044] The cold and hot air exchanging mechanism 11 includes an outer shell 20 and a cold air duct 21 arranged inside the outer shell 20. The outer shell 20 includes a cold air inlet 3 and a cold air outlet 4 communicating with the cold air duct 21, and a cold air outlet 4 arranged in the outer shell 20. The hot-blast air inlet 17 and the hot-blast air outlet on the side wall of the outer shell 20 (the back side of the cold and hot-air exchanging mechanism 11, not shown in the figure), the hot-blast air inlet 17 and the hot-blast air outlet are connected with the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com